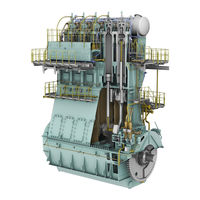

WinGD X62DF Manuals

Manuals and User Guides for WinGD X62DF. We have 1 WinGD X62DF manual available for free PDF download: Maintenance Manual

WinGD X62DF Maintenance Manual (902 pages)

Table of Contents

-

-

Preface24

-

-

2 Safety

47 -

-

Clearances64

-

-

Bedplate102

-

Main Bearing104

-

Thrust Bearing132

-

Axial Clearance135

-

Cover - Remove141

-

Cover - Install150

-

Engine Stays152

-

Tie Rod156

-

-

-

Cylinder Liner166

-

-

Valve Seat - Lap212

-

GAV - Assemble219

-

Piston Rod Gland224

-

Cylinder Cover234

-

-

-

Exhaust Valve292

-

Damper Settings318

-

-

Seal - Install345

-

-

-

Crankshaft350

-

Connecting Rod352

-

Turning Gear372

-

Connecting Rod378

-

Stop Plate378

-

Piston - Attach442

-

-

Crosshead444

-

Tools - Prepare448

-

Bracket - Attach449

-

Tools - Attach450

-

Crosshead - Move452

-

Clearance Checks459

-

Dimensions Check460

-

Tools - Remove469

-

-

Piston472

-

Piston - Remove482

-

Torque Values495

-

Piston - Install498

-

Piston Ring504

-

-

-

Driving Wheel510

-

-

Servo Oil Pump530

-

-

Fuel Pump550

-

-

-

-

-

Flaps - Remove631

-

Flaps - Install633

-

Auxiliary Blower634

-

Water Separator658

-

-

-

-

Bearing - Remove692

-

-

-

HP Fuel Pipe744

-

-

-

LDU-20 - Remove804

-

LDU-20 Rear View805

-

LDU-20 - Install808

-

LDU-20 Rear View809

-

CCM-20 - Remove812

-

CCM-20 - Install814

-

MCM-11 - Remove816

-

MCM-11 - Install818

-

IOM-10 - Remove820

-

IOM-10 - Install822

-

15 Tools

825-

Standard Tools828

Advertisement

Advertisement