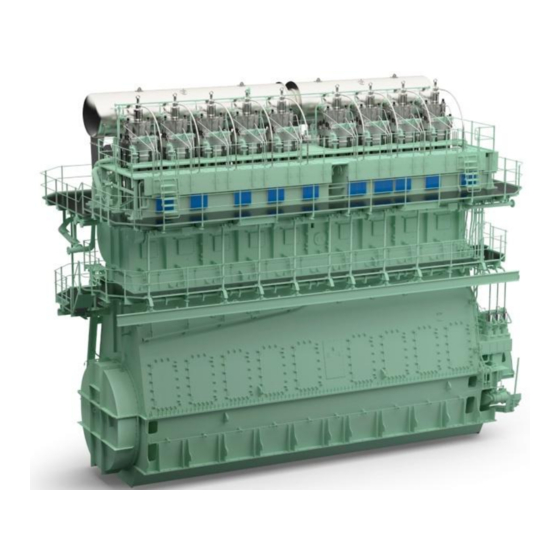

WinGD X82-B Marine Engine Manuals

Manuals and User Guides for WinGD X82-B Marine Engine. We have 2 WinGD X82-B Marine Engine manuals available for free PDF download: Maintenance Manual

WinGD X82-B Maintenance Manual (841 pages)

Table of Contents

-

-

Preface24

-

-

2 Safety

47 -

-

Clearances60

-

-

-

Supports110

-

-

Thrust Device143

-

Bearing Cover144

-

Thrust Device147

-

Thrust Device155

-

Roller Support156

-

Thrust Device162

-

Thrust Bearing166

-

Axial Clearance169

-

Cover - Remove175

-

Cover - Install184

-

Engine Stays186

-

Tie Rod190

-

-

Cylinder Liner200

-

Piston Rod Gland236

-

Cylinder Cover246

-

-

Exhaust Valve300

-

Damper Settings324

-

-

-

Connecting Rod333

-

Crankshaft336

-

Turning Gear358

-

Connecting Rod364

-

Stop Plate364

-

Piston - Attach388

-

Crosshead425

-

-

Tools - Prepare434

-

Bracket - Attach435

-

Tools - Attach436

-

Crosshead - Move438

-

Clearance Checks445

-

Dimensions Check446

-

Tools - Remove455

-

Piston458

-

Piston - Remove468

-

Torque Values481

-

Piston - Install484

-

Piston Ring490

-

-

-

Driving Wheels508

-

-

-

Servo Oil Pump530

-

Fuel Pump540

-

Supply Unit600

-

Rollers - Lift602

-

Oil Baffle603

-

Camshaft608

-

Bearing Bushes613

-

Filling Piece617

-

-

-

-

-

Relief Valve637

-

Flaps - Remove639

-

Flaps - Install641

-

Auxiliary Blower642

-

Water Separator666

-

-

-

HP Fuel Pipe720

-

-

-

15 Tools

769-

Standard Tools772

Advertisement

WinGD X82-B Maintenance Manual (606 pages)

Table of Contents

-

General10

-

Spare Parts10

-

General32

-

-

Fuel Pump55

-

1224−1/A1112

-

2124−1/A1127

-

2124−2/A1128

-

2124−2/A2138

-

2124−3/A1148

-

2303−1/A1158

-

Cylinder Cover168

-

2708−2/A1172

-

2728−1/A1190

-

2745−1/A1196

-

Exhaust Valve200

-

2751−1/A1200

-

-

2751−2/A1206

-

2751−3/A1214

-

2751−4/A1219

-

3103−1/A1222

-

Vibration Damper226

-

3130−1/A1227

-

3140−1/A1234

-

Connecting Rod250

-

3303−1/A1251

-

-

3303−2/A1252

-

3303−3/A1264

-

-

3303−4/A1272

-

3326−1/A1292

-

3326−2/A1296

-

Piston306

-

-

3403−1/A1306

-

3403−3/A1334

-

3403−4/A1341

-

3425−1/A1342

-

Group 4350

-

Driving Wheels350

-

4103−1/A1350

-

-

4103−2/A1356

-

5556−1/A1370

-

5556−2/A1390

-

5562−1/A1394

-

5562−2/A1400

-

5564−1/A1404

-

Fuel Pump Unit408

-

-

5581−1/A1408

-

5581−2/A1414

-

7218−1/A2478

-

8155−1/A1488

-

8460−1/A1500

-

HP Fuel Pipe507

-

8733−1/A1507

-

9403−4/A1552

-

Tool List556

-

9403−5/A1556

-

Standard Tools556

-

Advertisement