Endress+Hauser Fieldbus Micropilot M FMR245 Operating Instructions Manual

Level-radar

Hide thumbs

Also See for Fieldbus Micropilot M FMR245:

- Operating instructions manual (118 pages) ,

- Service information (8 pages) ,

- Operating instructions manual (104 pages)

Summary of Contents for Endress+Hauser Fieldbus Micropilot M FMR245

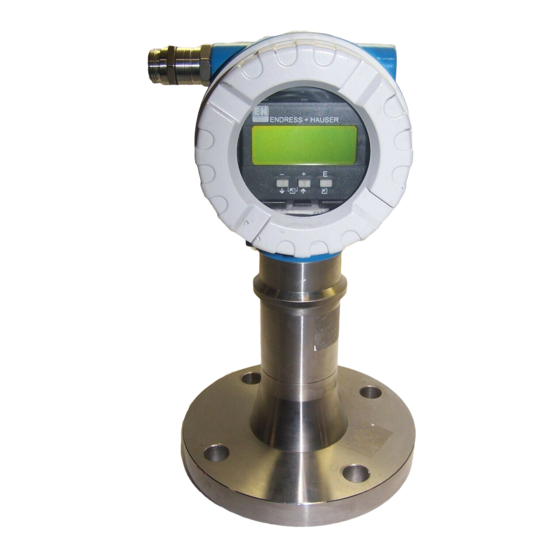

- Page 1 Operating Instructions Micropilot M FMR245 Level-Radar BA253F/00/en/05.06 Nr. 52012500 Valid as of software version: V 01.04.00 (amplifier) V 1.0 (communication)

- Page 2 An overview of all device functions can be found on Page 98. The operating manual BA 221F/00/en "Description of the instrument functions for Micropilot M" provides an extensive description of all device functions, which can be found on the enclosed CD-ROM. Endress+Hauser...

-

Page 3: Table Of Contents

Designated use ......4 Contact addresses of Endress+Hauser ... 92 Installation, commissioning and operation . -

Page 4: Safety Instructions

(1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. " Caution! Changes or modifications not expressly approved by the part responsible for compliance could void the user’s authority to operate the equipment. Endress+Hauser... -

Page 5: Notes On Safety Conventions And Symbols

A connection made to the plant grounding system which may be of type e.g. neutral star or equipotential line according to national or company practice Temperature resistance of the connection cables t >85°C States, that the connection cables must be resistant to a temperature of at least 85 °C. Endress+Hauser... -

Page 6: Identification

U CSA IS - Cl.I Div.1 Group A-D V CSA XP - Cl.I Div.1 Group A-D K TIIS EEx ia IIC T4 TIIS EEx d [ia] IIC T4 Special version Antenna: 50mm/2" 80mm/3" Special version FMR 245- Product designation (part 1) Endress+Hauser... - Page 7 D T12 Alu, coated IP65 NEMA4X+OVP, separate conn. compartment, OVP=overvoltage protection Special version Cable entry: Gland M20 Thread G1/2 Thread NPT1/2 Plug M12 Plug 7/8" Special version Additional option: A Basic version GL/ABS/NK marine certificate Special version FMR 245- Complete product designation Endress+Hauser...

-

Page 8: Scope Of Delivery

The device complies with the applicable standards and regulations as listed in the EC declaration of conformity and thus complies with the statutory requirements of the EG directives. Endress+Hauser confirms the successful testing of the device by affixing to it the CE mark. -

Page 9: Mounting

DN50 DN80…150 ANSI 2” ANSI 3…6” Allen key 4 mm/0.1” Installation in bypass: Mark on process connector 90° offset from the tank connections! mark at instrument flange ° ° DN50 DN80…150 ANSI 2” ANSI 3…6” ° L00-FMR245xx-17-00-00-en-001 Endress+Hauser... -

Page 10: Incoming Acceptance, Transport, Storage

Do not lift the measuring instrument by its housing in order to transport it. 3.2.3 Storage Pack the measuring instrument so that is protected against impacts for storage and transport. The original packing material provides the optimum protection for this. The permissible storage temperature is -40 °C…+80 °C. Endress+Hauser... -

Page 11: Installation Conditions

Micropilot M FMR245 with FOUNDATION Fieldbus Mounting Installation conditions 3.3.1 Dimensions Housing dimensions max. 110 ENDRESS+HAUSER F12 housing (Aluminium) L00-F12xxxx-06-00-00-en-001 max. 100 ENDRESS+HAUSER T12 housing (Aluminium) L00-T12xxxx-06-00-00-en-001 max. 94 F23 housing (316L) L00-F23xxxx-06-00-00-en-001 Endress+Hauser... - Page 12 D [mm] 152.4 190.5 279.4 C [mm] A [mm] A [mm] for PN 16 for 150 lbs Flange to JIS B2210 Flange DN 50 DN 80 DN 100 DN 150 b [mm] D [mm] A [mm] for 10K L00-FMR245xx-06-00-00-en-005 Endress+Hauser...

- Page 13 • Stilling well: a stilling well respectively a Wave Guide antenna can always be used to avoid interference. • Metallic screens (3) mounted at a slope spread the radar signals and can, therefore, reduce interference echoes. Please contact Endress+Hauser for further infor- L00-FMR2xxxx-17-00-00-xx-011 mation. Endress+Hauser...

- Page 14 >85°C ENDRESS ss+Ha ss+Ha user user MICROPIL +HAUSER OT II Endre Endre Order Code: Ser.-No.: Messbereich Measuring range max. 20 IP 65 U 16...36 4...20 mA V DC T >70°C t >85°C L00-FMR2xxxx-17-00-00-xx-013 Please contact Endress+Hauser for further information. Endress+Hauser...

- Page 15 3.80 m / 12.67 ft 2.10 m / 7.00 ft 15 m / 49 ft 4.75 m / 15.52 ft 2.63 m / 8.57 ft . tan 20 m / 65 ft — 3.50 m / 11.37 ft L00-FMR2xxxx-14-00-06-de-027 Endress+Hauser...

- Page 16 • The tank diameter should be greater than D (see Fig.), the tank height at least H (see Fig.). A [mm/inch] B [m/inch] C [mm/inch] D [m/inch] H [m/inch] FMR245 200 / 8 > 0,2 / > 8 50...150 / 2...6 > 0,2 / > 8 > 0,3 / > 12 Endress+Hauser...

- Page 17 5 m / 16 ft 20 m / 65 ft 20 m / 65 ft In the event of horizontal stress (e.g. agitators), mechanical support is required or provide the Wave Guide antenna with a protective pipe (maximum lateral load 100 Nm). Endress+Hauser...

-

Page 18: Installation Instructions

• After mounting, the housing can be turned 350° in order to simplify access to the display and the terminal compartment. • The antenna must be aligned vertically. Caution! The maximum range may be reduced, if the antenna is not vertically aligned. spring washers Ø D L00-FMR245xx-17-00-00-de-002 Endress+Hauser... - Page 19 44 / 1.8 75 / 3 H [mm/inch] < 500 / < 20 < 500 / < 20 Note! Please contact Endress+Hauser for application with higher nozzle. 3.4.3 Installation in stilling well Optimum mounting position marker at instrument flange DN50 DN80…150...

- Page 20 < 1/10 Ø pipe hole <1/10 pipe diameter, single sided or drilled through inside of holes deburred full bore ball valve Diameter of o pening of ball valve must always be equivalent to pipe diameter. Avoid edges and constrictions. L00-FMR245xx-17-00-00-en-006 Endress+Hauser...

- Page 21 • At any transition (i.e. when using a ball valve or mending pipe segments), no gap may be created exceeding 1 mm (0.04"). • In the area of the tank connections (~ ±20 cm / 8“) a reduced accuracy of the measurement has to be expected. Endress+Hauser...

- Page 22 Do not weld through the pipe wall. The inside of the bypass must remain smoth. Diameter of o pening of ball valve must always be equivalent to pipe diameter. Avoid edges and constrictions. 20 cm 8” 20 cm 8” L00-FMR2xxxx-17-00-00-en-019 Endress+Hauser...

-

Page 23: Post-Installation Check

• Have the flange screws been tightened up with the respective tightening torque? • Are the measuring point number and labeling correct (visual check)? • Is the measuring instrument adequately protected against rain and direct sunlight (→ Page 75)? Endress+Hauser... -

Page 24: Wiring

Micropilot M FMR245 with FOUNDATION Fieldbus Wiring Quick wiring guide Wiring in F12/F23 housing Before connection please note the following: " ENDRESS+HAUSER ● Foundation Fieldbus devices are marked on the nameplate MICROPILOT M (1). The voltage is determined by the Foundation Fieldbus Caution! - Page 25 Micropilot M FMR245 with FOUNDATION Fieldbus Wiring Wiring in T12 housing Before connection please note the following: " ENDRESS+HAUSER ● Foundation Fieldbus devices are marked on the nameplate MICROPILOT M (1). The voltage is determined by the Foundation Fieldbus IP65...

- Page 26 Wiring Micropilot M FMR245 with FOUNDATION Fieldbus Wiring with Foundation Fieldbus connector Before connection please note the following: " ENDRESS+HAUSER ● Foundation Fieldbus devices are marked on the nameplate MICROPILOT M (1). The voltage is determined by the Foundation Fieldbus...

-

Page 27: Connecting The Measuring Unit

• Is the cable gland tight? • Is the Foundation Fieldbus connector screwed tight? • Is the housing cover screwed tight? • If auxiliary power is available: Is the instrument ready for operation and does the liquid crystal display show any value? Endress+Hauser... -

Page 28: Operation

(e.g. "medium property (003)") Ü 5) Press ) once return to previous function (e.g. "tank shape (002)") Ü Press ) twice return to Group selection 6) Press ) to return to Measured value display L00-FMR2xxxx-19-00-00-en-001 Endress+Hauser... - Page 29 The third digit numbers the individual functions within the function group: → • tank shape • basic setup • medium property • process cond..Hereafter the position is always given in brackets (e.g. "tank shape" (002)) after the described function. Endress+Hauser...

-

Page 30: Display And Operating Elements

The VU331 LCD display can be removed to ease operation by simply pressing the snap-fit (see graphic above). It is connected to the device by means of a 500 mm cable. Note! To access the display the cover of the electronic compartment may be removed even in hazardous area (IS and XP). Endress+Hauser... - Page 31 This lock symbol appears when the instrument is locked,i.e. if no input is possible. COM_SYMBOL This communication symbol appears when a data transmission via e.g. HART, PROFIBUS PA or FOUNDATION Fieldbus is in progress. SIMULATION_SWITCH_ENABLE This communication symbol appears when simulation in FOUNDATION Fieldbus is enabled via the DIP switch. Endress+Hauser...

- Page 32 Contrast settings of the LCD Hardware lock / unlock After a hardware lock, an operation of the instrument via display or communication is not possible! The hardware can only be unlocked via the display. An unlock parameter must be entered to do so. Endress+Hauser...

-

Page 33: Local Operation

It is not possible to unlock the hardware by communication. All parameters can de displayed even if the instrument is locked. ⇒ ENDRESS + HAUSER press simultaneous – ⇓ ⇓ The LOCK_SYMBOL appears on the LCD. Endress+Hauser... - Page 34 There is no need to change these parameters under normal circumstances and consequently, they are protected by a special code known only to the E+H service organization. Please contact Endress+Hauser if you have any questions.

- Page 35 The tank map can also be reset in the "mapping" (055) function of the "extended calibr." (05) function group. This reset is recommended whenever an instrument with an unknown 'history' is to be used in an application or if a faulty mapping was started: • The tank map is deleted. The mapping must be recommenced. Endress+Hauser...

-

Page 36: Display And Acknowledging Error Messages

• The "diagnostics" (0A) function group can display current errors as well as the last errors that occurred. • If several current errors occur, use to page through the error messages. • The last occurring error can be deleted in the "diagnostics" (0A) function group with the funktion"clear last error" (0A2). Endress+Hauser... -

Page 37: Foundation Fieldbus Communication

– An FOUNDATION Fieldbus-H1 connecting card is needed for direct connection to a process control system. Note! Further information on FOUNDATION Fieldbus can be found in Operating Instructions BA013S "FOUNDATION Fieldbus Overview, Installation and Commissioning Guidelines", the FOUNDATION Fieldbus Specification or on the Internet at "http://www. fieldbus.org". Endress+Hauser... - Page 38 • When the configuration is complete, close the tool and the FOUNDATION Fieldbus stack (if open). The Micropilot M device descriptions can be ordered direct from Endress+Hauser or downloaded from our website "www.endress.com". They contain all data necessary to operate Endress+Hauser FOUNDATION Fieldbus devices.

- Page 39 The device ID is made up of the following components: Device_ID = 452B48100F-XXXXXXXX whereby: 452B48 ID code for Endress+Hauser 100F ID code for Micropilot M XXXXXXXX Device serial number, as printed on the nameplate A right-hand mouse click on the name opens up a menu from which the PD_TAG and...

- Page 40 Parameters that Primary value the process control system, describe the (main value) e.g. scaling, status device (calibration, linearisation etc.) Analog Input Function Block 2 parameters that are important to the process control system, Secondary value e.g. scaling, status (distance) L00-FMxxxxxx-02-00-00-en-002 Endress+Hauser...

- Page 41 Shows any configuration, hardware, connection and system problems in the lock. The cause of the alert is to be seen in the subcode field. The function of the resource block parameters not described here can can be taken from the FOUNDATION Fieldbus specification, see "www.fieldbus.org". Endress+Hauser...

- Page 42 Thus, the calibration procedure via the display module (Chapter 6.4) is equally valid for a calibration via a network configuration tool. A complete list of the configuration parameters can be found in the "Description of Instrument Functions", BA221F/00/en. Endress+Hauser...

- Page 43 PARRAMPINPERCENTPERMIN FloatingPoint static delay time PARDELAYTIMEONLOSTECHO Unsigned16 static safety distance PARLEVELWITHINSAFETYDISTANCE FloatingPoint static in safety dist. PARINSAFETYDISTANCE Unsigned8 static ackn. alarm PARACKNOWLEDGEALARM Unsigned8 dynamic Auto, OOS level/ullage PARLEVELULLAGEMODE Unsigned8 static linearisation PARLINEARISATION Unsigned8 static customer unit PARCUSTOMERUNIT Unsigned16 static Endress+Hauser...

- Page 44 Unsigned8 dynamic Auto, OOS distance unit PARDISTANCEUNIT Unsigned16 static download mode PARDOWNLOADMODE Unsigned8 static max meas dist 0D84 PARABSMAXMESSDIST FloatingPoint dynamic Auto, OOS max sample dist. 0D88 PAREDITRANGEMAXSAMPLEDIST FloatingPoint dynamic Auto, OOS present error PARACTUALERROR Unsigned16 dynamic Auto, OOS Endress+Hauser...

- Page 45 PAROPERATIONCODE Unsigned16 non-vol. protocol+sw-no. PARPROTSOFTVERSIONSTRING VisibleString const Auto, OOS If MODE_BLK refuses to be changed to AUTO, an error is present. Control all parameters, perform the required changes and try again to change MODE_BLK to AUTO. Endress+Hauser...

- Page 46 PARSEPARATIONCHARACTER Unsigned8 non-vol. Auto, OOS unlock parameter PAROPERATIONCODE Unsigned16 non-vol. If MODE_BLK refuses to be changed to AUTO, an error is present. Control all parameters, perform the required changes and try again to change MODE_BLK to AUTO. Endress+Hauser...

- Page 47 User description of the intended application of the block. BLOCK_ERROR Shows error status of software and hardware components – Out-of-Service: the block is in OOS mode – Simulation active: shows the setting of DIP-switch SIM. Input failure/process variable has BAD status. – configuration error Endress+Hauser...

- Page 48 VALUE SCALE × FIELD − SCALE SCALE The L_TYPE parameter influences the signal conversion: • Direct: PV = CHANNEL_VALUE • Indirect: FIELD VALUE × − SCALE SCALE SCALE • Indirect square root: FIELD VALUE × − SCALE SCALE SCALE Endress+Hauser...

- Page 49 8 - 15 Critical alarms of increasing priority Alarm status Parameter Description HI_HI_ALM The status of the HI_HI alarm HI_ALM The status of the HI alarm LO_ALM The status of the LO alarm LO_LO_ALM The status of the LO_LO alarm Endress+Hauser...

- Page 50 – Set the desired output damping in PV_TIME. – If appropriate, set the advisory and critical alarms. – Set MODE_BLK_TARGET to Auto. Link the function blocks in the function block editor. Download the configuration (menu configure). If appropriate, check the configuration by using the SIMULATE function. Endress+Hauser...

- Page 51 View Objects Arithmetic Function Block 3040 View Objects Input Selector Function Block 3050 View Objects Signal Characterizer Function Block 3060 View Objects Integrator Function Block 3070 View Objects Sensor Block 4000 View Object Diagnostic Block 4100 View Object Display Block 4200 Endress+Hauser...

- Page 52 5.5.12 ToF Tool operating program The ToF Tool is a graphical operating software for instruments from Endress+Hauser that operate based on the time-of-flight principle. It is used to support commissioning, securing of data, signal analysis and documentation of the instruments. It is compatible with the following operating systems: Win95, Win98, WinNT4.0 and Win2000.

- Page 53 • Service-interface with adapter FXA193 (RS232C) / FXA291 (USB) Hinweis! The Micropilot M can also be operated locally using the keys. If operation is prevented by the keys being locked locally, parameter entry via communication is not possible either. Endress+Hauser...

-

Page 54: Commissioning

Select the basic unit (this message appears the first time the instrument is switched on) ⇓ The current measured value is displayed ⇓ After is pressed, you reach the group selection. This selection enables you to perform the basic setup Endress+Hauser... -

Page 55: Basic Setup

005 F = full calibr. (= span) setting in 006 D = distance (distance flange / product) safety settings display in 0A5 = level display in 0A6 SD = safety distance setting in 015 linearisation extended calibr. L00-FMR245xx-19-00-00-en-001 Endress+Hauser... - Page 56 All functions are described in detail, as is the overview of the operating menu itself, in the manual “Description of the instrument functions − BA 221F”, which is found on the enclosed CD- ROM. Note! The default values of the parameters are typed in boldface. Endress+Hauser...

-

Page 57: Basic Setup With The Vu 331

Function "tank shape" (002) ⇒ ENDRESS + HAUSER – This function is used to select the tank shape. Selection: • dome ceiling • horizontal cyl • bypass • stilling well, also for Wave Guide antenna use. • flat ceiling • sphere L00-FMR2xxxx-14-00-06-en-007 Endress+Hauser... - Page 58 … 4...10 e.g. concentrated acids, organic solvents, esters, aniline, alcohol, acetone, … >10 conducting liquids, e.g. aqueous solutions, dilute acids and alkalis Treat Ammonia NH3 as a medium of group A, i.e. use FMR 230 in a stilling well. Endress+Hauser...

- Page 59 The output damping is set to 0. → smoothed meas. value → rapid reaction time → medium fast reaction time → possibly unsteady meas. value → minimization of effects by agitator blades Endress+Hauser...

- Page 60 This function is used to enter the distance from the flange (reference point of the measurement) to the minimum level (=zero). L00-FMR2xxxx-14-00-06-en-008 " Caution! For dish bottoms or conical outlets, the zero point should be no lower than the point at which the radar beam hits the bottom of the tank. Endress+Hauser...

- Page 61 If bypass or stilling well was selected in the "tank shape" (002) function, the pipe diameter is requested in the following step. Note! For FMR 245, the end of measuring range should not be chosen closer than 200 mm/ 8 inch to the tip of the antenna, especially if there is development of condensate. Endress+Hauser...

- Page 62 Microwaves propagate more slowly in pipes than in free space. This effect depends on the inside diameter of the pipe and is automatically taken into account by the Micropilot. It is only necessary to enter the pipe diameter for applications in a bypass or stilling well. Endress+Hauser...

- Page 63 • At the moment, an interference is being evaluated • Therefore, a mapping is carried out including the presently measured echoes • The range to be suppressed is suggested in the "range of mapping" (052) function Endress+Hauser...

- Page 64 • off → no mapping is carried out • on → mapping is started During the mapping process the message "record mapping" is displayed. " Caution! A mapping will be recorded only, if the device is not in alarm-state. Endress+Hauser...

- Page 65 • Distance correct − level incorrect → Check "empty calibr." (005) • Distance incorrect − level incorrect → continue with the next function, "check distance" (051) ⇒ ENDRESS + HAUSER – ⇓ After 3 s, the following message appears Endress+Hauser...

- Page 66 An orientation of the Micropilot can help to optimise measurement in applications with very weak level echos or strong interference echos by increasing the useful echo/reducing the interference echo (see "Orientation of the Micropilot" on Page 83). When using the Wave Guide antenna no orientation is required! Endress+Hauser...

- Page 67 Horizontal Zoom mode Firstly, go into the envelope curve display. Then press to switch to the envelope curve navigation. You are then in Horizontal Zoom mode. Either is displayed. • increases the horizontal scale. • reduces the horizontal scale. L00-FMxxxxxx-07-00-00-yy-007 Endress+Hauser...

- Page 68 The set increases and shifts are retained. Only when you reactivate the "recording curve" (0E2) function the Micropilot uses the standard display again. ⇒ ENDRESS + HAUSER – ⇓ After 3 s, the following message appears Endress+Hauser...

-

Page 69: Basic Setup With The Tof Tool

Basic Setup step 1/4: • Status image • Enter the measuring point description (TAG number). L00-FMR2xxxx-20-00-00-en-001 Note! • Each parameter that is changed must be confirmed with the RETURN key! • The "Next" button moves you to the next screen display: Endress+Hauser... - Page 70 Basic Setup step 3/4: If "dome ceiling" is selected in the "tank shape" function, the following display appears on the screen: • empty calibr. (for a description, see Page 60) • full calibr.(for a description, see Page 61) L00-FMR2xxxx-20-00-00-en-003 Endress+Hauser...

- Page 71 • empty calibr. (for a description, see Page 60) • full calibr.(for a description, see Page 61) • diameter of bypass / stilling well (for a description, see Page 62) L00-FMR2xxxx-20-00--00-en-005 Note! You can also specify the pipe diameter in this display. Endress+Hauser...

- Page 72 • full calibr.(for a description, see Page 61) L00-FMR2xxxx-20-00--00-en-006 Basic Setup step 4/4: • This step starts the tank mapping • The measured distance and the current measured value are always displayed in the header • A description is given on Page 63 L00-FMR2xxxx-20-00--00-en-007 Endress+Hauser...

- Page 73 When using the Wave Guide antenna: No orientation is required! 6.5.2 User-specific applications (operation) For details of setting the parameters of user-specific applications, see separate documentation BA221F/00/en "Description of the instrument functions for Micropilot M" on the enclosed CD-ROM. Endress+Hauser...

-

Page 74: Maintenance

They contain the related replacement instructions. All the spare parts kits which you can order from Endress+Hauser for repairs to the Micropilot M are listed with their order numbers on and . Please contact Endress+Hauser Service for further information on service and spare parts. -

Page 75: Accessories

Micropilot M FMR245 with FOUNDATION Fieldbus Accessories Accessories Various accessories, which can be ordered separately from Endress+Hauser, are available for the Micropilot M. Weather protection cover A Weather protection cover made of stainless steel is recommended for outdoor mounting (order code: 543199-0001). - Page 76 Micropilot M FMR245 with FOUNDATION Fieldbus Commubox FXA291 The Commubox FXA291 connects Endress+Hauser field instruments with CDI interface (= Endress+Hauser Common Data Interface) to the USB interface of a personal computer or a notebook. For details refer to TI405C/07/en. Note! For the following Endress+Hauser instruments you need the "ToF Adapter FXA291"...

- Page 77 20m/65ft; for HART 20m/65ft; for PROFIBUS PA/FOUNDATION Fieldbus Additional option: Basic version Mounting bracket, pipe 1"/ 2" FHX40 - Complete product designation For connection of the remote display FHX40 use the cable which fits the communication version of the respective instrument. Endress+Hauser...

-

Page 78: Trouble-Shooting

Correct configuration Communication ok? Ready does not function of COM port on PC Contact E+H Service Instrument Not ok measures Check basic setup Repeat Measurement ok? Ready incorrectly basic setup Proceed according to section 'Trouble shooting’ in OM L00-FMR2xxxx-19-00-00-en-010 Endress+Hauser... -

Page 79: System Error Messages

W611 less than 2 linearisation number of entered linearisation points < 2 correct linearisation table points for channel 1 W621 simulation ch. 1 on simulation mode is active switch off simulation mode Endress+Hauser... - Page 80 E651 level in safety distance - risk level in safety distance alarm will disappear as soon as level of overspill leaves safety distance; E671 linearisation ch1 not linearisation table is in edit mode activate linearisation table complete, not usable Endress+Hauser...

-

Page 81: Application Errors

2. If necessary, clean antenna antenna 3. If necessary, select better moun- ting position (see Page 13) actual 4. If necessary due to wide interfe- rence echos set function detec- tion window (0A7) to "off" expected t → L00-FMR2xxxx-19-00-00-en-014 Endress+Hauser... - Page 82 If the instrument is configured to Hold by loss of noise level during the Repeat once more empty calibr. echo) after turn on echo the output is set to any value/current. initialisation phase to (005). the power supply high. Caution! Before conformation change with to the edit mode. Endress+Hauser...

-

Page 83: Orientation Of The Micropilot

Turn the flange by one hole or screw the threaded boss by one eighth of a turn. Note the echo quality. Continue to turn until 360° is reached. Optimum alignment: L00-FMRxxxxx-19-00-00-en-002 Fig. 5: Vessel partly full, no interference echo obtained L00-FMRxxxxx-19-00-00-en-003 Fig. 6: Vessel partly full, interference echo obtained: Endress+Hauser... - Page 84 Micropilot M FMR245 with FOUNDATION Fieldbus L00-FMRxxxxx-19-00-00-en-004 Fig. 7: Vessel empty, no interference echo L00-FMRxxxxx-19-00-00-en-005 Fig. 8: Vessel empty, interference echo obtained Fix the flange or threaded boss in this position. If necessary, replace the seal. Carry out tank mapping, see Page 63. Endress+Hauser...

-

Page 85: Spare Parts

6 .. .3 x . 2 4 .. .2 > 7 0 ° C t > 8 5 ° C in a bottom view Ansicht von unten L00-FMR245xx-00-00-06-xx-001 Endress+Hauser... - Page 86 Terminal module 4pole, PROFIBUS PA, FOUNDATION Fieldbus 52014817 Terminal module 4pole, HART, ferrit (F12), GL marine certificate 52014818 Terminal module 4pole, PROFIBUS PA, FOUNDATION Fieldbus ferrit (F12), GL marine certificate 40 Display 52005585 Display VU331 50 Antenna assembly with process connection on request! Endress+Hauser...

- Page 87 Cladding, flange ANSI 2", PTFE disc 65 Sealing kit 535720-9010 consists of: 2 x gasket Pg13.5 FA 2 x O-ring 17.0x2.0 EPDM 1 x O-ring 49.21x3.53 EPDM 2 x O-ring 17.12x2.62 FKM 1 x O-ring 113.9x3.63 EPDM 1 x O-ring 72.0x3.0 EPDM Endress+Hauser...

- Page 88 6 .. .3 x . 2 4 .. .2 > 7 0 ° C t > 8 5 ° C bottom view Ansicht von unten L00-FMR245xx-00-00-06-xx-002 Endress+Hauser...

- Page 89 EEx d 52018949 Terminal module 4pole, 2-wire, HART, EEx ia, overvoltage protection 52018950 Terminal module 4pole, 2-wire, PROFIBUS PA / FOUNDATION Fieldbus, EEx ia, overvoltage protection 40 Display 52005585 Display VU331 50 Antenna assembly with process connection on request! Endress+Hauser...

- Page 90 Cladding, flange ANSI 2", PTFE disc 65 Sealing kit 535720-9010 consists of: 2 x gasket Pg13.5 FA 2 x O-ring 17.0x2.0 EPDM 1 x O-ring 49.21x3.53 EPDM 2 x O-ring 17.12x2.62 FKM 1 x O-ring 113.9x3.63 EPDM 1 x O-ring 72.0x3.0 EPDM Endress+Hauser...

- Page 91 Micropilot M FMR245 with FOUNDATION Fieldbus Trouble-shooting Spare parts Micropilot M FMR 245, F23 housing with combined wiring and electrinics compartment Stainless steel housing on request! 20 Cover 52018670 Cover F23, 316L, sight glass, gasket 52018671 DeCoverckel F23, 316L, gasket Endress+Hauser...

-

Page 92: Disposal

– HART-Communicator DXR 375 with Rev. 1, DD 1. Contact addresses of Endress+Hauser The addresses of Endress+Hauser are given on the back cover of this operating manual. If you have any questions, please do not hesitate to contact your E+H representative. Endress+Hauser... -

Page 93: Technical Data

Typical statements for reference conditions, include linearity, repeatability, and hysteresis: • FMR 245: up to10 m ±3 mm, off10 m ±0,03% of measuring range Resolution Digital / analog in % 4…20 mA • FMR 245: 1mm / 0.03 % of measuring range Endress+Hauser... - Page 94 — — 8.6 % — — — — — 22 % — 687.2 — — — — 41.8 % Note! When the pressure is known and constant, this measured error can, for example, be compensated by means of linearization. Endress+Hauser...

- Page 95 • in a stilling well/Wave Guide antenna: ε r ≥ 1,9 • in free space: 10.1.6 Mechanical construction Weight • F12/T12 housing: approx 4 kg + weight of flange • F23 housing: approx 7.4 kg + weight of flange Endress+Hauser...

- Page 96 Micropilot M FMR245 with FOUNDATION Fieldbus 10.1.7 Certificates and approvals CE approval The measuring system meets the legal requirements of the EC-guidelines. Endress+Hauser confirms the instrument passing the required tests by attaching the CE-mark. RF approvals R&TTE, FCC Overspill protection german WHG, see ZE 244F/00/de.

- Page 97 Note! This supplementary documentation can be found on our product pages on www.endress.com. Supplementary • Technical Information (TI345F/00/en) Documentation • Operating Instructions "Description of instrument functions" (BA221F/00/en) • Safety Manual "Functional Safety Manual" (SD150F/00/en). • Certificate "German WHG" (ZE244F/00/de). Endress+Hauser...

-

Page 98: Appendix

Note! The default values of the parameters are typed in boldface. L00-FMR2xxxx-19-00-01-en-038 Endress+Hauser... - Page 99 FMR230 only default: 5 s simulation sim. off sim. level simulation value sim. volume sep. character display test . point , comma measured dist. measured level detection window application par. not modified modified reset distance unit download mode L00-FMR2xxxx-19-00-02-en-038 Endress+Hauser...

-

Page 100: Description Of Functions

Micropilot M FMR245 with FOUNDATION Fieldbus 11.2 Description of functions Note! A detailed description of the function groups, functions and parameters is given in the documentation BA 221F/00/en "Description of the instrument functions of the Micropilot M" on the enclosed CD-ROM. Endress+Hauser... -

Page 101: Function And System Design

Refer to the above figure for the reference point for "E". The Micropilot is equipped with functions to suppress interference echoes. The user can activate these functions. They ensure that interference echoes (i.e. from edges and weld seams) are not interpreted as level echo. Endress+Hauser... - Page 102 • with a Personal Computer, FXA193 (RS232C) or FXA291 and ToF Adapter FXA291 (USB) and the operating software "ToF Tool - FieldTool Package" respectively "FieldCare". The ToF Tool is a graphical operating software for instruments from Endress+Hauser that operate based on the time-of-flight principle (radar, ultrasonic, guided micro-impulse). It assists with commissioning, securing data, signal analysis and documentation of the measuring point.

-

Page 103: Index

....... . 13 tank shape........57, 70 Endress+Hauser... - Page 104 ........24 Endress+Hauser...

- Page 105 Erklärung zur Kontamination und Reinigung Please reference the Return Authorization Number (RA#), obtained from Endress+Hauser, on all paperwork and mark the RA# clearly on the outside of the box. If this procedure is not followed, it may result in the refusal of the package at our facility.

- Page 106 www.endress.com/worldwide BA253F/00/en/05.06 52012500 CCS/FM+SGML 6.0 ProMoDo 52012500...