Endress+Hauser Micropilot M FMR250 Operating Instructions Manual

Level-radar

Hide thumbs

Also See for Micropilot M FMR250:

- Operating instructions manual (112 pages) ,

- Technical information (56 pages) ,

- Brief operating instructions (36 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Technical Information

Advertisement

Table of Contents

Summary of Contents for Endress+Hauser Micropilot M FMR250

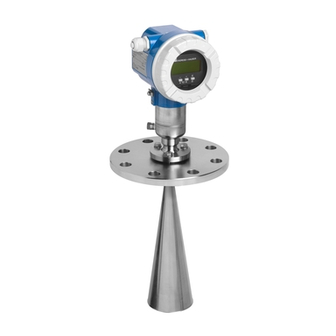

- Page 1 Operating Instructions Micropilot M FMR250 Level-Radar BA336F/00/EN/03.10 71112115 Valid as of software version: 01.05.00...

- Page 2 Micropilot M FMR250 FOUNDATION Fieldbus Brief operating instructions Micropilot M FMR240/244/245/250 - Brief operating instructions KA235F/00/a2/08.06 52025245 Contrast: measured dist./ value meas value Group selection process empty check start media tank tank medium full pipe dist./ range of type shape shape cond.

-

Page 3: Table Of Contents

Incoming acceptance, transport, storage ..10 9.10 Contact addresses of Endress+Hauser ... 87 Installation conditions ..... . 11 Installation instructions . -

Page 4: Safety Instructions

Safety instructions Micropilot M FMR250 FOUNDATION Fieldbus Safety instructions Designated use The Micropilot M is a compact level radar for the continuous, contactless measurement of predominantly solids. The device can also be freely mounted outside closed metal vessels because of its operating frequency of about 26 GHz and a maximum radiated pulsed energy of 1 mW (average power output 1 μW). -

Page 5: Notes On Safety Conventions And Symbols

Micropilot M FMR250 FOUNDATION Fieldbus Safety instructions Notes on safety conventions and symbols In order to highlight safety-relevant or alternative operating procedures in the manual, the following conventions have been used, each indicated by a corresponding symbol in the margin. -

Page 6: Identification

Identification Micropilot M FMR250 FOUNDATION Fieldbus Identification Device designation 2.1.1 Nameplate The following technical data are given on the instrument nameplate: ENDRESS+HAUSER Order Code: Ser.-No.: if modification see sep. label Dat./Insp.: Typenschild-FMxxxx-xx Information on the nameplate of the Micropilot M... - Page 7 Micropilot M FMR250 FOUNDATION Fieldbus Identification 2.1.2 Ordering structure This overview does not mark options which are mutually exclusive. Approval: A Non-hazardous area ATEX II 1/2G EEx ia IIC T6 ATEX II 1/2G EEx d [ia] IIC T6 G ATEX II 3G EEx nA II T6...

- Page 8 Identification Micropilot M FMR250 FOUNDATION Fieldbus Output; Operation: 4-20mA SIL HART; w/o display, via communication K 4-20mA SIL HART; prepared for FHX40, remote display (Accessory) C PROFIBUS PA; 4-line display VU331, envelope curve display on site D PROFIBUS PA; w/o display, via communication PROFIBUS PA;...

-

Page 9: Scope Of Delivery

The device complies with the applicable standards and regulations as listed in the EC declaration of conformity and thus complies with the statutory requirements of the EC directives. Endress+Hauser confirms the successful testing of the device by affixing to it the CE mark. -

Page 10: Installation

Installation Micropilot M FMR250 FOUNDATION Fieldbus Installation Quick installation guide At mounting adjust the marking at the instrument flange! Installation in vessel (free space): Mark on process connector facing the nearest vessel wall! Turn housing The housing can be turned 350° in order to simplify access to the... -

Page 11: Installation Conditions

Micropilot M FMR250 FOUNDATION Fieldbus Installation Installation conditions 3.3.1 Dimensions Housing dimensions 65 (2.56) 78 (3.07) max. 110 (4.33) ENDRESS+HAUSER F12 housing (Aluminium) 85 (3.35) mm (in) L00-F12xxxx-06-00-00-en-001 max. 100 (4.33) 94 (3.7) 65 (2.56) 78 (3.07) ENDRESS+HAUSER T12 housing (Aluminium) 85 (3.35) - Page 12 Installation Micropilot M FMR250 FOUNDATION Fieldbus Process connection and antenna (option "4, 5") F12 / T12 / F23 housing Threaded connection Flange DN80…100 Alignment unit with 1½” BSPT (R1½”) or equivalent E+H UNI flange DN 100/200/250 or 1½NPT ø60 ø60 ø60...

- Page 13 Micropilot M FMR250 FOUNDATION Fieldbus Installation Process connection and antenna (option "D, E, G, H") F12 / T12 / F23 housing Threaded connection Flange DN80…100 E+H UNI flange DN 200/250 Alignment unit with 1½” BSPT (R1½”) or equivalent E+H UNI flange DN 100/200/250 or 1½NPT...

- Page 14 Installation Micropilot M FMR250 FOUNDATION Fieldbus Endress+Hauser UNI flange The number of bolts has sometimes been reduced. The bolt-holes have been enlarged for adaption of dimensions, therefore, the flange needs to be properly aligned to the counterflange before the bolts are tightened.

- Page 15 Micropilot M FMR250 FOUNDATION Fieldbus Installation Top target positioner with Endress+Hauser UNI flange clamping screw 3 x M8 shifty at 120° ø85 E+H UNI flange Viton seal DN100/200/250 a0011477-en Endress+Hauser...

- Page 16 Installation Micropilot M FMR250 FOUNDATION Fieldbus 3.3.2 Engineering hints Orientation • Recommended distance (1) wall – outer edge of nozzle: ~1/6 of vessel diameter. However, the device should not, under any circumstances, be mounted less than 20 cm (7.87 in) from the vessel wall.

- Page 17 Micropilot M FMR250 FOUNDATION Fieldbus Installation Measurement in a plastic tank If the outer wall of the tank is made of a non-conductive material (e.g. GRP), microwaves can also be reflected off interfering installations outside the signal beam (e.g. metallic pipes (1), ladders (2), grates (3), …).

- Page 18 Installation Micropilot M FMR250 FOUNDATION Fieldbus Measuring conditions • The measuring range begins, where the beam hits the bottom. Particularly with conical outlets the level cannot be detected below this point. The maximum measuring range can be increased in such applications by using a top target positioner (→ ä 16).

- Page 19 Micropilot M FMR250 FOUNDATION Fieldbus Installation Measuring range The usable measuring range depends on the size of the antenna, the reflectivity of the medium, the mounting location and eventual interference reflections. The maximum configurable range is 70 m (230 ft).

-

Page 20: Installation Instructions

Installation Micropilot M FMR250 FOUNDATION Fieldbus Installation instructions 3.4.1 Mounting kit In addition to the tool needed for flange mounting, you will require the following tool: • A key AF60 for threaded boss • 4 mm (0.16 in) Allen wrench for turning the housing 3.4.2... - Page 21 Micropilot M FMR250 FOUNDATION Fieldbus Installation Standard installation FMR250 with horn antenna • Observe installation instructions, → ä 16. • Marker is aligned towards vessel wall. • The marker is always exactly in the middle between two bolt-holes in the flange.

- Page 22 Installation Micropilot M FMR250 FOUNDATION Fieldbus Standard installation FMR250 with parabolic antenna • Observe installation instructions, → ä 16. • Marker is aligned towards vessel wall. • The marker is always exactly in the middle between two bolt-holes in the flange.

- Page 23 Micropilot M FMR250 FOUNDATION Fieldbus Installation Examples for installation with small flange (< parabolic reflector) for parabolic antenna (option "G, H") standard installation nozzle for installation in nozzle you can dismantle the parabolic reflector Antenna size 200 mm (8”) 250 mm (10”) D [mm (inch)] 173 (6.81)

- Page 24 Installation Micropilot M FMR250 FOUNDATION Fieldbus FMR250 with top target positioner Using top target positioner it is possible to tilt the antenna axis by up to 15° in all directions. The top target positioner is used for the optimum alignment of the radar beam with the bulk solids surface.

-

Page 25: Post-Installation Check

Micropilot M FMR250 FOUNDATION Fieldbus Installation 3.4.3 Turn housing After mounting, the housing can be turned 350° in order to simplify access to the display and the terminal compartment. Proceed as follows to turn the housing to the required position: •... -

Page 26: Wiring

Wiring Micropilot M FMR250 FOUNDATION Fieldbus Wiring Quick wiring guide Wiring in F12/F23 housing " Before connection please note the following: ● Foundation Fieldbus devices are marked on the nameplate (1). The voltage is determined by the Caution! ENDRESS+HAUSER Made in Germany... - Page 27 Micropilot M FMR250 FOUNDATION Fieldbus Wiring Wiring in T12 housing " Before connection please note the following: ENDRESS+HAUSER ● Foundation Fieldbus devices are marked on the nameplate (1). Made in Germany MICROPILOT M D-79689 Maulburg Order Code: FMR2xx-14EALJAA2A The voltage is determined by the Foundation Fieldbus standard Caution! Ser.-No.:...

- Page 28 Wiring Micropilot M FMR250 FOUNDATION Fieldbus Wiring with Foundation Fieldbus connector Before connection please note the following: " ● FOUNDATION Fieldbus devices are marked on the ENDRESS+HAUSER Made in Germany MICROPILOT M D-79689 Maulburg nameplate (1). The voltage is determined by the...

-

Page 29: Connecting The Measuring Unit

Micropilot M FMR250 FOUNDATION Fieldbus Wiring Connecting the measuring unit 4.2.1 Cable entry • Cable gland: M20x1.5 (for Ex d: cable entry) • Cable entry: G½ or ½NPT 4.2.2 Supply voltage The following values are the voltages across the terminals directly at the instrument:... -

Page 30: Recommended Connection

Wiring Micropilot M FMR250 FOUNDATION Fieldbus Recommended connection For maximum EMC protection please observe the following points: • The external ground terminal on the transmitter must be connected to ground. • The continuity of the cable screening between tapping points must be ensured. -

Page 31: Operation

Micropilot M FMR250 FOUNDATION Fieldbus Operation Operation This chapter gives an overview of the different operating options for the device. The different methods of parameter access are described and the preconditions for each method are stated. The meaning of the parameters is not described in this chapter. Instead, refer to: •... - Page 32 Operation Micropilot M FMR250 FOUNDATION Fieldbus 5.1.1 On-site operation Options for on-site operation • Display and operating module • Endress+Hauser operating software "FieldCare" Parameter access by on-site operation The following parameters can be accessed by on-site operation: • Parameters of the device specific blocks (Sensor Block, Diagnostic Block, Display Block) •...

-

Page 33: Operation With The Display And Operating Module

Micropilot M FMR250 FOUNDATION Fieldbus Operation Operation with the display and operating module (liquid crystal display) Orde Orde Ser.- Ser.- r Cod r Cod No.: No.: sber surin sber surin eich eich g rang g rang U 16... U 16... - Page 34 Operation Micropilot M FMR250 FOUNDATION Fieldbus 5.2.1 Display Liquid crystal display (LCD): Four lines with 20 characters each. Display contrast adjustable through key combination. Headline Position indicator ENDRESS + HAUSER Symbol Main value Bargraph Unit – Selection list Function groups -> Functions HOME F000 F001 F002 F003 F004 ...

- Page 35 Micropilot M FMR250 FOUNDATION Fieldbus Operation 5.2.3 Function of the keys Key(s) Meaning Navigate upwards in the selection list. Edit numeric value within a function. Navigate downwards in the selection list. Edit numeric value within a function. Navigate to the left within a function group.

- Page 36 Operation Micropilot M FMR250 FOUNDATION Fieldbus 5.2.4 The operating menu General structure of the operating menu The operating menu is made up of two levels: • Function groups (00, 01, 03, …, 0C, 0D): The individual operating options of the instrument are split up roughly into different function groups.

- Page 37 Micropilot M FMR250 FOUNDATION Fieldbus Operation Navigation within the menu ENDRESS + HAUSER – >3 s media type basic setup Return to liquids tank shape medium property safety settings Group Selection solids dome ceiling unknown linearisation horizontal cyl DC: < 1.9 extended calibr.

-

Page 38: Operation With An Endress+Hauser Operating Program

FieldCare is an Endress+Hauser asset management tool based on FDT technology. With FieldCare, you can configure all Endress+Hauser devices as well as devices from other manufacturers that support the FDT standard. Hardware and software requirements you can find on the internet: www.endress.com È... - Page 39 Micropilot M FMR250 FOUNDATION Fieldbus Operation Signal analysis via envelope curve MicropilotM-en-306 Tank linearisation MicropilotM-en-307 Endress+Hauser...

-

Page 40: Operation With A Foundation Fieldbus Configuration Program

Operation Micropilot M FMR250 FOUNDATION Fieldbus Operation with a FOUNDATION Fieldbus configuration program 5.4.1 FOUNDATION Fieldbus configuration programs The user can obtain special configuration and operating programs offered by different manufacturers for use in configuration. These can be used for configuring both the FOUNDATION Fieldbus functions and all the device-specific parameters. -

Page 41: Operation With The Field Communicator

A FOUNDATION Fieldbus configuration tool offers two types of parameter representation: • Representation by parameter name Examples: "PAROPERATIONCODE", "PARRESET" • Representation by parameter label (identical to the labels on the display module and in an Endress+Hauser operation tool) Examples: "unlock parameter", "reset" Operation with the Field Communicator 375, 475 5.5.1 Connection The handheld terminal is directly connected to the FOUNDATION Fieldbus communication line. - Page 42 Operation Micropilot M FMR250 FOUNDATION Fieldbus 5.5.4 Example basic setup dsdmdm df das. asdas fa asas la. media type: liquids Fieldbus Live Device List Number of Devices found = 1 liquids Address solids E+H_MICROPILOT_M_XXXXXXX 247 375 Field Communicator NEXT CANCEL...

-

Page 43: Commissioning

• "Resetting the device", → ä 45 • "Commissioning by the display and operatig module", → ä 47 • "Basic Setup with the Endress+Hauser operating program", → ä 60 • "Commissioning with a FOUNDATION Fieldbus configuration tool", → ä 64 •... - Page 44 Commissioning Micropilot M FMR250 FOUNDATION Fieldbus 6.2.2 Key combination (display and operating module) Locking Press S, O and F simultaneously. Unlocking If you try to change a parameter, the following appears: L00-fmrxf0a4-20-00-00-de-001 Press S, O and F simultaneously. The "unlock parameter" (0A4) function appears.

-

Page 45: Resetting The Device

Micropilot M FMR250 FOUNDATION Fieldbus Commissioning Resetting the device It is advisable to reset the device parameters before the commissioning if you want to use a device with an unknown history. 6.3.1 Resetting the parameters of the FOUNDATION Fieldbus func-... - Page 46 – "inactive": deactivates the tank map but does not delete it. It can be re-activated when required. – "active": activates the tank map. Resetting the tank map with an Endress+Hauser operating program In the function group "extended calibr." select the "cust. tank map" (055) function. Select the required option ("reset", "inactive" or "active") Resetting the tank map with a FOUNDATION Fieldbus configuration tool In the Sensor Block select the parameter PARCUSTTANKMAP (cust tank map).

-

Page 47: Commissioning By The Display And Operatig Module

Micropilot M FMR250 FOUNDATION Fieldbus Commissioning Commissioning by the display and operatig module 6.4.1 Power up instrument After switching on the supply voltage, the instrument is first initialised. L00-fmp-fxxx-20-00-00-en-003 Then the following appear for approximately five seconds: • Device type •... - Page 48 Commissioning Micropilot M FMR250 FOUNDATION Fieldbus 6.4.2 Application parameters Function "media type" (001) ⇒ ENDRESS + HAUSER – This function is used to select the media type. Selection: • liquid • solid With the selection "liquid" only the With the selection "solids" only the...

- Page 49 Micropilot M FMR250 FOUNDATION Fieldbus Commissioning Function "tank shape" (002), liquids only ⇒ ENDRESS + HAUSER – This function is used to select the tank shape. Selection: • dome ceiling • horizontal cyl • bypass • stilling well • flat ceiling •...

- Page 50 Commissioning Micropilot M FMR250 FOUNDATION Fieldbus Function "process cond." (004) , liquids only ⇒ ENDRESS + HAUSER – This function is used to select the process conditions. Selection: • standard • calm surface • turb. surface • agitator • fast change •...

- Page 51 Micropilot M FMR250 FOUNDATION Fieldbus Commissioning Function "vessel / silo" (00A), solids only ⇒ ENDRESS + HAUSER – This function is used to select the vessel / silo. Selection: • unknown • metal silo • concrete silo • bin / bunker •...

- Page 52 Commissioning Micropilot M FMR250 FOUNDATION Fieldbus Function "process cond." (00C), solids only ⇒ ENDRESS + HAUSER – This function is used to select the process conditions. Selection: • standard • fast change • slow change • test:no filter Function "empty calibr." (005) ⇒...

- Page 53 Micropilot M FMR250 FOUNDATION Fieldbus Commissioning Function "full calibr." (006) ⇒ ENDRESS + HAUSER – This function is used to enter the distance from the minimum level to the maximum level (=span). In principle, it is possible to measure up to the tip of the antenna. However, due to considerations regarding corrosion and build-up, the end of the measuring range should not be chosen any closer than 50 mm (1.97 in) to the tip of the antenna.

- Page 54 Commissioning Micropilot M FMR250 FOUNDATION Fieldbus Function "dist./meas.value" (008) ⇒ ENDRESS + HAUSER – The distance measured from the reference point to the product surface and the level calculated with the aid of the empty adjustment are displayed. Check whether the values correspond to the actual level or the actual distance.

- Page 55 Micropilot M FMR250 FOUNDATION Fieldbus Commissioning dist. too big • This error cannot be remedied by interference echo mapping • Check the application parameters (002), (003), (004) and "empty calibr." (005) dist. unknown If the actual distance is not known, no mapping can be carried out.

- Page 56 Commissioning Micropilot M FMR250 FOUNDATION Fieldbus Function "dist./meas.value" (008) ⇒ ENDRESS + HAUSER – The distance measured from the reference point to the product surface and the level calculated with the aid of the empty adjustment are displayed. Check whether the values correspond to the actual level or the actual distance.

- Page 57 Micropilot M FMR250 FOUNDATION Fieldbus Commissioning 6.4.3 Envelope curve After the basic setup, an evaluation of the measurement with the aid of the envelope curve ("envelope curve" (0E) function group) is recommended. Function "plot settings" (0E1) ⇒ ENDRESS + HAUSER –...

- Page 58 Commissioning Micropilot M FMR250 FOUNDATION Fieldbus Function "envelope curve display" (0E3) The envelope curve is displayed in this function. You can use it to obtain the following information: quality of evaluated echo full calibr. evaluated echo is marked empty calibr.

- Page 59 Micropilot M FMR250 FOUNDATION Fieldbus Commissioning Move mode Then press to switch to Move mode. Either is displayed. • shifts the curve to the right. • shifts the curve to the left. L00-FMxxxxxx-07-00-00-yy-008 Vertical Zoom mode Press once more to switch to Vertical Zoom mode.

-

Page 60: Basic Setup With The Endress+Hauser Operating Program

Commissioning Micropilot M FMR250 FOUNDATION Fieldbus Basic Setup with the Endress+Hauser operating program To carry out the basic setup with the operating program, proceed as follows: • Start the operating program and establish a connection. • Select the "basic setup" function group in the navigation window. - Page 61 Micropilot M FMR250 FOUNDATION Fieldbus Commissioning Basic Setup step 2/4: • Enter the application parameters: – Vessel / silo – Medium property – Process cond. MicropilotM-en-412 Basic Setup step 3/4: If "metal silo", "concrete silo", "..." is selected in the "vessel / silo" function, the following display appears on the screen: •...

- Page 62 Commissioning Micropilot M FMR250 FOUNDATION Fieldbus Basic Setup step 4/4: • This step starts the tank mapping • The measured distance and the current measured value are always displayed in the header MicropilotM-en-404 6.5.1 Signal analysis via envelope curve After the basic setup, an evaluation of the measurement using the envelope curve is recommended.

- Page 63 Micropilot M FMR250 FOUNDATION Fieldbus Commissioning 6.5.2 User-specific applications (operation) For details of setting the parameters of user-specific applications, see separate documentation BA291F/00/EN "Description of Instrument Functions" on the enclosed CD-ROM. Endress+Hauser...

-

Page 64: Commissioning With A Foundation Fieldbus Configuration Tool

Commissioning Micropilot M FMR250 FOUNDATION Fieldbus Commissioning with a FOUNDATION Fieldbus configuration tool Note! For commissioning of the device with a FOUNDATION Fieldbus configuration tool you need to know the DEVICE_ID, which consists of the following parts: Device_ID = 452B48100F-XXXXXXXX... - Page 65 Micropilot M FMR250 FOUNDATION Fieldbus Commissioning 6.6.2 Parametrization of the Resource Block (Start Index: 400) Enter the desired block name (optional). Factory setting: RESOURCE_XXXXXXXX Opern the Resource Block On delivery, write protection is disabled so that you can access the write parameters via FOUNDATION Fieldbus.

- Page 66 Commissioning Micropilot M FMR250 FOUNDATION Fieldbus Open the FOUNDATION Fieldbus method "basic setup": FMR2xx-FF-Methode-in-NIConfig The method contains the following parameters a. Application parameters (→ ä 48) – PARMEDIATYPE (media type) With the selection "liquid" only the following application parameters can be adjusted: –...

- Page 67 This can be done in two different ways: – by the display and operating module (→ ä 57) – by an Endress+Hauser operating program (→ ä 62) 6.6.4 Parametrization of the Analog Input Blocks Prosonic M has two Analog Input Blocks that can be assigned to the various process variables.

- Page 68 Commissioning Micropilot M FMR250 FOUNDATION Fieldbus If required, use the following parameters to define the limit values for alarm and warning messages: – HI_HI_LIM -> Limit value for the upper alarm – HI_LIM -> Limit value for the upper warning –...

-

Page 69: Commissioning With The Field Communicator 375, 475

Micropilot M FMR250 FOUNDATION Fieldbus Commissioning Commissioning with the Field Communicator 375, 475 The steps of the commissioning procedure are the same as with a FOUNDATION Fieldbus configuration tool (→ ä 64). The blocks should be parametrized in the following order: •... -

Page 70: Maintenance

Repairs The Endress+Hauser repair concept assumes that the measuring devices have a modular design and that customers are able to undertake repairs themselves (→ ä 86, "Spare Parts"). Please contact Endress+Hauser Service for further information on service and spare parts. -

Page 71: Accessories

L00-FMR2xxxx-00-00-06-en-001 Commubox FXA291 The Commubox FXA291 connects Endress+Hauser field instruments with CDI interface (= Endress+Hauser Common Data Interface) to the USB interface of a personal computer or a notebook. For details refer to TI405C/07/EN. Note! For the instrument you need the "ToF Adapter FXA291" as an additional accessory. -

Page 72: Remote Display Fhx40

Accessories Micropilot M FMR250 FOUNDATION Fieldbus Remote display FHX40 Wall-mounting Pipe-mounting (without mounting bracket) (mounting bracket and plate supplied optionally, s. product structure) Separate housing FHX40 (IP 65) Micropilot M (4.8) Levelflex M Prosonic M O rd O rd S er... -

Page 73: Horn Cover For 80 Mm (3") And 100 Mm (4") Horn Antenna

Micropilot M FMR250 FOUNDATION Fieldbus Accessories Horn cover for 80 mm (3") and 100 mm (4") horn antenna 8.5.1 Technical data Materials Process conditions Horn cover PTFE Vessel pressure max. 0,5 bar (7.252 psi) Screws 316L Process temperature max. 130 °C (266 °F) - Page 74 Accessories Micropilot M FMR250 FOUNDATION Fieldbus mm (in) ³ DN150 450 (17.72) L00-FMR2xxxx-06-00-00-xx-003 Horn cover for horn antenna 100 mm (4") – for antenna diameter d = 95 mm (3.74 in) – for FMR240: antenna variant H, 5 – for FMR250: antenna variant E Note! The horn cover is not allowed to use in areas, where explosion proofed equipment is necessary.

-

Page 75: Trouble-Shooting

Micropilot M FMR250 FOUNDATION Fieldbus Trouble-shooting Trouble-shooting Trouble-shooting instructions Micropilot M FMR 250 -Trouble Shooting Check voltage and Not ok compare it with the Instrument does Connect the Instrument works? Ready specifications on the not respond correct voltage nameplate. Check the polarity... -

Page 76: System Error Messages

• Device display: error symbol in the "measured value" (000) function • Device display or Endress+Hauser operating program: in the "diagnostics" (0A) function group in the "present error" (0A0) function Only the highest priority error is displayed; in the case of multiple errors, you can scroll between the different error messages by pressing O or S. - Page 77 Micropilot M FMR250 FOUNDATION Fieldbus Trouble-shooting 9.2.3 Types of error Type of error Symbol Meaning The output signal assumes a value which can be set using the "output on alarm" (010) function: • MAX: 110% Alarm (A) • MIN: -10% •...

- Page 78 Trouble-shooting Micropilot M FMR250 FOUNDATION Fieldbus Code Description Possible cause Remedy A164 electronics defect hardware problem reset; if alarm prevails after reset, exchange electronics A171 electronics defect hardware problem reset; if alarm prevails after reset, exchange electronics A231 sensor 1 defect...

- Page 79 Micropilot M FMR250 FOUNDATION Fieldbus Trouble-shooting 9.2.5 Influence of the error codes on the output signal The following table describes the influence of the error codes on the status of the cyclic output values as well as on the parameters BLOCK_ERR and XD_ERROR in the Sensor Block.

-

Page 80: Application Errors In Liquids

Trouble-shooting Micropilot M FMR250 FOUNDATION Fieldbus Application errors in liquids Error Output Possible cause Remedy A warning or alarm Depending on the configuration See table of error 1. See table of error messages messages (→ ä 76) (→ ä 76) has occurred →... - Page 81 Micropilot M FMR250 FOUNDATION Fieldbus Trouble-shooting Error Output Possible cause Remedy → If the surface is not Signal is weakened by 1. Carry out tank mapping basic calm (e.g. filling, the rough surface – the setup emptying, agitator interference echoes are 100% 2.

-

Page 82: Application Errors In Solids

Trouble-shooting Micropilot M FMR250 FOUNDATION Fieldbus Application errors in solids Error Output Possible cause Remedy A warning or alarm Depending on the configuration See table of error 1. See table of error messages messages (→ ä 76) (→ ä 76) has occurred →... - Page 83 Micropilot M FMR250 FOUNDATION Fieldbus Trouble-shooting Error Output Possible cause Remedy → During filling/ Signal is weakened (e.g. 1. Carry out tank mapping basic emptying or by fluidisation of the setup 100% measumement the surface, extreme dust 2. Increase the output damping...

-

Page 84: Orientation Of The Micropilot

Trouble-shooting Micropilot M FMR250 FOUNDATION Fieldbus Orientation of the Micropilot For orientation a marker is found on the flange or threaded boss of the Micropilot. During installation this must be oriented as follows (→ ä 10): • In tanks: to the vessel wall •... - Page 85 Micropilot M FMR250 FOUNDATION Fieldbus Trouble-shooting L00-FMRxxxxx-19-00-00-en-004 Vessel empty, no interference echo L00-FMRxxxxx-19-00-00-en-005 Vessel empty, interference echo obtained Fix the flange or threaded boss in this position. If necessary, replace the seal. Carry out tank mapping, → ä 54. Top target positioner - optional Using top target positioner it is possible to tilt the antenna axis by up to 15°...

-

Page 86: Spare Parts

Trouble-shooting Micropilot M FMR250 FOUNDATION Fieldbus Spare Parts An overview of the spare parts for your device is available in the internet at www.endress.com. To obtain information on the spare parts, proceed as follows: Go to "www.endress.com" and select your country. -

Page 87: Return

Micropilot M FMR250 FOUNDATION Fieldbus Trouble-shooting Return The following procedures must be carried out before a transmitter is sent to Endress+Hauser e.g. for repair or calibration: • Remove all residue which may be present. Pay special attention to the gasket grooves and crevices where fluid may be present. -

Page 88: Technical Data

Technical data Micropilot M FMR250 FOUNDATION Fieldbus Technical data 10.1 Additional technical data 10.1.1 Input Measured variable The measured variable is the distance between a reference point and a reflective surface (i.e. medium surface). The level is calculated based on the tank height entered. - Page 89 Micropilot M FMR250 FOUNDATION Fieldbus Technical data 10.1.3 Data of the FOUNDATION Fieldbus interface Basic Data Device Type 100F (hex) Device Revision 05 (hex) DD Revision 01 (hex) CFF Revision 01 (hex) ITK Version ITK-Certification Driver-No. IT042000 Link Master (LAS) cabable Link Master / Basic Device yes;...

- Page 90 Technical data Micropilot M FMR250 FOUNDATION Fieldbus Function Blocks Block Content Execution time Functionality Resource Block The Resource Block contains all the data that uniquely enhanced identifies the field device. It is an electronic version of a nameplate of the device.

- Page 91 Micropilot M FMR250 FOUNDATION Fieldbus Technical data 10.1.4 Auxiliary energy Terminals Cable cross-section: 0.5 to 2.5 mm² (20 to 14 AWG) Cable entry • Cable gland M20x1.5 (recommended cable diameter 6 to 10 mm (0.24 to 0.39 in)) • Cable entry G½ or ½NPT •...

- Page 92 Technical data Micropilot M FMR250 FOUNDATION Fieldbus 10.1.5 Performance characteristics Reference operating • temperature = +20 °C ±5 °C (+68 °F ±41 °F) conditions • pressure = 1013 mbar abs. ±20 mbar (15 psi ±0.29 psi) • relative humidity (air) = 65 % ±20 % •...

- Page 93 (-14.5 psi to 232 psi) 316L/1.4404/1.4435 ↑ Ordering information, → ä 6 Endress+Hauser UNI flange: -1 bar to +1 bar (-14.5 psi to +14.5 psi) Optional top target positioner: ±15°, seal: FMK Viton GLT ε ε r ≥ 1.6 (for horizontal, even product surfaces: r ≥...

- Page 94 Technical data Micropilot M FMR250 FOUNDATION Fieldbus 10.1.8 Mechanical construction Weight • F12/T12 housing: approx 6 kg (13.32 lbs) + weight of flange • F23 housing: approx 9,4 kg (20.73 lbs) + weight of flange Material Materials of T12 and F12 housing (seawater-resistant, powder-coated)

- Page 95 Micropilot M FMR250 FOUNDATION Fieldbus Technical data Materials of F23 housing (corrosion-resistant) F23 housing 316L (1.4404/1.4435) L00-x12xxxx-16-00-00-en-001 Pos. Part Material Housing body: 1.4404; Sensor neck: 1.4435; F23 housing earth connection block: 1.4435 Cover 1.4404 Sealing Fa. SHS: EPDM 70pW FKN...

- Page 96 Screws Flange Endress+Hauser supplies DIN/EN flanges made of stainless steel according to AISI 316L (DIN/EN material number 1.4404 or 1.4435). With regard to their temperature stability properties, the materials 1.4404 and 1.4435 are grouped under 13E0 in EN1092-1 Tab. 18. The chemical composition of the two materials can be identical.

- Page 97 Micropilot M FMR250 FOUNDATION Fieldbus Technical data 10.1.9 Certificates and approvals CE approval The measuring system meets the legal requirements of the EC-guidelines. Endress+Hauser confirms the instrument passing the required tests by attaching the CE-mark. RF approvals R&TTE, FCC External standards and...

- Page 98 Technical data Micropilot M FMR250 FOUNDATION Fieldbus Ex approval Correlation of safety instructions (XA) and certificates (ZD, ZE) to the instrument: Feature Non-hazardous area ATEX II 1/2GD Ex ia IIC T6, Alu blind cover ATEX II 1/2G Ex ia IIC T6,ATEX II 1/3D...

- Page 99 Micropilot M FMR250 FOUNDATION Fieldbus Technical data 10.1.10 Supplementary Documentation Supplementary This supplementary documentation can be found on our product pages on www.endress.com. Documentation • Technical Information (TI390F/00/EN) • Operating Instructions "Description of instrument functions" (BA291F/00/EN) • Brief operating instructions (KA1017F/00/EN)

-

Page 100: Appendix

Appendix Micropilot M FMR250 FOUNDATION Fieldbus Appendix 11.1 Operating menu FOUNDATION Fieldbus basic setup media type tank shape medium cond. process cond. empty calibr. full calibr. liquid dome ceiling unknown standard enter value enter value horizontal cyl. DK: < 1.9... - Page 101 Micropilot M FMR250 FOUNDATION Fieldbus Appendix dist./meas.value check distance range of mapping start mapping dist./meas.value distance = ok input of D and L dist. too small mapping range are displayed manual D and L are displayed pipe diameter dist. unknown enter value dist.

-

Page 102: Block Model Of The Micropilot M

Appendix Micropilot M FMR250 FOUNDATION Fieldbus 11.2 Block model of the Micropilot M The Micropilot M contains the follwoing blocks: • Resource Block (RB2) see Operating Instructions BA013S/04/EN: "FOUNDATION Fieldbus - Overview" • Sensor Block (TBRL) contains the parameters relevant to the measurement •... -

Page 103: Resource Block

Micropilot M FMR250 FOUNDATION Fieldbus Appendix 11.3 Resource block The resource block contains the parameters used to describe physical resources of the device. It has no linkable inputs or outputs. 11.3.1 Operation The resource block is opened by a click on the resource line. -

Page 104: Sensor Block

Appendix Micropilot M FMR250 FOUNDATION Fieldbus 11.4 Sensor block The Sensor block contains the parameters required to calibrate the device. These parameters can also be addressed by using the display module. The calibration of the device, → ä 43ff.. 11.4.1 Operation Parameter changes from the tool are made off-line while the device is operating. - Page 105 Micropilot M FMR250 FOUNDATION Fieldbus Appendix 11.4.5 Methods The FOUNDATION Fieldbus specification provides for the use of so-called methods to simplify the operation of the device. A method is an interactive sequence of steps that must be followed in order to obtain a particular function from the device.

- Page 106 Appendix Micropilot M FMR250 FOUNDATION Fieldbus Parameter Position rel. Variable Name Size Type Access Storage Changeable Indicator Index [bytes] Class in Mode ackn. alarm PARACKNOWLEDGEALARM Unsigned8 dynamic Auto, OOS level/ullage PARLEVELULLAGEMODE Unsigned8 static linearisation PARLINEARISATION Unsigned8 static customer unit PARCUSTOMERUNIT...

-

Page 107: Diagnostic Block

Micropilot M FMR250 FOUNDATION Fieldbus Appendix 11.5 Diagnostic Block 11.5.1 Operation The diagnostic block contains the error messages of the instrument. These parameters can also be addressed by using the display module. The diagnostic block is opened by clicking on the "diagnostic"... -

Page 108: Display Block

Appendix Micropilot M FMR250 FOUNDATION Fieldbus 11.6 Display Block 11.6.1 Operation The display block contains the parameters required to parametrise the display module (which is contained in the remote display and operating unit FHX40). These parameters can also be addressed by using the display module. -

Page 109: Analog Input Block

Micropilot M FMR250 FOUNDATION Fieldbus Appendix 11.7 Analog input block The analog input block conditons the signal output by the Sensor block andoutputs signal to the PCL or other function blocks. L00-FMR2xxxx-05-00-00-en-008 11.7.1 Operation The resource block is opened by a click on the resource line. Parameter changes from the tool are made off-line while the device is operating. - Page 110 Appendix Micropilot M FMR250 FOUNDATION Fieldbus 11.7.3 Output values Parameter Description Either the primary/secondary Sensor block value used to execute the block or a process value associated with it. Comprises value and status. The primary value output as a result of executing the analog input block. Comprises value and status.

- Page 111 Micropilot M FMR250 FOUNDATION Fieldbus Appendix 11.7.5 Output response parameters Parameter Description LOW_CUT Not relevant to level measurement! Determines a threshold for square root linearization below which the output value is set to zero. PV_FTIME Sets the time constant for the output value.

- Page 112 Appendix Micropilot M FMR250 FOUNDATION Fieldbus 11.7.9 Simulation The SIMULATE parameter allows the Sensor block output value to be simulated, provided simulation has also been enabled at the device DIP switch. The simulation must be enabled, a value and/or status entered and the block must be in AUTO mode. During simulation the Sensor output value is substituted by the simulated value.

-

Page 113: List Of Start Indices

Micropilot M FMR250 FOUNDATION Fieldbus Appendix 11.8 List of start indices The following list indicates the start indices for all blocks and objects: Object Start Index Object Dictionary Object Start Index Resource Block Analog Input 1 Function Block Analog Input 2 Function Block... -

Page 114: Patents

Appendix Micropilot M FMR250 FOUNDATION Fieldbus 11.9 Patents This product may be protected by at least one of the following patents. Further patents are pending. • US 5,387,918 i EP 0 535 196 • US 5,689,265 i EP 0 626 063 •... - Page 115 Micropilot M FMR250 FOUNDATION Fieldbus Appendix Endress+Hauser...

- Page 116 Appendix Micropilot M FMR250 FOUNDATION Fieldbus Endress+Hauser...

-

Page 117: Index

Micropilot M FMR250 FOUNDATION Fieldbus Index Index accessories ........71 maintenance . - Page 118 Micropilot M FMR250 FOUNDATION Fieldbus Index weather protection ......16 weather protection cover ......71 wiring .

- Page 119 Erklärung zur Kontamination und Reinigung Please reference the Return Authorization Number (RA#), obtained from Endress+Hauser, on all paperwork and mark the RA# clearly on the outside of the box. If this procedure is not followed, it may result in the refusal of the package at our facility.

- Page 120 www.endress.com/worldwide BA336F/00/EN/03.10 71112115 71112115 CCS/FM+SGML 6.0...