Summary of Contents for Lincoln Series 1100

- Page 1 INSTALLATION & OPERATING INSTRUCTIONS ® IMPINGER II CONVEYOR OVENS ADVANTAGE CONVEYOR OVENS MODEL SERIES 1100 TO BE SERVICED ONLY BY AUTHORIZED PERSONS 1100opsman REV: 4/3/07 Part Number: 2810075...

-

Page 2: Warning And Safety Information

Oven as follows: any part which proves to be defective in materials or workmanship within the warranty period will, subject to the terms of this warranty, be repaired or replaced at Lincoln’s option. Repair or replacement is to be done by the assigned Lincoln Authorized Service Agency. Any claims under this warranty must be presented in writing to Lincoln through the assigned Authorized Service Agency promptly and within the warranty period. -

Page 3: Table Of Contents

Service Technician or a Lincoln Foodservice Products, LLC Service Representative. This service is required by Lincoln Foodservice Products, LLC in order to assist the purchaser in proper start-up of the oven on site. Please note the specific details on the Warranty and make certain that service connections are made to proper utility services. -

Page 4: Impinger Ii – Digital Advantage Ops Manual –Dom & Int'l

Three Phase: 240/415 VAC / 20 Amp; three active, one neutral & one earth/ground. All ovens require separate service and dedicated neutral. NOTE: Do not install the (these) oven(s) in any area with an ambient temperature in excess of 95°F / 35° C. Doing so will cause damage to the unit. -

Page 5: Model Number Key

00 = Special Unit Designation (02 = All Stainless Unit) B = Language NOTE: Date of manufacture is stamped on the rating plate of each oven at the end of the serial number. Example: XXX…01-96 CODE NOT USED A = Advantage Style... -

Page 6: Spacing Requirements

Hood dimensions and the positioning of the hood over the oven will vary with hood manufacturers. NOTE: Lincoln can provide oven spec sheets that show the dimensions of the oven, KW or BTU ratings and other information that will be useful to both the ventilation hood supplier and the HVAC contractor. -

Page 7: Canopy Ventilation Recommendations

3. The oven temperature must be set and operating at 550° F/288° C. TEST PROCEDURE: Note: Use Lincoln Smoke Candle #369361 (in Australia, an alternate method of coloring the air may be used). 1. Wear heat resistant gloves to prevent burns to your hands. -

Page 8: Exterior Dimensions - Impinger Ii

EXTERIOR DIMENSIONS ® IMPINGER II OVEN MODELS BODY: Stainless steel. Easy open front for simple cleaning. POWER: Electric, or Gas and Electric CONVEYOR: Stainless steel construction with flexible stainless steel belt, travel distances of 52 inches (1320 mm) with 24 inches (610 mm) in the baking area. Conveyor belt width is 18 inches (460 mm). -

Page 9: Exterior Dimensions - Impinger Ii Advantage

EXTERIOR DIMENSIONS ADVANTAGE OVEN MODELS BODY: Stainless steel. Easy open front for simple cleaning. POWER: Electric, or Gas and Electric CONVEYOR: Stainless steel construction with flexible stainless steel belt, travel distances of 52 inches (1320 mm) with 24 inches (610 mm) in the baking area. Conveyor belt width is 18 inches (460 mm). -

Page 10: Utility Service Layout

INSTALLATION CODES AND GUIDELINES GAS INSTALLATION Safe and satisfactory operation of this oven depends to a great extent upon its proper installation, and it should be installed, as applicable in accordance with the National Fuel Gas Codes, ANSI Z223.1/NFPA 54 latest version, Manufacturers’... -

Page 11: Electrical Installation

3. To prevent electrical shock an equal potential bonding ground lug is provided in the back. This allows the oven to be connected to an external bonding system. 4. If used as double or triple stack and each oven has its own disconnection switch, all switches should be close together. -

Page 12: General Information

GENERAL INFORMATION The instructions that follow are intended as a guide for preparing for the installation of the Impinger Conveyor Oven. First and foremost, each crate should be examined before signing the Bill of Lading to report any visible damage by the trucker in transit, and to account for the proper number of crates. -

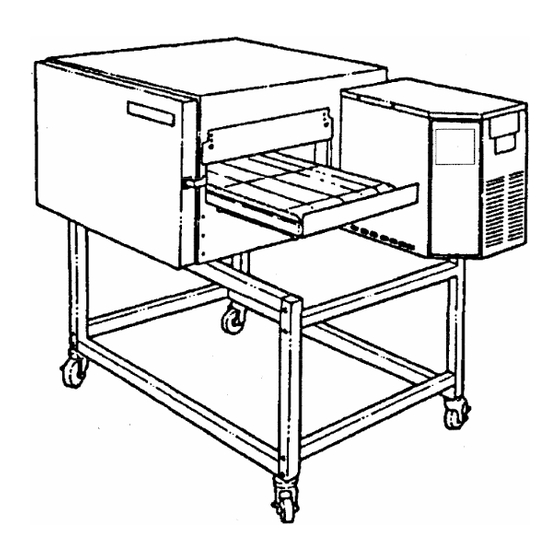

Page 13: Stacking Instructions

IMPINGER II AND ADVANTAGE STACKING INSTRUCTIONS FOR SINGLE OVEN CAUTION: USE EXTREME CARE SO OVEN DOES NOT SLIP OFF STAND BEFORE SCREWS HAVE SECURED OVEN. FOR DOUBLE OVEN (Step 2) TOP UNIT Remove door, conveyor and finger assemblies. Turn unit on left side, as shown. - Page 14 FOR TRIPLE OVEN (STEP 1) Remove door, conveyor and finger assemblies. Turn unit on side, as shown. Fasten base to oven with four ½ - 13 x ½” long Hex Head Bolts. Screw casters into base. (STEP 3) Prepare top for mounting as shown above.

-

Page 15: Conveyor Removal

4. Coupling will snap back allowing removal of conveyor. (Set screw on conveyor side is a spring loaded ball detent and is NOT to be tightened firmly. 6. Then return to control end of the conveyor and remove conveyor from oven cavity. Reassemble in reverse order. -

Page 16: Conveyor Disassembly For Cleaning

NOTE: The Conveyor Belt of the Impinger II and the Advantage oven does not have a tension adjustment. If the belt would become too lose, a link will have to be removed to tighten. A belt that is too tight will also cause operational problems due to excessive drag. -

Page 17: How To Obtain Service

HOW TO OBTAIN SERVICE If the oven fails to operate, check the circuit breaker to be sure it is turned on (on a gas oven check the manual gas valve to insure it is in the “ON” position). In addition, check the fuses on the back of the oven to be sure that they are good before you call the Authorized Service Agency. -

Page 18: Finger Columnating Plate Identification

Impinger II – Digital Advantage Ops Manual –Dom & Int’l... -

Page 19: Oven Start-Up - Impinger Ii

(START-UP CHECKOUT) by and Authorized Service Technician or a Lincoln Foodservice Products, LLC Service Representative. This service is required by Lincoln Foodservice Products, LLC in order to assure the oven(s) is/are properly installed and in working order. The warranty becomes effective upon verification of proper installation. -

Page 20: Diagnostic Messages

CAUTION: This message can occur when there is no gas supply to the oven. If the oven does not detect a temperature fluctuation in 5 minutes, the error message will appear. Be sure to check the gas valve and gas hose for proper connections. -

Page 21: Operator Maintenance

If the oven fails to operate, check the circuit breaker and gas valve to be sure they are turned on. Also, check the fuses on the control panel to be sure that they are good before you call the Authorized Service Agency. The name and phone number of the Authorized Service Agency should be located on the oven or contact the factory at area code (260) 432-9511 for the name of the nearest Authorized Service Agency. -

Page 22: Appendix A - Label Definitions

APPENDIX A – LABEL DEFINITIONS Impinger II – Digital Advantage Ops Manual –Dom & Int’l... -

Page 23: Preventive Maintenance

You must discuss the need for Preventive Maintenance with your Authorized Service Company to establish a proper program. If there is any question the service company cannot answer, contact the Lincoln Foodservice Product, LLC Service Department. CONCEPTS The Impinger Conveyor Oven produced by Lincoln Foodservice Products, LLC utilizes a revolutionary cooking concept, called “AIR IMPINGEMENT.”... - Page 24 Lincoln has developed a worldwide sales and service network second to none in our industry. It is headed by a sales, service and marketing management staff of more than 60 seasoned foodservice professionals. manufacture and market Impinger Conveyor Ovens, Wear-Ever and Centurion cookware, Redco food slicers, cutters and wedgers, Fresh-O-Matic food warmers that are stocked by a national network of more than 1400 distributors nationwide.

Need help?

Do you have a question about the Series 1100 and is the answer not in the manual?

Questions and answers