Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for EINHELL JS SERIES

- Page 1 JS SERIES SAWS OPERATIONS AND MAINTENANCE MANUAL SAVE THIS MANUAL AND MAKE AVAILABLE TO ALL USERS OF THIS TOOL! WARNING Read and understand operator's manual before using this machine. Failure to follow operating instructions could result in injury or damage to...

-

Page 2: Table Of Contents

Figure 20-JS SERIES SAWS top view....................23 Figure 21 -JS SERIES SAWS with flange detail...................24 Figure 22 - JS SERIES SAWS with belt and flange details ..............25 Figure 23-JS SERIES SAWS rear view with switch detail ..............26 Figure 24- Jack assembly exploded view ....................27 Figure 25-Warning sticker (decal) locations ..................28... -

Page 3: Instructions For Use Of Manual Sections

1-1/2" Blade nut wrench size: 1" Shaft diameter: ALVANIA® Grease 3 every 100 hours Flanged bearing grease: Assembly part numbers: JS SERIES SAWS 13 hp GAS SX77130 230v 1P Electric SX77100 208/480v 3P Electric SX77104 Recommended dust U.S. SAWS Mega -Vac Gas... -

Page 4: Applications

Applications Typical applications for the U.S. SAWS JS SERIES SAWS would be joint cleanout and trench cutting. The saw uses dry cut diamond blades in either 8" diameters or 10" diameters with an allowable maximum depth cut of 3". The blade rotates in an upward direction allowing for easy dust collection when connected to an appropriate vacuum system. -

Page 5: Rules For Safer Operation

Rules for safer operation WARNING WARNING Read and understand Use only diamond blades (steel operator's manual before centered diamond cutting-off using this machine. wheels) with this machine. RPM Failure to follow operating rating on blade must exceed Instructions could result machine max rpm rating. - Page 6 KNOW YOUR EQUIPMENT. Do not operate this machine unless you have read the operations and maintenance manual carefully. Read any additional instructions included from other manufacturers and organizations such as Honda® and the Masonry and Concrete Saw Manufacturers Institute. Learn the applications and limitations as well as the specific potential hazards related to this tool.

- Page 7 PROTECT YOUR HEARING. Observe all applicable local, state and federal safety regulations. Wear OSHA approved hearing protection. DRESS PROPERLY. Do not wear loose clothing or jewelry that can be caught in moving parts. Wear protective hair covering to contain long hair. Keep hair away from motor air vent. Rubber gloves and non-skid footwear are recommended when working outdoors.

- Page 8 4.19 CHECK BLADE AND MACHINE ROTATION DIRECTION. Never operate a blade in the wrong rotation direction. Check the machine rotation direction and blade direction when mounting a blade. 4.20 CHECK BLADE MAXIMUM ALLOWABLE SPEED. Check the maximum operating speed of the machine and blade. Never use a blade rated less than the machine's maximum speed rating.

-

Page 9: Pre-Operation Checklist

4.34 CHECK DAMAGED PARTS. Verify all machine guards are in good condition and will function properly before using the machine. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect machine operation. A guard, power switch or other part that is damaged should be properly repaired or replaced by an authorized service center unless indicated elsewhere in this instruction manual. -

Page 10: Figure 7-Warning Label - Engine Exhaust Contains Carbon Monoxide Gas

WARNING TO P RE VE NT S E RIO US I NJURY DO NOT OPERATE SAW WITHOUT P ROP ER TRAINING AND. UNDERSTANDING OF THE OWNERS MANUAL WHEN OPERATING THIS MACHINE ALWAYS WEAR SAFETY APPROVED HEARING PROTECTION EYE OR FACE PROTECTION HEAD RESPERATOR... -

Page 11: Figure 8-Max Rpm Label - Maximum Blade Speed

Be aware that some materials are explosive as a dust WARNING WARNING: The JS SERIES SAWS maximum blade operating speed is 5850 rpm as labeled on the blade guard. Use only dry cut diamond blades rated higher than 5850 rpm safe operating speed. Do not use a blade rated for less than 5850 rpm. -

Page 12: Figure 10-Warning Label - Inspect Blades Before Use

Remove bolt in the blade guard holding bracket. Hold the blade guard firmly and raise guard up into the holding bracket. Reinsert bolt in the blade guard holding bracket and tighten nut. Remove both blade change wrenches from the JS handle. Install dry cut diamond blade. See section 8.1 for detailed instructions on removing and installing blades. -

Page 13: Figure 12-Alignment Of Blade And The Pointer Wheels - Js Bottom View

FRONT POINTER WHEEL — BLADE INTENDED CUT LINE Figure 12 - Alignment of blade and the pointer wheels - JS bottom view 5.14 There are seven slots 1/4" apart in the jack assembly lower arm. As the bottom of the jack assembly upper arm moves past each 1/4"... - Page 14 CAUTION CAUTION: The blade depth is approximate and not exact. Many variables affect the exact blade depth such as the exact diameter of a worn diamond blade. If an accurate depth must be cut, install the blade to be used with the engine in the OFF position. Place the JS in a secure position that allows the blade to overhang and be visibly measured at full blade depth.

-

Page 15: Figure 14-Warning Label -Do Not Operate With Guard Removed

5.18 Slide the 4" diameter vacuum hose over the connector and tighten the worm drive hose clamp. Pull firmly on the hose to verify the connection will not slide off. 5.19 Check for missing or loose bolts. Tighten loose bolts and replace missing bolts before operating machine. -

Page 16: Operation

Operation Follow all pre-operating instructions in section 5.0. Turn handle counterclockwise until jack assembly upper arm is above the highest depth slot. See Figure 13. This will allow proper clearance between the work surface and the blade tip. WARNING WARNING: Never attempt to start the engine with the diamond blade inserted in a joint or previous cut. The blade will turn as soon as the JS is started. -

Page 17: Figure 17-Js Series Saws In Cutting Operation

POINTER WHEEL -AREA IN FRONT IS CLEAR FROM DOWN PEOPLE. TOOLS OR ANY LOOSE OBJECTS. ETC Figure 17-JS SERIES SAWS in cutting operation (Operator wearing personal protective equipment and dust collector are not shown) 6.15 When through cutting, turn handle counterclockwise with your right hand to raise the blade out of the work surface. -

Page 18: Table 3 - Js Series Saws Parts List

Table 3 - JS SERIES SAWS parts list (Note: Use Figure 18 to Figure 24 to locate item numbers. See section 7.4 for item #53 breakdown. JS SERIES SAWS parts are the same except for item #22.) ITEM QUANTITY PART NUMBER... -

Page 19: Parts List And Accessories

SX77021 WHEEL/3"X1-13/16" SX96507 5/16" NYLOCK NUT SX60472 3/8"-16 X 3-1/2" HEX HEAD BOLT SX98045 3/8"-16 X 3" TURNED EYE BOLT SX98052 1/2" FLAT WASHER SX91025 1/2"-13 X 1-1/2" HEX HEAD BOLT SX80504 1"-14 BLADE NUT SX77148 ADAPTER/3" SX98085 3/8-16 X 1-3/4" CARRIAGE BOLT SX98026 3/16"... -

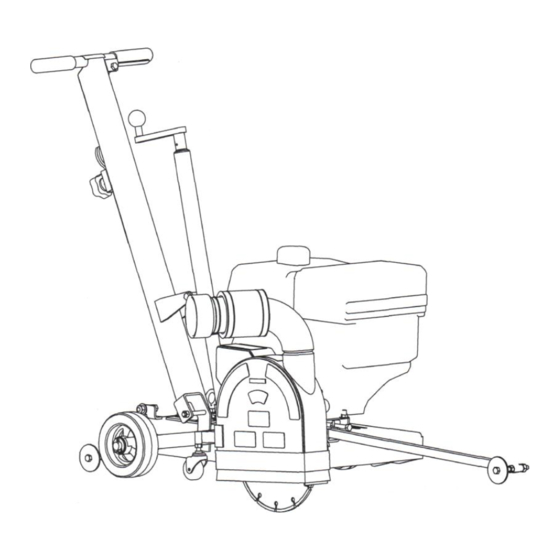

Page 20: Figure 18-Js Series Saws Top Front Right View

Figure 18 to Figure 23 of JS SERIES SAWS Figure 18-JS SERIES SAWS top front right view... -

Page 21: Figure 19-Js Series Saws Top Rear Left View

Figure 19 - JS SERIES SAWS top rear left view... -

Page 22: Figure 20-Js Series Saws Top View

Figure 20-JS SERIES SAWS top view... -

Page 23: Figure 21 -Js Series Saws With Flange Detail

, (2 Figure 21 - JS SERIES SAWS with flange detail... -

Page 24: Figure 22 - Js Series Saws With Belt And Flange Details

DETAIL D Figure 22 - JS SERIES SAWS with belt and flange details (Shown without belt guard, item #20, and blade guard, item #16. Never run a JS without both guards in place.) -

Page 25: Figure 23-Js Series Saws Rear View With Switch Detail

Figure 23 - JS SERIES SAWS rear view with switch detail (Shown without deadman switch cover on handle, item #5. Never run a JS without switch cover on handle.) -

Page 26: Figure 24- Jack Assembly Exploded View

WASHER/STEEL 1/2" X 1-1/16" X .10" THICK Table 5 - Jack assembly parts list (Note: Use Figure 24 to locate item numbers. Jack assembly is the same for the JS SERIES SAWS .) Figure 24 - Jack assembly exploded view... -

Page 27: Table 6- Dry Cut Diamond Blade List

WARNING WARNING: Recommended accessories for this tool including blades are listed in this manual or are available by calling customer service. The use of any other attachment or accessory might be hazardous. JS premium dry cut diamond blades, medium bond Part Number DIAMOND BLADE (Cleanout) Part Number... -

Page 29: Maintenance And Inspection

Maintenance and inspection WARNING WARNING: Release or disengage the deadman, turn the Honda engine switch to the OFF position, and turn the fuel valve lever to the OFF position before performing any maintenance and inspection. This will be referred to as the JS OFF position in sections 8.1 through 8.7. WARNING WARNING: Damaged diamond blades are hazardous and should never be used on a JS. -

Page 30: Figure 27-Js In Blade Change Position With Engine Off

DEADMAN LEVER DISENGAGED (RELEASED POSITION) HONDA ENGINE SWITCH AND FUEL VALVE LEVER TURNED TO "OFF" POSITION LOOSEN CLAMPING KNOB TO REMOVE BOTH WRENCHES BLADE IS AT COMPLETE STOP -— BLADE GUARD LOCKED IN UP I POSITION WITH BOLT ON HOLDING BRACKET Figure 27 - JS in blade change position with engine off (Never start engine or run JS in this position) -

Page 31: Figure 29 -Warning Label - Use Only Diamond Blades

WARNING Use only diamond blades (steel centered diamond cutting-off wheels) with this machine. RPM rating on blade must exceed machine max rpm rating. The use of any other blade could result in death or serious injury. 2 Hazard Communication Systems. LLC Reorder No. -

Page 32: Figure 32 - Blade Guard Caster Wheel Adjustment

Adjusting dust brush height and 2 inch blade guard caster wheel WARNING WARNING: Breathable silica may be generated by use of this product; Silica can cause severe and permanent lung damage, cancer, and other serious diseases. Do not breath the dust. Do not rely on your sight or smell to determine if the dust is in the air. -

Page 33: Warranty And Service

8.4.2 These bearings are exposed to excessive dust and require the same brand of high quality grease as supplied by the factory. Apply ALVANIA® Grease 3 with a hand grease gun to both flanged bearings on the blade shaft after every 100 hours of use. 8.4.3 The performance of the bearing is greatly influenced by the quantity of grease. - Page 34 9.1.1 Warranty Responsibility The distributor or the end user must prepare a Machine Warranty Information Card when the machine is delivered. Failure to comply will make any and all warranties on this equipment null and void. Credit for warranty repairs will be given only after receipt of the WARRANTY CLAIM FORM, properly completed with all the required details.

- Page 35 Customer Service US SAWS 3317 W. Warner Ave Santa Ana, CA 92704 1-877-817-6687 http://www.ussaws.com Honda is a registered trademark of Honda Motor Co, Ltd.

- Page 36 Warranty Registration card NOTICE! TO THE DELIVERING DISTRIBUTOR OR END USER To ensure the proper warranty coverage is extended to the owner of this machine, fill out the attached card COMPLETELY and ACCURATELY and return to US SAWS The warranty period will start on the delivery date entered below. The distributor or the end user must prepare a machine warranty information card when the machine is delivered.

- Page 37 Change of Owner or New Address Registration Card WARNING If you are not the owner of record as shown on the manual copy of the warranty registration card, do not operate this machine before contacting U.S. SAWS at 1-877-817-6687. Verify the following before operating the equipment: 1.

Need help?

Do you have a question about the JS SERIES and is the answer not in the manual?

Questions and answers