Summary of Contents for Weber MPE 750 Turbo Marine

- Page 1 Service Manual MPE 750 Turbo Marine Closed Loop MPE 750 Turbo Marine - Closed Loop This service manual is valid for the following engine variants: • 103160_MPE 750 Marine SO Closed Loop 3.1 103160_SHB_Rev2.1_080611...

-

Page 2: Table Of Contents

Service Manual MPE 750 Turbo Marine Closed Loop Table of contents About this document Meaning of the symbols in the text Safety Basic principle Meaning of the safety symbols General safety instructions Description Technical specifications Serial number Operating materials Running in the engine... -

Page 3: About This Document

Service Manual MPE 750 Turbo Marine Closed Loop About this document This chapter will familiarize you with the structure of this document so that you can find the information it contains quickly and easily. This document uses symbols and signs that allow you to find information quickly. Please read the explanations of the symbols and signs in this chapter. -

Page 4: Safety

Service Manual MPE 750 Turbo Marine Closed Loop Safety Basic principle This engine is state-of-the-art and built according to recognized safety-technical regulations. Nevertheless, people can be injured or the engine damaged if the safety instructions in this manual are disregarded. -

Page 5: General Safety Instructions

Service Manual MPE 750 Turbo Marine Closed Loop General safety instructions The engine may only be operated at idle speed for a maximum of 30 seconds without sea water. Engine damage due to overheating. ATTENTION See Chapter Operating the engine without sea water. -

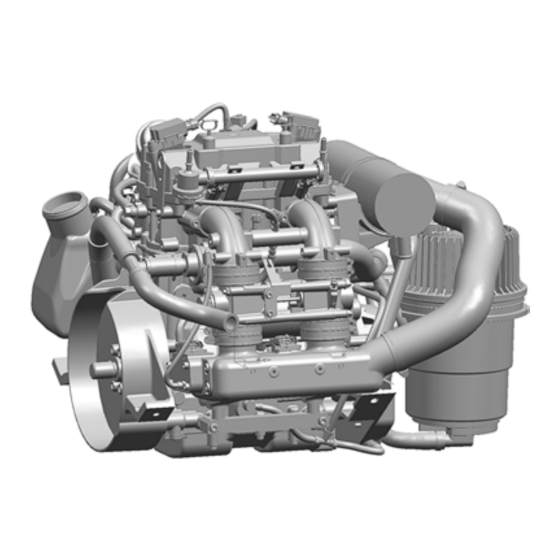

Page 6: Description

MPE 750 Turbo Marine Closed Loop Description The MPE 750 Turbo Marine - Closed Loop is a 2-cylinder in-line engine. It is intended for recreational watercraft. It is not designed for constant loads at high speeds as can occur during races, for example. -

Page 7: Operating Materials

Service Manual MPE 750 Turbo Marine Closed Loop Operating materials The use of other operating materials causes damage to the engine and the voiding of the warranty. ATTENTION Fuel Fuel quality Unleaded gasoline according to DIN 51607 („super unleaded“), with an octane rating of at least 95 ROZ [RON] or 85 MOZ [MON]. - Page 8 Service Manual MPE 750 Turbo Marine Closed Loop Coolant Coolant additive Coolant additive based on ethylene glycol Silicate- and nitrite-free. Suitable for aluminium engines. Anti-freeze mixture 50 % water + 50 % coolant additive Manufacturer’s fill provides frost protection up to -37 °C [-34.6 °F] Recommended minimum frost protection up to -30 °C [-22 °F]...

-

Page 9: Running In The Engine

MPE 750 Turbo Marine Closed Loop Running in the engine Weber Automotive GmbH recommends that during the first five hours of operation, you should not operate the engine over 6,000 U/min [RPM]. This protective running-in has a positive effect on the engine‘s lifespan. -

Page 10: Maintenance

Weber Motor service stations or in associated shops. If necessary, contact your vehicle dealer. Weber Automotive GmbH reserves the right to demand that proof of warranty be provided in writing for warranty service. See Proof of maintenance for work carried out. -

Page 11: Maintenance Work By The User Of The Vehicle

Start engine and operate only in idle. Do not accelerate. Ensure the water supply within 30 seconds. See Chapter Operating the engine without sea water. The Weber Automotive GmbH recommends to flush the sea water cooling circuit for one minute minimum. Discontinue water supply. -

Page 12: Maintenance Intervals

Service Manual MPE 750 Turbo Marine Closed Loop Maintenance intervals Activities on the engine must be carried out by trained service personnel. mainte- nance Maintenance interval after 25 every 50 every 100 Motor oil and oil Change ■ ■ ■... -

Page 13: Decommissioning At The End Of The Season

Service Manual MPE 750 Turbo Marine Closed Loop Decommissioning at the end of the season The decommissioning of the vehicle is necessary ..at the end of the season if the vehicle will be decommissioned during the winter months. -

Page 14: Motor Oil And Oil Filter

Service Manual MPE 750 Turbo Marine Closed Loop Motor oil and oil filter Oil level check Use a clean, lint-free cloth The oil level must be measured with oil warm from operation (approx. 80 °C [176 °F]) and with the motor at a standstill. Measurements with cold oil are not meaningful. - Page 15 Service Manual MPE 750 Turbo Marine Closed Loop Oil level check (continuation) Unscrew the oil dipstick (1) from the oil tank and wipe it clean with a cloth. Replace the oil dipstick in the oil tank. Do not screw it in. Then remove it again and read the oil level.

-

Page 16: Draining The Motor Oil

Service Manual MPE 750 Turbo Marine Closed Loop Changing the motor oil and oil filter Oil extraction pump Catch basin for old oil, fill volume at least 4 liters [4.3 qt (US)] Flathead screwdriver or wrench to open the screw clamps Torque wrench to close the screw clamps Torque wrench SW27 [1 1/16 “] for oil filter cover... - Page 17 Service Manual MPE 750 Turbo Marine Closed Loop Draining the motor oil (continuation) The motor oil in the dry sump tank is pumped out with the help of the engine dry sump pump. Remove the cable harness from the spark plugs and the injection valves.

-

Page 18: Changing The Oil Filter

Service Manual MPE 750 Turbo Marine Closed Loop Changing the oil filter Remove the screw clamp and sea water hose (3). Tightening torque: 3 Nm ± 10 % [2.2 ft. lb.] Unplug the plug from switch 70/65°C (4). Unscrew the oil filter cover (5). - Page 19 Service Manual MPE 750 Turbo Marine Closed Loop Changing the oil filter (continuation) Replace the oil filter (6) and O-ring (7). Coat the O-ring (7) lightly with motor oil. During reassembly, make sure that the oil filter snaps in. Assembly occurs in reverse order. Please note instructions after this symbol 103160_SHB_Rev2.1_080611...

-

Page 20: Refilling The Motor Oil

Service Manual MPE 750 Turbo Marine Closed Loop Refilling the motor oil Fill oil tank with 2.5 liters of motor oil. Close the oil tank with the oil dipstick. Warm up the motor in a body of water for approx. 10 minutes at 4000 - 4500 U/min. -

Page 21: Engine Cooling Circuit

Service Manual MPE 750 Turbo Marine Closed Loop Engine cooling circuit Coolant level check Check the coolant level with a cold engine. With a cold engine, the coolant level should be between the MIN and MAX markings (1) of the compensation tank. -

Page 22: Changing The Coolant

Service Manual MPE 750 Turbo Marine Closed Loop Changing the coolant Catch basin for the coolant, fill volume at least 4 liters [4.3 qt (US)] Torque wrench SW19 [47/64 “] (screw) Flathead screwdriver or wrench to open the screw clamps... - Page 23 Service Manual MPE 750 Turbo Marine Closed Loop Draining the coolant (continuation) Loosen the screw and gaskets (2). Both gaskets must be replaced. Tightening torque: 40 Nm ± 10 % [29.5 ft. lb.] Remove screw clamps, hoses (3) on both sides and drain coolant.

-

Page 24: Refilling The Coolant

Service Manual MPE 750 Turbo Marine Closed Loop Refilling the coolant Open the cover of the compensation tank. See Chapter Draining the coolant. Add new coolant up to the MAX marking compensation tank. See Chapter Coolant level check. Close the cover of the compensation tank. -

Page 25: Spark Plugs

Service Manual MPE 750 Turbo Marine Closed Loop Spark plugs Checking the spark plugs Socket wrench SW16 [5/8 “] Feeler gauge, measurement range 0.69 mm - 0.84 mm [0.0272 - 0.0331 in.] Torque wrench 2x spark plugs, see spare parts catalogue... - Page 26 Service Manual MPE 750 Turbo Marine Closed Loop Removing the spark plugs (continuation) Remove the screws and washers (4). Remove the ignition coils (5) Install the spark plugs only in a cold engine. Grease the threads of the spark plugs with commercial graphite grease.

-

Page 27: Checking The Spark Plugs

Service Manual MPE 750 Turbo Marine Closed Loop Checking the spark plugs Check the electrode distance of the spark plugs with the help of the feeler gauge. 0,69 - 0,84 mm [0.0272 - 0.0331 in.] 103160_SHB_Rev2.1_080611 Page 25... -

Page 28: Valve Play

Service Manual MPE 750 Turbo Marine Closed Loop Valve play Checking and setting the valve play Hex wrench SW5 [3/16 “] Feeler gauge, measurement range 0.08 mm - 0.25 mm [0.0031 - 0.0098 in.] Valve adjustment tool, see spare parts catalogue Combination wrench 24mm [15/16 “]... - Page 29 Service Manual MPE 750 Turbo Marine Closed Loop Removing the valve cover (continuation) Unscrew the valve cover (2) along with bracket and valve (3). Tightening torque: 10 Nm ± 10 % [7.4 ft. lb.] The sequence of the connection occurs according figure.

- Page 30 Service Manual MPE 750 Turbo Marine Closed Loop Desmontar la tapa de válvula Checking the valve play of the first cylinder Start the vehicle’s starter and let Exhaust side the engine crank until both cams of the second cylinder are pointing upwards.

-

Page 31: Adjusting The Valve Play

Service Manual MPE 750 Turbo Marine Closed Loop Adjusting the valve play To adjust the valve play on the intake side, it is necessary to remove the fuel distributor rail. Remove the cable harness on the coolant sensor (7). Loosen the screws and washers (8) and remove the fuel distributor rail (9). - Page 32 Service Manual MPE 750 Turbo Marine Closed Loop Adjusting the valve play (continuation) Replace the O-rings (9) on the injector valves. Coat the O-rings lightly with motor oil. Mount the valve adjustment tool (11) with two screws. Tightening torque: 10 Nm ± 10 % [7.4 ft. lb.] The engine may not be turned over until all valve plays of the first cylinder are adjusted.

- Page 33 Service Manual MPE 750 Turbo Marine Closed Loop Adjusting the valve play (continuation) Press the rocker downwards with a 24 combination wrench (12). Clamp both valves by pressing in the sliding piece (13). Remove the adjustment plate with the bar magnet.

-

Page 34: Malfunctions

If you cannot correct a malfunction yourself using the table below, contact your vehicle dealer‘s customer service. In case of improperly-made repairs, the warranty is voided and Weber Automotive GmbH is not liable for any resulting subsequent damage. Engine does not crank... - Page 35 Service Manual MPE 750 Turbo Marine Closed Loop Engine cranks but does not start Possible cause Remedy Lanyard not plugged in. Plug in lanyard. Defective fuse. Check the fuses in the cable harness. Too little or no fuel in the tank.

- Page 36 Service Manual MPE 750 Turbo Marine Closed Loop Engine stalls and cannot be started again Possible cause Remedy Lanyard not plugged in. Plug in lanyard. Defective fuse. Check the fuses in the cable harness. Too little or no fuel in the tank.

- Page 37 Service Manual MPE 750 Turbo Marine Closed Loop Engine loses power (speed limitations) Fault Possible cause Remedy Engine does not accept Control unit Reset control unit: Plug in lanyard. gas. Throttle Unplug and plug main relay into the cable harness. Wait at least a minute before starting the engine again.

- Page 38 Service Manual MPE 750 Turbo Marine Closed Loop Fault Possible cause Remedy Engine speed limited to Engine DO NOT LET THE ENGINE RUN 3000 U/Min [RPM] and overheating. LONGER THAN 30 SECONDS. the water temperature Check the coolant level. See Chapter warning lamp lights up.

-

Page 39: Terminology

Service Manual MPE 750 Turbo Marine Closed Loop Terminology Adjusting the valve play 29 Serial number 4 Submerged engine 3 Changing the coolant 20 Changing the oil filter 16 Technical specifications 4 Checking the spark plugs 25 Checking the valve play 28... -

Page 40: Appendix

(USA family designation, adjusted to the model year annually) Directives Weber Automotive GmbH thus confirms that the construction of the engine corresponds to the following pertinent conditions: – EU directive about sport boats 94/25/EG with addendum 2003/44/EG – USA EPA Federal Register 40 CFR Part 91 –... -

Page 41: Exhaust Type Authorizations

Test number M 14 93 1 06 01 All originals are present and can be viewed at any time. They can be called up on the Internet at www.weber-automotive.com. Appendices to this service manual: „Declaration of Conformity for Recreational Craft Propulsion Engines“... -

Page 42: Proof Of Maintenance For Work Carried Out

Service Manual MPE 750 Turbo Marine Closed Loop Proof of maintenance for work carried out _ _ _ _ _ _ _ _ _ _ _________________ Motor - serial number (8-digit) Date of initial registration Work carried out: Work carried out:... - Page 43 Service Manual MPE 750 Turbo Marine Closed Loop Work carried out: Work carried out: Motor oil change Motor oil change Oil filter change Oil filter change Date: Date: Spark plug change Spark plug change Valve play checked Valve play checked...

Need help?

Do you have a question about the MPE 750 Turbo Marine and is the answer not in the manual?

Questions and answers