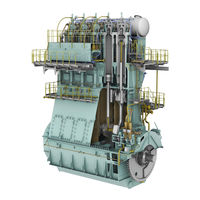

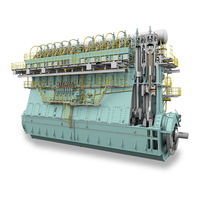

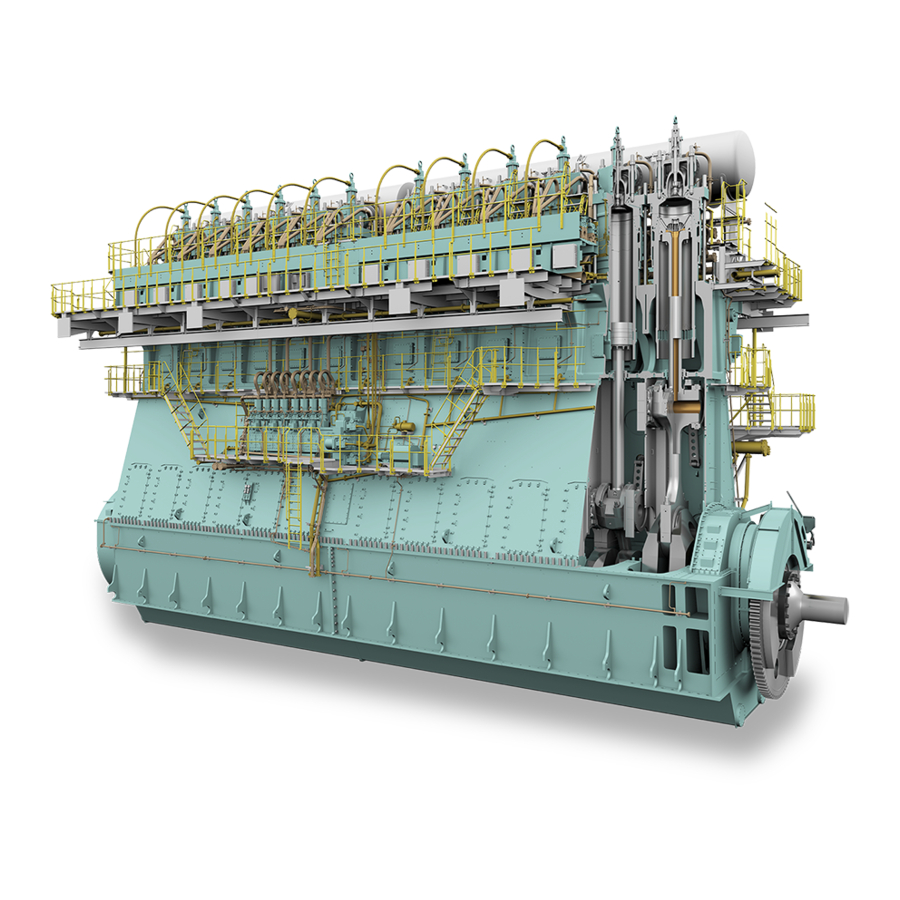

WinGD X72 Manuals

Manuals and User Guides for WinGD X72. We have 3 WinGD X72 manuals available for free PDF download: Maintenance Manual, Operation Manual

WinGD X72 Operation Manual (516 pages)

Table of Contents

-

-

Main Bearing31

-

Safety

50 -

-

Line Codes66

-

Supply Unit86

-

Fuel Pump88

-

-

Hp Scr99

-

Control Box E50102

-

Page - HP SCR108

-

Page - LP SCR123

-

Example of SPC124

-

-

-

Turbocharger137

-

Auxiliary Blower138

-

-

Bedplate140

-

Main142

-

-

Main Bearing142

-

Thrust Bearing144

-

-

-

Monoblock Column146

-

Tie Rod148

-

-

-

-

Cylinder Liner150

-

Piston Rod Gland154

-

Starting Valve158

-

-

Exhaust Valve160

-

-

-

-

Servo Oil Pump188

-

Supply Unit190

-

Fuel Pump192

-

-

-

-

Turbocharger204

-

-

Ielba - Function217

-

-

ECS Modules233

-

-

Pages - General242

-

Page - MAIN242

-

-

Ca Sensor Status250

-

Exhaust Valves264

-

Failure List266

-

Fuel System270

-

Knock Control272

-

Knock Control273

-

Log Messages274

-

Software Info288

-

Imo Crc Info290

-

Software Tools292

-

System Status294

-

System Settings296

-

User Parameters300

-

Log Entry Data302

-

Page - DATE304

-

Page - ETHERNET306

-

-

Select: Tier III376

-

Select: Tier II377

-

-

-

Failure Messages438

-

Special Failures439

-

Technical Data

487-

General Data488

-

Rated Power489

-

Function Code492

-

Signal Codes492

-

Function Group493

-

Applied System493

-

Fuel System494

-

Advertisement

WinGD X72 Maintenance Manual (556 pages)

Table of Contents

-

-

Removal4

-

-

-

-

-

Procedure One146

-

Procedure Two152

-

Cylinder Cover

157 -

2722−1/A1

173 -

-

Injection Valve180

-

Removal181

-

-

2728−1/A1

187 -

-

2751−1/A1191

-

-

Exhaust Valve

189

-

-

-

-

-

Removal

342-

Preparation343

-

Setpoint Check344

-

-

5562−1/A1

342 -

5562−1/A2

347-

Removal351

-

-

5562−2/A1

352 -

Installation

353 -

5562−3/A1

355 -

General

367 -

Servo Pump Unit

371

-

-

-

Assemble380

-

Disassemble380

-

5612−1/A1

381-

Installation381

-

Completion381

-

Relief Valve382

-

-

Group 6

383 -

6420-1/A1

385

-

-

Maintenance

389-

General389

-

2 Procedure One

390-

Preparation390

-

Removal390

-

-

6545-1/A1

391-

Installation392

-

-

3 Procedure Two

393-

Preparation393

-

Removal393

-

Installation394

-

-

6606-1/A1

397 -

1 General

397 -

6708-1/A1

415 -

6735-1/A1

421 -

Group 7

423

-

-

-

Flex Lube Pump

427 -

7218−1/A1

428 -

-

Flex Lube Pump428

-

Oil Pipes428

-

-

Duplex Filter

429

-

-

1 General

432-

7758−1/A1433

-

-

2 Preparation

433 -

-

Removal434

-

5 Check

439-

Measure Backlash439

-

Adjust Bearings441

-

6 Final Steps

443

-

WinGD X72 Operation Manual (514 pages)

Table of Contents

-

-

General

63 -

-

-

Causes114

-

-

-

Procedure114

-

-

Causes116

-

Procedures117

-

General

147-

Heavy Fuel Oil

148-

0710-1/A1148

-

-

-

Viscosity151

-

Density152

-

Sulphur152

-

Flash Point152

-

Acid Number153

-

Pour Point153

-

Water153

-

-

-

Viscosity156

-

Density156

-

Cetane Index156

-

Sulphur156

-

Flash Point156

-

Acid Number157

-

Sediment157

-

Pour Point157

-

Water157

-

-

Fuel Additives

158 -

General

159-

0720-1/A1160

-

-

-

Lubricating Oils

167-

System167

-

0750/1A1168

-

Oil Care168

-

Turbocharger Oil180

-

Turning Gear Oil180

-

-

2303-1/A1220

-

Piston Rod Gland220

-

General221

-

-

3326-1/A1237

-

Group 4243

-

-

-

-

4002-1/A1246

-

-

-

Power Supplies251

-

Redundancy251

-

-

-

4002-2/A1268

-

Ldu−20268

-

ME Tachometer268

-

Telegraph268

-

Components268

-

Remote Control268

-

General270

-

User Guide271

-

MAIN Page272

-

Fuel System276

-

Fuel Injection280

-

Exhaust Valve282

-

User Parameters286

-

Performance Data289

-

Crank Angle292

-

Software Info294

-

Log Messages295

-

System Status297

-

USB Page299

-

System Settings301

-

Ethernet302

-

Date303

-

Screenshot303

-

-

Engine Control

309-

4003-1/A1310

-

Engine Control310

-

Preparation310

-

Engine Start310

-

Reverse310

-

Engine Stop310

-

Control Transfer311

-

General312

-

ECS Start313

-

Servo Oil System316

-

Fuel System317

-

Overspeed Limit319

-

-

Designations322

-

4003-2/A1329

-

4325-1/A1354

-

4605-1/A1355

-

4605-1/A2359

-

6420-1/A1384

-

6545-1/A1391

-

Switch Box392

-

6606-1/A1394

-

6735-1/A1399

-

-

-

7218-1/A1408

-

Servo Oil Supply409

-

General419

-

-

7218-3/A3420

-

-

8016-1/A1434

-

Servo Oil System436

-

Servo Oil436

-

-

Servo Oil Rail441

-

Pressurization441

-

Pressure Release441

-

-

General443

-

8825-1/A1467

-

And467

-

-

-

Function482

-

Operation Modes489

-

Tier490

-

User Interfaces493

-

AMS Alarms504

-

General505

Advertisement

Advertisement