Bromic Heating Platinum 300 Service Manual

Radiant

Hide thumbs

Also See for Platinum 300:

- Installation, instruction and service manual (27 pages) ,

- Installation, instruction and service manual (55 pages)

Table of Contents

Advertisement

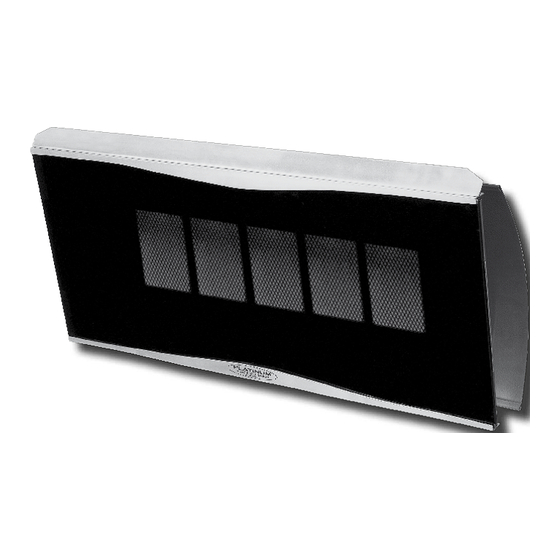

Platinum Smart-heat™

GaS heater

BY BrOmiC

InstallatIon, InstructIon and

servIce manual

SUITABLE FOR GAS RADIANT HEATER MODELS:

PLATINUM 300 - BURNER AND PLATINUM 500 - BURNER

If you smell gas:

1.

Shut o gas to the appliance

2.

Extinguish any open ame

3.

If odor continues, keep away from the

appliance and immediately call your gas

supplier or re department.

!

WARNING: For Outdoor or Amply

Ventilated area use and for NON

DOMESTIC INDOOR APPLICATION

Version 3.5 AUS

DANGER

!

WARNING

!

Do not store or use petrol or other amable vapor

and liquids in the vicinity of this or any other

appliance.

An LP-cylinder not connected for use shall not be

stored in the vicinity of this or any other appliance.

!

WARNING: Improper installation,

adjustment, alteration, service or maintenance

can cause property damage, injury or death.

Read the installation, operating and

maintenance instructions thoroughly before

installing or servicing this equipment.

Advertisement

Table of Contents

Summary of Contents for Bromic Heating Platinum 300

- Page 1 GaS heater BY BrOmiC InstallatIon, InstructIon and servIce manual SUITABLE FOR GAS RADIANT HEATER MODELS: PLATINUM 300 - BURNER AND PLATINUM 500 - BURNER DANGER WARNING Do not store or use petrol or other amable vapor If you smell gas: and liquids in the vicinity of this or any other appliance.

- Page 2 Email: info@bromicheating.com Web: www.bromicheating.com Note: Bromic Heating reserves the right to make changes to specifications, parts, components and equipment without prior notification. This Installation, operation and service manual may not be reproduced in any form with prior written consent from Bromic Heating. www.bromicheating.com...

-

Page 3: Table Of Contents

CONTENTS IMPORTANT NOTES & WARNINGS PRODUCT OVERVIEW PRODUCT DESCRIPTION SPECIFICATIONS GENERAL INFORMATION PRODUCT FEATURES INSTALLATION REQUIREMENTS GAS REQUIREMENTS INSTALLATION CLEARANCES INSTALLATION INSTRUCTIONS HEATER INSTALLATION INSTRUCTIONS GAS SUPPLY INSTALLATION POWER SUPPLY INSTALLATION LEAKAGE TEST OPERATING INSTRUCTIONS TURNING THE APPLIANCE ON TURNING THE APPLIANCE OFF SERVICING REGULAR SERVICE REQUIREMENTS EXTERIOR SERVICING... -

Page 4: Important Notes & Warnings

IMPORTANT NOTES AND WARNINGS excessive abrasion or wear, or if the hose is damaged. WarnInG • The replacement hose assembly must be AGA approved. • THIS APPLIANCE SHALL NOT BE INSTALLED OR USED • The hose assembly is not to be located in areas where IN RESIDENTIAL DOMESTIC INDOOR AREAS the hose may be subject to accidental damage. -

Page 5: Product Overview

The heaters have been designed to withstand the rigors of the outdoors and will operate effectively in high wind applications. sPecIFIcatIons PLATINUM Smart-Heat 300 PLATINUM Smart-Heat 500 Gas type NATURAL GAS NATURAL GAS Manufactured by BROMIC HEATING PTY LTD AGA Approval No. 7289 7289 7289 7289 Gas Consumption 25 MJ/hr 25 MJ/hr... -

Page 6: General Information

PRODUCT OVERVIEW CONTINUED... General InFormatIon The Platinum Smart-Heat Gas radiant heaters are suitable for outdoor and non-residential indoor spaces. In addition to the installation instructions provided, authorised installers must abide by the Australian installation code AS-5601-2010. Please note that these standards are subject to change. The heater is designed to function in winds up to 18Km/h. -

Page 7: Installation Clearances

INSTALLATION REQUIREMENTS CONTINUED... InstallatIon clearances When selecting the installation location for the Platinum Smart-Heat Heaters, the following mounting clearances should be followed. Care should be taken to ensure that the heater is not installed: • Where heat/ignition can cause damage to gas cylinders/ lines • Near other combustible materials • In open locations subject to rain... -

Page 8: Installation Instructions

INSTALLATION INSTRUCTIONS Heater InstallatIon InstructIons 2. Connect AGA approved Flexible Gas Connector (as supplied) to the inlet fitting on the heater using 2 wrenches to tighten. Leak Test by applying compressed WarnInG air (1/2” PSI) to open end of flexible hose. Spray gas fittings with a soapy water solution and Check for leaks. - Page 9 INSTALLATION INSTRUCTIONS CONTINUED... 4. Attach Heater to Wall Bracket/Control Housing 5. Connect the AGA approved flexible connector to the Gas Valve Outlet Fitting • Remove Front Cover from Control Housing • Position heater and hose so that the gas hose and • Attach Heater to Wall Bracket/Control Housing fitting are in alignment by inserting Mounting Arm into lower channel of...

- Page 10 INSTALLATION INSTRUCTIONS CONTINUED... • Insert Black Ignitor Cable directly into control box 6. Insert Pivot Bolt using 2.8mm spade connector, located on the side • Position Arm so that the rear hole’s on the mounting of the controller arm and Control Housing are in alignment • Insert Bolt and washer (as supplied) through Control Housing and Mount Arm, using the hole located on the bottom surface of the Control Housing, towards...

-

Page 11: Gas Supply Installation

INSTALLATION INSTRUCTIONS CONTINUED... 1. Connect gas inlet fitting to mains gas supply in accordance with local gas installation code and gas For White rodger supply installation section of manual. Leak test with • Insert Black Ignitor Cable directly into Control Box at soapy water. -

Page 12: Gas Supply Installation

INSTALLATION INSTRUCTIONS CONTINUED... Gas suPPlY InstallatIon PoWer suPPlY InstallatIon WarnInG ImPortant This heater is equipped with a three-prong (grounding) • All gas supply installation work must be performed by plug for your protection against shock hazard and should trained and authorized person(s) and comply with the be plugged directly into a properly grounded three-prong requirements of local Gas Installation Codes. - Page 13 INSTALLATION INSTRUCTIONS CONTINUED... washers (as supplied). 4. Fix Heater to Lower paddles using suitable fixtures. NOTE: Platinum Smart-Heat Heating recommends running power and gas lines, to the heater, inside the pole to reduce visibility and likelihood of damage. Heat-deFlector InstallatIon 1.

-

Page 14: Operating Instructions

OPERATING INSTRUCTIONS turnInG tHe aPPlIance on gas supply. 1. Ensure that gas installation and power installation has NOTE: The appliance must be completly shutoff for a period been carried out in accordance with the manufacturers of 5 minutes before being relighted. instructions outlined in this document. -

Page 15: Optimum Mounting Distance

ImPortant Do not apply any additional surface coating to the heater under any circumstances. Use of additional coating other than those applied during manufacture could result in hazardous reactions such as toxic fumes or fires. Additional coatings will void the warranty. OPTIMUM MOUNTING DISTANCE Model Model... - Page 16 OPERATION DATA - HONEYWELL CONTROL BOX CONTINUED... Directions for use Operation • Automatic controls are safety devices and shall not be At every start, the control unit proceeds to a self-checking opened. The manufacturer’s responsibility and guarantee of its own components. During the pre-purge or waiting are invalid if the control is unduly opened.

-

Page 17: Operation Data - Brahma Control Box

OPERATION DATA - BRAHMA CONTROL BOX The following operation sequence is valid only where the • A regulation shutdown must occur every 24hours to components are installed according to the manufactures enable the unit to check its own efficiency (systems for assembly and installation instructions. -

Page 18: Operation Data - White Rodgers Valve

OPERATION DATA - WHITE RODGER VALVE: The White Rodgers Gas Valve is a compact multi-functional TECHNICAL DATA control which incorporates an adjustable direct acting Max Working pressure 50 mbar pressure regulator. It is designed for quiet operation with Installation group Group 2 cushioned solenoid stops and operates on 220/240V. - Page 19 WIRING DIAGRAM - HONEYWELL CONTROL, HONEYWELL GAS VALVE ELECTRICAL DIAGRAM SEE INSTRUCTION MANUAL FOR DETAILS ON HOW TO CONNECT THE ELECTRICAL COMPONENTS. Ionisation Ignition + Brown 230 V Red 230 V Blue Blue HONEYWELL White Black Yellow/Green www.bromicheating.com...

-

Page 20: Wiring Diagram

WIRING DIAGRAM ELECTRICAL DIAGRAM SEE INSTRUCTION MANUAL FOR DETAILS ON HOW TO CONNECT THE ELECTRICAL COMPONENTS. Gas Valve Blue Orange Ignition + Ionisation Blue Purple Brown Black Brahma Control Box CE11U White Yellow/Green www.bromicheating.com... -

Page 21: Replacement Parts

REPLACEMENT PARTS White rodger honeywell www.bromicheating.com... - Page 22 REPLACEMENT PARTS DISCRIPTION No. Description Part No. 300 Series Part No. 500 Series Glass Retainer - Top 2620801 2620802 Glass Retainer - Bottom 2620803 2620804 Wind Kicker 2620805 2620806 Glass 2620807 2620808 Reflector Assembly 2620809 2620810 Glass Retainer Side 2620811 2620811 Side Shield 2620812...

-

Page 23: Post-Installation Report

FOR PLATINUM GAS RADIANT HEATERS aFter heater inStallatiOn PleaSe PhOtOCOPY, COmPlete, & SenD thiS rePOrt BY: FaX tO (02) 9748 4289 or BY mail tO Bromic heating Pty ltd, 1 Suttor Street, Silverwater nSW 2128 australia or SCan anD email tO info@bromicheating.com... -

Page 24: Troubleshooting

TROUBLESHOOTING SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION Heater will not turn on 1. No power 1. Have authorised electrician check 2. No gas power supply 2. Have authorised gas fitter check gas supply Heater turns on, but then cycles on 1. Insufficient flame on ionisation rod and off 2. -

Page 25: Appendix A

APPENDIX A www.bromicheating.com... - Page 26 APPENDIX A CONTINUED... www.bromicheating.com...

- Page 27 APPENDIX A CONTINUED... www.bromicheating.com...

-

Page 28: Warranty

WARRANTY Smart-Heating Warranty Conditions Bromic Pty Limited (‘Bromic’) warrants to the original purchaser (‘the Purchaser’) of products supplied by Bromic Heating (‘the Goods’) that the Goods will be free from defects and/or faults in materials and/or workmanship for Twelve (12) months from the date of Bromic invoice. Subject to the following conditions of this Warranty, if a defect and/or fault in materials and/or workmanship are found during the warranty period, Bromic will replace or repair the Goods (at its option) without charge. - Page 29 WARRANTY CONTINUED... 19. Bromic does not warrant the Goods where the Goods were installed and/or used in conjunction with goods of a supplier other than Bromic (‘the other goods’) in such a way as to exceed the capacity and/or performance capabilities of the Goods or the other goods and denies all liability for any damage whatsoever suffered by any person arising from such use.

- Page 30 25. All warranty enquiries and/or claims should be directed to Bromic’s Head Office via its postal address - P0 Box 6062 Silverwater NSW 1811 or by telephoning 1300 276 642 (within Australia) or sending a fax to +61 2 9748 4289. 26.

Need help?

Do you have a question about the Platinum 300 and is the answer not in the manual?

Questions and answers