Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Frontier ST0726

- Page 1 ST0726 Snow Thrower OPERATOR’S MANUAL MTF−051056L...

-

Page 2: Responsibility Of The Owner

INTRODUCTION Congratulations on your purchase of a Frontier Snowthrower. It has been designed, engineered and manufactured to give you the best possible dependability and performance. However, like all mechanical products, your machine will occasionally re- quire adjustment and maintenance. This handbook should be read before operating or performing and adjustments on your machine. -

Page 3: Hazard Symbols And The Meanings

RULES FOR SAFE OPERATION Operating Symbols and their meanings This manual contains safety information to make you aware of the hazards and risks associated with snow These symbols are used on your equipment and defined in your operating throwers, and how to avoid them. The snow thrower is designed and manual. - Page 4 RULES FOR SAFE OPERATION DANGER DANGER Avoid death or serious injury from rotating auger. Objects can be picked up by auger and thrown from chute. Keep hands, feet and clothing away. Never throw snow toward people or cars, and never allow anyone in front of the snow thrower.

- Page 5 RULES FOR SAFE OPERATION WARNING WARNING Running engines produce heat. Engine parts, especially muffler, Gasoline and its vapors are extremely flammable and explosive. become extremely hot. Fire or explosion can cause severe burns or death. Severe thermal burns can occur on contact. WHEN ADDING FUEL Combustible debris, such as leaves, grass, brush, etc.

-

Page 6: Table Of Contents

TABLE OF CONTENTS HAZARD SYMBOLS AND THE MEANINGS ..... . . OPERATING SYMBOLS AND THEIR MEANINGS ....SAFETY DECALS . -

Page 7: Safety Decals

SAFETY DECALS the meaning, then thoroughly read all safety and operation WARNING: If safety decals are dam- instructions in this Owner’s Manual or contact your local aged or missing, replace immediately. dealer. If any safety decals become worn or damaged and cannot Look for this symbol to indicate important safe- be read, order replacement decals from your local dealer. -

Page 8: Warranty

THREE YEAR LIMITED WARRANTY Murray warrants to the original purchaser of this Frontier Branded Snowthrower that this unit shall be free from defects in material and workmanship under normal use and service for a period of Three (3) Year from the date of purchase; however,... -

Page 9: Assembly

ASSEMBLY TOOLS REQUIRED FOR ASSEMBLY CONTENTS OF SHIPPING CARTON 1 − Knife 1− Snowthrower 2 − 1/2” wrenches (or adjustable wrenches) 1− Container of Fuel Stabilizer (Located in Parts Bag) 2 − 9/16” wrenches (or adjustable wrenches) 1− Snow Chute Assembly 2 −... -

Page 10: Unpacking

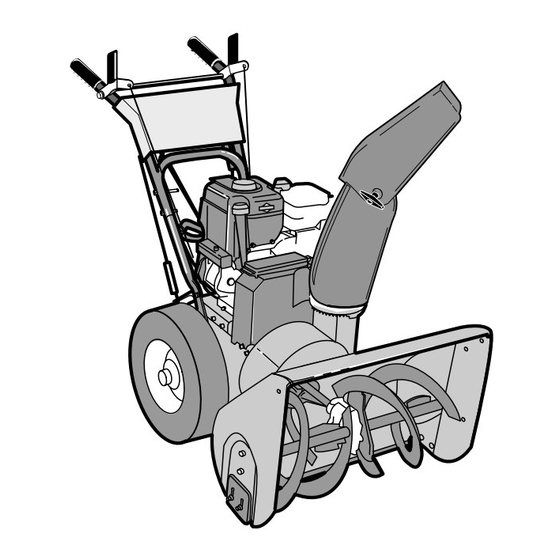

ASSEMBLY Figure 2 shows the snowthrower in the shipping position. Figure 3 shows the snowthrower completely assembled. Reference to right and left hand side of the snowthrower is from the operator’s position at the handle. UNPACKING Figure 2 1. Locate the two tear tabs at the bottom of the carton. Auger Drive Lever Traction Drive Lever 2. -

Page 11: Upper Handle And Crank Assembly

ASSEMBLY UPPER HANDLE AND CRANK ASSEMBLY Crank 1. Loosen, but do not remove the screws, flatwashers, lock- washers and hex nuts in the upper holes of the lower han- Bolt dle. Lockwasher 2. Remove the fasteners and the crank assembly eyebolt Locknut from the lower holes of the lower handle. -

Page 12: Snow Chute Assembly

ASSEMBLY SNOW CHUTE ASSEMBLY 1. Position the snow chute to the INSIDE of the snow chute flange. Align the three holes in the snow chute with holes Chute Extension in snow chute flange. (See Figure 8) Snow Chute Deflector 2. Place three 5/16−18 carriage bolts from inside of chute as shown in Figure 8. -

Page 13: Operation

OPERATION READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR SNOWTHROWER. Compare the illustrations with your SNOWTHROWER to familiarize yourself with the location of various controls and adjustments. Save this manual for future reference. Gas Fill Auger Drive Clutch Lever Choke Control Traction Drive Clutch Lever Primer Button... -

Page 14: Snowthrower Operation

OPERATION The operation of any snowthrower can result in foreign objects being thrown into the eyes,which can result in severe eye damage. Always wear safety glasses or eye shields before beginning snowthrower Operation. We recommend standard safety glasses or Wide Vision Safety Mask for over spectacles. SNOWTHROWER OPERATION 4. -

Page 15: Wheel Lock Out Pin

OPERATION TO THROW SNOW WARNING: Never run engine indoors or in an 1. Push down the auger driver lever (right hand). See enclosed, poor ventilated area. Engine exhaust Figure 11. contains CARBON MONOXIDE, 2. To stop throwing snowl, release the auger drive lever. DERLESS and DEADLY GAS. -

Page 16: How To Set The Drift Cutters

OPERATION HOW TO SET THE DRIFT CUTTERS Drift Cutter (OPTIONAL ACCESSORY ON SOME MODELS) Drift cutters are used to cut a path through snow deeper than the auger housing. 1. Loosen the wingnuts that secure the drift cutters to the auger housing (see Figure 16). -

Page 17: Before Starting Engine

OPERATION BEFORE STARTING ENGINE use leaded gasoline. We recommend that fuel stabilizer be added to the fuel each time that gasoline is added to Check the oil the fuel tank. NOTE: The engine was shipped from the factory filled NOTE: Winter grade gasoline has higher volatility to with oil. -

Page 18: To Stop Engine

OPERATION TO STOP ENGINE WARNING: The electric starter is equipped with a three−wire power cord and plug designed to CAUTION: To stop the engine, do not move the choke operate on 120 volt AC house hold current. The control to CHOKE position. Backfire or engine damage power cord must be properly grounded at all times to can occur. - Page 19 Then, disconnect the power cord from the switch box. If after following the preceding instructions, your engine fails to start, have the engine checked by a John Deere/Frontier dealer. NOTE: Do not lose the safety/ignition key. Keep the safety/ignition key is a safe place. The engine will not start without the safety/ignition key.

-

Page 20: How To Cleara Clogged Discharge Chute

OPERATION FROZEN STARTER WARNING: Never run engine indoors or in en- closed, poorly ventilated areas. Engine exhaust If the starter is frozen and will not turn engine: contains CARBON MONOXIDE, AN ODORLESS AND DEADLY GAS. Keep hands, feet, hair and loose 1. -

Page 21: Operating Tips

OPERATION OPERATING TIPS 1. For optimum snow blower efficiency, adjust ground 6. On gravel or crushed rock surfaces, the skids should be speed, not the throttle. REMEMBER − if the wheels slip, set at 1−1/4 inch (32 mm) below the scraper bar (see To forward speed will be reduced. -

Page 22: Service Recommendations

SERVICE RECOMMENDATIONS SERVICE RECOMMENDATIONS FIRST BEFORE EVERY EVERY EVERY BEGINNING EACH EACH BEFORE PROCEDURE HOUR OFTEN HOURS HOURS HOURS SEASON STORAGE √ √ √ Tighten all screws and nuts Check Traction Clutch √ √ Cable Adjustment (See Cable Adjustment) Check Auger clutch Cable √... -

Page 23: Maintenance

MAINTENANCE Some adjustments will need to be made periodically to Remove filler plug (Figure 25), once a year. If grease is properly maintain your snowthrower. visible, do not add. If grease is not visible, use a piece of fine wire, like a dipstick to check if there is grease in the gear box. All adjustments in the MAINTENANCE section of this manual Mobilux EP1 and Shell Aldania EP1 are suitable equivalents. - Page 24 MAINTENANCE LUBRICATION − EVERY 25 HOURS Chute Rotation Gear Chute Rotation Gear Lubricate the chute rotation gear with automotive type oil. (see Figure 26). Figure 26 Chains 4. Lubricate the chains with a chain type lubricant. 5. Wipe the hexshaft and sprockets with 5W30 motor oil. 1.

-

Page 25: Engine

MAINTENANCE ENGINE Check Crankcase Oil Level before starting engine and after Oil Fill Cap/Dipstick each 5 hours of continuous use (see Figure 28). Add proper motor oil as required. FULL NOTE: Overfilling the engine can affect performance. Tighten the oil fill cap securely to prevent leakage. Change Oil every 25 hours of operation or at least once a year, even if the snowthrower is not used for twenty−five hours. -

Page 26: Auger Housing Height Adjustment

MAINTENANCE WARNING: Always turn unit off, remove igni- To adjust skids, proceed as follows: tion key and disconnect the spark plug wire be- 1. Place a block (equal to height from ground desired) un- fore making any repairs or adjustments. der scraper bar near but not under skid. -

Page 27: Belt Adjustment

MAINTENANCE BELT ADJUSTMENT Traction Drive Belt The traction drive belt has constant spring pressure and does not require an adjustment. If the traction drive belt is slipping, replace the belt. See “How To Replace The Belts” in the Maintenance section. Auger Drive Belt If your snowthrower will not discharge snow, check the control cable adjustment. -

Page 28: How To Replace The Belts

MAINTENANCE HOW TO REPLACE THE BELTS The drive belts are of special construction and must be 16. Install the belt cover. Tighten screw (See Figure 31). replaced with original factory replacement belts available 17. Check the adjustment of the cables. See “How To Check from your nearest authorized service center. - Page 29 MAINTENANCE Traction Drive Belt Engine Pulley Belt Guide Auger Drive Pulley Traction Drive Idler Pulley Auger Drive Belt Idler Pulley Traction Drive Spring Traction Drive Belt E−Ring Traction Drive Pulley Swing Plate Axle Rod Engine Pulley Figure 35 MTF−051056L...

- Page 30 MAINTENANCE How To Remove the Traction Drive Belt If the snow thrower will not move forward, check the traction 11. Install and adjust the auger drive belt. See “How To Re- drive belt for wear or damage. If the traction drive belt is worn move The Auger Drive Belt”...

-

Page 31: Belt Guide Adjustment

MAINTENANCE BELT GUIDE ADJUSTMENT 1. Remove spark plug wire. 2. Have someone engage auger drive. Belt Guide 1/8 Inch (3.175 mm) 3. Measure the distance between the belt guide and belt. The distance should be 1/8 inch (3.175 mm) for guide. Auger Idler See Figure 37. -

Page 32: Traction Drive Cable Adjustment

MAINTENANCE Traction Drive Cable Adjustment Bolt WARNING: Drain the gasoline outdoors, away Bottom Panel from fire or flame. 1. Remove the gas from the gas tank. Stand the snow Auger Housing thrower up on the front end of the auger housing. 2. -

Page 33: How To Adjust Or Replace The Friction Wheel

MAINTENANCE HOW TO ADJUST OR REPLACE 5. Install the bottom panel (see Figure 43). THE FRICTION WHEEL 6. Tighten the bolts on each side of the bottom panel. How To Check The Friction Wheel If the snow thrower will not move forward, check the traction Bolt Bottom Panel drive belt, the traction drive cable or the friction wheel. - Page 34 MAINTENANCE How To Replace The Friction Wheel If the friction wheel is worn or damaged, the snow thrower will not move forward. The friction wheel must be replaced as follows. Drive Sprocket Axle 1. Remove the gas from the gas tank. Stand the snow thrower up on the front end of the auger housing (4).

- Page 35 MAINTENANCE 10. Remove the three fasteners that hold the friction wheel to the hub (see Figure 49). 11. Remove the friction wheel from the hub. Slip the fric- tion wheel off the hex shaft. Washer 12. Assemble the new friction wheel onto hub with the fas- teners removed earlier.

-

Page 36: How To Remove The Snow Hood

MAINTENANCE HOW TO REMOVE THE SNOW HOOD To access the spark plug, the snow hood must be removed as follows: 1. Remove the choke control knob (see Figure 51). 2. Remove the ON/OFF key. 3. Remove the four mounting screws. 4. -

Page 37: Auger Shear Bolt Replacement

MAINTENANCE AUGER SHEAR BOLT REPLACEMENT The augers are secured to the auger shaft with special bolts that are designed to break if an object becomes lodged in the auger housing. Use of a harder bolt will reduce the protection provided by the shear bolt. To replace a broken shear bolt, Shear Pin proceed as follows: WARNING: To insure safety and performance... -

Page 38: Storage

STORAGE OFF SEASON STORAGE 4. Thoroughly clean the snowthrower. 5. Lubricate all lubrication points (see “Lubrication“ in the WARNING: Never store the engine, with fuel in the tank, indoors or in a poor ventilated enclo- Maintenance section). sure where fuel fumes could reach an open 6. -

Page 39: Trouble Shooting Chart

If you have any questions concerning parts, service, or technical data, contact your nearest John Deere/Frontier dealer. For complete warranty information refer to the warranty in the Owner’s Information section of this manual. - Page 40 NOTES MTF−051056L...

- Page 41 NOTES MTF−051056L...

-

Page 42: Replacement Parts

PART NUMBERS MAY CHANGE. When you order replacement parts, use the part numbers listed below and on the fol- lowing pages. If a part number changes, your John Deere/Frontier dealer will have the latest part number. WHEN YOU ORDER PARTS, your John Deere/Frontier dealer must have your snowthrower model and serial number and your engine model number. -

Page 43: Parts Schematics

FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C ENGINE 25−2 Á Á 25−1 Á 25−3 25−4 25−2 Ref.Drive Page Ref. Auger Housing Page Key No. Part No. Description Key No. Part No. Description MT6219 CORD, STARTER MT53704 SPRING, IDLER TRACTION DRIVE MT1502120 PULLEY, IDLER −... - Page 44 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C FRAME Ref. Engine Page Ref. Auger Housing Page Ref. Drive Page MTF−051056L...

- Page 45 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C FRAME Key No. Part No. Description MT1501055E701 COVER, BOTTOM MT310169 SCREW, 1/4−20X .63 MT1501111 YZ IDLER ASSEMBLY, AUGER MT711682 PIN, HAIR .38DIAX1.64LG MT761761 PIN, CLEVIS 3/16” DIA MT165x160 SPRING, TENSION MT761675 YZ ASSY., SPRING ATTACH MT585781 BOLT, 3/8−16X1.25 CARR.

- Page 46 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C DRIVE Ref. Shift Yoke Page Ref. Frame Page Ref. Wheel Page Ref. Wheel Page Ref. Wheel Page Ref. Wheel Page MTF−051056L...

- Page 47 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C DRIVE Key No. Part No. Description MT1501092 YZ LF AXLE, SWING PLATE YZ MT579851 CHAIN, ROLLER #420x19.00 MT334163 BEARING AND RETAINER, ASSY MT579858 WASHER MT25x020 SCREW, TAP 5/16−18x0.5 MT1501100 ASSY, HEX SHAFT MT579868 CHAIN, ROLLER #420x18.00 LG...

- Page 48 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C AUGER HOUSING Ref. Gear Case Page MTF−051056L...

- Page 49 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C AUGER HOUSING Key No. Part No. Description MT762146 PULLEY, 4L 6.12X .67 MT577400 SCREW, 5/16−18X.63 MT2001022 KEY, SQUARE 3/16 X 3/4 MT1501158 SPACER, FRICTION PULLEY MT582957 YZ RETAINER, BALL BRNG MT1501389 BEARING, BALL MT001X92 BOLT, HEX 5/16−18X .50...

- Page 50 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C DISCHARGE CHUTE Pop Rivets Ref. Auger Housing Page MTF−051056L...

- Page 51 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C DISCHARGE CHUTE Key No. Part No. Description MT340720 BOLT, CARRIAGE 5/16−18 X.75 MT12021 WASHER, PLASTIC MT71038 NUT, 5/16−18 REGHEX NYLOCK MT6711 WASHER, PLASTIC MT12021 WASHER, PLASTIC MT6711 WASHER, PLASTIC MT71071 WASHER, FLAT MT71060 WASHER, SPLIT...

- Page 52 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C HANDLE Ref. Engine Page MTF−051056L...

- Page 53 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C HANDLE Key No. Part No. Description MT1501205E701 HANDLE, UPPER LH MT1501206E701 HANDLE, UPPER RH MT11234 SCREW, 5/16−18X2.75 MT71071 WASHER, FLAT MT71060 WASHER, SPTLK .31X.58X.08 MT15X144 NUT, 5/16−18 REGHEX MT11261 STOP, RED PLASTIC MT337399 GRIP−HANDLE FINGER...

- Page 54 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C SHIFT YOKE Key No. Part No. Description MT581631E701 ROD, SHIFT MT302628 SCREW, 1/4−20X.75 MT73826 NUT, 1/4−20 MT318486 NUT, JAM MT304438 KNOB MT760564 LEVER, SPRING MT302628 SCREW, 1/4−20X.75 MT73826 NUT, 1/4−20 MT579944 BEARING, FLANGED MT1501085 YZ ROD ASSY., SPEED SELECT...

- Page 55 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C CHUTE ROD Ref. Handle Assy 852−9 852−5 852−8 852−13 852−10 Ref. Auger Housing Assy 852−11 852−1 852−2 852−6 869 852−4 852−7 852−3 Key No. Part No. Description Key No. Part No. Description 852−1 MT1501533 YZ ASSEMBLY, YOKE &...

- Page 56 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C CONTROL PANEL Key No. Part No. Description MT1501203E511 PANEL MT002x99 BOLT, CARRIAGE MT71067 WASHER MT15x145 MTF−051056L...

- Page 57 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C WHEELS Ref. Drive Page Key No. Part No. Description MT1501562 SHAFT, AXLE MT1501089 SPRKT & HUB MT01x193 SCREW, 1/4−20 x 1.75 MT15x145 NUT, 1/4−20 HEX NYLOCK MT1501114 BEARING, AXLE MT017x83 FLATWASHER MT1501139 BUSHING, WHEEL MT1501822 TIRE &...

- Page 58 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C GEAR CASE Key No. Part No. Description MT10577 CASE, GEAR, RH MT10576 CASE, GEAR, LH MT710025 SCREW,1/4−20X.75 MT15X143 NUT,1/4−20 MT9344 SCREW, 3/8−16X.50 MT9566 SEAL, OIL MT50304 BEARING, FL MT48275 WASHER, FLAT MT340287 SHAFT, AUGER OUTPUT...

- Page 59 FRONTIER MODEL ST0726 FACTORY MODEL 626750x16C DECALS Key No. Part No. Description MT48x5289 DECAL, HAND CONTROL MT7390 DECAL, V−BELTS MT7859 DECAL, OVER ADJUSTMENT MT48x5967 DECAL, ROTATING AUGER MT48x5578 DECAL, THROWN OBJECTS MT48x5965 DECAL, UNCLOGGING CHUTE MT48x5284 DECAL, SPEED CONTROL MT760983...

-

Page 60: Specifications

SPECIFICATIONS ST0726 Engine Briggs & Stratton Intek Snow OHV Horsepower 7.5 hp Starter Electric / Recoil Fuel Capacity 4 quarts Drive System Friction Disc Speeds 6 Forward / 2 Reverse 13” Tire Diameter Traction Control Pin Lock Clearing Width 26”...

Need help?

Do you have a question about the ST0726 and is the answer not in the manual?

Questions and answers