Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for WinGD X82-B

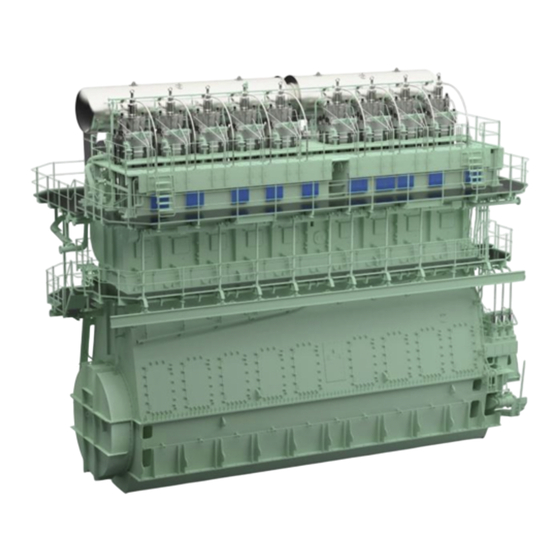

- Page 1 Maintenance Manual “Marine” Vessel: Type: Engine No.: Document ID: Winterthur Gas & Diesel Ltd. 24hrs Support: Schützenstrasse 1−3 Wärtsilä Services Switzerland Ltd. CH-8400 Winterthur Zürcherstrasse 12 Switzerland CH 8400 Winterthur Switzerland +41 52 262 80 10 technicalsupport.chts@wartsila.com...

- Page 2 E 2017 Winterthur Gas & Diesel Ltd. – All rights reserved No part of this publication may be reproduced or copied in any form or by any means (electron- ic, mechanical, graphic, photocopying, recording, taping or other information retrieval systems) without the prior written permission of the copyright holder.

- Page 3 Maintenance Manual “Marine” Vessel: Type: Engine No.: Document ID: Winterthur Gas & Diesel Ltd. 24hrs Support: Schützenstrasse 1−3 Wärtsilä Services Switzerland Ltd. CH-8400 Winterthur Zürcherstrasse 12 Switzerland CH 8400 Winterthur Switzerland +41 52 262 80 10 technicalsupport.chts@wartsila.com...

- Page 4 E 2017 Winterthur Gas & Diesel Ltd. – All rights reserved No part of this publication may be reproduced or copied in any form or by any means (electron- ic, mechanical, graphic, photocopying, recording, taping or other information retrieval systems) without the prior written permission of the copyright holder.

-

Page 5: 0330-1/A1

SCR Valve Removal New document and Installation 9403-5/A1 2018 WinGD Input Tools Pge 41: New lifting tool 94815 added. Date of publication 2018-04 0330-1/A1 Dec-18 WinGD Input Clearance Table Pge 3: Gp1132 bearing shell clearance changed Date of publication 2018-12 05/12/2018... - Page 6 General Information Bedplate and Tie Rod Cylinder Liner and Cylinder Cover Crankshaft, Connecting Rod and Piston Driving Wheels and Shut-off Valve for Starting Air Supply Unit, Injection and Exhaust Valve Control Scavenge Air Receiver and Auxiliary Blower Cylinder Lubrication Piping Crank Angle Sensor Unit, Tools...

- Page 7 Intentionally blank...

-

Page 8: Table Of Contents

Group0 Maintenance General Information Group 0 For Particular Attention ..........0000−1/A1 Preface . - Page 9 Intentionally blank...

-

Page 10: General

0000−1/A1 Maintenance For Your Attention General This manual is for the operator and is for use only for the related type of diesel engine (the engine described in this manual). The data in this manual is confidential. Make sure that you read carefully the Operation Manual before you operate the engine. - Page 11 Intentionally blank...

- Page 12 0001−1/A1 Maintenance Preface The instructions contained in this Maintenance Manual are intended to help to ensure that the maintenance which must be carried out at specific intervals is correctly carried out. It is a condition that the personnel who do such important work have the necessary training and experience.

- Page 13 Intentionally blank...

- Page 14 0002−1/A1 Maintenance Table of Contents Table of Contents General Information Group 0 For Particular Attention ..........0000−1/A1 Preface .

- Page 15 0002−1/A1 Maintenance Table of Contents Bedplate and Tie Rod Group 1 Bedplate and Thrust Bearing: Checking the Foundation Bolts ....1112−1/A1 Main Bearing − Loosening and Tensioning of Elastic Studs .

- Page 16 0002−1/A1 Maintenance Table of Contents Crankshaft, Connecting Rod and Piston Group 3 Crankshaft: Measuring Crank Deflection ........3103−1/A1 Vibration Damper −...

- Page 17 0002−1/A1 Maintenance Table of Contents Supply Unit, Injection and Exhaust Valve Control Group 5 Fuel Pump − Dismantling and Assembling ......... . 5556−1/A1 −...

- Page 18 0002−1/A1 Maintenance Table of Contents Piping Group 8 Exhaust Waste Gate (Low-Load Tuning) ........8135−1/A1 Selective Catalytic Reduction System .

- Page 19 Intentionally blank...

- Page 20 0008−1/A1 Maintenance General Engine Numbering and Designations Turbocharger 2 Turbocharger 1 Cylinder Numbering FREE DRIVING Thrust Bearing Pads Main Bearing Numbering Rail Unit FUEL EXHAUST SIDE SIDE Servo Pump Unit Fuel Pump Unit Fuel Pump Unit Clockwise Rotation Fig. 1 WCH01188 2017 1/ 2...

- Page 21 0008−1/A1 Maintenance flex Parts: Fuel Pump B1 Fuel Pump B2 Fuel Pump B3 Actuator B1 Servo Oil Pump 3 Servo Oil Pump 2 Actuator B2 Servo Oil Pump 1 Actuator B3 Fuel Pump A1 Fuel Pump A2 Fuel Pump A3 Actuator A1 Actuator A2 EXHAUST SIDE...

-

Page 22: General Safety Precautions

0011−1/A1 Maintenance General Guidelines for Maintenance Safety Measures and Warnings General ............General safety precautions . - Page 23 0011−1/A1 Maintenance Safety Measures and Warnings Precautions before the Start of Maintenance CAUTION Damage Hazard: Do not use water or cleaning fluid to clean the electronic components and control boxes on the engine and the rail unit. Damage can occur if water or cleaning CAUTION Damage Hazard: When electrical welding is done near or on the engine, electromagnetic fields or peak voltage can occur.

- Page 24 0011−1/A1 Maintenance Safety Measures and Warnings Special safety measures WARNING Injury Hazard: After engine operation in gas mode, gas fuel can stay in the gas inlet pipes. There is a risk of explosion. You must replace the gas fuel with inert gas (e.g. nitrogen). For the procedure, refer to the documentation of the gas valve unit manufacturer.

- Page 25 0011−1/A1 Maintenance Safety Measures and Warnings Recommendations Read the data in 3301−1 Work Platform. Do the work carefully. Make sure that all parts and equipment are clean. Use only the applicable tools and equipment for the maintenance tasks. For data about the tools and equipment, refer to 9403−5 Tool List.

- Page 26 0012−1/A1 Maintenance General Guidelines for Lifting Tools Wire Rope Slings, Span-sets, Eye Bolts, etc. General ............Lifting Equipment .

- Page 27 0012−1/A1 Maintenance Wire Rope Slings, Span-sets, Eye Bolts, etc. Lifting capacity (for information purposes only): Table 1: Values Lifting capacity [kg] Eye bolts and eye nuts, single-strand double-strand (45°) thread size 1200 1800 1290 3200 2300 4600 3300 6300 4500 8600 6100 11 500...

- Page 28 0012−1/A1 Maintenance Wire Rope Slings, Span-sets, Eye Bolts, etc. 2.41. RUD Eye Bolts RUD eye bolts must be fully attached to the seating surfaces. Use the applicable star-profile wrenches to tighten RUD eye bolts with your hand (do not use an extension). After the RUD eye bolt is tightened, remove the star-profile wrench (Fig.

- Page 29 0012−1/A1 Maintenance Wire Rope Slings, Span-sets, Eye Bolts, etc. 2.42. RUD Swivel Lugs RUD swivel lugs must be fully attached to the seating surfaces. Use an open-ended wrench to tighten the RUD swivel lugs with your hand. Align the RUD swivel lug with the direction of force before a load is applied (Fig.

- Page 30 0012−1/A1 Maintenance Wire Rope Slings, Span-sets, Eye Bolts, etc. Data to Attach Ropes and Slings You must know the data that follow: A sling with one strand has the total of load weight For a sling with two strands, each strand has one half of the load weight For a sling with four strands of equal load, each strand has one quarter of the load weight.

- Page 31 Intentionally blank...

-

Page 32: General

0330−1/A1 Maintenance Clearance Table General ............Crankshaft and Thrust Bearing . -

Page 33: Crankshaft And Thrust Bearing

0330−1/A1 Maintenance Clearance Table Crankshaft and Thrust Bearing 016.893/08 Fig. 1 016.851/08 018.678/09 Fig. 2 Fig. 3 2017 2/ 25 Winterthur Gas & Diesel Ltd. - Page 34 0330−1/A1 Maintenance Clearance Table Crankshaft and Thrust Bearing Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 1132 Main bearing Bearing shell width Lateral clearance per side 1203 Thrust bearing 1224 − 0.5 Thrust bearing pad thickness −...

-

Page 35: Crankshaft And Main Bearing

0330−1/A1 Maintenance Clearance Table Crankshaft and Main Bearing 016.778/08 Fig. 4 Fig. 5 MAIN BEARING MAIN BEARINGS No. 1 No. 2 to ... Fig. 6 016.893/08 2017 4/ 25 Winterthur Gas & Diesel Ltd. - Page 36 0330−1/A1 Maintenance Clearance Table Crankshaft and Main Bearing Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 1132 Main bearing No. 1 Crankshaft outer ∅ 1020 − 0.10 Main bearing inner ∅ 1020 Bearing clearance vertical 0.4−0.7...

-

Page 37: Crosshead Guide

0330−1/A1 Maintenance Clearance Table Crosshead Guide EXHAUST SIDE Fig. 7 016.783/08 2017 6/ 25 Winterthur Gas & Diesel Ltd. - Page 38 0330−1/A1 Maintenance Clearance Table Crosshead Guide Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 3326 Crosshead guide + 0.25 Guide bar (column) transverse 1390 − 0.20 Guide shoe transverse 1390 − 0.30 Guide way clearance 0.2−1.3 Guide rail...

-

Page 39: Cylinder Liner

0330−1/A1 Maintenance Clearance Table Cylinder Liner Fig. 8 017.003/08 Fig. 10 016.501/07 Fig. 9 2017 8/ 25 Winterthur Gas & Diesel Ltd. - Page 40 0330−1/A1 Maintenance Clearance Table Cylinder Liner Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 2130 Water guide jacket on cylinder cover + 0.50 Water guide jacket upper part Ø 1137 + 0.30 Clearance total 0.60−1.00...

-

Page 41: Piston Rod Gland

0330−1/A1 Maintenance Clearance Table Piston Rod Gland 016.997/08 99.7406 Fig. 11 2017 10/ 25 Winterthur Gas & Diesel Ltd. - Page 42 0330−1/A1 Maintenance Clearance Table Piston Rod Gland Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 2303 Piston rod gland Ring width radial min. 25 Ring width radial min. 22.20 Ring width radial min.

-

Page 43: Exhaust Valve

0330−1/A1 Maintenance Clearance Table Exhaust Valve VALVE SPINDLE GUIDE BUSH 016.995/08 Fig. 13 016.994/08 Fig. 12 2017 12/ 25 Winterthur Gas & Diesel Ltd. - Page 44 0330−1/A1 Maintenance Clearance Table Exhaust Valve Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 2751 Valve spindle − 0.19 Spindle outer ∅ 79.40 − 0.23 2751 Guide bush + 0.03 Bore inner ∅ 80.45 + 0.03 Bore...

-

Page 45: Top And Bottom End Bearings To Connecting Rod

0330−1/A1 Maintenance Clearance Table Top and Bottom End Bearings to Connecting Rod 016.783/08 Fig. 15 Fig. 14 016.993/08 016.993/08 Fig. 16 2017 14/ 25 Winterthur Gas & Diesel Ltd. - Page 46 0330−1/A1 Maintenance Clearance Table Top and Bottom End Bearings to Connecting Rod Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 3303 Top end bearing 3326 Crosshead pin outer ∅ − 0.09 Bearing inner ∅...

-

Page 47: Piston Cooling And Crosshead Lubricating Link

0330−1/A1 Maintenance Clearance Table Piston Cooling and Crosshead Lubricating Link EXHAUST SIDE 016.996/08 003.314/00 Fig. 17 2017 16/ 25 Winterthur Gas & Diesel Ltd. - Page 48 0330−1/A1 Maintenance Clearance Table Piston Cooling and Crosshead Lubricating Link Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 3603 Piston cooling and crosshead lubricating link outer ∅ Bearing clearance radial 0.03−0.09 0.20 Bearing width Lateral clearance...

-

Page 49: Piston And Piston Rings

0330−1/A1 Maintenance Clearance Table Piston and Piston Rings Fig. 18 2017 18/ 25 Winterthur Gas & Diesel Ltd. - Page 50 0330−1/A1 Maintenance Clearance Table Piston and Piston Rings Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 3406 Piston head − 0 Head (tapered part) outer ∅ 813.2 − 0.2 − 0 Head outer ∅...

-

Page 51: Driving Wheels For Supply Unit

0330−1/A1 Maintenance Clearance Table Driving Wheels for Supply Unit INTERMEDIATE WHEEL FOR FUEL PUMP UNIT 016.823/08 Fig. 19 INTERMEDIATE WHEEL FOR SERVO PUMP UNIT 2a 3a 3a 2a Fig. 21 Fig. 20 016.661/08 016.662?08 2017 20/ 25 Winterthur Gas & Diesel Ltd. - Page 52 0330−1/A1 Maintenance Clearance Table Driving Wheels for Supply Unit Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 4122 Intermediate wheel fuel pump Shaft outer ∅ Bearing clearance vertical *0.096−0.170 0.27 Axial clearance total 0.6−1.1 4121...

-

Page 53: Fuel And Servo Pump Units

0330−1/A1 Maintenance Clearance Table Fuel and Servo Pump Units FUEL PUMP UNIT 016.862/08 Fig. 22 SERVO PUMP UNIT Fig. 23 WCH01164 2017 22/ 25 Winterthur Gas & Diesel Ltd. - Page 54 0330−1/A1 Maintenance Clearance Table Fuel and Servo Pump Units Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 5581 Fuel pump unit Pinion outer ∅ − 0.025 + 0.212 Bearing (fitted) inner ∅ + 0.153 Bearing clearance radial...

-

Page 55: Fuel Pump

0330−1/A1 Maintenance Clearance Table Fuel Pump PLUNGER & CYLINDER Fig. 25 014.104/06 WCH00832 Fig. 24 2017 24/ 25 Winterthur Gas & Diesel Ltd. - Page 56 0330−1/A1 Maintenance Clearance Table Fuel Pump Description Measured Nominal Maximum Clearance, Direction Dimension Dimension (mm) (mm) (usual, new) (because of worn components) 5556 Fuel pump Plunger (40, 44 and 46 mm) Clearance (plunger / cylinder) A−B radial 0.035−0.038 0.045 Clearance (plunger / cylinder) B−C radial 0.025−0.028 0.035...

- Page 57 Intentionally blank...

- Page 58 0352−1/A1 Maintenance Tightening Values of Important Screwed Connections Note: Do not use the values given in brackets eg [900 Nm] as the tightening value. These values are for data only, to be used comparison. When using different hydraulic jacks, the applicable pressure in bar must be calculated in relation to the jack piston surface.

- Page 59 0352−1/A1 Maintenance Tightening Values of Important Screwed Connections 2017 2/ 6 Winterthur Gas & Diesel Ltd.

- Page 60 0352−1/A1 Maintenance Tightening Values of Important Screwed Connections 2017 3/ 6 Winterthur Gas & Diesel Ltd.

- Page 61 0352−1/A1 Maintenance Tightening Values of Important Screwed Connections 2017 4/ 6 Winterthur Gas & Diesel Ltd.

- Page 62 0352−1/A1 Maintenance Tightening Values of Important Screwed Connections 2017 5/ 6 Winterthur Gas & Diesel Ltd.

- Page 63 0352−1/A1 Maintenance Tightening Values of Important Screwed Connections 2017 6/ 6 Winterthur Gas & Diesel Ltd.

- Page 64 0352−2/A1 Maintenance Tightening Values of Standard Screwed Connections Standard screws We highly recommend the torque values given in the table below for aII standard metric screws of grade 8.8. This applies to all threaded connections not shown on page 0352−1. The threads and base of the head must be lubricated with oil SAE 30. For the screws in high temperature areas (exhaust pipes, expansion pieces etc), a heat resistant lubricant, e.g.

- Page 65 0352−2/A1 Maintenance Tightening Values of Standard Screwed Connections Elastic studs ⇒ Read the data in the manual of the jointing compound manufacturer. ⇒ Remove the grease and clean the sealing surfaces of the new elastic stud. ⇒ Remove the grease and other unwanted material from the tap hole and the area where the elastic stud will be installed.

- Page 66 0360−1/A1 Maintenance Masses (Weights) Components each in kg Group Component Execution Main bearing cover (special) 900 (568) 1115 1134 Main bearing shell (special) 232 (159) 1224 Thrust bearing pad 1717 Casing (top part) free end Casing (top part) (9−cyl has two parts) driving end 65.1 to 169 1720...

- Page 67 0360−1/A1 Maintenance Components each in kg Group Component Execution 3303 Connecting rod All parts 6561−6569 Elastic stud with nut for bottom end bearing Elastic stud with nut for top end bearing 3306 Connecting rod shank 5491−5498 3306 Bearing cover for bottom end All parts bearing with elastic studs 3310...

- Page 68 0360−1/A1 Maintenance Components each in kg Group Component Execution 5591 Servo pump unit Dynex Bosch 5556 Fuel pump All parts 5564 Injection control unit All parts 5580 Fuel pump unit assembly With 4 fuel pumps 5581 Fuel pump unit With 4 fuel umps 5591 Servo pump unit with pumps, gear With 2 SOP...

- Page 69 Intentionally blank...

- Page 70 0380−1/A1 Maintenance Maintenance Schedule Inspection and Overhaul Intervals (Guidelines) Group Component Procedure Intervals and Service Life (operation hours) Lubricating oil − Laboratory analysis 3000 Main fuel and − Do a check of the filter elements −specially for 3000 white metal particles (clean or replace filter as lubricating oil filters necessary).

- Page 71 0380−1/A1 Maintenance Inspection and Overhaul Intervals (Guidelines) Group Component Procedure Intervals and Service Life (operation hours) 1715−1 Engine stays − Hydraulic type: Do a check of the oil pressure monthly at the gauge 1903−1 Tie rod − Do a check of the pre−tension, if necessary 30000 apply tension again.

- Page 72 0380−1/A1 Maintenance Inspection and Overhaul Intervals (Guidelines) Group Component Procedure Intervals and Service Life (operation hours) 2722−1 Injection valve − Do an external heck for tightness before engine start (main fuel after a longer engine injector) stop − Do a function check (nozzle tip inspection, 6000 opening pressure).

- Page 73 0380−1/A1 Maintenance Inspection and Overhaul Intervals (Guidelines) Group Component Procedure Intervals and Service Life (operation hours) 3103−1 Crankshaft − Always measure the crank deflection after the 6000 ship has run aground, and after each docking. 3130−1 Torsional − Get a silicon oil sample from viscous vibration first time after vibration damper (the damper manufacturer will make a...

- Page 74 0380−1/A1 Maintenance Inspection and Overhaul Intervals (Guidelines) Group Component Procedure Intervals and Service Life (operation hours) 3403−1 Piston − Remove and clean 36000 − Do a check for tightness on the installed piston after installation and with running oil pump. Do a visual check through scavenge ports 3403−3 −...

- Page 75 0380−1/A1 Maintenance Inspection and Overhaul Intervals (Guidelines) Group Component Procedure Intervals and Service Life (operation hours) 4325−1 Starting air − Estimated service life: Starting air shut−off Service life of engine shut-off valve valve Control air filter − Drain the filter weekly −...

- Page 76 0380−1/A1 Maintenance Inspection and Overhaul Intervals (Guidelines) Group Component Procedure Intervals & Service Life (operation hours) − Estimated service life: Fuel pressure control Service life of engine valve 5562−2 Fuel − Do a function check on the test bench 24000 to 36000 overpressure safety valve / Relief Valve...

- Page 77 0380−1/A1 Maintenance Inspection and Overhaul Intervals (Guidelines) Group Component Procedure Intervals & Service Life (operation hours) 6420−1 Air filter − Clean the filter at an np increase of 50% as necessary compared to the shop test value at the same engine load (see Operation Manual 6510−1) 6545−1 Auxiliary blower...

- Page 78 0380−1/A1 Maintenance Inspection and Overhaul Intervals (Guidelines) Group Component Procedure Intervals and Service Life (operation hours) 8135−1 Exhaust waste − General Inspection. During a longer operation In accordance with period at low engine load, manually open the gate (LLT) instructions of valve butterfly valve (refer to Operation Manual manufacturer 8135−1)

- Page 79 0380−1/A1 Maintenance Inspection and Overhaul Intervals (Guidelines) Group Component Procedure Intervals and Service Life (operation hours) 9223−1 Crank angle − Replace the proximity sensor as necessary sensor (CAS) unit on gear wheel 9308−1 Cylinder cover − − Do a check of the blow−off pressure as necessary Relief valve 9314−1...

- Page 80 0803−1/A1 Maintenance Engine Cross Section and Longitudinal Section Cross Section 2728−1 8460−1 8733−1 2722−1 6545−1 5562−1 5612−1 6420−1 4325−1 8447−1 6606−1 3326−1 6708−1 3326−2 3301−1 3206−1 4103−1 4103−2 1112−1 018.263/09 2017 1/ 2 Winterthur Gas & Diesel Ltd.

- Page 81 0803−1/A1 Maintenance Engine Cross Section and Longitudinal Section Longitudinal Section 2751−1 2708−1 2751−4 2708−3 2124−1 1903−1 2124−3 2138−1 3403−1 3403−4 3425−1 8752−1 2303−1 3326−1 5556−1 3326−2 5591−1 3303−1 5581−1 3303−4 3140−1 4103−1 9223−1 1132−1 1132−2 3103−1 1203−1 1224−1 3130−1 3130−2 018.264/09 2017 2/ 2...

-

Page 82: Bedplate And Tie Rod Group

Group1 Maintenance Bedplate and Tie Rod Group 1 Bedplate and Thrust Bearing: Checking the Foundation Bolts ....1112−1/A1 Main Bearing − Loosen and Apply Tension to Elastic Studs . - Page 83 Intentionally blank...

-

Page 84: Bedplate And Thrust Bearing Checking The Foundation Bolts

1112−1/A1 Maintenance Bedplate and Thrust Bearing Checking the Foundation Bolts Tools: Key to Illustrations: 1 Feeler gauge 94122 1 Vent screw 11 Nut 1 Pre-tensioning jack 94145 2 Cylinder 12 Conical socket 1 HP oil pump 94931 3 Piston 13 Joint disc 2 Hydraulic distributors 94934A 4 Nut... - Page 85 1112−1/A1 Maintenance Bedplate and Thrust Bearing Checking the Foundation Bolts Foundation bolts − Loosen or Apply Tension You start the procedure to apply tension to the foundation at the driving end, and from one side to the other. The procedure is completed at the free end. ⇒...

- Page 86 1112−1/A1 Maintenance Checking the Foundation Bolts ⇒ Do not move the piston (3) of the pre−tensioning jack (94145) to more than the red limit groove (LG). ⇒ Put the feeler gauge (94122) through the slot (8). Do a check for clearance between the round nut (4) and the bush (7).

- Page 87 Intentionally blank...

-

Page 88: Main Bearing

1132−1/A1 Maintenance Main Bearing Loosen and Apply Tension to Elastic Studs Tools: Key to Illustrations: 2 Double pre-tensioning jacks 94114 1 Main bearing girder 1 Feeler gauge 94122 2 Main bearing cover (special) 1 Special feeler gauge 94123 3 Main bearing cover 2 Connection pieces 94215B 4 Elastic stud... - Page 89 1132−1/A1 Maintenance Main Bearing: Loosen and Apply Tension to Elastic Studs 94934A 94215B 94114 94935 94942 94114 94934G 017.662/08 016.894/08 Loosen ⇒ Attach the double pre-tensioning jacks as given in paragraph 2. ⇒ Start the hydraulic unit 94942. ⇒ When oil that has no air comes out, close the vent screws 8 on the jacks.

- Page 90 1132−1/A1 Maintenance Main Bearing: Loosen and Apply Tension to Elastic Studs Elastic Studs − Apply Tension After the installation of the main bearing cover as given in 1132−2, apply tension to the elastic studs 4: ⇒ Attach the double pre-tensioning jacks as given in paragraph 2. ⇒...

- Page 91 Intentionally blank...

-

Page 92: 1132−2/A1

1132−2/A1 Maintenance Main Bearing Removal and Installation Tools: Key to Illustrations: 2 Manual ratchets 94016A 1 Crankshaft 1 Assembling and dismantling device 94110 2 Bearing girder 1 Lifting tool (bearing shell) 94116 3 Main bearing cover (special) 1 Lifting tool (bearing shell special) 94116A 4 Main bearing cover 1 Lug with 4 screws M16x35... - Page 93 1132−2/A1 Maintenance Main Bearing: Removal and Installation 017.096/08 I - I 5, 6 3, 4 5a, 6a 017.622/08 2017 2/ 17 Winterthur Gas & Diesel Ltd.

- Page 94 1132−2/A1 Maintenance Main Bearing: Removal and Installation Device 94110 − Install Attention! Do not use the tool 94110 to lift the bearing cover. You use the device 94110 to expand the top part of main bearing cover 4 to remove it from the bearing girder 2.

- Page 95 1132−2/A1 Maintenance Main Bearing: Removal and Installation Main Bearing Cover (special) − Removal ⇒ Attach the wire rope / shackle 94120K to the manual ratchet H1 and the lug 94116B. ⇒ Operate the manual ratchet H1 to lift the bearing cover. ⇒...

- Page 96 1132−2/A1 Maintenance Main Bearing: Removal and Installation 018.173/09 018.173/09 018.173/09 2017 5/ 17 Winterthur Gas & Diesel Ltd.

- Page 97 1132−2/A1 Maintenance Main Bearing: Removal and Installation Main Bearing Cover No. 2 to No. # − Removal ⇒ Install the device 94110, refer to paragraph 2. ⇒ Install the roller support 94117 to the column with the pin. ⇒ Attach the double spring clip. ⇒...

- Page 98 1132−2/A1 Maintenance Main Bearing: Removal and Installation 94120K 94117 94121A 94142 017.625/08 94332 94120K 94120K 94117A 017.626/08 2017 7/ 17 Winterthur Gas & Diesel Ltd.

- Page 99 1132−2/A1 Maintenance Main Bearing: Removal and Installation Bottom Bearing Shell − Removal Attention! Do not remove two adjacent main bearing shells at the same time. Damage to equipment can occur. The removal procedure for the bottom bearing shells 6a (Fig. A) is the same for all main bearings with the exception of main bearing No.

- Page 100 1132−2/A1 Maintenance Main Bearing: Removal and Installation 50 mm 50 mm 0.3 mm 5a, 6a 009.810/02 ⇒ Make sure that the horizontal clearances on each side of crankshaft between the crankshaft and the bearing shell y1, y2 are the same. ⇒...

- Page 101 1132−2/A1 Maintenance Main Bearing: Removal and Installation 94120K 94936 94141 PROTECTION 017.628/08 CONNECTION SEE 9403−2 94120K 94119 94118 94118 ⇒ Remove the device 94118. ⇒ Attach the lifting tool 94116A to the bearing shell 5a. ⇒ Attach the manual ratchet H6 and wire rope 94120K to the lifting tool 94116A. ⇒...

- Page 102 1132−2/A1 Maintenance Main Bearing: Removal and Installation ⇒ Move the manual ratchet H7 to the bottom platform. ⇒ Attach the manual ratchet to the lifting tool 94116A. ⇒ Operate the manual ratchet H7 to hold the weight of the bearing shell 5a. ⇒...

- Page 103 1132−2/A1 Maintenance Main Bearing: Removal and Installation Bottom Bearing Shell No. 2 to No. # ⇒ Operate the turning gear to move the crank to approximately 90_ after TDC. ⇒ Install the platform 94142. ⇒ Lift the crankshaft, refer to paragraphs 5.1 and 5.2. ⇒...

- Page 104 1132−2/A1 Maintenance Main Bearing: Removal and Installation 94121B 94119 94121B 94118A 94936 94141 017.631/08 CONNECTION SEE 9403−2 94117 94116 017.632/08 ⇒ Remove the device 94118A. ⇒ Operate the manual ratchet H6 to move the bearing shell until the tool 94116 is in the vertical position.

- Page 105 1132−2/A1 Maintenance Main Bearing: Removal and Installation ⇒ Attach the lifting ring 94332 to the cylinder jacket with its screws (Fig. H4 to Fig. H7) ⇒ Torque the screws to 600 Nm. ⇒ Attach the manual ratchet H7 to the lifting ring 94332. ⇒...

- Page 106 1132−2/A1 Maintenance Main Bearing: Removal and Installation Main Bearing Shells − Examine Attention! Do not use a scraper in the running area of the bearing shell. Damage to the bearing shell will occur. ⇒ Use a soft cloth to clean the bearing shell. ⇒...

- Page 107 1132−2/A1 Maintenance Main Bearing: Removal and Installation Bearing Cover − Installation ⇒ Make sure that the work area and all tools and equipment are clean and in good condition. ⇒ Remove all plugs from the oil bore (OB). ⇒ Use the applicable equipment to get the bearing cover in the correct position above the crankshaft as follows: Use the device 94110 to install the bearing cover No.

- Page 108 1132−2/A1 Maintenance Main Bearing: Removal and Installation 17, 16 017.635/08 2017 17/ 17 Winterthur Gas & Diesel Ltd.

- Page 109 Intentionally blank...

-

Page 110: Thrust Bearing

1203−1/A1 Maintenance Thrust Bearing Checking the Axial Clearance Tools: Key to Illustrations: 1 Inside micrometer 94101 1 Crankshaft flange 6a Thrust bearing pads 1 Feeler gauge 94238 2 Oil baffle, top part for AHEAD 3 Oil baffle, bottom part 7 Cover 4 Thrust flange 8 Dial gauge 5 Crankshaft... - Page 111 1203−1/A1 Maintenance Thrust Bearing: Checking the Axial Clearance Procedure 2 ⇒ Start the engine in the direction AHEAD to move the crankshaft fully forward. The crankshaft must touch the thrust pads. ⇒ Stop the engine. ⇒ Make sure that the crankshaft does not move. ⇒...

-

Page 112: 1224−1/A1

1224−1/A1 Maintenance Thrust Bearing Thrust Bearing Pads − Removal and Installation Tools: Key to Illustrations: 1 Turning-out device 94155 1 Casing 7 Support (with 1-part gear wheel) 2 Oil baffle (upper part) 8 Temperature sensor 1 Turning-out device 94155A 3 Screw 9 Cover (with 2-part gear wheel) 4, 4a Arbor support... - Page 113 1224−1/A1 Maintenance Thrust Bearing Pads − Removal and Installation ⇒ Attach the RUD-eye bolt EB to the thrust bearing pads 5 or 5a. ⇒ Attach the manual ratchets H1, H2 to the supports on the platform 7 and the eye bolt EB. ⇒...

- Page 114 1224−1/A1 Maintenance Thrust Bearing Pads − Removal and Installation Installation ⇒ Make sure that the thrust pads are clean. ⇒ Apply clean engine oil to the thrust pads. Remark: You must install thrust pads that you removed before in the same positions.

- Page 115 1224−1/A1 Maintenance Thrust Bearing Pads − Removal and Installation CONFIGURATION OF THRUST BEARING PADS WITH FIXED PITCH PROPELLER CLOCKWISE ROTATING ENGINE ASTERN AHEAD SUPPORT SURFACE VIEW FROM DRIVING END VIEW FROM DRIVING END PADS AT DRIVING END PADS ON ENGINE SIDE DRIVING END ENGINE SIDE PROPELLER THRUST...

- Page 116 1715−1/A2 Maintenance Hydraulic Engine Stays General Two hydraulic engine stays (1, Fig. A) are installed on the exhaust side and two on the fuel side of the engine. Oil around a nitrogen filled bladder in the accumulator body dampens the vibrations.

- Page 117 1715−1/A2 Maintenance Oil Pressure Checks WCH03839 ENGINE SIDE WCH03839 Fig. A Key 1 Hydraulic engine stays 5 Rod 2 Accumulator body (with inner bladder) 6 Plug ⅜ inch NPT 3 Pressure gauge 7 Ball valve 4 Damping control valve 8 Hydraulic cylinder 2017 2/ 2 Winterthur Gas &...

-

Page 118: 1903−1/A1

1903−1/A1 Maintenance Tie Rod Pre-tension Checks and Apply Tension Tools: Key to Illustrations: 1 Rod 94005C 1 Cylinder jacket 12 Bearing girder 1 Feeler gauge 94122 2 Intermediate ring 13 Lower backing ring 2 Pre-tensioning jacks 94180 3 Upper tie rod nut 14 Lower tie rod nut 1 Connection block 94934... - Page 119 1903−1/A1 Maintenance Pre-tension Checks and Apply Tension 94934A 94934G 94934 94935 94935 94005C 94942 WCH02797 PRE-TENSIONING JACK IN PRE-TENSIONING JACK IN POSITION TO TIGHTEN POSITION TO LOOSEN 2017 2/ 5 Winterthur Gas & Diesel Ltd.

- Page 120 1903−1/A1 Maintenance Pre-tension Checks and Apply Tension Loosen and Apply Tension Loosen If the tie rods were removed and installed, do the procedure that follows: Remark: Start with the tie rods in the middle of the engine a−a, then b−b etc. ⇒...

- Page 121 1903−1/A1 Maintenance Tie Rod Pre-tension Checks and Apply Tension Apply Tension in one procedure: Do not move the pistons 5 of the pre-tensioning jacks to more than the red limiting grooves LG (Fig. A). ⇒ Attach the pre-tensioning jacks to the hydraulic unit 94942. ⇒...

- Page 122 1903−1/A1 Maintenance Tie Rod Pre-tension Checks and Apply Tension I - I WCH01111 FLUSH 2017 5/ 5 Winterthur Gas & Diesel Ltd.

- Page 123 Intentionally blank...

-

Page 124: Cylinder Liner And Cylinder Cover Group

Group2 Maintenance Cylinder Liner and Cylinder Cover Group 2 Cylinder Liner − Bore − Measure ........... . . 2124−1/A1 −... - Page 125 Intentionally blank...

- Page 126 2124−1/A1 Maintenance Cylinder Liner Bore − Measure Tools: Key to Illustrations: 1 Inside micrometer 94101 1 Cylinder liner 1 Ladder 94224 2 Measuring holes (points A to …) 1 Gauge 94225 3 Running surface 4 Non-running surface SS Setting screw Note: Some parts of the cylinder liner can look different.

-

Page 127: 2124−1/A1

2124−1/A1 Maintenance Cylinder Liner Bore − Measure ⇒ Use the formula below to calculate the rate: WR = (D1−D2) x 1000 Where: WR = Wear rate (mm/1000 hours) T1 = Total running hours (h) D1 = Maximum liner diameter of running surface (point B and below) (mm) D2 = Liner diameter of non−running surface (point A) (mm). -

Page 128: 2124−2/A1

2124−2/A1 Maintenance Cylinder Liner Removal and Installation Tools: Key to Illustrations: 1 Lifting device 94201 1 Cylinder jacket 10 Centering pin 1 Angled lever 94202A 2 Cylinder liner 11 O-ring 2 Distance plates 94202C 3 Water guide jacket 12 O-ring 8 Distance plates 94202D (bottom part) - Page 129 2124−2/A1 Maintenance Cylinder Liner: Removal and Installation Cylinder Liner − Removal Lifting Tool − Install ⇒ Loosen the screws 9. ⇒ Remove (or add) the distance plates 94202D to get the applicable clearance of 2.0 mm to 5.0 mm shown. ⇒...

- Page 130 2124−2/A1 Maintenance Cylinder Liner: Removal and Installation Removal ⇒ Remove the screws 8. ⇒ Remove the pipe connection 7 and transition tubes 6 from the water guide jacket 3 and 5 (Fig. B). Remark: The transition tubes 6 are a push−fit in the connection tubes 7. WCH03840 WCH03840 2017...

- Page 131 2124−2/A1 Maintenance Cylinder Liner: Removal and Installation ⇒ Operate the engine room crane to carefully lift cylinder liner 2. ⇒ Move the cylinder liner 2 to an applicable area. ⇒ Lower the cylinder liner 2 on a wooden underlay. ⇒ Put the cylinder liner 2 into safe storage, refer to paragraph 6. 94201 FUEL SIDE 94206...

- Page 132 2124−2/A1 Maintenance Cylinder Liner: Removal and Installation ⇒ Apply a non-hardening sealing compound to the seating surfaces SS (Fig. E). ⇒ Operate the engine room crane to lower the cylinder liner 2. ⇒ Align the centering hole with the holder 15 and the centering pin 10 of the cylinder jacket 1.

- Page 133 2124−2/A1 Maintenance Cylinder Liner: Removal and Installation ⇒ Attach the connection tubes 7 to the transition tubes 6 on the water guide jackets 3 and 5 (Fig. E). ⇒ Install all the lubricating quills refer to 2138−1. ⇒ Operate the cylinder lubricating pump until oil flows from the lubricating grooves in the applicable cylinder.

- Page 134 2124−2/A1 Maintenance Cylinder Liner: Removal and Installation Water Guide Jacket Removal ⇒ Remove the cylinder liner, refer to paragraph 2. ⇒ Attach the three eye bolts EB to the water guide jacket 3. ⇒ Attach the manual ratchets the eye bolts EB. ⇒...

- Page 135 2124−2/A1 Maintenance Cylinder Liner: Removal and Installation Insulation Bandage Removal ⇒ Remove the cylinder liner, refer to paragraph 2. ⇒ Remove water guide jacket, refer to paragraph 4. ⇒ Use the assembly tool 94345E to remove the tension springs 21. ⇒...

- Page 136 2124−2/A1 Maintenance Cylinder Liner: Removal and Installation Safe Storage ⇒ Install the lifting device 94201, refer to paragraph 2.1. 94201 94202A 018.168/09 ⇒ Attach the the lever 94202A to the lifting tool 94201 (Fig. J). ⇒ Attach the engine room crane to the lever 94202A. ⇒...

- Page 137 2124−2/A1 Maintenance Cylinder Liner: Removal and Installation 94201 018.167/09 018.167/09 018.167/09 2017 10/ 10 Winterthur Gas & Diesel Ltd.

-

Page 138: 2124−2/A2

2124−2/A2 Maintenance Cylinder Liner: Removal and Installation Tilted Removal Tools: Key to Illustrations: 1 Rod 94005A 1 Cylinder jacket 13 O-ring 4 Suspension straps 94208 2 Cylinder liner 14 Cylinder cover 1 Lifting hook 94209 3 Water guide jacket 15 Holder 1 Lifting tool 94210 (bottom part) - Page 139 2124−2/A2 Maintenance Cylinder Liner: Removal and Installation Tilted Removal Cylinder Liner − Removal ⇒ Remove the screws 8. ⇒ Remove the pipe connection 7 and transition tubes 6 from water guide jacket 3 and 5 (view I). Remark: The transition tubes are a push−fit in the connection tubes 6. WCH03840 WCH03840 2017...

- Page 140 2124−2/A2 Maintenance Cylinder Liner: Removal and Installation Tilted Removal 2-part cylinder cover stud − Disassemble Attention: Do not use tools such as a pipe wrench etc. This could cause damage to the stud shank. Attention: The sleeve 24 weighs 116 kg. Use applicable equipment to lift and move the sleeve.

- Page 141 2124−2/A2 Maintenance Cylinder Liner: Removal and Installation Tilted Removal Cylinder Liner − Lift ⇒ On the lifting tool 94210, connect the crane hooks to the pins 17. ⇒ Operate carefully the engine room crane to lift cylinder liner 2. ⇒ Move the cylinder liner 2 over the the starting air pipe and rail unit as shown in Fig.

- Page 142 2124−2/A2 Maintenance Cylinder Liner: Removal and Installation Tilted Removal WCH03840 WCH03840 WCH03840 ⇒ Apply a non-hardening sealing compound to the seating surfaces SS. ⇒ Turn the cylinder liner 2 to align the centering hole in the holder 15 with the centering pin 10 of the cylinder jacket 1.

- Page 143 2124−2/A2 Maintenance Cylinder Liner: Removal and Installation Tilted Removal ⇒ Apply oil to the thread of the bottom part of the elastic bolt 23. ⇒ Put the sleeve 24 in position as shown in Fig. B. make sure that there is a distance of 257 mm to the cylinder jacket.

- Page 144 2124−2/A2 Maintenance Cylinder Liner: Removal and Installation Tilted Removal Water Guide Jacket Removal ⇒ Remove the cylinder liner, refer to paragraph 2. ⇒ Attach the eye bolts EB to the water guide jacket 3 (Fig. H and Fig. I). ⇒ Attach the manual ratchets the eye bolts EB. ⇒...

- Page 145 2124−2/A2 Maintenance Cylinder Liner: Removal and Installation Tilted Removal Insulation Bandage Removal ⇒ Remove the cylinder liner, refer to paragraph 2. ⇒ Remove water guide jacket, refer to paragraph 4. ⇒ Use the assembly tool 94345E to remove the tension springs 21. ⇒...

- Page 146 2124−2/A2 Maintenance Cylinder Liner: Removal and Installation Tilted Removal Safe Storage ⇒ Make sure that the water guide jacket is removed, refer to paragraph 4.1. ⇒ Make sure that the insulation bandage is removed, refer to paragraph 5.1. ⇒ Attach the lifting tool 94210A and the ring 94210D to the double jib crane. ⇒...

- Page 147 2124−2/A2 Maintenance Cylinder Liner: Removal and Installation Tilted Removal 94210A 94210D 94210 WCH01181 2017 10/ 10 Winterthur Gas & Diesel Ltd.

-

Page 148: 2124−3/A1

2124−3/A1 Maintenance Cylinder Liner Wear Ridge Remove, Repair the Finish to Lubricating Grooves and Scavenge Ports − Tools: Key to Illustrations: 1 Grinding device 94299 1 Roller support 9 Thread nozzle 2 Holder 10 Carbide milling cutter 3 Holder 11 Cylinder liner 4 Spacer roller 12 Top piston ring 5 Pipe (column) - Page 149 2124−3/A1 Maintenance Cylinder Liner: Wear Ridge Remove, − Repair the Finish to Lubricating Grooves and Scavenge Ports 94299 2.0 mm to 3.0 mm 1.0 mm 009.004/01 2017 2/ 4 Winterthur Gas & Diesel Ltd.

- Page 150 2124−3/A1 Maintenance Cylinder Liner: Wear Ridge Remove, − Repair the Finish to Lubricating Grooves and Scavenge Ports Lubricating Grooves Make sure that you keep the initial shape of the lubricating grooves when you remove sharp edges. ⇒ If the depth of the lubricating grooves LG, Fig. B has decreased to less than 1.5 mm, do as follows: ⇒...

- Page 151 2124−3/A1 Maintenance Cylinder Liner: Wear Ridge Remove, − Repair the Finish to Lubricating Grooves and Scavenge Ports 003.267/00 EDGES EDGES ROUNDED OFF ROUNDED OFF II - II WCH01183 2017 4/ 4 Winterthur Gas & Diesel Ltd.

- Page 152 2138−1/A2 Maintenance Lubricating Quill Removal and Installation with Pulse Jet Lubrication Tool: Key to Illustrations: 1 Case, measurement set 94720C 1 Cylinder liner 14 Pin (tool) 1 HP hose 94935 2 Lubricating pump 15 Shut-off valve servo oil 1 HP oil pump 94931 3 Accumulator 16 Vent valve servo oil...

- Page 153 2138−1/A2 Maintenance Lubricating Quill − Removal and Installation with Pulse Jet Lubrication Remark: The steps that follow are only necessary if the cylinder liner must be removed. ⇒ Remove all the pipe brackets 18 (Fig. A). ⇒ Remove the eight pipes 11. ⇒...

- Page 154 2138−1/A2 Maintenance Lubricating Quill − Removal and Installation with Pulse Jet Lubrication WCH01183 WCH01115 2017 3/ 6 Winterthur Gas & Diesel Ltd.

- Page 155 2138−1/A2 Maintenance Lubricating Quill − Removal and Installation with Pulse Jet Lubrication Function Check You do a function check to make sure that the non−return valve (3) operates correctly. The pressure that opens the non−return valve is 5.0 bar. For the function check, use an oil with a viscosity as given in the specifications that follow: SAE 50 at 40_C (approx.

- Page 156 2138−1/A2 Maintenance Lubricating Quill − Removal and Installation with Pulse Jet Lubrication Cylinder Lubricating System − Bleed Attention! Before you operate the turning gear, make sure that no personnel are near the flywheel, or in the engine. Remark: When you bleed the cylinder lubricating system, always start at the first cylinder at the free end.

- Page 157 2138−1/A2 Maintenance TO LUBRICATING QUILLS 019.125/10 019.002/09 2 17 6/ 6 Winterthur Gas & Diesel Ltd.

-

Page 158: 2303−1/A1

2303−1/A1 Maintenance Piston Rod Gland Removal, Disassemble, Measure Worn Parts, Assemble, Installation Tools: Key to Illustrations: 2 Platforms 94142 1 Housing (2-part) 13 Sealing ring 2 Supports 94143 2 Screw 14 Ring support 1 Support 94344 3 Dowel pin 15 Scraper ring 4 Stays 94344A 4 Support... - Page 159 2303−1/A1 Maintenance Piston Rod Gland: Removal, Disassemble, Measure Worn Parts, Assemble, Installation Procedure One Piston Rod Gland − Removal Attention: Before you operate the turning gear, make sure that no personnel are near the flywheel, or in the engine. ⇒ Operate the turning gear to move the piston to BDC. ⇒...

- Page 160 2303−1/A1 Maintenance Piston Rod Gland: Removal, Disassemble, Measure Worn Parts, Assemble, Installation I - I II - II SPRING DOWEL PIN MUST BE REMOVED WCH01156 2017 3/ 9 Winterthur Gas & Diesel Ltd.

- Page 161 2303−1/A1 Maintenance Piston Rod Gland: Removal, Disassemble, Measure Worn Parts, Assemble, Installation Assemble (Fig. C and Fig. D) ⇒ Make sure that the hinged covers 22 of the support device 94350 are folded down. ⇒ Attach the 2−part clamp ring 94345B to the piston rod 21. ⇒...

- Page 162 2303−1/A1 Maintenance Piston Rod Gland: Removal, Disassemble, Measure Worn Parts, Assemble, Installation ⇒ Put the gauge 94345C (Fig. E) over the assembled rings. Make sure that all parts are in the correct position. If necessary, correct their positions. ⇒ Apply bearing oil to the piston rod and the assembled rings. ⇒...

- Page 163 2303−1/A1 Maintenance Piston Rod Gland: Removal, Disassemble, Measure Worn Parts, Assemble, Installation GROOVE a GROOVE b GROOVES c−g 016.855/08 Installation (Fig. E) ⇒ Apply lubricating oil to the opening in the cylinder jacket and to the area of the O−rings on the housing 1. ⇒...

- Page 164 2303−1/A1 Maintenance Piston Rod Gland: Removal, Disassemble, Measure Worn Parts, Assemble, Installation 94350 94345C 94345C 94345 016.877/08 2017 7/ 9 Winterthur Gas & Diesel Ltd.

- Page 165 2303−1/A1 Maintenance Piston Rod Gland: Removal, Disassemble, Measure Worn Parts, Assemble, Installation Procedure 2 Removal (Fig. G) Before you operate the turning gear, make sure that no personnel are near the flywheel, or in the engine. ⇒ Operate the turning gear to move the piston to BDC. ⇒...

- Page 166 2303−1/A1 Maintenance Piston Rod Gland: Removal, Disassemble, Measure Worn Parts, Assemble, Installation 94344 94344A 94344 94344A 94143 94142 WCH01172 018.654/09 2017 9/ 9 Winterthur Gas & Diesel Ltd.

- Page 167 Intentionally blank...

-

Page 168: Cylinder Cover

2708−1/A1 Maintenance Cylinder Cover Cylinder Cover and Water Guide Jacket − Removal and Installation Tools: Key to Illustrations: 1 Suspension device 94265 1 Cylinder cover 11 Elastic Stud 1 Retaining bracket 94266 2 Exhaust valve cage 12 Screw M20x40 3 Cylinder liner 13 Fixing screw 4 Joint ring M20x240... - Page 169 2708−1/A1 Maintenance Cylinder Cover and Water Guide Jacket − Removal and Installation Cylinder Cover − Removal ⇒ Loosen nuts of elastic studs 11, refer to see 2708−2. Water Guide Jacket 3.1 Water Guide Jacket − Removal ⇒ Turn the screws 13 fully back. ⇒...

- Page 170 2708−1/A1 Maintenance Cylinder Cover and Water Guide Jacket − Removal and Installation Cylinder Cover − Installation ⇒ Make sure that the compression space is clean. ⇒ Make sure that the eating surfaces on the cylinder cover and cylinder liner are clean and have no damage.

- Page 171 2708−1/A1 Maintenance Cylinder Cover and Water Guide Jacket − Removal and Installation PUSH FIT 017.640/08 WCH01175 2017 4/ 4 Winterthur Gas & Diesel Ltd.

-

Page 172: 2708−2/A1

2708−2/A1 Maintenance Cylinder Cover Cylinder Cover Elastic Studs − Apply and Release Tension Tools: Key to Illustrations: Hydraulic tensioning device 94215 1 Cylinder cover includes: 2 Elastic stud Pre-tensioning jacks 94215A 3 Nut Connection pieces with HP hoses 94215B 4 Round nut Lifting tool 94215C 4(8*) Connecting elements... - Page 173 2708−2/A1 Maintenance Cylinder Cover Elastic Studs − Apply and Release Tension Elastic Studs − Apply Tension Round Nuts − Remove Remark: Apply tension to the eight elastic studs 2 at the same time (Fig. B). ⇒ Operate the hydraulic unit 94942 to apply 1500 bar to the eight elastic studs 2. ⇒...

- Page 174 2708−2/A1 Maintenance Cylinder Cover Elastic Studs − Apply and Release Tension 94215B 94215E 94215A (94215F) 94215B 94935 94934 016.717/08 94934A 94935 94942 2017 3/ 4 Winterthur Gas & Diesel Ltd.

- Page 175 2708−2/A1 Maintenance Cylinder Cover Elastic Studs − Apply and Release Tension Configuration with 1-part lifting tool (optional) 94215E 94215H 94215A (94215F) 94215H 94215G 94215I 94215D 94935 019.373/10 94934 94934A 94935 94209A 94942 94215E (94215F) 2017 4/ 4 Winterthur Gas & Diesel Ltd.

- Page 176 2708−3/A1 Maintenance Cylinder Cover Sealing Face − Grind Tools: 1 Grinding device 94270G 1 Stencil General 94270G The sealing face in the cylinder cover for the injection valve must be clean and have no damage. Sealing Face − Grind WCH03837 Clean the injection valve bore in the cylinder cover 1 (Fig.

- Page 177 Intentionally blank...

-

Page 178: Injection Valve With Fast

2722−1/A2 Maintenance Injection Valve Disassemble, Checks, Adjust, Assemble Injection Valve with FAST Tools: Key to Illustrations: 1 Torque spanner 94011 1 Injection valve 16 Dowel pin 1 Slugging wrench 94269A−70 2 Nozzle holder 17 Fixing piece 1 Hydraulic cylinder 94269B 3 Intermediate piece 18 Snap ring 1 Socket wrench insert... - Page 179 2722−1/A2 Maintenance Injection Valve: Disassemble, Checks, Adjust, Assemble Injection Valve with FAST Injection Valve − Checks Attention: Fire Hazard. Do not use welding or grinding equipment near the work area. Attention: Health Hazard. Calibration fluid is harmful to your health. Attention: Injury Hazard: Do not put your fingers near the holes in the nozzle tip.

- Page 180 2722−1/A2 Maintenance Injection Valve: Disassemble, Checks, Adjust, Assemble Injection Valve with FAST ⇒ Start the test bench. ⇒ At regular intervals, use a master pressure gauge to do checks of the pressure gauges on the test bench. If necessary, adjust the pressure gauges. ⇒...

- Page 181 2722−1/A2 Maintenance Injection Valve: Disassemble, Checks, Adjust, Assemble Injection Valve with FAST ⇒ Remove the locknut 7. ⇒ Use the wrench 94269A−70 and the hydraulic cylinder 94269B to loosen the coupling nut 6. ⇒ Remove the coupling nut 6. ⇒ Remove the nozzle body 4 together with the: Needle 5 Nozzle tip 12 Intermediate piece 3...

- Page 182 2722−1/A2 Maintenance Injection Valve: Disassemble, Checks, Adjust, Assemble Injection Valve with FAST Injection Valve − Assemble ⇒ Make sure that the sealing faces of the intermediate piece Fig. D and the related faces in the injection valve 1: Are clean and dry Are in a satisfactory condition Have no lubricant.

- Page 183 2722−1/A2 Maintenance Injection Valve: Disassemble, Checks, Adjust, Assemble Injection Valve with FAST I - I II - II WCH00879 DESIGN OF NOZZLE BODY MANUFACTRER x DRG. NO. x EXECUTION x NEEDLE LIFT 2017 6/ 11 Winterthur Gas & Diesel Ltd.

- Page 184 2722−1/A2 Maintenance Injection Valve: Disassemble, Checks, Adjust, Assemble Injection Valve with FAST Opening pressure − Adjust ⇒ Disassemble the injection valve, refer to paragraph 4. ⇒ Install temporarily two shim rings 9 (total thickness of 6.0 mm). ⇒ Assemble the injection valve, refer to paragraph 5. ⇒...

- Page 185 2722−1/A2 Maintenance Injection Valve: Disassemble, Checks, Adjust, Assemble Injection Valve with FAST Nozzle Tip − Replace Make sure that the specified nozzle tips are used in accordance with the IMO Technical File of the engine. Removal It is not recommended but possible to replace the nozzle tip with the needle installed.

- Page 186 2722−1/A2 Maintenance Injection Valve: Disassemble, Checks, Adjust, Assemble Injection Valve with FAST Installation 94278B ⇒ Make sure that the needle 5, is removed from the nozzle body 4, see Fig. E. ⇒ Attach the nozzle body 4 and the coupling nut 6 to the injection valve 1 on the injection test bench.

- Page 187 2722−1/A2 Maintenance Injection Valve: Disassemble, Checks, Adjust, Assemble Injection Valve with FAST Spring cage − Assemble ⇒ Make sure that the cup springs, 23 Fig. H are installed in the spring cage 20 as shown. ⇒ You must use the shims 25 to adjust the distance X to 1.6 ±...

- Page 188 2722−1/A2 Maintenance Injection Valve: Disassemble, Checks, Adjust, Assemble Injection Valve with FAST Nozzle Tip − Protection Make sure that the protection cap 94271 is installed when the injection valve is removed. 94271 017.083/08 Storage ⇒ Keep the injection valve in its original packing. ⇒...

- Page 189 Intentionally blank...

-

Page 190: 2728−1/A1

2728−1/A1 Maintenance Starting Valve Removal, Disassemble, Grind, Assemble and Installation Tools Key to Illustrations: 1 Wire rope sling 94333D 1 Cylinder cover 13 Control valve (solenoid valve) Lifting tool, starting 942719 2 Housing 14 Plug air valve. Includes: 3 Cover 15 Joint ring 2 Caps 942719D... - Page 191 2728−1/A1 Maintenance Starting Valve: Removal, Disassemble, Grind, Assemble and Installation Grind Seat faces that have light damage can be ground manually. Seat faces that more than light damage must first be machined and then ground. Remark: The valve spindle 4 has an angle of 91_, but, the valve seat angle is 90_. Assemble ⇒...

- Page 192 2728−1/A1 Maintenance Starting Valve: Removal, Disassemble, Grind, Assemble and Installation 942719B 942719B WCH03805 WCH03805 94333D 942719D 94333D 942719B 942719D 942719C WCH03805 WCH03805 2017 3/ 5 Winterthur Gas & Diesel Ltd.

- Page 193 2728−1/A1 Maintenance Starting Valve: Removal, Disassemble, Grind, Assemble and Installation I - I 016.856/08 Stroke 22 mm 016.856/08 2017 4/ 5 Winterthur Gas & Diesel Ltd.

- Page 194 2728−1/A1 Maintenance Starting Valve: Removal, Disassemble, Grind, Assemble and Installation 942719A Starting Valve WCH03806 942719A Ship Structure WCH03806 Assembly tool welded to the ship structure 2017 5/ 5 Winterthur Gas & Diesel Ltd.

- Page 195 Intentionally blank...

-

Page 196: 2745−1/A1

2745−1/A1 Maintenance Cylinder Cover − Relief Valve Blow-off Pressure Check Tools: Key to Illustrations: 1 OBEL test bench 94272 1 Cylinder cover 10 Receiver 1 Valve holder 94272C 2 Relief valve 11 Gasket 1 HP oil pump 94931 3 Indicator valve 12 Gasket 2 Hydraulic distributors 94934A... - Page 197 2745−1/A1 Maintenance Relief Valve: Blow-off Pressure Check Removal ⇒ Stop the engine. ⇒ Open the indicator valve to make sure that there is no pressure in the compression chamber. ⇒ Remove the relief valve 2 and the gasket 11. ⇒ Do a check of the gasket 11 for damage. If necessary, replace the gasket. WCH03808 WCH03808 2017...

- Page 198 2745−1/A1 Maintenance Relief Valve: Blow-off Pressure Check Relief Valve Check There are two alternative procedures to do a check of the relief valve. Procedure One ⇒ Read the data in the manual for the test bench 94272. ⇒ Read the data about calibration fluid in 2722−2, paragraph 1. You can use the test and calibration fluid, or a low viscosity oil as a test fluid.

- Page 199 2745−1/A1 Maintenance Relief Valve: Blow-off Pressure Check Procedure Two ⇒ Attach the relief valve 2, (Fig. B) to the valve holder 94272C. ⇒ Connect the HP oil pump 94931 and the hose 94935 to the pressure gauge 94934A. ⇒ Connect the pressure gauge to the valve holder 94272C. ⇒...

-

Page 200: Exhaust Valve

2751−1/A1 Maintenance Exhaust Valve Exhaust Valve − Removal and Installation, Elastic Studs − Replace Tools: Key to Illustrations: 1 Dismantling tool 94008A−M90 1 Terminal box 6 Expansion piece 1 Assembly and transport device 94810 2 Plug 7 Protection pipe 1 Wire rope sling 94209 3 Valve cage 8 Elastic stud... - Page 201 2751−1/A1 Maintenance Exhaust Valve − Removal and Installation, Elastic Studs − Replace ⇒ Attach the device 94810 to the expansion piece 6 (Fig. B). ⇒ Attach the wire rope sling 94209 to the engine room crane and the device 94810. ⇒...

- Page 202 2751−1/A1 Maintenance Exhaust Valve − Removal and Installation, Elastic Studs − Replace Installation ⇒ Clean all the sealing surfaces of the exhaust valve and the cylinder covers. ⇒ Examine the sealing surfaces of the exhaust valve and cylinder cover for damage.

- Page 203 2751−1/A1 Maintenance Exhaust Valve − Removal and Installation, Elastic Studs − Replace Elastic studs When you install a new elastic stud of the cylinder cover or exhaust valve cage, obey the instructions given below. ⇒ Read the data in the manual of the jointing compound manufacturer. ⇒...

- Page 204 2751−1/A1 Maintenance Exhaust Valve − Removal and Installation, Elastic Studs − Replace Jointing Compound See the table below for the recommended manufacturers of jointing compounds and adhesive primers: Jointing Hardener Adhesive Manufacturer compound primer Elastosil RT 622 B G 790 Wacker-Chemie Gmbh RT 622 A Geschäftsbereich Silicone...

- Page 205 Intentionally blank...

-

Page 206: 2751−2/A1

2751−2/A1 Maintenance Exhaust Valve Disassemble and Assemble Tools: Key to Illustrations: 1 Thrust pin 94259 1 Valve cage 24 Screw plug 2 Jack screws 94263 2 Bottom housing 25 Damper 2 Jack screws 94263A 3 Top housing 26 Shim 1 Depth gauge 4 Outer piston 27 Transmitter housing 1 Torque wrench... - Page 207 2751−2/A1 Maintenance Exhaust Valve: Disassemble and Assemble 016.875/08 015.753/08 2017 2/ 8 Winterthur Gas & Diesel Ltd.

- Page 208 2751−2/A1 Maintenance Exhaust Valve: Disassemble and Assemble Exhaust valve − Disassemble Valve Drive − Disassemble Danger: Do not weld or grind materials in the area. The sparks from welding equipment and grinding tools can cause a fire. ⇒ Put the exhaust valve on a wooden underlay WU (Fig.

- Page 209 2751−2/A1 Maintenance Exhaust Valve: Disassemble and Assemble Guide Bush − Remove 11 10 ⇒ Remove the four Allen screws 12 ⇒ Remove the spacer 10. ⇒ Remove and discard the rod seal ring 11. ⇒ Attach the jack screws 94263 to the flange of guide bush 9.

- Page 210 2751−2/A1 Maintenance Exhaust Valve: Disassemble and Assemble Exhaust Valve − Assemble Valve Spindle − Install ⇒ Measure the dimensions of the valve spindle 7. ⇒ Compare the values with those given in 0330−1, Exhaust valve. ⇒ Do a check of the piston seal ring 17 for damage. If you find damage, replace the piston seal ring.

- Page 211 2751−2/A1 Maintenance Exhaust Valve: Disassemble and Assemble 015.753/08 2017 6/ 8 Winterthur Gas & Diesel Ltd.

- Page 212 2751−2/A1 Maintenance Exhaust Valve: Disassemble and Assemble Damper Setting You set the damper 25 only after you replace a valve spindle or valve seat, or after one of the seating faces is ground. ⇒ Remove the damper 25. ⇒ Make sure that the bores (4) in the damper are clear.

- Page 213 2751−2/A1 Maintenance Exhaust Valve: Disassemble and Assemble Valve Stroke Sensor − Install ⇒ Clean the parts that follow: The valve stroke sensor 28, Fig. G. The transmitter housing 27. The bore and collar in the top housing 3. ⇒ Put oil on the O−ring 41 and the valve stroke sensor 28.

-

Page 214: 2751−3/A1

2751−3/A1 Maintenance Exhaust Valve Valve Seat − Replace, Grind Tools: Key to Illustrations: 1 Feeler gauge 94122 1 Valve seat SF Seating face 1 Tool, valve seat remove / install 94261 2 Valve cage EB Eye bolt 1 Gauge 94279 3 O-ring 1 Valve grinding device 94291... - Page 215 2751−3/A1 Maintenance Exhaust Valve: Valve Seat − Replace, Grind Valve seat − Grind Use only the grinding tool 94291, Fig. B to grind the valve seats. ⇒ Read the data in the manufacturer’s manual for the grinding tool 94291. ⇒ Put the valve seat 1 in the correct position on the grinding tool 94291.

- Page 216 2751−3/A1 Maintenance Exhaust Valve: Valve Seat − Replace, Grind Valve seat − Check You do this procedure to make sure that the sealing face of the valve spindle correctly touches the sealing face of the valve seat. ⇒ Attach the eye bolt EB, Fig. C to the valve spindle.

- Page 217 2751−3/A1 Maintenance Exhaust Valve: Valve Seat − Replace, Grind Valve seat − Install ⇒ Clean the bores and the sealing faces of the valve cage 2 and the valve seat 1, Fig. E. ⇒ Apply oil (or lubricants e.g. Never−Seez NBST−8, Loctite anti−seize compound) to the bores and sealing faces of the valve seat 1 and the valve cage 2.

- Page 218 2751−4/A1 Maintenance Exhaust Valve Valve Head − Grind the Seating Surface Tools: 1 Feeler gauge 94122 1 Valve grinding device 94291 1 Gauge 94292 SEATING SURFACE General ANGLE ON VALVE Use only the tool 94291, Fig. A to grind the valve a = between: head.

-

Page 219: 2751−4/A1

2751−4/A1 Maintenance Exhaust Valve: Valve Head − Grind the Seating Surface ⇒ If the measured values are more than the limits given on the gauge (94122), you can repair the valve spindle (see the data below). ⇒ If more than 3.0 mm is ground off: ⇒... -

Page 220: Crankshaft, Connecting Rod And Piston Group

Group3 Maintenance Crankshaft, Connecting Rod and Piston Group 3 Crankshaft: Crank Deflection − Measure ........3103−1/A1 Vibration Damper −... - Page 221 Intentionally blank...

-

Page 222: 3103−1/A1

100 operation hours. If the ship has touched the sea bed. In such conditions, it is recommended that you speak to WinGD Ltd. The crankshaft equipment (94305) is held between the crank webs in the center punch marks. When the crankshaft turns, the change in distance between the crank webs can be read from the dial gauge. - Page 223 3103−1/A1 Maintenance Crank Deflection − Measure Equipment Settings Injury Hazard: Before you operate the turning gear, make sure that no personnel are near the flywheel, or in the engine. Remark: During the procedure, the flywheel (1, Fig. A) and pinion 2 of the turning gear must turn in the directions shown.

- Page 224 3103−1/A1 Maintenance Crank Deflection − Measure Calculate 94305 nB.D.C nT.D.C The difference between the values shown shows the crank deflection during one full turn of the crankshaft (Fig. B). Where values are measured that are more than the maximum permitted limits, the cause must be found.

- Page 225 Intentionally blank...

-

Page 226: Vibration Damper

3130−1/A1 Maintenance Vibration Damper Silicone Fluid Sample Key to Illustrations: 1 Casing trough 7 Crankshaft 2 Casing cover 8 Cap nut 3 Screw plug 4 O-ring 5 Sealing ring CP Center punch mark 6 Coupling bolts SC Sample container General Viscous vibration dampers that Hasse &... -

Page 227: 3130−1/A1

3130−1/A1 Maintenance Silicone Fluid Sample Metaldyne Silicone Oil Samples and STE ” BSF (M16) Metaldyne and STE Remark: Two different threads are used for sample bores Metaldyne International and STE vibration dampers. Remark: The sample container lets you get a specified quantity of silicone oil from the damper. - Page 228 3130−1/A1 Maintenance Silicone Fluid Sample ⇒ Send the sample to: Metaldyne International UK Ltd131 Parkinson Lane Halifax HX1 3RD United Kingdom Tel: +44 1422 357 234 Fax: +44 1422 354 432 Remark: For STE Schwingungstechnik manufactured vibration dampers, send the samples to Hasse & Wrede (see paragraph 3.2). Hasse &...

- Page 229 3130−1/A1 Maintenance Silicone Fluid Sample ⇒ Send the sample to: Hasse & Wrede Georg−Knorr−Strasse 4 D−12681 Berlin Germany Tel: +49 30 93 92 3135 Fax: +49 30 70 09 0835 If you cannot get a sample as given in paragraphs 3.1 and 3.2, do the procedure that follows: ⇒...

-

Page 230: Inspection (Geislinger Vibration Damper)

3130−2/A1 Maintenance Vibration Damper Inspection (GEISLINGER Vibration Damper) Key to Illustrations: 1 Crankshaft 5 Sealing ring 2 Damper casing 6 Oil supply pipe 3 Vibration damper 7 Coupling disc 4 Hexagon head bolt (crank angle sensor unit) General Some engine designs can have a Geislinger manufactured vibration damper installed at the free end of the crankshaft. - Page 231 3130−2/A1 Maintenance Inspection (GEISLINGER Vibration Damper) Inner Spring Tips and Groove Flanks Remark: You must only disassemble the vibration damper if you think there is damage, or the parts have become worn to more than the specified limits. You must speak to the manufacturer for instructions. Remark: Only specialists can make adjustments of the vibration damper.

- Page 232 3130−2/A1 Maintenance Inspection (GEISLINGER Vibration Damper) 017.009/10 000.940/93 DATA FOR STEEL SPRING DAMPER 2017 3/ 3 Winterthur Gas & Diesel Ltd.

- Page 233 Intentionally blank...

-

Page 234: 3140−1/A1

3140−1/A1 Maintenance Axial Damper Disassemble and Assemble Tools Key to Illustrations: 1 Spur-geared chain block 94018−016 1 Casing, top part 15 Throttle 1 Wire rope sling 94209 2 Pipe 16 Gasket 2 Manual ratchet 94016−007 3 Axial damper monitoring 17 Gasket 2 RUD eye bolt 94040−M36 4 Top cylinder part... - Page 235 3140−1/A1 Maintenance Axial Damper: Disassemble and Assemble ⇒ Remove the bolts 9 and 6, Fig. B. ⇒ Remove the six bolts 7 from the top cylinder part 4. On engines that have a vibration damper pull out six the bolts as far as possible. I - I 016.923/08 2017...

- Page 236 3140−1/A1 Maintenance Axial Damper: Disassemble and Assemble ⇒ Attach the two eye bolts 94040−M36 to the top cylinder part 4. ⇒ Attach the wire rope sling 94209 to the eye bolts EB. ⇒ Attach the manual ratchets 94016−007 to the platform and the wire rope sling 94209.

- Page 237 3140−1/A1 Maintenance Axial Damper: Disassemble and Assemble ⇒ Operate carefully the manual ratchets 94016−007 to lift the top cylinder part 4 (see Fig. D). Remark: Make sure that top cylinder part moves freely to prevent damage to the 2−part gaskets 11, 13. ⇒...

- Page 238 3140−1/A1 Maintenance Axial Damper: Disassemble and Assemble Axial Damper: Disassemble and Assemble Throttle If it becomes necessary to remove or replace a spindle, you must measure the distance X. You must adjust the spindle to the same dimension during assembly. Do not turn back the spindle more than 16 turns (which equals a distance of 16 mm).

- Page 239 Intentionally blank...

- Page 240 3206−1/A1 Maintenance Turning Gear Teeth and Screwed Connections 6 to 8 Cylinder Engines Tools: Key to Illustrations: 1 Feeler gauge 94122 1 Turning gear 9 Elastic bolt 1 Pre-tensioning jack 94320 2 Pinion 10 Round nut 1 Round nut 94320A 3 Flywheel 11 Slot 1 HP oil pump...

- Page 241 3206−1/A1 Maintenance Turning Gear: Teeth and Screwed Connections Pinion and Flywheel Teeth Procedure Make sure that only a thin layer of lubricant is applied to the tooth flanks of the pinion (2) and the flywheel (3). This makes sure that the lubricant stays on the tooth surfaces during engine operation.

- Page 242 3206−1/A1 Maintenance Turning Gear: Teeth and Screwed Connections 6 to 8 Cylinder Engines Pre−tension Check ⇒ Clean the round nuts, the threads of the elastic bolts and the seating surfaces. ⇒ Put the pre−tensioning jack 94320, (Fig. B) in position on the applicable elastic bolt 9.

- Page 243 3206−1/A1 Maintenance Turning Gear: Teeth and Screwed Connections 6 to 8 Cylinder Engines Loosening and tensioning the bolts ⇒ Put the round nut 10 in position to get the distance of approximately 25 mm. ⇒ Put the pre−tensioning jack 94320 in position on the applicable elastic bolt. ⇒...

- Page 244 3206−1/A2 Maintenance Turning Gear Teeth and Screwed Connections Cylinder Engines Tools: Key to Illustrations: 1 Feeler gauge 94122 1 Turning gear 9 Bolt 1 Pre-tensioning jack 94320 2 Pinion 10 Round nut 1 Round nut 94320A 3 Toothing of flywheel 11 Slot 1 HP oil pump 94931...

- Page 245 3206−1/A2 Maintenance Turning Gear: CTeeth and Screwed Connections Cylinder Engines Pinion and Flywheel Teeth Procedure Make sure that only a thin layer of lubricant is applied to the tooth flanks of the pinion (2) and the flywheel (3). This makes sure that the lubricant stays on the tooth surfaces during engine operation.

- Page 246 3206−1/A2 Maintenance Turning Gear: Teeth and Screwed Connections Cylinder Engines Pre−tension Check ⇒ Clean the round nuts, the threads of the elastic bolts and the seating surfaces. ⇒ Put the pre−tensioning jack 94320, (Fig. B) in position on the applicable elastic bolt 9.

- Page 247 3206−1/A2 Maintenance Turning Gear: Teeth and Screwed Connections Cylinder Engines Apply and Loosen the Tension ⇒ Put the round nut 10 in position to get the distance of approximately 25 mm. ⇒ Put the pre−tensioning jack 94320 in position on the applicable elastic bolt. ⇒...

- Page 248 3301−1/A1 Maintenance Crankcase Platform Tools: Key to Illustrations: 2 Platforms, each platform includes three grids 94142 1 Longitudinal beam 2 Supports 94143 2 Crank web 3 Step 4 Strap General Attention: Injury and Damage Hazard: Do not turn the crankshaft when the platforms and/or supports are installed.

- Page 249 Intentionally blank...

-

Page 250: Connecting Rod

3303−1/A1 Maintenance Connecting Rod Connecting Rod Elastic Studs − Loosen and Apply Tension Tools: Key to Illustrations: 1 Feeler gauge 94122 1 Connecting rod 2 Pre-tensioning jacks (2-part) 94215E 2 Bottom end bearing 2 Back-up rings 94215F 3 Top end bearing 2 Pre-tensioning jacks 94315 4 Elastic stud −... -

Page 251: 3303−1/A1

3303−1/A1 Maintenance Connecting Rod Elastic Studs − Loosen and Apply Tension Loosen and Apply Tension Bottom end bearing The 2−part pre−tensioning jack can be disassembled to put the tools 94215F and 94215E on the elastic studs. Do not tighten the M6x90 Allen screws. ⇒... -

Page 252: 3303−2/A1

3303−2/A1 Maintenance Connecting Rod Bottom End Bearing − Removal, Inspection and Installation Tools: Key to Illustrations: 1 Deviation pipe 94117A 1 Connecting rod stud 10 Top bearing shell 1 Platform 94142 2 Nut 2 Stays 94323 3 Crank pin 12 Allen screw 1 Removal and installation tool 94326 4 Bearing cover... - Page 253 3303−2/A1 Maintenance Bottom End Bearing − Removal, Inspection and Installation Bearing Cover Removal ⇒ Remove the round nuts 2, refer to 9304−4. ⇒ Carefully lower the bearing cover 4. ⇒ Examine the bearing shell 7. Remark: If the bearing shell is in good condition, lower the bearing cover on to the bottom of the crankcase.

- Page 254 3303−2/A1 Maintenance Bottom End Bearing − Removal, Inspection and Installation ⇒ Remove the manual ratchet H2 (see Fig. C). ⇒ Install the deviation pipe 94117A as shown. ⇒ Operate the turning gear to move the crank 3 approximately 70_ to the exhaust side.

- Page 255 3303−2/A1 Maintenance Bottom End Bearing − Removal, Inspection and Installation Bearing Shell − Remove ⇒ Remove the two screws 8. ⇒ Attach the four eye bolts EB2 to the bearing shell 7 as shown. ⇒ Attach the wire rope sling 94209 to the four eye bolts EB2. ⇒...

- Page 256 3303−2/A1 Maintenance Bottom End Bearing − Removal, Inspection and Installation 94323 016.791/08 017.680/08 017.680/08 ⇒ Operate the turning gear to move the crankshaft to the fuel side until the guide shoe touches the stays 94323 . ⇒ Put the chain of the manual ratchet around the connecting rod 5 as shown. ⇒...

- Page 257 3303−2/A1 Maintenance Bottom End Bearing − Removal, Inspection and Installation 94323 017.680/08 Top Bearing Shell − Removal ⇒ Make sure that the bottom bearing cover 4 is removed from the crankcase. ⇒ Make sure that the deviation pipe 94117A is installed. ⇒...

- Page 258 3303−2/A1 Maintenance Bottom End Bearing − Removal, Inspection and Installation H3, H5 Round bar 94326 94117A 94326 012.265/04 94142 Screw Shackle 017.679/08 ⇒ Attach the tool 94326 to the top bearing shell 10 with the four screws Fig. G. ⇒ Attach the manual ratchet H2, to the shackle on the tool 94326. ⇒...

- Page 259 3303−2/A1 Maintenance Bottom End Bearing − Removal, Inspection and Installation 94209 017.679/08 017.679/08 Bearing Shells − Installation Top Bearing Shell ⇒ Clean the seating surface of the connecting rod 5, the crank pin 3 and the bearing shell 10. ⇒ Put the bearing shell 10 on the tool 94326. ⇒...

- Page 260 3303−2/A1 Maintenance Bottom End Bearing − Removal, Inspection and Installation ⇒ Operate the manual ratchets H3, H5 to move the tool 94326 and bearing shell 10 into position (see Fig. G). Remark: Make sure that the distance between each end of the bearing shell and the connecting rod rod is the same.

- Page 261 3303−2/A1 Maintenance Bottom End Bearing − Removal, Inspection and Installation Bearing Cover − Installation ⇒ Attach the chain block H4 to the eye bolt EB1 on the bearing cover 4 (see Fig. I). ⇒ Operate the chain block H4 to lift the bearing cover 4. ⇒...

- Page 262 3303−2/A1 Maintenance Bottom End Bearing − Removal, Inspection and Installation ⇒ Put the round nuts 2 on the elastic studs 1, Fig. J. ⇒ Put the round nuts 2 on the elastic studs. ⇒ Tighten the round nuts 2 equally with a round bar. 016.679/08 Supplier Type...

- Page 263 3303−2/A1 Maintenance Bottom End Bearing − Removal, Inspection and Installation ⇒ Measure the distances (X1, X2) between the edges of the bearing shells and the bearing cover. ⇒ For new bearing shells, the dimensions X1 plus X2 must be between 1.45 mm and 1.61 mm.

-

Page 264: 3303−3/A1

3303−3/A1 Maintenance Connecting Rod Top End Bearing − Removal, Inspection, Installation Tools: Key to Illustrations: 1 Platform 94142 1 Crankshaft 12 Connecting rod stud 2 Stays 94323 2 Connecting rod 13 Instruction plate 1 Lifting plate 94324 3 Piston rod 14 Head screw 1 Wire rope sling 94209... - Page 265 3303−3/A1 Maintenance Top End Bearing − Removal, Inspection, Installation ⇒ Attach the two RDU-eye bolts EB into the guide shoe 6 (Fig. B). ⇒ Attach the stop plate 94335 to bearing cover 5 and guide shoe 6. ⇒ Attach the lifting rings 94332 to cylinder jacket 8 with the screws 7. ⇒...

- Page 266 3303−3/A1 Maintenance Top End Bearing − Removal, Inspection, Installation ⇒ Attach the RUD-eye bolts EB2 to each side of the the connecting rod (Fig. C). ⇒ Attach the manual ratchets H1, H2 to the RUD-eye bolts EB2. ⇒ Operate the manual ratchets H1, H2 to put a light tension on their chains. ⇒...

- Page 267 3303−3/A1 Maintenance Top End Bearing − Removal, Inspection, Installation Piston Removed ⇒ Remove the four nuts 4, refer to 3303−1. ⇒ Attach the stop plate 94335 to the bearing cover 5 and guide shoe 6. ⇒ Attach the lifting plate 94324 to the crosshead pin 3 with the nuts of the from the piston rod foot.

- Page 268 3303−3/A1 Maintenance Top End Bearing − Removal, Inspection, Installation Bearing Shell − Removal ⇒ Remove the toggle lever 15 Fig. E from the connecting rod. ⇒ Hold the toggle lever up with a rope as shown in Fig. F. ⇒ Remove the platform 94142. ⇒...

- Page 269 3303−3/A1 Maintenance Top End Bearing − Removal, Inspection, Installation Bearing Shell − Install ⇒ Clean the seating surface of the bearing shell 11, Fig. F. ⇒ Make sure that there is no damage to the bearing shell 11. ⇒ Put oil on the bearing shell as follows: ⇒...

- Page 270 3303−3/A1 Maintenance Top End Bearing − Removal, Inspection, Installation ⇒ Put the round nuts 4 on the elastic studs (see Fig. G). ⇒ Tighten equally the rounds nuts 4 with a round bar. ⇒ Measure the distance (X1, X2) between the edges of the bearing shells and the connecting rod 2.

- Page 271 3303−3/A1 Maintenance Top End Bearing − Removal, Inspection, Installation Bearing Lubrication To decrease the risk of dry−running on new bearing shells, it is necessary to apply a mixture of high−viscosity oil (steam engine cylinder oil, ISO VG 1000/1500) and bearing oil. ⇒...

-

Page 272: 3303−4/A1

3303−4/A1 Maintenance Connecting Rod Removal and Installation Tools: Key to Illustrations: 1 Deviation pipe 94117A 1 Toggle lever 12 Screw 2 Stays 94323 2 Connecting rod 13 Spur−geared chain block 2 Lifting rings 94332 3 Crosshead pin 14 Screw 1 Holder: includes: 94331 4 Piston rod 15 Screw... - Page 273 3303−4/A1 Maintenance Removal and Installation Holder 94331 − Install Attention: Injury Hazard: Before you operate the turning gear, make sure that no personnel are near the flywheel, or in the engine. ⇒ Install the deviation pipe 94117A. ⇒ Operate the turning gear to move the crankshaft approximately 70_ to the exhaust side.

- Page 274 3303−4/A1 Maintenance Removal and Installation 94331B 017.679/08 ⇒ Operate the manual ratchets H1, H2 to lift the plate 94331A into position. ⇒ Attach the lug 5 to the nut 6. ⇒ Torque the lug 5 to 800 Nm. ⇒ Operate the manual ratchets H1, H2 to lift the plate 94331A, (Fig. D). ⇒...

- Page 275 3303−4/A1 Maintenance Removal and Installation ⇒ Operate the turning gear to move the applicable crank BDC. ⇒ Attach the three RUD-eye bolts EB1, EB2 and EB3 to the connecting rod (see Fig. E). ⇒ Attach the manual ratchets H1, H2 to the two eye bolts EB1, EB2. ⇒...

- Page 276 3303−4/A1 Maintenance Connecting Rod: Removal and Installation Removal Crosshead Lift − Piston Removed Remark: The piston is removed, see 3403−1. ⇒ Attach the rings 94332 to the cylinder jacket with the eight bolts 18. ⇒ Torque the eight bolts 18 to 200 Nm. ⇒...

- Page 277 3303−4/A1 Maintenance Connecting Rod: Removal and Installation ⇒ Attach the two stays 94323 to the holes in the guide ways, refer to the instructions on the instruction plate 16 (Fig. G): Attach the four pins to the connecting rods. Tighten the two screws M12 14with your hand. Turn the M27 screws fully to the bottom.

- Page 278 3303−4/A1 Maintenance Connecting Rod: Removal and Installation Crosshead Lift − Piston Installed ⇒ Do the procedure in 3403−2 to hold up the piston. ⇒ Remove the bottom bearing cover, refer to paragraph 1.1. ⇒ Make sure that the applicable crank pin is in the position BDC. ⇒...

- Page 279 3303−4/A1 Maintenance Connecting Rod: Removal and Installation ⇒ Attach the two manual ratchets H1, H2 to the eye bolts EB2 on the connecting rod and the column. ⇒ Operate equally the manual ratchets H1, H2 to hold the connecting rod in the center position.

- Page 280 3303−4/A1 Maintenance Connecting Rod: Removal and Installation Connecting Rod − Removal ⇒ Attach the shackle 94019L to the tool 94337. ⇒ Attach the tool 94019L to the connecting rod with the three screws 15. ⇒ Torque symmetrically the three screws 15 to 230 Nm. 94337 Instructions 94337...

- Page 281 3303−4/A1 Maintenance Connecting Rod: Removal and Installation ⇒ Operate the manual ratchets H1, H2 to move the connecting rod approximately 25_ to the fuel side. ⇒ Remove the manual ratchet H1 from the eye bolt EB1. ⇒ Attach the chain block H3 to the eye bolt EB2. ⇒...

- Page 282 3303−4/A1 Maintenance Connecting Rod: Removal and Installation ⇒ Operate the turning gear to move the crankshaft counterclockwise until crank pin is approximately 45_ before TDC. At the same time, operate the chain block H3 to keep tension on the connecting rod (Fig. M). ⇒...

- Page 283 3303−4/A1 Maintenance Connecting Rod: Removal and Installation ⇒ Remove the plate 94331A (Fig. O and Fig. P). ⇒ Attach the connecting element 94331C to the threaded rod 94331B. ⇒ Remove the applicable bottom plates from the middle platform. Attention − Injury Hazard: To prevent an accident, close immediately the openings after you remove the bottom plates.

- Page 284 3303−4/A1 Maintenance Connecting Rod: Removal and Installation 94333D 94333D WCH03809 WCH03809 94333D 2017 13/ 15 Winterthur Gas & Diesel Ltd.

- Page 285 3303−4/A1 Maintenance Connecting Rod: Removal and Installation ⇒ Remove the chain block H5. ⇒ Operate the chain blocks H4 and the manual ratchet H1 to move the connecting rod full out of the engine (see Fig. Q and Fig. R). Connecting Rod −...

- Page 286 3303−4/A1 Maintenance Connecting Rod: Removal and Installation Crosshead − Lower Crosshead Lower − Piston Removed ⇒ Attach the chain block H4 to the shackle on the tool 94324 (see Fig. F). ⇒ Operate the chain block H4 to lift the crosshead a small distance. ⇒...

- Page 287 Intentionally blank...

-

Page 288: 3303−5/A1

3303−5/A1 Maintenance Connecting Rod Top End Bearing Cover − Removal and Installation Tools: Key to Illustrations: 1 Deviation pipe 94117A 1 Piston 1 Working platform 94142 2 Bearing cover 1 Chain (double sling) 94666 3 Elastic stud 1 Spur-geared chain block H3 94018−006 4 Crosshead pin 1 Spur-geared chain block H4... - Page 289 3303−5/A1 Maintenance Top End Bearing Cover − Removal and Installation ⇒ Attach the two shackles S1, S2 to the attachment points in the cylinder jacket (see Fig. B). ⇒ Attach the two shackles S3, S4 to the eye bolts on the bearing cover 2. ⇒...

- Page 290 3303−5/A1 Maintenance Top End Bearing Cover − Removal and Installation ⇒ Install the deviation pipe 94117A (Fig. C). ⇒ Attach the chain block H3 to the attachment point as shown. ⇒ Attach the chain block H4 to the crane rail. ⇒...

- Page 291 3303−5/A1 Maintenance Top End Bearing Cover − Removal and Installation Installation ⇒ Remove the protection from the crosshead pin 4. ⇒ Make sure that the bearing cover 2 and crosshead pin 4 have no damage. ⇒ Attach the double sling chain 94666 to the shackles S3, S4 on the bearing cover 2 (Fig.

-

Page 292: Crosshead

3326−1/A1 Maintenance Crosshead Guide Shoes − Clearances Checks and Installation Tools: Key to Illustrations: 1 Feeler gauge 94238 1 Crosshead pin 6 Guide rail 2 Device 94324C 2 Guide shoe 7 Shim 3 Locking plate 8 Screw 4 Guide way in engine column 9 M20x45 Screw 5 Top end bearing General... - Page 293 3326−1/A1 Maintenance Guide Shoes − Clearances Checks and Installation Clearance Checks Radial Clearance ⇒ Measure the radial clearance between the guide shoe 2 and crosshead pin at all positions of the crosshead. Guide Shoe and Guide Way ⇒ Make sure that the related crank pin is in a position so that the guide shoes 2 touch the guide ways 4 on the fuel side (or exhaust side).

- Page 294 3326−1/A1 Maintenance Guide Shoes − Clearances Checks and Installation Guide Shoe and Top End Bearing ⇒ Attach the two devices 94324C to the crosshead pin with the four M20x45 screws 1 as shown in Fig. C. ⇒ Measure the full lateral clearance between the top end bearing 5 and the the guide shoes 2.