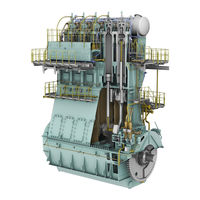

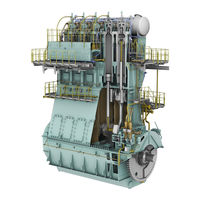

WinGD X72DF Manuals

Manuals and User Guides for WinGD X72DF. We have 2 WinGD X72DF manuals available for free PDF download: Maintenance Manual, Installation Manual

WinGD X72DF Maintenance Manual (902 pages)

Table of Contents

-

-

Preface24

-

-

2 Safety

47 -

-

Clearances64

-

-

Bedplate102

-

Main Bearing104

-

Thrust Bearing132

-

Axial Clearance135

-

Cover - Remove141

-

Cover - Install150

-

Engine Stays152

-

Tie Rod156

-

-

-

Cylinder Liner166

-

-

Valve Seat - Lap212

-

GAV - Assemble219

-

Piston Rod Gland224

-

Cylinder Cover234

-

-

-

Exhaust Valve292

-

Damper Settings318

-

-

Seal - Install345

-

-

-

Crankshaft350

-

Connecting Rod352

-

Turning Gear372

-

Connecting Rod378

-

Stop Plate378

-

Piston - Attach442

-

-

Crosshead444

-

Tools - Prepare448

-

Bracket - Attach449

-

Tools - Attach450

-

Crosshead - Move452

-

Clearance Checks459

-

Dimensions Check460

-

Tools - Remove469

-

-

Piston472

-

Piston - Remove482

-

Torque Values495

-

Piston - Install498

-

Piston Ring504

-

-

-

Driving Wheel510

-

-

Servo Oil Pump530

-

-

Fuel Pump550

-

-

-

-

-

Flaps - Remove631

-

Flaps - Install633

-

Auxiliary Blower634

-

Water Separator658

-

-

-

-

Bearing - Remove692

-

-

-

HP Fuel Pipe744

Advertisement

WinGD X72DF Installation Manual (237 pages)

Table of Contents

-

Preface22

-

System29

-

Power Range41

-

Sea Margin42

-

Piping59

-

Drawings65

-

Seating66

-

Assembly67

-

Tools69

-

Design70

-

Tightening70

-

Engine Stays71

-

System77

-

Pre-Heating88

-

System Oil95

-

Drain Tank103

-

Fuel Gas System108

-

Tank Type113

-

Fuel Gas Venting131

-

Fuel Oil System139

-

Mixing Unit141

-

Mixing Unit142

-

End-Heater143

-

Viscometer144

-

Fuel Oil Filter152

-

Settling Tanks153

-

Service Tanks153

-

Control Air159

-

Air Vents166

-

Piping175

-

Pipe Connections175

-

Requirements176

-

Denis183

-

DENIS Concept184

-

Safety System188

-

Telegraph System188

-

Options189

-

Split Solution193

-

The Wide System195

-

Engine Dynamics198

-

H-Type Vibration204

-

X-Type Vibration204

-

Axial Vibration212

-

Hull Vibration214

-

Concept216

-

Engine Emissions220

-

Low-Pressure SCR221

-

Engine Noise223

-

Air-Borne Noise223

-

Exhaust Noise225

Advertisement