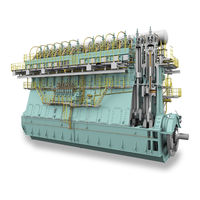

WinGD X92DF Manuals

Manuals and User Guides for WinGD X92DF. We have 1 WinGD X92DF manual available for free PDF download: Operation Manual

WinGD X92DF Operation Manual (608 pages)

Table of Contents

-

-

Introduction19

-

-

2 Safety

43 -

-

Fuel System98

-

Gas System102

-

-

Page - LP SCR119

-

Hp Scr129

-

Control Box E48129

-

Control Box E49129

-

Control Box E50132

-

Page - HP SCR138

-

Example of SPC140

-

-

-

Bedplate148

-

Main150

-

-

Main Bearing150

-

Thrust Bearing152

-

-

-

Monoblock Column154

-

Tie Rod156

-

-

-

-

Cylinder Liner158

-

-

Piston Rod Gland164

-

Starting Valve168

-

Relief Valve170

-

-

Exhaust Valve172

-

-

-

-

Group 8 - Pipes

242

-

-

6 Control System

251-

ECS Modules255

-

Gvu-Ed279

-

Gvu-Od280

-

-

Ca Sensor Status306

-

Exhaust Valves322

-

Failure List324

-

Fuel System330

-

Gas Pressure332

-

Gvu & Valve Test338

-

Knock Control340

-

Knock Control341

-

Log Messages342

-

Page Index346

-

Software Info360

-

Imo Crc Info362

-

Software Tools364

-

System Status366

-

System Settings368

-

User Parameters372

-

Gas Leak Test374

-

Log Entry Data376

-

Ielba Control382

-

Ielba Control383

-

-

System Info388

-

MCP Page - TREND390

-

MCP Page - MAIN396

-

-

User Parameters416

-

LED Color Codes422

-

8 Operation

427-

Start the Engine440

-

-

Stop the Engine472

-

-

-

-

-

-

General Data574

-

Engine Data574

-

Rated Power575

-

Function Code578

-

Signal Codes578

-

Function Group579

-

Applied System579

-

Fuel System580

-

Gas System580

-

Failure Messages591

-

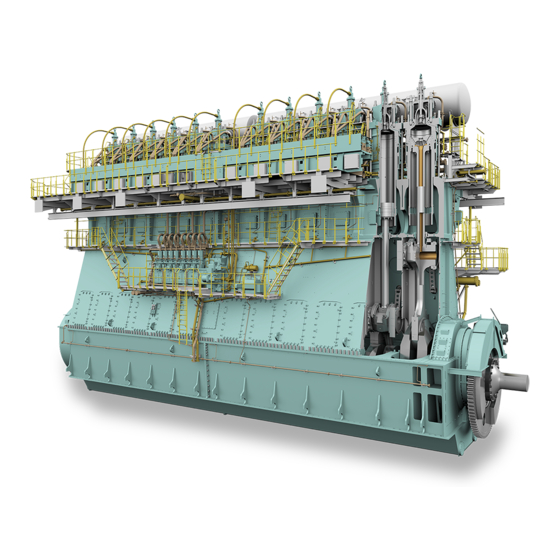

Cross Section593

-

-

Advertisement

Advertisement