Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for WinGD X82-B

- Page 1 Maintenance Manual X82-B Issue 001 2020-10 Winterthur Gas & Diesel Ltd. Schützenstrasse 3 Tel. +41 (0)52 264 8844 Winterthur Gas & Diesel AG P.O. Box 414, 8401 Fax +41 (0)52 264 8866 Winterthur Gas & Diesel S.A. Winterthur, Switzerland www.wingd.com...

- Page 2 Information in this publication is subject to change without notice. NO LIABILITY, WHETHER DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL, IS ASSUMED WITH RESPECT TO THE INFORMATION CONTAINED HEREIN. THIS PUBLICATION IS INTENDED FOR INFORMATION PURPOSES ONLY. www.wingd.com...

-

Page 3: Table Of Contents

X82-B Maintenance Manual Table of contents Introduction Maintenance Manual - change record........ - Page 4 X82-B Maintenance Manual 6.3.1 Main bearing - bearing shell - No. 2 to # - prepare before removal..118 6.3.2 Main bearing - bearing shell - No. 2 to # - remove..... . .

- Page 5 X82-B Maintenance Manual 7.4.2 Cylinder cover - grind the sealing face for injection valve....252 7.4.3 Cylinder cover - install..........

- Page 6 X82-B Maintenance Manual 8.5.3 Connecting rod - install..........

- Page 7 X82-B Maintenance Manual 10.1.3 Servo oil pump - install..........

- Page 8 X82-B Maintenance Manual 11.2.2 Auxiliary blower - install..........

- Page 9 X82-B Maintenance Manual 15.3 Recommended tools........... . .

- Page 10 X82-B Maintenance Manual Page left intentionally blank - 10 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

- Page 11 X82-B Maintenance Manual List of tables Introduction Change record ..................... Data module codes (procedural data) ............Data module codes (descriptive data) ............Data module codes (illustrated parts data) ..........List of abbreviations and acronyms ............. General data for maintenance Lifting capacities (for information only) ............

- Page 12 X82-B Maintenance Manual 13-1 Distance X for HP servo oil pipe ..............13-2 Distance X for hydraulic pipe exhaust valve ..........- 12 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

- Page 13 X82-B Maintenance Manual List of illustrations Introduction Side view (generic) ..................End view (generic, seen from the driving end) ..........Standard and LEFT engine (generic, seen from the driving end) ....Engine numbering (generic) ................ General data for maintenance RUD-eye bolts .....................

- Page 14 X82-B Maintenance Manual 6-17 Bearing cover - move .................. 6-18 Thrust device ....................6-19 Bearing cover - install .................. 6-20 Bearing cover - move .................. 6-21 Bearing cover - oil pipe ................6-22 Oil pipe and round nuts ................6-23 Thrust device ....................

- Page 15 Injection valve - removal ................7-30 Preparation of injection valve for test ............7-31 Adjust the opening pressure of the injection valve (X82 or X82-B) ..... 7-32 Injection valve (example) - disassemble ............. 7-33 Nozzle tip (example) - replace ..............

- Page 16 X82-B Maintenance Manual Axial vibration damper - housing and pipes ..........Axial vibration damper ................. Axial vibration damper - move ..............8-10 Axial vibration damper - install ..............8-11 Axial vibration damper - bolts ..............8-12 Axial vibration damper - housing and pipes ..........

- Page 17 X82-B Maintenance Manual 8-55 Crosshead - remove ..................8-56 Guide shoes - remove ................. 8-57 Clearance checks ..................8-58 Dimensions check ..................8-59 Guide shoe - move ..................8-60 Crosshead - move ..................8-61 Guide shoes - install ..................8-62 Connecting rod - move ................

- Page 18 X82-B Maintenance Manual 10-4 Toothed rack removal .................. 10-5 Pump cylinder removal ................10-6 Non-return valve removal ................10-7 Pump cylinder installation ................10-8 Pump cover installation ................10-9 Toothed rack assembly ................10-10 Pump plunger and bottom housing assembly ..........

- Page 19 X82-B Maintenance Manual 11-7 Electric motor (driving end) - remove ............11-8 Electric motor (free end) - move ..............11-9 Auxiliary blower - remove ................11-10 Auxiliary blower - move ................11-11 Electric motor (free end) - install ..............11-12 Auxiliary blower (driving end) move ............

- Page 20 X82-B Maintenance Manual Group 9 - Monitoring instruments 14-1 Proximity sensor (flywheel) - remove ............14-2 Proximity sensor (flywheel) - install ............. 14-3 Proximity sensor - remove ................14-4 Proximity sensor - install ................Tools 15-1 Standard Tools .................... 15-2 Recommended Tools ...................

- Page 21 X82-B Maintenance Manual 1 Introduction Maintenance Manual - change record........

-

Page 22: Maintenance Manual - Change Record

AA00-0000-00AAA-003B-A X82-B Maintenance Manual Maintenance Manual - change record Maintenance Manual - change record Tab 1-1 Change record Data module code, issue Status Chapter number - technical name Reason for change New issue 001, 2020-10 All data modules Initial issue of the fully new structured Maintenance Manual. The existing Maintenance Manual published on 2018-12 is no more applicable. - Page 23 AA00-0000-00AAA-003B-A X82-B Maintenance Manual Maintenance Manual - change record Page left intentionally blank - 23 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 24: Preface

The data, instructions, graphics and illustrations etc in this manual are related to drawings from WinGD. These data relate to the date of issue of the manual (the year of the issue is shown on the title page and on the footer). All instructions, graphics and illustrations etc can change because of continuous new development and modifications. - Page 25 AA00-0000-00AAA-018A-A X82-B Maintenance Manual Preface Page left intentionally blank - 25 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 26: Technical Documentation Set

AA00-0000-00AAA-018B-A X82-B Maintenance Manual Technical documentation set Technical documentation set Because of the continuous development of the engine, the technical documentation for the engine changes and is regularly updated. The change record shows all changes. Important data and changes are given directly to the customer in the service bulletins. -

Page 27: Technical Documentation Set

External supplier documentation The documentation from external suppliers gives data about the parts of the engine that are not supplied by WinGD, such as turbocharger, automatic filter or damper. Most of this documentation also contains data about spare parts. 1.3.5... -

Page 28: Data Module Codes (Procedural Data)

00 = applicable to all engines inde- acters [0-9] pendent of the number of cylinders; ## = applicable only to engines with that specific number of cylinders. #### WinGD design group number 4 numeric char- arbitrary 5556 acters [0-9] Used for sequential numbering for the... -

Page 29: Data Module Codes (Procedural Data)

AA00-0000-00AAA-018E-A X82-B Maintenance Manual Data module codes (procedural data) Code Description Length/type Property Example Shipdex item location code. A = infor- 1 alphabetic Shipdex specif- mation related to items installed on the character [A-D] product; B = information related to items installed on a major assembly re- moved from the product;... -

Page 30: Data Module Codes (Descriptive Data)

00 = applicable to all engines inde- acters [0-9] pendent of the number of cylinders; ## = applicable only to engines with that specific number of cylinders. #### WinGD design group number 4 numeric char- arbitrary 5551 acters [0-9] Used for sequential numbering of data... - Page 31 AA00-0000-00AAA-018D-A X82-B Maintenance Manual Data module codes (descriptive data) Page left intentionally blank - 31 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 32: Data Module Codes (Illustrated Parts Data)

00 = applicable to all engines inde- acters [0-9] pendent of the number of cylinders; ## = applicable only to engines with that specific number of cylinders. #### WinGD design group number 4 numeric char- arbitrary 5562 acters [0-9] Used for sequential numbering of data... - Page 33 AA00-0000-00AAA-018F-A X82-B Maintenance Manual Data module codes (illustrated parts data) Page left intentionally blank - 33 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 34: About This Book

X82-B Maintenance Manual About this book About this book In the sections that follow you find the definitions of WinGD for this book. 1.7.1 Definitions for general text For general text in this book the definitions that follow are applicable: •... - Page 35 AA00-0000-00AAA-018C-A X82-B Maintenance Manual About this book 1.7.2 Warnings Warnings in procedures give data about a hazard. Warnings have the basic structure that follows: • Signal word The signal words that follow are applicable: ○ WARNING ○ CAUTION • Hazard The hazard data gives the dangerous situation.

-

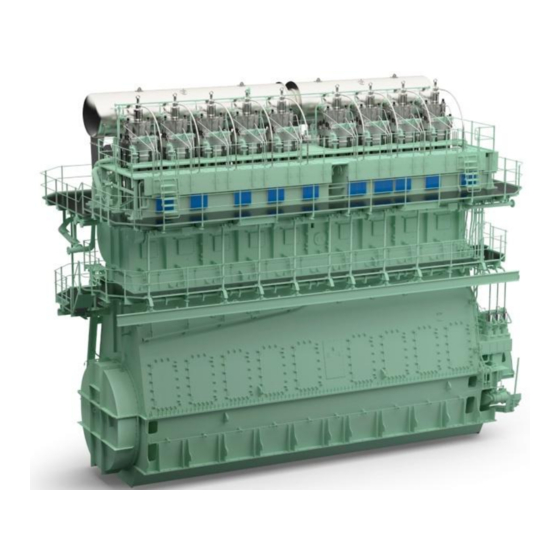

Page 36: About The Engine

Maintenance Manual About the engine About the engine In the sections that follow you find the definitions of WinGD for the engine. 1.8.1 Groups of components Each component of the engine has a four-digit material number. WinGD has divided these components related to the first digit of the number into 9 groups: •... -

Page 37: Side View (Generic)

AA00-0000-00AAA-018L-A X82-B Maintenance Manual About the engine 1.8.2 Engine sides and ends - names The sides and ends of the engine have the names and abbreviations that follow (refer to Figure Figure 1-2): • DE - Driving End (end that has a flange to attach the propeller shaft) •... -

Page 38: End View (Generic, Seen From The Driving End)

AA00-0000-00AAA-018L-A X82-B Maintenance Manual About the engine Fig 1-2 End view (generic, seen from the driving end) Legend Exhaust side Fuel side Turbocharger Supply unit Auxiliary blower Rail unit Flywheel - 38 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. - Page 39 AA00-0000-00AAA-018L-A X82-B Maintenance Manual About the engine 1.8.3 Standard and LEFT engine An engine is one of two types (refer to Figure 1-3): • A standard engine has the exhaust side (ES) on the right side of the engine (seen from the driving end).

-

Page 40: Engine Numbering (Generic)

AA00-0000-00AAA-018L-A X82-B Maintenance Manual About the engine 1.8.4 Numbering of items WinGD uses the definitions for the numbering of items as follows (refer to Figure 1-4): • In axial direction the numbering starts from the flywheel. • In radial direction the numbering starts from the center of the flywheel. - Page 41 AA00-0000-00AAA-018L-A X82-B Maintenance Manual About the engine Page left intentionally blank - 41 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 42: List Of Abbreviations

AA00-0000-00AAA-005A-A X82-B Maintenance Manual List of abbreviations List of abbreviations Tab 1-5 List of abbreviations and acronyms Short form Full form, meaning Angle Calculation Module crank Angle Determination Algorithm ahead alarm Alarm and Monitoring System as required astern ASTM American Society for Testing and Materials... - Page 43 AA00-0000-00AAA-005A-A X82-B Maintenance Manual List of abbreviations Short form Full form, meaning Emission Control Area Engine Control Room Engine Control System eg or e.g. for example (exempli gratia) Exhaust Gas Recirculation ELBA ELectrical BAlancer Exhaust Side Engine Safety System FAME...

- Page 44 AA00-0000-00AAA-005A-A X82-B Maintenance Manual List of abbreviations Short form Full form, meaning Injection Control Unit ie or i.e. that is (id est) iELBA integrated ELectrical BAlancer iGPR integrated Gas Pressure Regulation International Maritime Organization Ind. Indenture Input Output Module International Standard Organization...

- Page 45 Top Dead Center UNIC UNIfied Controls Universal Serial Bus exhaust Valve Control Unit Variable Exhaust valve Closing Variable Exhaust valve Opening Variable Injection Timing WECS-9520 WinGD Engine Control System 9520 - 45 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

- Page 46 AA00-0000-00AAA-005A-A X82-B Maintenance Manual List of abbreviations Short form Full form, meaning Waste Heat Recovery WiCE WinGD Integrated Control Electronics WinGD Winterthur Gas & Diesel Ltd. Work Load Limit - 46 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 47: Safety

X82-B Maintenance Manual 2 Safety Safety precautions and safety rules......... -

Page 48: Safety Precautions And Safety Rules

AA00-0000-00AAA-012A-A X82-B Maintenance Manual Safety precautions and safety rules Safety precautions and safety rules 2.1.1 General safety precautions Use the data given below as a guide to the personnel. • Lighting Make sure that there is good permanent lighting in the engine room. Have a sufficient number of hand lamps available at different locations in the engine room. - Page 49 AA00-0000-00AAA-012A-A X82-B Maintenance Manual Safety precautions and safety rules 2.1.2 General safety rules If you do work at or near the engine, obey the rules that follow to prevent risks of harm or damage to personal, to equipment, or to environment.

- Page 50 AA00-0000-00AAA-012A-A X82-B Maintenance Manual Safety precautions and safety rules • Rules for electric welding Do electric welding near the engine only if the engine is stopped. Set to OFF the electronic system and wait a minimum of one minute. Disconnect electronic modules or sensors in a radius of two meters from the welding place.

-

Page 51: General Data For Maintenance

X82-B Maintenance Manual 3 General data for maintenance Lifting tools............. . -

Page 52: Lifting Tools

AA00-0000-00AAA-066A-A X82-B Maintenance Manual Lifting tools Lifting tools The permissible capacities of the engine crane, lifting tools, ropes, chains, lifting eye bolts, etc. must always correspond with the weights of the parts to be lifted. NOTE: The admissible lifting (max. loading) capacity in kg corresponds to the WLL = Working Load Limit. -

Page 53: Lifting Capacities (For Information Only)

AA00-0000-00AAA-066A-A X82-B Maintenance Manual Lifting tools Tab 3-1 Lifting capacities (for information only) Thread size Lifting capacity [kg] single-strand double-strand (45 degree) 1200 1800 1290 3200 2300 4600 3300 6300 4500 8600 6100 11500 8300 Full load is only permissible in the direction of the ring, thus the eye bolts or eye nuts must be put to the right position, if necessary by using distance rings. - Page 54 AA00-0000-00AAA-066A-A X82-B Maintenance Manual Lifting tools 3.1.4.1 Use of RUD-eye bolts • The RUD-eye bolts must be completely screwed down, lying fully on the seating surfaces. • The RUD-eye bolts are hand-screwed with their own star-profile wrenches (do not use any extension).

-

Page 55: Rud-Swivel Lugs

AA00-0000-00AAA-066A-A X82-B Maintenance Manual Lifting tools Fig 3-2 RUD-swivel lugs Force Direction Force Force Direction Direction 00285 3.1.5 Shackles Only those shackles may be used which are in accordance with American Standard RR−C −271A or which fulfil or exceed these values, including the safety factor. -

Page 56: Jointing Compounds

AA00-0000-00AAA-701A-A X82-B Maintenance Manual Jointing compounds Jointing compounds Tab 3-2 Jointing compound Jointing compound Hardener Adhesive primer Manufacturer Elastosil RT 622 A RT 622 B G 790 Wacker-Chemie GmbH Geschäftsbereich Silicone Hanns-Seidel-Platz 4 D-81737 München Silcoset 105 RTV Silcoset Curing Silcoset Primer Ambersil House Ltd. - Page 57 AA00-0000-00AAA-701A-A X82-B Maintenance Manual Jointing compounds Page left intentionally blank - 57 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 58: Clearances - General

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances - general Clearances - general The chapter that follows gives the values for each group of components. The values given in the columns “Nominal dimension” in the tables that follow are related to design and manufacturing values, or to the settings on a new engine. - Page 59 AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances - general Page left intentionally blank - 59 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 60: Clearances

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances Clearances 3.4.1 Crankshaft and thrust bearing Fig 3-3 Crankshaft and Thrust Bearing Tab 3-3 Crankshaft and thrust bearing - clearances Location Item Measured di- Nominal di- Maximum code rection mension (usu- clearance di- al, new) [mm]... -

Page 61: Crankshaft And Main Bearings

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances 3.4.2 Crankshaft and main bearings Fig 3-4 Crankshaft and Main Bearing - 61 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. - Page 62 AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances Tab 3-4 Crankshaft and main bearings Location Item Measured di- Nominal di- Maximum code rection mension (usu- clearance di- al, new) [mm] mension (be- cause of wear) [mm] Narrow main bearings of crank- 1132 shaft half at free end...

-

Page 63: Crosshead Guide

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances 3.4.3 Crosshead guide Fig 3-5 Crosshead Guide Tab 3-5 Crosshead guide Location Item Measured di- Nominal di- Maximum code rection mension (usu- clearance di- al, new) [mm] mension (be- cause of wear) [mm] 3326 Crosshead guide 0.20 to 1.3... -

Page 64: Cylinder Liner

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances 3.4.4 Cylinder liner Fig 3-6 Cylinder Liner Tab 3-6 Cylinder liner Location Item Measured di- Nominal di- Maximum code rection mension (usu- clearance di- al, new) [mm] mension (be- cause of wear) [mm] 2130 Water guide jacket on cylinder cov- Clearance 0.60 to 1.00... -

Page 65: Piston Rod Gland

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances 3.4.5 Piston rod gland Fig 3-7 Piston rod gland Tab 3-7 Piston rod gland Location Item Measured di- Nominal di- Maximum code rection mension (usu- clearance di- al, new) [mm] mension (be- cause of wear) -

Page 66: Exhaust Valve - Spindle And Guide Bush

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances 3.4.6 Exhaust valve Fig 3-8 Exhaust valve Tab 3-8 Exhaust valve - spindle and guide bush Location Item Measured di- Nominal di- Maximum code rection mension (usu- clearance di- al, new) [mm] mension (be- cause of wear) -

Page 67: Connecting Rod - Top And Bottom End Bearings

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances 3.4.7 Connecting rod - top and bottom end bearings Fig 3-9 Connecting rod - top and bottom end bearings Tab 3-9 Connecting rod - top and bottom end bearings Location Item Measured di- Nominal di-... -

Page 68: Piston And Piston Rings

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances 3.4.8 Piston and piston rings Fig 3-10 Piston and piston rings Tab 3-10 Piston and piston rings Location Item Measured di- Nominal di- Maximum code rection mension (usu- clearance di- al, new) [mm] mension (be-... - Page 69 AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances Location Item Measured di- Nominal di- Maximum code rection mension (usu- clearance di- al, new) [mm] mension (be- cause of wear) [mm] 3415 Piston rod Outer diameter 324 -0.062 Minimum 322.9 -0.119 3425 Piston rings...

-

Page 70: Supply Unit - Drive Wheels

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances 3.4.9 Supply unit - drive wheels Fig 3-11 Supply unit - drive wheels - 70 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. - Page 71 AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances Tab 3-11 Supply unit - drive wheels Location Item Measured di- Nominal di- Nominal di- code rection mension (usu- mension (usu- al, new) [mm] al, new) [mm] 4104 Intermediate wheel Axial clearance Total 0.60 to 1.10...

-

Page 72: Fuel And Servo Pump Units

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances 3.4.10 Fuel and servo pump units Fig 3-12 Fuel and servo pump units - 72 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. - Page 73 AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances Tab 3-12 Fuel and servo pump units Location Item Measured di- Nominal di- Maximum code rection mension (usu- clearance di- al, new) [mm] mension (be- cause of wear) [mm] 5581 Fuel pump unit Axial clearance Total 0.30 to 0.65...

-

Page 74: Fuel Pump

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances 3.4.11 Fuel pump Fig 3-13 Fuel pump - 74 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. -

Page 75: Fuel Pump

AA00-0000-00AAA-034C-A X82-B Maintenance Manual Clearances Tab 3-13 Fuel pump Location Item Measured di- Nominal di- Maximum code rection mension (usu- clearance di- al, new) [mm] mension (be- cause of wear) [mm] 5556 Fuel pump Plunger (diameters 40 mm, 44 mm... -

Page 76: Torque Values - Standard Screws

X82-B Maintenance Manual Torque values - standard screws Torque values - standard screws WinGD highly recommends to use the torque values given in Table 3-15 - Torque values - standard screws for aII standard metric screws of grade 8.8. Lubricate the threads and base of the head of the screws with oil SAE 30. - Page 77 AA00-0000-00AAA-034A-A X82-B Maintenance Manual Torque values - standard screws Tab 3-15 Torque values - standard screws Standard thread - Grade 8.8 Fine thread - Grade 8.8 Torque value [Nm] M3 x 0.35 M4 x 0.5 M5 x 0.5 M6 x 0.75 M8 x 1 M10 x 1.25...

- Page 78 AA00-0000-00AAA-034A-A X82-B Maintenance Manual Torque values - standard screws Page left intentionally blank - 78 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 79: General Maintenance Procedures

X82-B Maintenance Manual 4 General maintenance procedures Do maintenance work - general procedure........ -

Page 80: Do Maintenance Work - General Procedure

AA00-0000-00AAA-012F-A X82-B Maintenance Manual Do maintenance work - general procedure Do maintenance work - general procedure Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 81 AA00-0000-00AAA-012F-A X82-B Maintenance Manual Do maintenance work - general procedure PROCEDURE Make sure that the pressure in all pipes is released. Make sure that you know the procedure for the access to engine spaces, refer to the Operation Manual. Make sure that no personnel and components are in the danger areas (crankcase, piston underside, propeller shaft, etc.).

-

Page 82: Tighten A Round Nut With A Pre-Tensioner

AA00-0000-00AAA-711A-A X82-B Maintenance Manual Tighten a round nut with a pre-tensioner Tighten a round nut with a pre-tensioner Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 83 AA00-0000-00AAA-711A-A X82-B Maintenance Manual Tighten a round nut with a pre-tensioner PROCEDURE Make sure that the threads of the elastic stud (008, Figure 4-1), of the round nut (004) and of the pre-tensioner are smooth and clean. NOTE: If you have to install the complete set of elastic studs, obey the sequence given in the related figures (refer to section 16.1 Tightening...

- Page 84 AA00-0000-00AAA-711A-A X82-B Maintenance Manual Tighten a round nut with a pre-tensioner NOTE: Make sure that the piston (002) does not move above the limit of the red groove (011). NOTE: If you have to install the complete set of elastic studs, do the procedure in two steps as noted.

- Page 85 AA00-0000-00AAA-711A-A X82-B Maintenance Manual Tighten a round nut with a pre-tensioner Page left intentionally blank - 85 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 86: Loosen A Round Nut With A Pre-Tensioner

AA00-0000-00AAA-510A-A X82-B Maintenance Manual Loosen a round nut with a pre-tensioner Loosen a round nut with a pre-tensioner Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 87 AA00-0000-00AAA-510A-A X82-B Maintenance Manual Loosen a round nut with a pre-tensioner PROCEDURE Make sure that the threads of the elastic stud (008, Figure 4-2) and of the pre-tensioner are smooth and clean. Put the applicable pre-tensioner on the elastic stud (008).

- Page 88 AA00-0000-00AAA-510A-A X82-B Maintenance Manual Loosen a round nut with a pre-tensioner NOTE: Make sure that the piston (002) does not move above the limit of the red groove (011). Keep the applied pressure constant. Loosen the round nut (004). Get the applicable round bar (012) from the round bar kit.

- Page 89 AA00-0000-00AAA-510A-A X82-B Maintenance Manual Loosen a round nut with a pre-tensioner Page left intentionally blank - 89 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 90: Do A Check Of The Pre-Tension

AA00-0000-00AAA-360A-A X82-B Maintenance Manual Do a check of the pre-tension Do a check of the pre-tension Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 91 AA00-0000-00AAA-360A-A X82-B Maintenance Manual Do a check of the pre-tension PROCEDURE Make sure that the threads of the elastic stud (008, Figure 4-3) and of the pre-tensioner are smooth and clean. Put the applicable pre-tensioner on the elastic stud (008).

- Page 92 AA00-0000-00AAA-360A-A X82-B Maintenance Manual Do a check of the pre-tension NOTE: Make sure that the piston (002) does not move above the limit of the red groove (011). Keep the applied pressure constant. Make sure that there is no clearance between the round nut (004) and the plate (007).

-

Page 93: Maintenance Schedule

X82-B Maintenance Manual 5 Maintenance schedule Maintenance schedule........... . . -

Page 94: Maintenance Schedule

Maintenance schedule The maintenance intervals are given in each procedure related to the recommendations of WinGD. The shown operating hours (or working hours) are always the total running hours of the engine. Data found during operation will show if it is possible to increase or decrease these maintenance intervals. -

Page 95: Group 1 - Engine Frame And Bearings

X82-B Maintenance Manual 6 Group 1 - Engine frame and bearings Foundation bolts 6.1.1 Bedplate - do a check of the foundation bolts...... -

Page 96: Foundation Bolts

AA00-1115-00AAA-360A-A X82-B Maintenance Manual Bedplate - do a check of the foundation bolts Foundation bolts 6.1.1 Bedplate - do a check of the foundation bolts Periodicity Description One Time - after first working hours 1 500 Working hours 12 000 Duration for performing preliminary requirements 1.0 man-hours... - Page 97 AA00-1115-00AAA-360A-A X82-B Maintenance Manual Bedplate - do a check of the foundation bolts PROCEDURE Do a check of the pre-tension of the foundation bolts, refer to section 4.4 Do a check of pre-tension. NOTE: In the area of the thrust bearing, the bedplate (003,...

-

Page 98: Main Bearing - Bearing Shell Number

AA00-1132-00AAA-523A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - prepare before removal Main bearing - bearing shell number 1 6.2.1 Main bearing - bearing shell - No. 1 - prepare before removal Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours... - Page 99 AA00-1132-00AAA-523A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - prepare before removal PROCEDURE Read the data in 3.1 Lifting tools General Guidelines for Lifting Tools. Operate the turning gear to turn the crank to the exhaust side approximately 90° after TDC.

-

Page 100: Main Bearing - Bearing Shell - No. 1 - Remove

AA00-1132-00AAA-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - remove 6.2.2 Main bearing - bearing shell - No. 1 - remove Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours... - Page 101 AA00-1132-00AAA-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - remove PROCEDURE Hydraulic rams - install Put the chain block 94017-2.5-5.4 (003, ) on the main bearing girder as shown. Put the two hydraulic rams (001) on the bracket (003) as shown.

-

Page 102: Crankshaft And Flywheel - Lift

AA00-1132-00AAA-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - remove Fig 6-2 Crankshaft and flywheel - lift 50 mm 50 mm 0.3 mm 009.810/02 00606 Bearing shell - remove Attach the shackle (WLL 2000 kg) (004, Figure 6-3) to the position shown. - Page 103 AA00-1132-00AAA-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - remove Remove the two Allen screws (007) from the top of the bearing shell (002). Attach the turning out device (009) to the bearing shell (002). Put the wire ropes (006) around the edges of the main bearing shell (002).

-

Page 104: Bearing Shell - Remove

AA00-1132-00AAA-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - remove Fig 6-3 Bearing shell - remove WCH03015 WCH03486 00607 3.10 Attach the lifting tool (002, Figure 6-4) to the bearing shell (003). - 104 - Issue 001 2020-10... -

Page 105: Bearing Shell - Lift

AA00-1132-00AAA-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - remove Fig 6-4 Bearing shell - lift 00608 3.11 Turn the bearing shell (003) sufficiently to attach the chain block (001). 3.12 Attach the chain block (001) to the lifting tool (003). - Page 106 AA00-1132-00AAA-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - remove 3.14 Attach the engine room crane to the lifting tool (002). 3.15 Operate the engine room crane and the chain block (001) to lift and move the bearing shell (003) out of the engine.

- Page 107 AA00-1132-00AAA-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - remove Page left intentionally blank - 107 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 108: Main Bearing Shell - No.1 - Do A Check

AA00-1135-00AAA-311A-A X82-B Maintenance Manual Main bearing shell - No.1 - do a check 6.2.3 Main bearing shell - No.1 - do a check Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 0.25 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 109 AA00-1135-00AAA-311A-A X82-B Maintenance Manual Main bearing shell - No.1 - do a check PROCEDURE Use a soft cloth to clean the bearing shell. Examine the bearing shell for damage e.g. breakouts or cracks. CAUTION Damage Hazard: Do not use a scraper in the running area of the bearing shell. Damage to the bearing shell will occur.

-

Page 110: Main Bearing - Bearing Shell - No. 1 - Install

AA00-1132-00AAA-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - install 6.2.4 Main bearing - bearing shell - No. 1 - install Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours... - Page 111 AA00-1132-00AAA-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - install PRELIMINARY OPERATIONS • None - 111 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

- Page 112 AA00-1132-00AAA-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - install PROCEDURE Bearing shell - install NOTE: The bearing shell has the mark DRIVING END and must be installed in the correct position. Make sure that the items that follow are clean and in good condition: •...

- Page 113 AA00-1132-00AAA-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - install Fig 6-5 Bearing shell - lift 00608 Remove carefully the engine room crane from the lifting tool (002). 1.10 Operate carefully the chain block (001) to lower the bearing shell (003) on to the crankshaft.

- Page 114 AA00-1132-00AAA-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - install 1.11 Remove the chain block (001) and the lifting tool (002). 1.12 Put the wire ropes (006) of the turning-out device (006, Figure 6-6) over the bearing shell (002) and under the crankshaft.

-

Page 115: Bearing Shell - Move

AA00-1132-00AAA-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - install Fig 6-6 Bearing shell - move WCH03015 WCH03486 00607 Crankshaft - lower On the HP oil pump, release the pressure to fully lower the crankshaft. Remove the hydraulic rams (001, Figure 6-7) and the HP oil pump. -

Page 116: Crankshaft And Flywheel - Lift

AA00-1132-00AAA-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - install Remove the bracket (004) and steel plate. Fig 6-7 Crankshaft and flywheel - lift 50 mm 50 mm 0.3 mm 009.810/02 00606 - 116 - Issue 001 2020-10... - Page 117 AA00-1132-00AAA-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 1 - install CLOSE UP • Install the No.1 bearing cover, refer to 6.4.2 Main bearing cover - No.1 - install - 117 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 118: Main Bearing - Bearing Shell Number 2 To

AA00-1132-00AAB-523A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - prepare before removal Main bearing - bearing shell number 2 to # 6.3.1 Main bearing - bearing shell - No. 2 to # - prepare before... - Page 119 AA00-1132-00AAB-523A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - prepare before removal PROCEDURE Read the data in 3.1 Lifting tools General Guidelines for Lifting Tools. Operate the turning gear to turn the crank to the exhaust side approximately 90° after TDC.

-

Page 120: Main Bearing - Bearing Shell - No. 2 To # - Remove

AA00-1132-00AAB-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - remove 6.3.2 Main bearing - bearing shell - No. 2 to # - remove Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours... - Page 121 AA00-1132-00AAB-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - remove Spare Parts Description Part No. None SAFETY PRECAUTIONS CAUTION Damage Hazard: Do not remove two adjacent main bearing shells at the same time. Damage can occur to the bearing shells.

- Page 122 AA00-1132-00AAB-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - remove PROCEDURE Hydraulic rams - install Put the bracket 94141 (003, Figure 6-8) on the main bearing girder as shown. - 122 - Issue 001 2020-10...

- Page 123 AA00-1132-00AAB-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - remove Fig 6-8 Crankshaft and flywheel - lift 50 mm 50 mm 0.3 mm 009.810/02 00606 Put the two hydraulic rams 94936 (001) on the bracket (003) as shown.

- Page 124 AA00-1132-00AAB-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - remove Put the steel plate on top of the hydraulic ram (001). Connect the hydraulic jacks (001) to the HP oil pump. Put the dial gauge (006) in position on the crankshaft (007) in the vertical axis.

-

Page 125: Bearing Shell No_2_To_N

AA00-1132-00AAB-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - remove Fig 6-9 Bearing shell No_2_to_n WCH03486 00609 Attach the deviation pipes 94117B and 94117C (006 and 007, Figure 6-10) to the column as shown. - Page 126 AA00-1132-00AAB-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - remove NOTE: If the bearing shell (002) does not move freely during the removal procedure, you must attach the lifting plate to the other side of the turning out device.

- Page 127 AA00-1132-00AAB-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - remove Fig 6-10 Bearing shell_move - 127 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

- Page 128 AA00-1132-00AAB-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - remove CLOSE UP • Install the bearing shell, refer to 6.3.4 Main bearing - bearing shell - No. 2 to # - install - 128 - Issue 001 2020-10 Winterthur Gas &...

- Page 129 AA00-1132-00AAB-520A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - remove Page left intentionally blank - 129 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 130: Main Bearing Shell - No.2 To # - Examine

AA00-1134-00AAA-311A-A X82-B Maintenance Manual Main bearing shell - No.2 to # - examine 6.3.3 Main bearing shell - No.2 to # - examine Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 0.25 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 131 AA00-1134-00AAA-311A-A X82-B Maintenance Manual Main bearing shell - No.2 to # - examine PROCEDURE Use a soft cloth to clean the bearing shell. Examine the bearing shell for damage e.g. breakouts or cracks. CAUTION Damage Hazard: Do not use a scraper in the running area of the bearing shell. Damage to the bearing shell will occur.

-

Page 132: Main Bearing - Bearing Shell - No. 2 To # - Install

AA00-1132-00AAB-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - install 6.3.4 Main bearing - bearing shell - No. 2 to # - install Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours... - Page 133 AA00-1132-00AAB-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - install SAFETY PRECAUTIONS WARNING Injury and Damage Hazard: Do not turn the crankshaft when the platforms, tools and/or supports, are installed. This will cause injury to personnel and damage to equipment.

- Page 134 AA00-1132-00AAB-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - install PROCEDURE Bearing shell - install NOTE: The bearing shell has the mark DRIVING END and must be installed in the correct position. Make sure that the items that follow are clean and in good condition: •...

-

Page 135: Bearing Shell_Move

AA00-1132-00AAB-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - install Fig 6-11 Bearing shell - move Make sure that the crankshaft and the running surface of the bearing shell (002) are clean and fully lubricated with clean engine oil. - Page 136 AA00-1132-00AAB-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - install Attach the engine room crane to the lifting tool (001). Operate the engine room crane to move the bearing shell (002) to an applicable position.

- Page 137 AA00-1132-00AAB-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - install Fig 6-12 Bearing shell No_2_to_n WCH03486 00609 Crankshaft - lower On the HP oil pump, release the pressure to fully lower the crankshaft. Remove the hydraulic rams (001, Figure 6-13) and the HP oil pump.

- Page 138 AA00-1132-00AAB-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - install Fig 6-13 Crankshaft and flywheel 50 mm 50 mm 0.3 mm 009.810/02 00606 - 138 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

- Page 139 AA00-1132-00AAB-720A-A X82-B Maintenance Manual Main bearing - bearing shell - No. 2 to # - install CLOSE UP • Install the bearing cover, refer to 6.5.2 Main bearing cover - No. 2 to #- install - 139 - Issue 001 2020-10...

-

Page 140: Main Bearing Cover - No. 1

AA00-1132-01AAA-520A-A X82-B Maintenance Manual Main bearing cover - No.1 - remove Main bearing cover - No. 1 6.4.1 Main bearing cover - No.1 - remove Periodicity Description Unscheduled Personnel Description Specialization Engine crew Basic Support equipment Description Part No. Spur-geared chain block,... - Page 141 AA00-1132-01AAA-520A-A X82-B Maintenance Manual Main bearing cover - No.1 - remove PROCEDURE Remove the cover (001, Figure 6-14) and the holder (002). Remove the oil pipe (003). Do a check of the bearing clearance, refer to 3.3 Clearances - general.

-

Page 142: Cover And Oil Pipe

AA00-1132-01AAA-520A-A X82-B Maintenance Manual Main bearing cover - No.1 - remove Fig 6-14 Cover and oil pipe WCH03014 WCH03021 00611 Attach the lug (001, Figure 6-15) to the bearing cover (002). Make sure that the thrust device (004) is clean. -

Page 143: Thrust Device

AA00-1132-01AAA-520A-A X82-B Maintenance Manual Main bearing cover - No.1 - remove WARNING Injury Hazard: The thrust device has a WLL of only 70 kg. Do not use the thrust device to lift the bearing cover. Injury to personnel can occur. -

Page 144: Bearing Cover

AA00-1132-01AAA-520A-A X82-B Maintenance Manual Main bearing cover - No.1 - remove Fig 6-16 Bearing cover WCH03014 00612 Attach the shackle 94019K (004, Figure 6-17) to the lug 94116C (003). Attach engine room crane to the shackle 94109K (004). Operate the engine room crane to put a light tension on the chain. -

Page 145: Bearing Cover - Move

AA00-1132-01AAA-520A-A X82-B Maintenance Manual Main bearing cover - No.1 - remove Fig 6-17 Bearing cover - move 00614 CLOSE UP • Remove the No. 1 bearing shell, refer to 6.2.2 Main bearing - bearing shell - No. 1 - remove... -

Page 146: Main Bearing Cover - No.1 - Install

AA00-1132-01AAA-720A-A X82-B Maintenance Manual Main bearing cover - No.1 - install 6.4.2 Main bearing cover - No.1 - install Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... -

Page 147: Thrust Device

AA00-1132-01AAA-720A-A X82-B Maintenance Manual Main bearing cover - No.1 - install PROCEDURE Clean all surfaces that touch on the bearing cover and bearing girder. Make sure that the oil bore in the bearing cover is clear. Attach the lug (001, Figure 6-18) to the bearing cover (002). -

Page 148: Bearing Cover - Install

AA00-1132-01AAA-720A-A X82-B Maintenance Manual Main bearing cover - No.1 - install Fig 6-19 Bearing cover - install 00616 Attach the shackle 94019K (004, Figure 6-20) to the lug 94116C (003). Attach engine room crane to the shackle 94109K (004). Operate the engine room crane to move the bearing cover to an applicable position on the platform. - Page 149 AA00-1132-01AAA-720A-A X82-B Maintenance Manual Main bearing cover - No.1 - install Fig 6-20 Bearing cover - move 00614 Clean the pipes (003, Figure 6-21). Install the pipes (003), their gaskets and new tab washers (006). Tighten the screws (005). Lock the screws (005) with the new tab washers (006).

-

Page 150: Bearing Cover - Oil Pipe

AA00-1132-01AAA-720A-A X82-B Maintenance Manual Main bearing cover - No.1 - install Fig 6-21 Bearing cover - oil pipe 00617 CLOSE UP • None - 150 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. - Page 151 AA00-1132-01AAA-720A-A X82-B Maintenance Manual Main bearing cover - No.1 - install Page left intentionally blank - 151 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 152: Main Bearing Cover - No. 2 To # - Remove

AA00-1132-01AAB-520A-A X82-B Maintenance Manual Main bearing cover - No. 2 to # - remove Main bearing cover - No. 2 to # 6.5.1 Main bearing cover - No. 2 to # - remove Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours... - Page 153 AA00-1132-01AAB-520A-A X82-B Maintenance Manual Main bearing cover - No. 2 to # - remove SAFETY PRECAUTIONS WARNING Injury and Damage Hazard: Do not turn the crankshaft when the platforms, tools and/or supports, are installed. This will cause injury to personnel and damage to equipment.

-

Page 154: Oil Pipe And Round Nuts

AA00-1132-01AAB-520A-A X82-B Maintenance Manual Main bearing cover - No. 2 to # - remove PROCEDURE Use the feeler gauge 94123 to record the bearing clearance, refer to 3.3 Clearances - general. Remove the oil pipe (002, Figure 6-22). Remove the round nuts (001), refer to 4.3 Loosen a round nut with a... -

Page 155: Thrust Device

AA00-1132-01AAB-520A-A X82-B Maintenance Manual Main bearing cover - No. 2 to # - remove Fig 6-23 Thrust device Copper paste 00613 WARNING Injury Hazard: The thrust device has a WLL of only 70 kg. Do not use the thrust device to lift the bearing cover. -

Page 156: Roller Support

AA00-1132-01AAB-520A-A X82-B Maintenance Manual Main bearing cover - No. 2 to # - remove Attach the manual ratchet (003) to the lug (002) on the bearing cover. Fig 6-24 Roller support CAUTION Damage Hazard: Use the roller support only as shown on its Warning plate. The maximum permitted load is 16000 N at 45°. -

Page 157: Bearing Cover No.2 To # - Lift And Lower

AA00-1132-01AAB-520A-A X82-B Maintenance Manual Main bearing cover - No. 2 to # - remove Fig 6-25 Bearing cover No.2 to # - lift and lower Attach the sling 94039-015 (005, Figure 6-26) to the gallery. Attach the chain block 94017-029 (003) to the sling (005). -

Page 158: Bearing Cover No. 2 To # - Remove

AA00-1132-01AAB-520A-A X82-B Maintenance Manual Main bearing cover - No. 2 to # - remove Fig 6-26 Bearing cover No. 2 to # - remove CLOSE UP • Remove the applicable bearing shell, 6.5.2 Main bearing cover - No. 2 to #- install... - Page 159 AA00-1132-01AAB-520A-A X82-B Maintenance Manual Main bearing cover - No. 2 to # - remove Page left intentionally blank - 159 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 160: Main Bearing Cover - No. 2 To #- Install

AA00-1132-01AAB-720A-A X82-B Maintenance Manual Main bearing cover - No. 2 to #- install 6.5.2 Main bearing cover - No. 2 to #- install Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 161 AA00-1132-01AAB-720A-A X82-B Maintenance Manual Main bearing cover - No. 2 to #- install • The work area and all tools and equipment must be clean and in good condition. - 161 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 162: Thrust Device

AA00-1132-01AAB-720A-A X82-B Maintenance Manual Main bearing cover - No. 2 to #- install PROCEDURE Clean all surfaces that touch on the bearing cover and bearing girder. Make sure that the oil bore in the bearing cover is clear. Attach the lug (001, Figure 6-27) to the bearing cover (002). - Page 163 AA00-1132-01AAB-720A-A X82-B Maintenance Manual Main bearing cover - No. 2 to #- install Operate the chain block to lift the bearing cover (002) Attach the manual ratchet (004) to the shackle on the bearing cover (002). Operate the chain block (003) and the manual ratchet (004) to move the bearing cover into the engine.

-

Page 164: Bearing Cover No.2 To # - Install

AA00-1132-01AAB-720A-A X82-B Maintenance Manual Main bearing cover - No. 2 to #- install Operate the manual ratchet (004) to lower the bearing cover on to the bearing girder. Make sure that the two spring dowel pins (001) engage correctly. Make sure that you do not cause damage to the elastic studs (004). - Page 165 AA00-1132-01AAB-720A-A X82-B Maintenance Manual Main bearing cover - No. 2 to #- install Fig 6-30 Bearing cover - oil pipe 00617 Remove all tools and equipment from the work area. Measure the bearing clearance and compare the value measured in 6.5.1 Main bearing...

-

Page 166: Thrust Bearing

AA00-1203-00AAA-310A-A X82-B Maintenance Manual Thrust bearing - examine the housing Thrust bearing 6.6.1 Thrust bearing - examine the housing Periodicity Description Working hours 7000 Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 0.5 man-hours Duration for performing the requirements after job completion 0.0 man-hours... -

Page 167: Visual Examination

AA00-1203-00AAA-310A-A X82-B Maintenance Manual Thrust bearing - examine the housing PROCEDURE Remove the cover (003, Figure 6-31). Do a check of the thrust bearing housing. If necessary, remove particles from the area (001). Make sure th the channel (002) is clear. -

Page 168: Thrust Bearing - Do A Check Of The Axial Clearance With A Dial Gauge

AA00-1203-00AAA-360A-A X82-B Maintenance Manual Thrust bearing - do a check of the axial clearance with a dial gauge 6.6.2 Thrust bearing - do a check of the axial clearance with a dial gauge Periodicity Description Working hours 7000 Duration for performing preliminary requirements 0.0 man-hours... -

Page 169: Axial Clearance

AA00-1203-00AAA-360A-A X82-B Maintenance Manual Thrust bearing - do a check of the axial clearance with a dial gauge PROCEDURE Start the engine in the direction AHEAD to move the crankshaft (002, Figure 6-32) fully forward. The crankshaft must touch the thrust pads. -

Page 170: Thrust Bearing - Do A Check Of The Axial Clearance With A Inside Micrometer

AA00-1203-00AAA-360B-A X82-B Maintenance Manual Thrust bearing - do a check of the axial clearance with a inside micrometer 6.6.3 Thrust bearing - do a check of the axial clearance with a inside micrometer Periodicity Description Working hours 7000 Duration for performing preliminary requirements 0.0 man-hours... -

Page 171: Axial Clearance - Micrometer

AA00-1203-00AAA-360B-A X82-B Maintenance Manual Thrust bearing - do a check of the axial clearance with a inside micrometer PROCEDURE Start the engine in the direction AHEAD to move the crankshaft fully forward. The crankshaft (003, Figure 6-33) must touch the thrust pads (002). - Page 172 AA00-1203-00AAA-360B-A X82-B Maintenance Manual Thrust bearing - do a check of the axial clearance with a inside micrometer CLOSE UP • None - 172 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

- Page 173 AA00-1203-00AAA-360B-A X82-B Maintenance Manual Thrust bearing - do a check of the axial clearance with a inside micrometer Page left intentionally blank - 173 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 174: Thrust Bearing - Remove The Pads

AA00-1203-00AAA-520A-A X82-B Maintenance Manual Thrust bearing - remove the pads 6.6.4 Thrust bearing - remove the pads Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... -

Page 175: Cover - Remove

AA00-1203-00AAA-520A-A X82-B Maintenance Manual Thrust bearing - remove the pads PROCEDURE Read the data in 3.1 Lifting tools. Remove the cover (001, Figure 6-34). Fig 6-34 Cover - remove 00020 Record the positions of the thrust bearing pads. Remove the three bolts (001, Figure 6-35) from each of the four arbor supports (002). - Page 176 AA00-1203-00AAA-520A-A X82-B Maintenance Manual Thrust bearing - remove the pads WARNING Injury hazard. Before you operate the turning gear, make sure that no personnel are near the flywheel, or in the engine. Operate the turning gear to move the crankshaft in the applicable direction.

-

Page 177: Thrust Pad - Removal

AA00-1203-00AAA-520A-A X82-B Maintenance Manual Thrust bearing - remove the pads Fig 6-35 Thrust pad - removal NOTE: If some of the thrust pads are removed, the remaining thrust pads will keep the crankshaft in position. If all thrust pads from the same side are removed, for example all the astern pads, the crankshaft can move. - Page 178 AA00-1203-00AAA-520A-A X82-B Maintenance Manual Thrust bearing - remove the pads 23.1 Get a piece of hardwood that has the same dimensions as a thrust pad. 23.2 Put the hardwood in the position of the removed thrust pads. CLOSE UP •...

- Page 179 AA00-1203-00AAA-520A-A X82-B Maintenance Manual Thrust bearing - remove the pads Page left intentionally blank - 179 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 180: Thrust Bearing - Install The Pads

AA00-1203-00AAA-720A-A X82-B Maintenance Manual Thrust bearing - install the pads 6.6.5 Thrust bearing - install the pads Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 181 AA00-1203-00AAA-720A-A X82-B Maintenance Manual Thrust bearing - install the pads PROCEDURE Make sure that the thrust pads are clean. Apply clean engine oil to the thrust pads. NOTE: You must install thrust pads that you removed before in the same positions.

-

Page 182: Thrust Pad - Install

AA00-1203-00AAA-720A-A X82-B Maintenance Manual Thrust bearing - install the pads Fig 6-36 Thrust pad - install Install the temperature sensors removed before. Do a check of the clearances between the arbor supports and the thrust pads, refer to section 6.6.2 Thrust bearing - do a check of the axial clearance with a dial gauge... -

Page 183: Thrust Pads - Configuration

AA00-1203-00AAA-720A-A X82-B Maintenance Manual Thrust bearing - install the pads section 6.6.3 Thrust bearing - do a check of the axial clearance with a inside micrometer. NOTE: When you replace new thrust pads (or thrust pads that have new metal), you must make sure that the dimensions are the same as the adjacent pad(s). -

Page 184: Cover - Install

AA00-1203-00AAA-720A-A X82-B Maintenance Manual Thrust bearing - install the pads Fig 6-38 Cover - install 00020 CLOSE UP • None - 184 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. - Page 185 AA00-1203-00AAA-720A-A X82-B Maintenance Manual Thrust bearing - install the pads Page left intentionally blank - 185 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 186: Engine Stays

AA00-1715-00AAA-360A-A X82-B Maintenance Manual Engine stays (friction shims) - do a check of the pre-tension Engine stays 6.7.1 Engine stays (friction shims) - do a check of the pre-tension Periodicity Description Working hours 7000 Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 8.0 man-hours... - Page 187 AA00-1715-00AAA-360A-A X82-B Maintenance Manual Engine stays (friction shims) - do a check of the pre-tension PROCEDURE For the applicable value for pre-tension refer to section 16.1 Tightening instructions. Do a check of the pre-tension of the engine stays, refer to section 4.4 Do a check of the...

-

Page 188: Engine Stays (Hydraulic) - Do A Check Of The Oil Pressure

AA00-1715-00AAA-360B-A X82-B Maintenance Manual Engine stays (hydraulic) - do a check of the oil pressure 6.7.2 Engine stays (hydraulic) - do a check of the oil pressure Periodicity Description Months Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 8.0 man-hours... -

Page 189: Engine Stays - Pressure Check

AA00-1715-00AAA-360B-A X82-B Maintenance Manual Engine stays (hydraulic) - do a check of the oil pressure PROCEDURE Do a check of the distance (X) to make sure that the engine is not tilted. The distance (X) must be zero before you do a check of the pressure gauges (007, Figure 6-39). -

Page 190: Tie Rod

AA00-1903-00AAA-360A-A X82-B Maintenance Manual Tie rod - do a check of the pre-tension Tie rod 6.8.1 Tie rod - do a check of the pre-tension Periodicity Description Working hours 27 000 Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours... -

Page 191: Pre-Tension Checks

AA00-1903-00AAA-360A-A X82-B Maintenance Manual Tie rod - do a check of the pre-tension PROCEDURE Remove the protection cover (001, Figure 6-40) from all tie rods (002). Clean the faces of the intermediate rings (004). Do a check of the pre-tension of the first pair of tie rods a-a, refer to section 4.4 Do a... -

Page 192: Tie Rod - Remove

AA00-1903-00AAA-520A-A X82-B Maintenance Manual Tie rod - remove 6.8.2 Tie rod - remove Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... -

Page 193: Tie Rod - Removal

AA00-1903-00AAA-520A-A X82-B Maintenance Manual Tie rod - remove PROCEDURE Remove the protection cover (001, Figure 6-41) from the tie rods (004). Clean the surface of the intermediate ring (003). Attach the two pre-tensioning jacks to the applicable tie rod (004). -

Page 194: Tie Rod - Install

AA00-1903-00AAA-720A-A X82-B Maintenance Manual Tie rod - install 6.8.3 Tie rod - install Periodicity Description Unscheduled Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 195 AA00-1903-00AAA-720A-A X82-B Maintenance Manual Tie rod - install PROCEDURE Remove the applicable holder (008 or 010, Figure 6-42). Make sure that the nut (007) is correctly attached. Apply Molykote paste G to the bottom thread of the tie rod (003).

-

Page 196: Tie Rod - Apply Tension

AA00-1903-00AAA-720A-A X82-B Maintenance Manual Tie rod - install Apply a tension of 100 bar to the tie rod (002), refer to section 4.2 Tighten a round nut with a pre-tensioner. Record the length of the tie rod (002) at L. -

Page 197: Group 2 - Cylinder

X82-B Maintenance Manual 7 Group 2 - Cylinder Cylinder liner 7.1.1 Cylinder liner - do a check of the bore........ - Page 198 X82-B Maintenance Manual 7.7.6 Exhaust valve - grind the seat.........

- Page 199 X82-B Maintenance Manual Page left intentionally blank - 199 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 200: Cylinder Liner

AA00-2124-00AAA-360A-A X82-B Maintenance Manual Cylinder liner - do a check of the bore Cylinder liner 7.1.1 Cylinder liner - do a check of the bore Periodicity Description Unscheduled After each piston removal and installation Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours... - Page 201 AA00-2124-00AAA-360A-A X82-B Maintenance Manual Cylinder liner - do a check of the bore CAUTION Injury Hazard: Hot parts can cause injury to personnel. Be careful when you do work in areas where there are hot parts. PRELIMINARY OPERATIONS • The cylinder cover must be removed, refer to section 7.4.1 Cylinder cover - remove...

- Page 202 AA00-2124-00AAA-360A-A X82-B Maintenance Manual Cylinder liner - do a check of the bore PROCEDURE Operate the turning gear to move the piston to BDC. Lock the lever of the cooling water valve in the closed position. Put the ladder (007, Figure 7-1) in position in the cylinder liner (004).

-

Page 203: Cylinder Liner - Dimension Check

AA00-2124-00AAA-360A-A X82-B Maintenance Manual Cylinder liner - do a check of the bore Fig 7-1 Cylinder liner - dimension check Clean the area (001) above the running surface (002). Remove the bottom part of the measuring gauge (005). - 203 - Issue 001 2020-10 Winterthur Gas &... - Page 204 AA00-2124-00AAA-360A-A X82-B Maintenance Manual Cylinder liner - do a check of the bore Put the measuring gauge (005) in position on the top face of the cylinder liner (004) in line with the longitudinal axis of the engine. Make sure that the top hole (00A) is above the ridge (003) in the non-running surface of the cylinder liner (004).

- Page 205 AA00-2124-00AAA-360A-A X82-B Maintenance Manual Cylinder liner - do a check of the bore Page left intentionally blank - 205 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 206: Cylinder Liner - Remove

AA00-2124-00AAA-520A-A X82-B Maintenance Manual Cylinder liner - remove 7.1.2 Cylinder liner - remove Periodicity Description Unscheduled As necessary Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 207 AA00-2124-00AAA-520A-A X82-B Maintenance Manual Cylinder liner - remove PROCEDURE Remove the water guide jacket. If necessary, attach the lifting tools (002, Figure 7-2) to the lifting tool (001) as follows: 1.1.1 Make sure that the shackle (011) is attached to the middle hole in the lifting tool (001).

-

Page 208: Water Guide Jacket

AA00-2124-00AAA-520A-A X82-B Maintenance Manual Cylinder liner - remove Fig 7-2 Water guide jacket Remove the pipes to the lubricating quills as follows Remove the applicable pipe holders. Disconnect the related pipes. - 208 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. - Page 209 AA00-2124-00AAA-520A-A X82-B Maintenance Manual Cylinder liner - remove Seal the pipes with applicable seals to prevent contamination. Attach the two plates (004, Figure 7-3) to the lifting tool (002) as follows: Remove the two lifting tools from the lifting tool (002).

-

Page 210: Cylinder Liner (Example) - Move

AA00-2124-00AAA-520A-A X82-B Maintenance Manual Cylinder liner - remove Fig 7-4 Cylinder liner (example) - move CLOSE UP • None - 210 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. - Page 211 AA00-2124-00AAA-520A-A X82-B Maintenance Manual Cylinder liner - remove Page left intentionally blank - 211 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 212: Cylinder Liner - Preserve

AA00-2124-00AAA-810A-A X82-B Maintenance Manual Cylinder liner - preserve 7.1.3 Cylinder liner - preserve Periodicity Description Unscheduled As necessary Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 0.5 man-hours Duration for performing the requirements after job completion 0.0 man-hours... -

Page 213: Cylinder Liner - Storage

AA00-2124-00AAA-810A-A X82-B Maintenance Manual Cylinder liner - preserve PROCEDURE Attach the chain (002, Figure 7-5) to the lifting tool (003) and the engine room crane (001) as shown. Fig 7-5 Cylinder liner - storage Put the wooden underlay (005, 007) and the wooden chocks (006) in position as shown Figure 7-6. - Page 214 AA00-2124-00AAA-810A-A X82-B Maintenance Manual Cylinder liner - preserve Fig 7-6 Cylinder liner - storage 2 CLOSE UP • None - 214 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

- Page 215 AA00-2124-00AAA-810A-A X82-B Maintenance Manual Cylinder liner - preserve Page left intentionally blank - 215 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 216: Cylinder Liner - Grind

AA00-2124-00AAA-655A-A X82-B Maintenance Manual Cylinder liner - grind 7.1.4 Cylinder liner - grind Periodicity Description Unscheduled As necessary Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 217 AA00-2124-00AAA-655A-A X82-B Maintenance Manual Cylinder liner - grind PROCEDURE CAUTION Make sure that you do not cause damage to the running surface of the cylinder liner when you operate the grinding device. Put applicable protection below the cylinder liner to keep particles out of the area.

-

Page 218: Cylinder Liner - Grind The Lubricating Groove

AA00-2124-00AAA-655B-A X82-B Maintenance Manual Cylinder liner - grind the lubricating groove 7.1.5 Cylinder liner - grind the lubricating groove Periodicity Description Unscheduled as necessary Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... -

Page 219: Lubricating Grooves - Grind

AA00-2124-00AAA-655B-A X82-B Maintenance Manual Cylinder liner - grind the lubricating groove PROCEDURE If necessary, operate the turning gear to move the piston to BDC. If the depth of the lubricating grooves (001, Figure 7-8) has decreased to less than 1.5 mm, do as follows:... -

Page 220: Cylinder Liner - Grind The Scavenge Ports

AA00-2124-00AAA-655C-A X82-B Maintenance Manual Cylinder liner - grind the scavenge ports 7.1.6 Cylinder liner - grind the scavenge ports Periodicity Description Unscheduled as necessary Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... -

Page 221: Scavenge Ports - Grind

AA00-2124-00AAA-655C-A X82-B Maintenance Manual Cylinder liner - grind the scavenge ports PROCEDURE WARNING Before you operate the turning gear, make sure that no personnel are near the flywheel, or in the engine. CAUTION When you polish the scavenge ports, make sure that you do not cause damage to the running surface of the cylinder liner. -

Page 222: Cylinder Liner - Install

AA00-2124-00AAA-720A-A X82-B Maintenance Manual Cylinder liner - install 7.1.7 Cylinder liner - install Periodicity Description Unscheduled As necessary Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... -

Page 223: Insulation Bandage

AA00-2124-00AAA-720A-A X82-B Maintenance Manual Cylinder liner - install PROCEDURE Put the insulation bandage (001, Figure 7-10) around the water channel on the cylinder liner. Make sure that there is an overlap of approximately 30 mm. Put the plate (003) over the insulation bandage (001). - Page 224 AA00-2124-00AAA-720A-A X82-B Maintenance Manual Cylinder liner - install Fig 7-11 Cylinder liner (example) Attach the chain (001, Figure 7-12) to the shackle on the lifting tool (002). Operate the engine room crane to lift the cylinder liner (008) into the bottom water guide jacket (007).

- Page 225 AA00-2124-00AAA-720A-A X82-B Maintenance Manual Cylinder liner - install Fig 7-12 Water guide jacket (example) Attach the flanges (004, Figure 7-11) to the cylinder liner with the special screws (005). Attach the holder and pin (003) to the cylinder block with the bolts.

- Page 226 AA00-2124-00AAA-720A-A X82-B Maintenance Manual Cylinder liner - install Apply a non-hardening sealing compound to the cylinder block. Operate the engine room crane to lift and move the cylinder liner into position above the cylinder block. Operate the engine room crane to lower the cylinder liner into the cylinder block. Make sure that the pin (003) engages with the hole in the holder.

- Page 227 AA00-2124-00AAA-720A-A X82-B Maintenance Manual Cylinder liner - install Page left intentionally blank - 227 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 228: Lubricating Quill

AA00-2138-00AAA-520A-A X82-B Maintenance Manual Lubricating quill - remove Lubricating quill 7.2.1 Lubricating quill - remove Periodicity Description Unscheduled at each piston removal Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 229 AA00-2138-00AAA-520A-A X82-B Maintenance Manual Lubricating quill - remove PROCEDURE Loosen the nuts (005, Figure 7-13) of the unions. Carefully remove the pipe (002) from the lubricating quill (003). Seal the pipe (002) with an applicable plug to prevent contamination. Remove two the bolts (004).

-

Page 230: Lubricating Quill - Do A Functional Test

AA00-2138-00AAA-340A-A X82-B Maintenance Manual Lubricating quill - do a functional test 7.2.2 Lubricating quill - do a functional test Periodicity Description Unscheduled at each piston removal Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 0.25 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 231 AA00-2138-00AAA-340A-A X82-B Maintenance Manual Lubricating quill - do a functional test PROCEDURE If necessary, remove the union (007, Figure 7-14) on the lubricating quill (002). Fig 7-14 Lubricating quill Attach the distributing piece (004) to the HP oil pump (006).

-

Page 232: Lubricating Quill - Install

AA00-2138-00AAA-720A-A X82-B Maintenance Manual Lubricating quill - install 7.2.3 Lubricating quill - install Periodicity Description Unscheduled at each piston removal Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... -

Page 233: Sealing Surface

AA00-2138-00AAA-720A-A X82-B Maintenance Manual Lubricating quill - install PROCEDURE CAUTION Damage Hazard: The surfaces of the cylinder liner and the nozzle tip make a metallic seal. The seat angles in the cylinder liner and on the nozzle tip are different. Do not use a gasket between the cylinder liner and the nozzle tip. - Page 234 AA00-2138-00AAA-720A-A X82-B Maintenance Manual Lubricating quill - install Fig 7-16 Lubricating quill (example) CLOSE UP • Bleed the cylinder lubrication system, refer to 12.1.2 Cylinder lubrication system - bleed - 234 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

- Page 235 AA00-2138-00AAA-720A-A X82-B Maintenance Manual Lubricating quill - install Page left intentionally blank - 235 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 236: Piston Rod Gland

AA00-2303-00AAA-520A-A X82-B Maintenance Manual Piston rod gland - remove Piston rod gland 7.3.1 Piston rod gland - remove Periodicity Description Unscheduled at each piston removal Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... -

Page 237: Piston Rod Gland - Remove And Install

AA00-2303-00AAA-520A-A X82-B Maintenance Manual Piston rod gland - remove PROCEDURE Remove the piston rod gland together with the piston, refer to the related procedure. Remove and discard the two O-rings (002, Figure 7-17). Remove the four screws and nuts (003, 006). -

Page 238: Piston Rod Gland - Disassemble

AA00-2303-00AAA-520A-A X82-B Maintenance Manual Piston rod gland - remove Fig 7-18 Piston rod gland - disassemble CLOSE UP • None - 238 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. - Page 239 AA00-2303-00AAA-520A-A X82-B Maintenance Manual Piston rod gland - remove Page left intentionally blank - 239 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 240: Piston Rod Gland - Do A Check Of The Wear

AA00-2303-00AAA-360A-A X82-B Maintenance Manual Piston rod gland - do a check of the wear 7.3.2 Piston rod gland - do a check of the wear Periodicity Description Unscheduled at each piston removal Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours... - Page 241 AA00-2303-00AAA-360A-A X82-B Maintenance Manual Piston rod gland - do a check of the wear PROCEDURE Compare the wear of the parts that follow with the maximum permitted dimensions given in section 3.3 Clearances - general. • Scraper rings (001, 007,...

-

Page 242: Piston Rod Gland - Install

AA00-2303-00AAA-720A-A X82-B Maintenance Manual Piston rod gland - install 7.3.3 Piston rod gland - install Periodicity Description Unscheduled at each piston removal Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 243 AA00-2303-00AAA-720A-A X82-B Maintenance Manual Piston rod gland - install PRELIMINARY OPERATIONS • None - 243 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 244: Piston Rod Gland - Assemble

AA00-2303-00AAA-720A-A X82-B Maintenance Manual Piston rod gland - install PROCEDURE Attach the two parts of the clamp ring 94231A (011, Figure 7-20) to the piston rod. Put the three parts of the ring support (010) and the scraper ring 3-part (008) on the clamp ring (011). - Page 245 AA00-2303-00AAA-720A-A X82-B Maintenance Manual Piston rod gland - install Put the scraper ring 4-part (001) on the top of the scraper ring (003). Make sure that there is an equal distance between the four parts. Use the assembly tool to attach the tension spring (002).

-

Page 246: Cylinder Cover

AA00-2708-00AAA-520A-A X82-B Maintenance Manual Cylinder cover - remove Cylinder cover 7.4.1 Cylinder cover - remove Periodicity Description Unscheduled at each piston removal Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 4.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 247 AA00-2708-00AAA-520A-A X82-B Maintenance Manual Cylinder cover - remove PRELIMINARY OPERATIONS • The engine must be stopped and made safe for maintenance, refer to section 4.1 Do maintenance work - general procedure - 247 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 248: Cylinder Cover - Pipes And Expansion Piece (Example)

AA00-2708-00AAA-520A-A X82-B Maintenance Manual Cylinder cover - remove PROCEDURE Remove the applicable hydraulic pipe (005, Figure 7-22), refer to the related procedure. Remove the applicable HP fuel pipes (004), refer to the related procedure. Remove the applicable injection valves (003), refer to the related procedure. -

Page 249: Lifting Tool - Pre-Tensioner (Example)

AA00-2708-00AAA-520A-A X82-B Maintenance Manual Cylinder cover - remove Fig 7-23 Lifting tool - pre-tensioner (example) Attach the engine room crane to the eye bolt (001, Figure 7-24) on the exhaust valve (002). Operate the engine room crane to lift the cylinder cover (003) together with the exhaust valve (002) and top water guide jacket (007). -

Page 250: Cylinder Cover, Exhaust Valve Cage And Water Guide Jacket (Example)

AA00-2708-00AAA-520A-A X82-B Maintenance Manual Cylinder cover - remove Fig 7-24 Cylinder cover, exhaust valve cage and water guide jacket (example) Attach the engine room crane to the lifting tool (002, Figure 7-25). Operate the engine room crane to lift the lifting tool (002). -

Page 251: Cylinder Cover And Exhaust Valve Cage (Example)

AA00-2708-00AAA-520A-A X82-B Maintenance Manual Cylinder cover - remove Fig 7-25 Cylinder cover and exhaust valve cage (example) CLOSE UP • None - 251 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. -

Page 252: Cylinder Cover - Grind The Sealing Face For Injection Valve

AA00-2708-00AAA-655A-A X82-B Maintenance Manual Cylinder cover - grind the sealing face for injection valve 7.4.2 Cylinder cover - grind the sealing face for injection valve Periodicity Description Unscheduled as necessary Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 1.0 man-hours... - Page 253 AA00-2708-00AAA-655A-A X82-B Maintenance Manual Cylinder cover - grind the sealing face for injection valve PROCEDURE Make sure that the stop sleeve (008, Figure 7-26) is attached to the spindle (009) of the grinding device (002). Use the applicable grade of emery cloth related to the quantity of metal you want to remove.

-

Page 254: Fuel Injection Valve Position - Grind

AA00-2708-00AAA-655A-A X82-B Maintenance Manual Cylinder cover - grind the sealing face for injection valve Fig 7-26 Fuel injection valve position - grind CLOSE UP • None - 254 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd. - Page 255 AA00-2708-00AAA-655A-A X82-B Maintenance Manual Cylinder cover - grind the sealing face for injection valve Page left intentionally blank - 255 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 256: Cylinder Cover - Install

AA00-2708-00AAA-720A-A X82-B Maintenance Manual Cylinder cover - install 7.4.3 Cylinder cover - install Periodicity Description Unscheduled at each piston removal Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 2.0 man-hours Duration for performing the requirements after job completion 0.0 man-hours... - Page 257 AA00-2708-00AAA-720A-A X82-B Maintenance Manual Cylinder cover - install PROCEDURE Clean the items that follow: • O-ring grooves (005, Figure 7-27) • Sealing surfaces of the cylinder cover (004). Put oil on the O-rings. Clean the threads of the two elastic studs (003).

-

Page 258: Assemble Before Installation (Example)

AA00-2708-00AAA-720A-A X82-B Maintenance Manual Cylinder cover - install Fig 7-27 Assemble before installation (example) Lower the cylinder cover together with the exhaust valve and top water guide jacket on to the bottom water guide jacket. Remove the engine room crane from the eye bolt from the exhaust valve. - Page 259 AA00-2708-00AAA-720A-A X82-B Maintenance Manual Cylinder cover - install Put the round nuts (004, Figure 7-28) on the elastic studs (005). Attach the engine room crane to the lifting tool (006). Operate the engine room crane to move the lifting tool (006) and the pre-tensioners above the cylinder cover (002).

- Page 260 AA00-2708-00AAA-720A-A X82-B Maintenance Manual Cylinder cover - install CLOSE UP • None - 260 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

- Page 261 AA00-2708-00AAA-720A-A X82-B Maintenance Manual Cylinder cover - install Page left intentionally blank - 261 - Issue 001 2020-10 Winterthur Gas & Diesel Ltd.

-

Page 262: Conventional Injection Valve

AA00-2722-01AAA-520A-A X82-B Maintenance Manual Conventional injection valve - remove Conventional injection valve 7.5.1 Conventional injection valve - remove Periodicity Description Unscheduled as necessary Duration for performing preliminary requirements 0.0 man-hours Duration for performing the procedure 0.5 man-hours Duration for performing the requirements after job completion 0.0 man-hours... -

Page 263: Injection Valve - Removal