Summary of Contents for Frontier SB1174

- Page 1 OPERATOR'S MANUAL SNOWBLOWERS SB1174 Serial # : 1XFSB11X_B0111288 & up OM 0408SB1174-A 09/11...

-

Page 3: Table Of Contents

TABLE OF CONTENT SPECIFICATIONS ............................3 INTRODUCTION – TO THE PURCHASER ....................4 SAFETY PRECAUTIONS .......................... 5-11 Before Operation ............................ 5 Notice ..............................6 The Snowblower ..........................6-8 Before Operation........................6 Snowblower Operation ......................7-8 The Tractor ............................. 9 General Information ........................ 9 Operating the Tractor ...................... - Page 4 Driveline – Troubleshooting ........................ 37-39 PARTS ................................. 40-49 Introduction ..............................40 Manual Holder ............................... 40 Snowblower - SB1174 ..........................41-43 Gearbox 5RD663485 ............................ 44 Driveline 5RD4700159 ..........................45 5RDF0046 - Manual Rotation ........................46 5RDF0047 - Hydraulic Rotation ........................47 5RDF0048 - Hydraulic Deflector ........................

-

Page 5: Specifications

SPECIFICATIONS Features and Specifications SB1174 Working Width 74" Transport Width 74" Working Height 26" Length 47 3/4" Single/Dual Auger Single Auger Diameter 15" Auger Flighting Thickness 5/16" Impeller Diameter 24" Impeller Width 9" Impeller Shaft Diameter 1 3/8" Number of Impeller blades... -

Page 6: Introduction - To The Purchaser

INTRODUCTION O THE URCHASER All products are designed to give safe, dependable Illustrations service if they are operated and maintained The illustrations may not necessarily reproduce according to instructions. Read and understand the full detail and the exact shape of the parts or this manual before operation. -

Page 7: Safety Precautions

SAFETY PRECAUTIONS SAFETY FIRST This symbol, the industry's "Safety Alert Symbol", is used throughout this manual and on labels on the machine itself to warn of the possibility of personal injury. Read these instructions carefully. It is essential that you read the instructions and safety regulations before you attempt to assemble or use this unit. -

Page 8: Notice

SAFETY PRECAUTIONS - continued OTICE A safe operator is the best insurance against accidents. All operators, no matter how experienced they may be, should read this Operator's Manual and all other related manuals before attempting to operate an implement. Please read the following section and pay particular attention to all safety recommendations contained in this manual and those labeled on the implements and on the tractor. -

Page 9: Snowblower Operation

SAFETY PRECAUTIONS - continued Snowblower Operation 1. Before leaving tractor/snowblower 10. If snowblower starts vibrate unattended, take all possible precautions. abnormally, disengage the PTO, stop the Park tractor/snowblower level engine immediately and check for cause. ground, place the transmission in neutral, Excessive vibration is generally a sign of set the parking brake, disengage the PTO, trouble. - Page 10 SAFETY PRECAUTIONS- continued 22. Make sure the tractor is counterweighted as recommended by your dealer. Weights provide the necessary balance to improve stability, traction and steering. 23. Always make sure snowblower components are properly installed and securely fastened BEFORE operation. 24.

-

Page 11: The Tractor

SAFETY PRECAUTIONS - continued RACTOR General Information 1. Read the operator's manual carefully before 14. A minimum 20% of tractor and equipment using tractor. Lack of operating knowledge weight must be on the tractor front wheels can lead to accidents. when attachments are in transport position. -

Page 12: Maintenance

SAFETY PRECAUTIONS - continued AINTENANCE ALWAYS USE GENUINE PARTS WHEN 7. Do not attempt to service machine, clear REPLACEMENT PARTS ARE REQUIRED obstructions or unclog the snowblower with the engine running. Always shut off engine 1. Keep the tractor and snowblower properly and allow all motion to cease. -

Page 13: Transporting

SAFETY PRECAUTIONS - continued RANSPORTATION 1. If the tractor/snowblower is to be driven on public roads, it must be equipped with an SMV (Slow Moving Vehicle) sign. Check local traffic codes that may apply to unit usage on public roads and highways in your area. 2. -

Page 14: Safety Decals

SAFETY DECALS Replace immediately if damaged. 5RD2500833 5RD2500813 5RD2500827 5RD2500616 5RD2500783 5RD2500608 5RD2500782 5RD2500620 5RD655834 5RD2500783 5RD2500791 5RD2500785 5RD2500786 5RD2500795 5RD2500792 5RD2500794 OM 0408SB1174-A... -

Page 15: Assembly

ASSEMBLY RACTOR REPARATION See Dealer for Tractor Preparation information. NOWBLOWER SSEMBLY The snowblower is assembled at the factory except for the parts in the hardware bag provided with the snowblower, the chute and the options if appropriate. Use the present manual and lay out all parts for assembly. -

Page 16: Installation Of Chute

ASSEMBLY Installation of the Chute (Figure 3) 1. Figure 3: Place the rotation bushing (item 1) on the chute base of the snowblower. 2. Figure 3: Install the chute (item 2) over the rotation bushing and install the three 3/16" spacers (item 3) and the 3/8"... -

Page 17: Installation Of Snowblower With Three Point Hitch

ASSEMBLY Installation of Snowblower with Three Point Hitch (Figure 4) 1. Install the two cat.1 pins (item 1) on the right 6. Adjust the snowblower using the tractor upper and left snowblower hitches in the lower holes link so that the snowblower operates parallel to as shown on figure. -

Page 18: Installation Of Snowblower With Quick Hitch

ASSEMBLY Installation of Snowblower with Quick Hitch (Figure 5) CATEGORY 1 only 1. Install the two cat.1 pins (item 2) on the right CAUTION and left snowblower hitches in the upper holes leaving 3 1/4" between the jam nut and Before connecting snowblower driveline to the end of the pin as shown on figure. -

Page 19: Installation Of Manual Rotation Kit 5Rdf0046

ASSEMBLY Installation of Manual Rotation Kit 5RDF0046 (Figures 6-7-8-9) NOTE: The rotation handle can be installed on 6. Figure 7: Install handle support bracket the right or left side of the three point hitch. (item 5) on the bracket (item 1) using a 3/4’’NC x 1 1/2’’... - Page 20 ASSEMBLY 9. Figure 8: Install plastic handle (item 5) over 14. Figure 9: Make sure the worm engages the rotation handle (item 6). completely when it reaches the end of the chute gear. The rotation handle is well 10. Figure 8: Insert assembled rotation tube (item adjusted when the chute rotates easily 1) inside the rotation worm assembly (items 2).

-

Page 21: Installation Of Hydraulic Rotation Kit 5Rdf0047

ASSEMBLY Installation of Hydraulic Rotation Kit 5RDF0047 (Figures 10 to 14) 1. Install the chute according to the instructions contained in the snowblower Operator's Manual. 2. Figure 10: Place the motor spacer (item 2) on the motor top (item 1) by aligning the holes. Install the motor (item 1) under the frame base of the snowblower and secure with four 3/8’’NC x 1’’... - Page 22 ASSEMBLY Figure 12: Install a 0.052" flow restrictor (item 2) in each motor input (item 1). 6. Figure 12: Connect the two hoses (item 3) on the motor flow restrictors (item 2). Direct the hose elbows toward the snowblower upper arm. 7.

- Page 23 ASSEMBLY PROBLEM: HYDRAULIC CHUTE ROTATION IS SLOW OR DOESN'T TURN When activating the chute rotation, it turns very slowly or not at all. WARNING 3. Figure 14: Check if there is residue in the avoid serious personal injury hydraulic circuit. To do so, first verify if the chute always wear safety glasses while doing the rotates well in one direction.

-

Page 24: Installation Of Hydraulic Deflector Kit 5Rdf0048

ASSEMBLY Installation of Hydraulic Deflector Kit 5RDF048 (Figures 15 to 20) 1. Install the chute according to the instructions in the snowblower Operator Manual. Figure 15 2. Figure 15: Remove the two manual adjustment knobs (item 1) and bolts (item 2) from each side of deflector and replace with two 5/16”... - Page 25 ASSEMBLY 8. Figure 18: Install the hose support (item 1) on the three point upper hitch CAUTION bracket (item 2) right or left (right one is recommended) using two 3/8’’NC x 1 To avoid serious personal injury. Escaping 1/2’’ bolts (item 3) and two 3/8"NC nylon hydraulic/ diesel fluid under pressure can penetrate insert locknuts (item 4).

-

Page 26: Installation Of Electric Deflector Kit 5Rdf0021

ASSEMBLY Installation of Electric Deflector Kit 5RDF0021 (Figures 21 to 24 & Electrical Diagram) PRE-ASSEMBLY 1. Figure 21A: Install the clevis with the 1 1/32" 3. Figure 21 & diagram: Connect the wires to diam. hole (item 1) on the actuator base the switch as follows: •... - Page 27 ASSEMBLY ASSEMBLY 4. Figure 22: Retract completely the pre- For Chute with knob adjustment: assembled actuator rod (item 10). Attach the 1. Figure Remove manual actuator to the deflector bracket (item 5) and to adjustment knobs and the bolts on each the base bracket (item 7), with two 1"...

- Page 28 ASSEMBLY 7. Figure 23: Insert the switch (item 4) in the Figure 21: Connect the ring terminal of the switchbox (item 2), secure with the two nuts ground wire (item 1) to a ground screw of the (items 1-3) provided with the switch, and vehicle.

-

Page 29: How To Determine Driveline Angles

ASSEMBLY Danger: Tractors Too Big IMPORTANT A proper initial installation will give you years of It is dangerous to use a tractor that is too big and satisfactory service on your equipment. Please powerful. The tractor will always be able to read carefully following instructions that have overload the blower, even if the machine is been specially included to help you and ensure... -

Page 30: Angles At Each End Of Driveline

ASSEMBLY Unequal Angles at Driveline Joints Equal Angles at Driveline Joints Avoid Recommended Angles at Each End of Driveline A popular habit is to change the snowblower angle in order to obtain a better scraping effect. This practice can become harmful to the driveline since the angle at each end is unequal. - Page 31 ASSEMBLY NOTE: Before cutting, make sure the two shafts 6. Figure 26A: File down tubes and remove intersect by at least 7 3/4" when in working chips. position that is when the snowblower rests on the 7. Apply grease to inside of outer telescopic ground.

-

Page 32: Driveline Installation

ASSEMBLY Driveline Installation (Figure 27) 1. Separate the snowblower from the three point or quick hitch. 2. Remove paint from snowblower gearbox shaft (item 1) and grease driveline sliding surfaces and yoke (item 2). 3. Remove the bolts (items 3) from the driveline yoke (item 2) and slide yoke over drive shaft using the sliding action of the driveline. -

Page 33: Removing Snowblower From Tractor

ASSEMBLY Removing Snowblower from Tractor (Figures 28 to 31) Three Point Hitch 1. Set parking brake and turn engine off. 2. Figure 28: Remove the wire round lock pin (item 2), lower the parking stand (item 1) Figure 28 completely to the ground to release all pressure from the three-point and reinsert the wire round lock pin in the lower hole (item 3). -

Page 34: Assembly

ASSEMBLY Quick Hitch 1. Set parking brake and turn engine off. Figure 30 2. Figure 30: Remove the wire round lock pin (item 2), lower the parking stand (item 1) and reinsert the wire round lock pin in the lower hole (item 3). -

Page 35: Operation

OPERATION ENERAL REPARATION DJUSTMENTS 1. Read the operator’s manual carefully before Chain Tension Adjustment using the tractor and snowblower. Be (Figure 32) thoroughly familiar with the controls and The premature wear of the chain may be caused by proper use of the equipment. Know how to tension being too tight. -

Page 36: Snow Removal Methods

OPERATION EMOVAL ETHODS When removing snow, do not use the snowblower as a dozer blade to push snow. Let the snowblower work its way through deep drifts. If the speed of your tractor is too fast, the snowblower may become overloaded and clog. -

Page 37: Maintenance

MAINTENANCE AINTENANCE Shearbolts Check the shearbolts indicated on the figure WARNING below at frequent intervals for proper tightness to be sure the blower is in safe working condition. Provide adequate blocking before working Figure 33: To access the shear bolts, pull up the under the snowblower when in the raised access pannel (item 1) located near the chain. -

Page 38: Lubrication

MAINTENANCE UBRICATION Use oil or a grease gun and lubricate as follows: DESCRIPTION INTERVAL LUBRICATION REQUIRED Grease each universal joint. Separate the sliding 8 hours parts and cover each one of them with grease Driveline 16 hours Oil the push pins 4 hours Chain Lubricate with chain lube... -

Page 39: Driveline - Troubleshooting

MAINTENANCE RIVELINE ROUBLESHOOTING AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS Quick-disconnect pin tight or Quick-disconnect pin dirty Clean, oil and follow service UICK DISCONNECT YOKE completely seized. (insufficient maintenance). instructions. Quick-disconnect pin Replace quick-disconnect pin. Quick-disconnect pin defective (forced ... - Page 40 MAINTENANCE AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS Cross arms broken. Extreme torque peak or Use appropriate safety device. ROSS shock load. Change to a larger driveline Axial loads too high. size. Shorten driveline shaft. ...

-

Page 41: Maintenance

MAINTENANCE AVOIDABLE DAMAGES POSSIBLE CAUSES CORRECTIVE ACTIONS Excessive wear of shield Insufficient lubrication. Follow lubrication instructions. SHIELD bearings. Incorrect chain mounting. Mount chain to allow Shield interfering with maximum angularity. Avoid contact of the shields implement. -

Page 42: Parts

PARTS NTRODUCTION All parts are illustrated in "exploded views" which show the individual parts in their normal relationship to each other. Reference numbers are used in the illustrations. These numbers correspond to those in the "Reference Number" (REF) column, and are followed by the description and quantity required. Right Hand and Left Hand are determined by those seen by the conductor standing behind the equipment. -

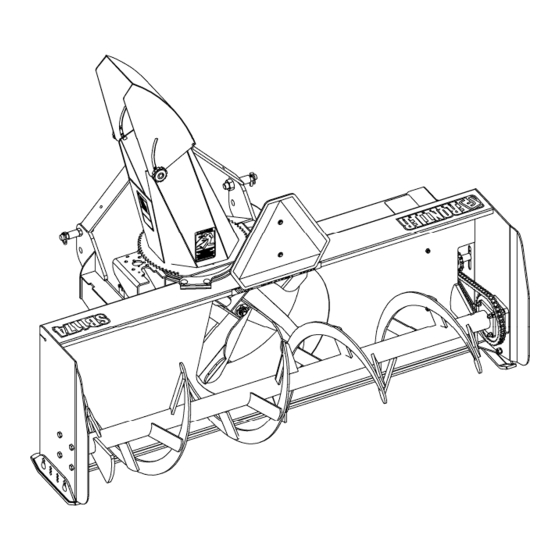

Page 43: Snowblower - Sb1174

PARTS – SB1174 NOWBLOWER OM 0408SB1174-A... - Page 44 PARTS – SB1174 NOWBLOWER ESCRIPTION Housing Chute (including decals) 5RD669782 Knob 5RD657309 Spacer 3/8" thick x 1.25" larg. x 4.5 lg 5RD669178 Spacer 3/16" thick x 1.25" larg. x 4.5 lg 5RD669179 Retaining plate 5RD665935 Carriage bolt 1/2" NC x 1 3/4" gr.5 PTD...

- Page 45 PARTS – SB1174 NOWBLOWER ESCRIPTION Coupling link #60 5RD654839 Spacer ring .656"ID x 1.760 x 1" ext. 5RD668093 Idler sprocket 60A12 5RD3300022 Spacer ring .656"ID x .807 x 1" ext. 5RD667777 Carriage bolt 5/16" NC x 1" gr.5 PTD 5RD0300003 Carriage bolt 1/2"...

-

Page 46: Gearbox 5Rd663485

PARTS 5RD663485 EARBOX ESCRIPTION Casing 5RD659848 Bearing 5RD659844 Shim 5RD656649 Input shaft 5RD664663 Shim 5RD659855 Oil seal 5RD659852 Snap ring 5RD656652 Gear 5RD662236 Parallel key 5RD659850 Output shaft 5RD659853 Bearing 5RD659844 Plug 5RD659847 O-ring 5RD661144 Allen socket head cap screw M8 x 1.25mm x 55mm – 8.8. 5RD0800032 Stover locknut M8 x 1.25mm - 8 5RD0900063... -

Page 47: Driveline 5Rd4700159

PARTS 5RD4700159 RIVELINE ESCRIPTION Yoke ass'y 5RD660764 Journal cross 5RD660765 Yoke for female tube 5RD663189 Female tube 5RD4700160 Male tube 5RD4700161 Yoke for male tube 5RD663193 Yoke ass'y 5RD4700058 Bolt M12 x 1.25 x 70 with nut 5RD662199 Grease fitting 5RD 663129 Ball Ø1/4"... -

Page 48: 5Rdf0046 - Manual Rotation

PARTS 5RDF0046 - M ANUAL OTATION ESCRIPTION Rotation handle 5RD667425 Rotation tube 5RD660188 Rotation yoke 5RD659595 Universal block 5RD658193 Rotation worm 5RD665953 Rotation worm support 5RD665952 Spring pin 1/4" x 1 1/4" 5RD1600015 Hairpin 4mm x 80mm, PTD 5RD1800002 Plastic handle 5RD656797 Bushing 1 5/16"... -

Page 49: 5Rdf0047 - Hydraulic Rotation

PARTS 5RDF0047 - H YDRAULIC OTATION ESCRIPTION Hydraulic motor 50cc 5RD3910092 - Seal Kit 5RD3910093 Key 1/4" x 1" woodruff (incl. in 5RD3910092) 5RD659191 Motor gear 5RD669705 Flow restrictor 0.052" 5RD664362 Rubber hose 1/4" x 75"lg. 5RD664920 Reducer 1/4"NPT female x 1/2" NPT male 5RD2600223 Male quick coupler 5RD656480... -

Page 50: 5Rdf0048 - Hydraulic Deflector

PARTS 5RDF0048 - H YDRAULIC EFLECTOR ESCRIPTION Allen flat socket head capscrews 5/16" x 3/4" 5RD0700003 Nylon insert locknut 5/16" NC 5RD1000005 Serrated flange nut 5/16" NC 5RD0900036 Carriage bolt 5/16" NC x 3/4" Gr.5 5RD0300002 5RD654438 Elbow 90° 3/8" NPT STM x 1/4" NPT SWF Deflector bracket 5RD660142 Deflector base bracket... -

Page 51: 5Rdf0021- Electric Deflector

PARTS 5RDF0021- E LECTRIC EFLECTOR ESCRIPTION Actuator 5RD662983 Switchbox 5RD667557 Switch 5RD663383 Rubber cap 5RD658666 Switchbox clamp 5RD667558 Clevis – rod 5RD666049 Clevis – base 5RD666050 Pin 1" 5RD666057 Ground wire 72" (black) 5RD666054 Tap connector 5RD656665 Fuse wire72" (red) 5RD666055 Actuator wire assembly 5RD666056... -

Page 52: Torque Specification Table

TORQUE SPECIFICATION TABLE GENERAL SPECIFICATION TABLE Use the following torques when special torques are not given NOTE: These values apply to fasteners as received from supplier, dry, or when lubricated with normal engine oil. They do not apply if special graphited or moly sidulphide greases or other extreme pressure lubricants are used. - Page 56 PART NO. 5RDO4081174A All Rights Reserved...

Need help?

Do you have a question about the SB1174 and is the answer not in the manual?

Questions and answers