Summary of Contents for Blastrac BG-250-230

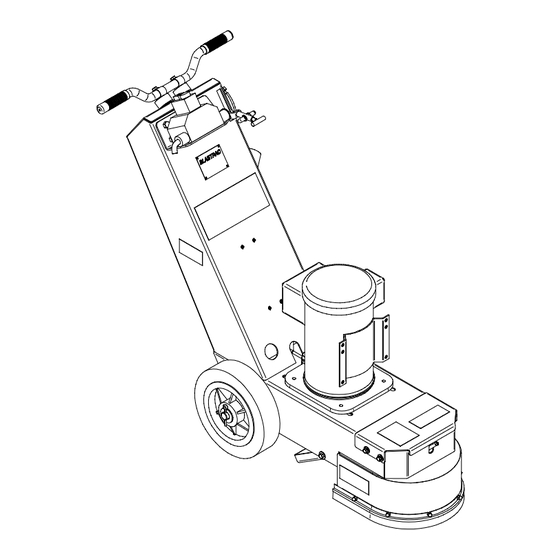

- Page 1 BG-250-230/60 Electric 230v, 1ph Concrete Grinder Blastrac 6215 N. Aluma Valley Dr. Oklahoma City, OK 73121 1-800-256-3440 © Copyright Blastrac Revision (A) 10-20-05...

- Page 2 Operating Instructions BG-250-230/60 Technical Data October 2005 Contents Chapter 1 1.1 Rating 1.2 Unit specifications 1.3 Operating range and correct usage 1.4 Machine type designation 1.5 Advice for operators of the machine © Copyright Blastrac Revision (A) 10-20-05...

-

Page 3: Rating

Tool diameter 10 in (250 mm) Working width 10 in (250 mm) Dust hose connection 3 in (75 mm) Recommended Dust Collector Blastrac® Turbo-Vac II or Blastrac 1-13DC Noise Level 78 DBA Vibration Level < 2,5 ms² © Copyright Blastrac... -

Page 4: Operating Range And Correct Usage

Weight 271 lbs (123 kg) 1.3 Operating range and correct usage The BG-250-230/60 is exclusively designed to grind horizontal surfaces. The machine may not be used for other purposes. The manufacturer will not be liable for damage or injury resulting from such incorrect usage. -

Page 5: Advice For Operators Of The Machine

Technical Data October 2005 1.5 Advice for operators of the machine When you use the BG-250-230/60 it is possible to exceed the maximum allowable sound level of 85 db(A). That sound level will vary depending on the location. If the sound level reaches 85 db(A) or more, the operator and the surrounding personnel must wear OSHA approved hearing protection. -

Page 6: Table Of Contents

Operating Instructions BG-250-230/60 Safety October 2005 Contents Chapter 2 2.1 Warnings and symbols 2.2 Organizational measures 2.3 Personnel selection and qualification 2.4 Safety precautions applicable to some operating sequences 2.5 Special work instructions 2.6 Definition of the Maintenance Mode 2.7 Possible dangerous aspects of the equipment 2.8 Electrical... -

Page 7: Warnings And Symbols

Operating Instructions BG-250-230/60 Safety October 2005 2.1 Warnings and symbols The following symbols are used in the Operating Instructions to highlight areas of particular importance: Symbol of operational safety. In these Operating Instructions this symbol will be shown next to safety precautions that are to be taken in order to increase safe operation of the machine. - Page 8 Operating Instructions BG-250-230/60 Safety October 2005 Information, instructions and restrictions with regard to possible risks to personnel and/or to extensive machine damage. © Copyright Blastrac Revision (A) 10-20-05...

- Page 9 Operating Instructions BG-250-230/60 Safety October 2005 Warning against dangerous voltages. Indications relating to protective devices in electrical appliances. Indications where consultation with manufacturer is required. Instructions relating to periodic checks. Reference to important instructions contained in the Operating Instructions. ©...

-

Page 10: Organizational Measures

Operating Instructions BG-250-230/60 Safety October 2005 .2 Organizational measures The Operating Instructions are to be kept near the machine all times. In addition to the Operating Instructions, general and legal regulation regarding acciden t prevention and environmental protection must be complied with. -

Page 11: Personnel Selection And Qualification

Operating Instructions BG-250-230/60 Safety October 2005 If safety-critical changes occur to the machine or its working method, the machine must be shut down immediately. The cause of the fault must be established immediately and corrected prior to further operation of the machine. -

Page 12: Safety Precautions Applicable To Some Operating Sequences

Operating Instructions BG-250-230/60 Safety October 2005 Personnel being trained on the equipment may only be deployed on the machine under constant supervision of an experienced person. Work on electrical equipment or operating materials may only be undertaken by a skilled electrician or by trained persons under the guidance and supervision of a skilled electrician as well as in accordance with the electrical engineering regulations. -

Page 13: Special Work Instructions

Operating Instructions BG-250-230/60 Safety October 2005 Before switching on the machine make sure that no-one can be endangered when the machine starts up. Do not switch off or remove the exhaust and ventilation devices when the machine is running. All persons in the proximity of the machine, when it is working, must wear ear protection and safety shoes. - Page 14 Operating Instructions BG-250-230/60 Safety October 2005 Always dispose of the contents of the dust bin of a possible connected dust collector used before loading it on van or truck. Observe the waste disposal regulations; if uncertain situation ask your supervisor.

-

Page 15: Definition Of The Maintenance Mode

Operating Instructions BG-250-230/60 Safety October 2005 2.6 Definition of the Maintenance Mode Definition: The machine is in a safe condition when it cannot generate any hazard. Putting the equipment in the Maintenance Mode means: Lift up the machine (see Chapter 5) Switch off the machine. -

Page 16: Possible Dangerous Aspects Of The Equipment

Operating Instructions BG-250-230/60 Safety October 2005 2.7 Possible dangerous aspects of the equipment Any machine, if it is not used according the regulations, may be hazardous for operating, setting-up and service personnel. The operating authority is responsible for compliance with the... - Page 17 Operating Instructions BG-250-230/60 General October 2005 Contents Chapter 3 3.1 Range of application 3.2 Scope of supply 3.3 Description of the machine 3.4 Operating elements 3.5 The tools 3.6 Care and maintenance © Copyright Blastrac Revision (A) 10-20-05...

-

Page 18: Range Of Application

Blastrac Operating Instructions The dust collector you have chosen for your machine ensures nearly dust free operation and also improves machine and tool life. Blastrac uses specially designed dust collection systems with high separation efficiency, thus extending the life of the machine components. -

Page 19: Operating Instructions

Driving motor Brush seal (see Fig 3.4) The Blastrac grinding machine BG-250-230/60 can produce a pattern of 10 inches (250 mm) and distinguishes itself by its high economic efficiency and easy handling. The machine levels uneven and undulating floors, therefore is also suitable for optimisation of surfaces before blasting. -

Page 20: Operating Elements

Handgrip and Jack Stand Operating lever Fig. 3.2 Before Switching on the BG-250-230/60, the front part of the grinding machine must be lifted by pushing down on the handgrip (2) and pulling back on the jack stand operating lever (1). When the machine has started, retract the jack stand and slowly lower the disc to the work surface. - Page 21 Grab handle with one hand and depress “On” button with free hand. Emergency Stop switch Pressing this switch immediately interrupts the power supply of the machine. This red button can also be used as an OFF switch. © Copyright Blastrac Revision (A) 10-20-05...

-

Page 22: The Tool

Operating Instructions BG-250-230/60 General October 2005 3.5 The Tools Fig. 3.4 Brush seal Flexible-Coupling Diamond grinding disc Bearing-Unit Adapter Jack stand Spacer © Copyright Blastrac Revision (A) 10-20-05... -

Page 23: Care And Maintenance

Contact Blastrac with any questions regarding the operation or maintenance of the machine. Never operate the machine if you are unsure. Be sure the BG-250-230/60 is clean and free of any debris before operating. Turn off the machine and check the cleanliness periodically and clean if necessary. - Page 24 Operating Instructions BG-250-230/60 Transport October 2005 Contents Chapter 4 4.1 Unit specifications 4.2 Manual mode of moving the machine 4.3 Transport with cranes or lifts 4.4 Transport of the machine with vehicle © Copyright Blastrac Revision (A) 10-20-05...

- Page 25 Now you can move the machine to the new position. The machine will be transported after being separated into: • Grinding machine • Dust collector unit (Turbo Vac II or 1-13 DC) • General accessories © Copyright Blastrac Revision (A) 10-20-05...

- Page 26 (2) Sling under wheel axle between wheel and chassis (3) sling under wheel axle between wheel and chassis on other side of machine Lift the load slowly and make sure it is stable before transporting. © Copyright Blastrac Revision (A) 10-20-05...

- Page 27 Enclosed trailers or vehicles may be dangerous due to the gasoline present in the machine. Be aware of fumes that may exist in transport and storage. These fumes may present a fire hazard if exposed to extreme heat, spark or open flame. © Copyright Blastrac Revision (A) 10-20-05...

- Page 28 Operating Instructions BG-250-230/60 Initial Operation October 2005 Contents Chapter 5 5.1 Preparation for initial operation 5.2 Initial operation © Copyright Blastrac Revision (A) 10-20-05...

- Page 29 The operator/owner is responsible for compliance with the safety regulations during operation and maintenance of safety devices supplied with the machine as well as the provision of appropriate additional safety devises. © Copyright Blastrac Revision (A) 10-20-05...

- Page 30 Handgrip and Operating lever Fig. 5.1 Before Switching on the BG-250-230/60, the front part of the grinding machine must be lifted by pushing down on the handgrip (2) and pulling back on the operating lever (1). Pulling back on the operating lever (1) will lower the kick stand and take the weight off the grinding disc.

-

Page 31: Initial Operation

See “Handgrip and Operating Lever” and make sure the diamond disc is off the ground and the machine is secure before starting. Verify all electrical connections are made and surrounding area is clear. Grab handle with one hand and depress “On” button with free hand. © Copyright Blastrac Revision (A) 10-20-05... - Page 32 (2) and pulling back on the operating lever (1). Pulling back on the operating lever (1) will lower the kick stand and take the weight off the grinding disc. Push E-stop (3). Figure 5.4 © Copyright Blastrac Revision (A) 10-20-05...

- Page 33 Operating Instructions BG-250-230/60 Initial Operation October 2005 Notes © Copyright Blastrac Revision (A) 10-20-05...

- Page 34 Operating Instructions BG-250-230/60 Operation October 2005 Contents Chapter 6 6.1 Operation 6.2 Switching-off the machine 6.3 Emergency Shutdown 6.4 Safety shutdown 6.5 Restarting after a fault 6.6 Procedures after lengthy down time © Copyright Blastrac Revision (A) 10-20-05...

- Page 35 A regular inspection is necessary to prevent downtimes of your grinding machine. See chapter 7 "Maintenance". Pay attention to following aspects during operation of the Blastrac Grinding machine BG-250-230/60 • Before beginning daily grinding work, be sure all fasteners are tight and secure.

- Page 36 BG-250-230/60 Operation October 2005 The normal start up of the Blastrac BG-250-230/60 in the daily operation does not differ from the described process in chapter 5.2 "Initial operation". Fig. 6.1 (Electric BG 250 shown) After connecting the suction tube to the air intake (2) of the machine, you can treat the surface as described in the following.

- Page 37 CG-1020DBT These diamond grinding discs are specially designed to be use on the concrete surfaces. For questions about your application, please contact your local Blastrac representative. Some blades are available in a variety of segment hardnesses. Segment hardness may be matched to specific jobs resulting in successful applications and improved diamond life.

- Page 38 Before carrying out inspection or maintenance work make sure that all turning machine parts are stopped. Observe the "Maintenance Mode” condition, chapter 2.6. Read and understand the entire Blastrac Operating Instructions before operating or servicing this machine. Do not depend on individual chapters for all safety and operating procedures.

- Page 39 6.6 Procedures after lengthy down time Steps before storage If the Blastrac grinding machine will be stored for a long period or time, follow the below steps: Rest the machine onto the kick stand so that the brush seals and the flexible coupling are not touching the floor.

- Page 40 7.2 Maintenance and inspection list 7.3 Repairing 7.4 Grinding disc replacement / assembly 7.5 Bearing-Unit 7.6 Flexible coupling 7.7 The V-Belt drive 7.8 The driving motor 7.9 Additional maintenance 7.10 Spare parts 7.11 Influences on the grinding pattern © Copyright Blastrac Revision (A) 10-27-05...

- Page 41 Our specialists will be happy to assist you with more advice. Follow additional operating and maintenance of OEM if included during your service and maintenance work. Pay attention to special notice given by instructions for electric-motors or combustion engines. © Copyright Blastrac Revision (A) 10-27-05...

- Page 42 • Check the tension of the V-belt, tension again if necessary. • Check the brush seal • Lubricate the bearing-unit and the Quarterly (Monthly) castor. • Replace the flexible coupling • Full overhaul and cleaning of the Annually complete machine. © Copyright Blastrac Revision (A) 10-27-05...

- Page 43 As already mentioned in Chapter 5 “Initial operation” we recommend executing the first repair work on the machine under the supervision of Blastrac personnel. You should stock all spare or wear parts that cannot be supplied quickly. As a rule, downtime is more expensive than the cost for the corresponding spare part.

- Page 44 Remove the block (2) and tilt the machine forwards. When replacing the grinding disc (4), also check the condition of the coupling and the grinding disc adapter (5). Always replace the worn screws (7). © Copyright Blastrac Revision (A) 10-27-05...

- Page 45 (3). Finally wipe the excess of grease with a cleaning cloth (machine in Maintenance Mode). Blastrac recommends using grease that is appropriate for a temperature range between 77-270° F (25-130 ° C). Most lithium based greases will be appropriate. Consult the label for temperature range.

- Page 46 2 Unscrew the hexagonal head screws (7) and the nuts fitted at the bearing-unit (2). Check the condition of the screws (4) and of the spacer tubes (6). Always replace all worn or damaged parts. © Copyright Blastrac Revision (A) 10-27-05...

- Page 47 V-belt. Collection of dirt due to oil, grease or chemicals must be avoided. In order to get perfect power transmission the V-belt drive has to be checked regularly. Fig. 7.4 (electric unit shown) © Copyright Blastrac Revision (A) 10-27-05...

- Page 48 Hand tighten the motor fastening screws. Stretch the belt tension with the tensioning screw attached to the motor base. (Note the max permissible tension according to Fig. 7.6). Tighten the motor fastening screws Screw on the cover. © Copyright Blastrac Revision (A) 10-27-05...

- Page 49 7.8 The driving motor The motor is designed for a long working life. In case of malfunction of the motor, please contact Blastrac. If the malfunction can not be repaired, please inform the Blastrac service center. © Copyright Blastrac Revision (A) 10-27-05...

- Page 50 Apply oil on the adjusting pin of the kick stand operating lever and other moving parts at regular intervals. 7.10 Spare Blastrac recommends having the following spare parts on stock to avoid long down times. Part No. Description Qty.

- Page 51 Operating Instructions BG-250-230/60 Maintenance October 2005 Notes © Copyright Blastrac Revision (A) 10-27-05...

- Page 52 Operating Instructions BG-250-230/60 Electrical October 2005 Contents Chapter 8 8.1 Directions for electrical engineering 8.2 Electric circuits diagrams © Copyright Blastrac Revision A 10-27-05...

- Page 53 Order the electric items with reference to the circuit diagrams in Section 8.2 or call a Blastrac service center. © Copyright Blastrac Revision A 10-27-05...

- Page 54 Operating Instructions BG-250-230/60 Electrical October 2005 8.2 Wiring Schematic © Copyright Blastrac Revision A 10-27-05...

- Page 55 Operating Instructions BG-250-230/60 Troubleshooting October 2005 Contents Chapter 9 9.1 Grinder troubleshooting 9.2 Electrical troubleshooting © Copyright Blastrac Revision (A) 10-27-05...

- Page 56 Inappropriate grinding tool Replace the grinding tools with for the application appropriate grinding tools for the surface to be treated V-belt tension low Tension the V-belt © Copyright Blastrac Revision (A) 10-27-05...

- Page 57 Remedy Motor does E-Stop depressed Pull out E-Stop not start Cables not correctly Verify proper connection to site connected to site power. power. Site power not turned on. Verify site power is turned on. © Copyright Blastrac Revision (A) 10-27-05...

-

Page 58: Spare Parts

Operating Instructions BG-250-230/60 Spare Parts October 2005 Contents Chapter 10 10.1 Spares Parts List BG-250-230/60 © Copyright Blastrac Revision (A) 10-27-05... - Page 59 Operating Instructions BG-250-230/60 Spare Parts October 2005 © Copyright Blastrac Revision (A) 10-27-05...

- Page 60 Operating Instructions BG-250-230/60 Spare Parts October 2005 © Copyright Blastrac Revision (A) 10-27-05...

- Page 61 Operating Instructions BG-250-230/60 Spare Parts October 2005 © Copyright Blastrac Revision (A) 10-27-05...

- Page 62 Operating Instructions BG-250-230/60 Spare Parts October 2005 © Copyright Blastrac Revision (A) 10-27-05...

- Page 63 SCR/CAP HEX 0.312-18 X 1.000 500114 WASHER/LOCK 5/16" 5001040 WASHER/FLAT 3/8" 5007670 SCR/CAP HEX 0.375-16 X 1.000 P000008 DECAL / BLASTRAC 4-3/8" X 10-1/2" WHITE/CLEAR 05-65643 DECAL/WARNING-EYE AND EAR PROTECTION SHEAVE 2GR3V 5.6-1610 TAPERLOCK (DODGE P/N P004015 112195) 6300025 BUSHING/1610 x 1.125" DIA. T/L...

- Page 64 PLUNGER (BOLT) P004055 851-0031 ELEC. ENCLOSURE BRACKET BG-250 230V 1PH 6956420 SCR/CAP HEX 0.500-13 X 1.000 G 8 STL P004057 MOTOR/ELECTRIC 230V 1PH 5HP 5001020 WASHER/FLAT 1/4" 05-72000 NUT/HEX NYLOC 1/4"-20UNC P004054 851-0027 HOSE/DUST © Copyright Blastrac Revision (A) 10-27-05...

- Page 65 Operating Instructions BG-250-230/60 Spare Parts October 2005 Notes © Copyright Blastrac Revision (A) 10-27-05...

Need help?

Do you have a question about the BG-250-230 and is the answer not in the manual?

Questions and answers