Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Glunz & Jensen PlateWriter 2500

- Page 1 Operating Manual PlateWriter™ 2500/3000...

- Page 3 Operating Manual PlateWriter™ 2500/3000 T11296 Edition CE, December 2013 This book has part No 10055648...

- Page 4 This manual is published by: GLUNZ & JENSEN A/S Selandia Park 1 DK-4100 Ringsted Denmark Phone:+45 57 68 81 81 E-mail: gjhq@glunz-jensen.com Internet: www.glunz-jensen.com © 2010 Glunz & Jensen A/S. All rights reserved. Operating Manual - PlateWriter 2500/3000 1206...

-

Page 5: Table Of Contents

Loading plates on PlateWriter 2500 ........2-4... -

Page 6: Table Of Contents

Using more than one method........4-47 Enhanced file management and printing for Mac users ....4-47 Operating Manual - PlateWriter 2500/3000 1350... - Page 7 Indicator status and error codes ........5-3 1350 Operating Manual - PlateWriter 2500/3000...

-

Page 8: Table Of Contents

Table of contents Operating Manual - PlateWriter 2500/3000 1347... -

Page 9: Part 1: Introduction

The operator must observe and/or act according to the Caution information in order to avoid any mechanical or electrical damage to the equipment. The operator must observe and/or act according to the Warning information in order to avoid any personal injury. 1206 Operating Manual - PlateWriter 2500/3000... -

Page 10: Important

Before using the equipment it is assumed that it has been properly installed and con- • figured as described in the installation manuals delivered with the system. The manufacturer cannot be held responsible for any damage caused by incorrect • use of this equipment. Operating Manual - PlateWriter 2500/3000 1206... -

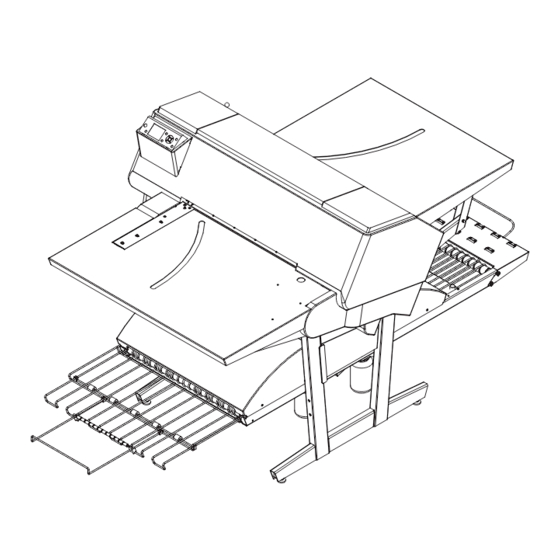

Page 11: The Platewriter System

An integrated plate finisher that executes all of the steps necessary to produce press-ready plates, e. g.: curing, gumming and drying of the plates after they are im- aged in the PlateWriter engine. T11312 1206 Operating Manual - PlateWriter 2500/3000... -

Page 12: Platewriter 2500 Overview

Gum dryer: dries the plate to provide a finished, dry plate. Plate exit tray: holds the finished plates. 10 Ink cartridges: the compartment contains 5 cartridges. 11 Water bottle: contains demineralised water for replenish of the gum. Operating Manual - PlateWriter 2500/3000 1206... - Page 13 22 USB-cable: connects the finishing unit with the RIP workstation. 23 Control cable: connects the print head protection with the finishing unit. 24 Status indicator LED: indicates the alignment of the plates and the temperature deviation of the print bed. 1350 Operating Manual - PlateWriter 2500/3000...

-

Page 14: Platewriter 3000 Overview

13 Side register: ensures that plates are aligned correctly prior to entering the imaging unit. 14 Front register: ensures that plates are aligned correctly prior to entering the imaging unit. 15 Exit tray extension. Operating Manual - PlateWriter 2500/3000 1206... - Page 15 26 USB-cable: connects the finishing unit with the RIP workstation. 27 Control cable: connects the print head protection with finishing unit. 28 Status indicator LED: indicates the alignment of the plates and the temperature deviation of the print bed. 1350 Operating Manual - PlateWriter 2500/3000...

- Page 16 Introduction PlateWriter 3000 overview Operating Manual - PlateWriter 2500/3000 1206...

-

Page 17: Part 2: Daily Use

(3) with fresh finisher solution. " Half a bottle is sufficient. Empty the waste ink bottle (4) if it is full. • Refill the water bottle (5) with demineral- • ised water if it is empty. T11241 1206 Operating Manual - PlateWriter 2500/3000... - Page 18 The unit will run gum fluid through the system for approximately three minutes to • ensure an even gumming of the plates. T11243 T11244 Switch on the PlateWriter by pressing the button. • The PlateWriter initializes and when finished, the display shows ”READY”. • Operating Manual - PlateWriter 2500/3000 1206...

-

Page 19: Making A Proof

Print. The file will be ripped and will appear in the Active Queue of the Output Moni- • tor/Controller window. Uncheck Disable Output in the Output Controller/Monitor window. The proof will • be printed. 1206 Operating Manual - PlateWriter 2500/3000... -

Page 20: Making Plates

Save the file to a folder, either on the computer running Navigator RIP or on a server. • Loading plates on PlateWriter 2500 The input table ensures that plates are fed into the printer correctly. The side register rollers enable correct and easy alignment prior to entering the printer. -

Page 21: Loading Plates On The Platewriter 3000

If LED lights red or is off, repeat the procedure again. " LED flashes green even before the plate is inserted. This indicates deviation in temperature on the print bed. When less than 3 flashes, then the temperature is ready to image plates. 1206 Operating Manual - PlateWriter 2500/3000... -

Page 22: Adjusting The Printer Exit Wheel Guide

Press the button and slide the rollers to make it fit the edges of the plate. • T11314 " Remember to adjust the printer exit wheel guide every time the plate size is changed. Operating Manual - PlateWriter 2500/3000 1206... -

Page 23: Imaging The Plate

Select your file and click on Info. • The ThroughPut Info window appears. • Be sure that Change all pages in job is checked. • 1350 Operating Manual - PlateWriter 2500/3000... - Page 24 For subsequent plates, make sure that Disable Output is checked, load a plate into • the PlateWriter, drag one separation from the Held Queue to the Active Queue, and then uncheck Disable Output. Operating Manual - PlateWriter 2500/3000 1206...

-

Page 25: Finishing

300 mm or approx. two minutes between every 4-8 plates in order for the gum replenish system to work properly. When the plate is cured and finished then • it appears on the exit tray (6). T11248 1206 Operating Manual - PlateWriter 2500/3000... -

Page 26: Daily Shut-Down

(5) Cut button - make sure that this is set to the sheet mode. Otherwise the roll mode or roll mode with cutter will not work. (6) Secure button - this button is used to activate the registration system. Use this button to load and release the plate. Check Menu Operating Manual - PlateWriter 2500/3000 1347... -

Page 27: Part 3: Cleaning And Maintenance

Topping up the gum/finisher solution (daily) • Replacing the gum/finisher solution (weekly) • Running the gum rinse program (weekly) • Cleaning of the gum/finisher rollers (monthly) • For more information about cleaning and maintenance see the Maintenance Chart. 1206 Operating Manual - PlateWriter 2500/3000... -

Page 28: Inks And Fluids

The Cleaning Fluid is also used for dripping in and wetting the head cap to prevent the ink from drying out the ink pump system. Operating Manual - PlateWriter 2500/3000 1206... -

Page 29: Replacing The Ink Cartridges

1 gram. Cartridges can then be weighed before and after the ink charge giving a more precise indication of the amount of fluid that has been charged. 1347 Operating Manual - PlateWriter 2500/3000... - Page 30 Move the small label supplied with each cartridge and place in inside the ink cover lid. This is to mark which slots have Liquid Dot cartridges and which has Maintenance Fluid cartridges for later reference. Operating Manual - PlateWriter 2500/3000 1350...

-

Page 31: Other Printer Cleaning Tasks

Wipe the operating panel and LCD display gently with a clean, soft cloth. • Do NOT put wet plates back in the printer. This will cause the image to transfer to the rollers and on every subsequent plate! T11313 1347 Operating Manual - PlateWriter 2500/3000... -

Page 32: Cleaning The Printer Ink System

(then the carriage unit moves and the wiper cleaner assy moves to the replacement position). Open the top cover and then open the • service hatch by removing the 2 finger screws. Operating Manual - PlateWriter 2500/3000 1347... - Page 33 Moisten a cleaning stick with the WB Cleaning Fluid and then clean the head cap • seal (rubber lip). Also gently clean the foam inside each top cap for any residue of ink if needed. 1347 Operating Manual - PlateWriter 2500/3000...

- Page 34 Cleaning and maintenance Other printer cleaning tasks T11122 Operating Manual - PlateWriter 2500/3000 1347...

-

Page 35: Additional Printer Settings And Check

• plate by sliding into place as shown, the left side is magnetic and snaps into posi- tion. You can also remove the covers of the curing oven and gum dryer for easier access. 1347 Operating Manual - PlateWriter 2500/3000... -

Page 36: Cleaning Of Gum/Finisher Rollers

Reinstall all parts in reverse order, making sure that the bearings (4) click properly • into place. Cleaning the finishing unit body Use a cloth moistened with water then wrung well, and wipe gently to clean all surfaces and conveyor belts. Operating Manual - PlateWriter 2500/3000 1347... -

Page 37: Gum/Water Replenishing System

If there is less than 25% gum remaining in the bottle when commencing work with the printer in the morning, it is a good idea to top up. 1347 Operating Manual - PlateWriter 2500/3000... - Page 38 Cleaning and maintenance 3-12 Finishing unit Operating Manual - PlateWriter 2500/3000 1347...

-

Page 39: Part 4: Using The Rip

- which in this case is either the PlateWriter 2500, PlateWriter or a proofing device. In general, a software application or hardware device that performs this task is known as ®... -

Page 40: Basic Concepts And Definitions

PM1414HD 2Ch HDMW14 and the iScreen2 screening. For proofing we have enabled the RIP to support Epson 4800, 4880, 7800, 7880, 9800 and 9880 printers. Within the Config dialogue box for each proofing device are Operating Manual - PlateWriter 2500/3000 1347... - Page 41 Tone Curves: are used to adjust dot gain further (they can be used to create a cooler • looking image, or to create more saturated images). No tone curves are installed with the Glunz & Jensen factory default, these can be • generate by the user. 1325 Operating Manual - PlateWriter 2500/3000...

-

Page 42: Setting Up Devices

There can be circumstances where files arrive in a format where incorrect colours have been used and you want the RIP to override the separations. A more extensive explanation is found in the Xitron RIP Manual. Operating Manual - PlateWriter 2500/3000 1325... - Page 43 Creating Separation Styles When opening the Separations Manager window there will be separation styles al- • ready entered if the factory default has been used or when the RIP is started first time. Click on New. 1325 Operating Manual - PlateWriter 2500/3000...

- Page 44 If you select Yes, all separations will be produced, even if they are blank. If you want SPOT colours to be printed, then set Other colours in job to Yes or Not Blank as well. Operating Manual - PlateWriter 2500/3000 1325...

- Page 45 Leave the Generate extra gray levels box unchecked. • Click OK in the Edit Style dialogue. • Now your style will appear in the list in the Separations Manager dialogue. • Click OK to save the changes. 1325 Operating Manual - PlateWriter 2500/3000...

-

Page 46: Creating Page Setups For Platemaking

To make things easier, if you printed the Glunz & Jensen factory default file as described earlier, then it will have already installed some separations styles for you. Select Navigator -> Page Setup Manager from the Navigator RIP menu. • Operating Manual - PlateWriter 2500/3000 1325... -

Page 47: Creating Page Setups

Page Setups loaded by the Glunz & Jensen factory default file, see the section “Duplicating and editing a Page Setup” on page 4-30. Creating Page Setups Select Navigator -> Page Setup Manager from the Navigator RIP menu. • 1347 Operating Manual - PlateWriter 2500/3000... - Page 48 In the Output Device section select the device PM1414HD and check that the values • in the Resolution section change to 1400 x 1400. Click on the Configure device button in the Output Device section. • Operating Manual - PlateWriter 2500/3000 1325...

- Page 49 The configuration window for the PlateWriter plug-in opens. • The screenshot shows the set up as made by the Glunz&Jensen factory default file. • This may be altered as described on the following pages. Click OK to continue. • 1350 Operating Manual - PlateWriter 2500/3000...

-

Page 50: Platewriter Plug-In Functionality

Windows system. In Port window select the printer to use. File window is currently not enabled. Printing to a file is still possible by setting up a printer in windows, which prints to file. Operating Manual - PlateWriter 2500/3000 1350... -

Page 51: Margins

10 files for the standard head height. Each of the 10 files will print using a different printing row. Select a file which prints using the correct head height as well as from a printing row which is currently used. E.g. BidirNarrowPK1.prn or BidirStandardY1.prn. 1350 Operating Manual - PlateWriter 2500/3000... - Page 52 Read the bidirectional setting to the left of the row. For further information please refer to the Hardware Installation manual. " Bi-directional printing is disabled on the PlateWriter 2500. Plate Vacuum % The vacuum on the plate during transportation and printing can be set in a range from 0 –...

-

Page 53: Imaging Mode

One cartridge will supply a double row pair with ink. E.g. the ‘Cyan’ cartridge will supply the C1 and C2 print head rows. It is possible to use all rows for printing, however Maintenance Fluid will not work and print in the press. 1350 Operating Manual - PlateWriter 2500/3000... - Page 54 In general it is recommended to use the gradient transition as this will minimize potential patterns from each print head scan. When printing fast, i.e. 8 passes or fewer, selecting the step transition may improve the print quality. Operating Manual - PlateWriter 2500/3000 1350...

-

Page 55: Print Head Row Selection

The check box in the lower right corner in print head row selection section will indicate if a valid combination is selected. Some buttons/rows will be disabled based on what is currently selected if that combination will not be possible. 1350 Operating Manual - PlateWriter 2500/3000... -

Page 56: Screening Linearisation Control

The maximum achievable ink coverage increases with resolution. E.g. 2880x1440 dpi can jet twice the amount of ink compared to 1440x1440 dpi. It is therefore necessary to decrease the ink coverage when the resolution increases. Operating Manual - PlateWriter 2500/3000 1350... - Page 57 A setting of 0% will retain the solid as a result of the ‘’Solids entry point’’ setting. A setting of 100% will render the solid at full coverage. Curvature This function will adjust the shape of the iScreen internal calibration curve. 1347 Operating Manual - PlateWriter 2500/3000...

-

Page 58: Saving The Page Setup

– Set Actual Press to LiquidDot (S37) or another curve that matches your request. – This linearises the output on the press sheet, thus compensating for individual press characteristics and the effect of the Deeds screening. Operating Manual - PlateWriter 2500/3000 1347... - Page 59 None). In the Cassette & Page section click the Page layout... button to open the Page Lay- • out window. Select units (inches or mm) for media size and margins. • 1347 Operating Manual - PlateWriter 2500/3000...

-

Page 60: Setting The Plate Size

If the Page Setup is for proofing set the Media Width and Media Length to the • width and length of your proofing material. Note that this will generally be a differ- ent size than your printing plates. Operating Manual - PlateWriter 2500/3000 1347... -

Page 61: Setting The Gripper And Job Position On The Plate

Media Width, and the Top Margin will be the Gripper Margin plus the plate bend. “Gripper Offset” or “Top Margin” Job positioned “Centre on Media Width” Plate Centre of Plate Width Media Width 1347 Operating Manual - PlateWriter 2500/3000... - Page 62 Operating Manual - PlateWriter 2500/3000 1347...

- Page 63 In the appearing Save Setup dialogue… • ...give your Page Setup a name which reflects the press size, and if necessary the Separations Style so it will be easy to select later. Click the Save button. 1347 Operating Manual - PlateWriter 2500/3000...

- Page 64 In this case, the PostScript or PDF file should be set to centred on the shortened Media Length, and the Left Margin will be set to the gripper plus the plate bend on the printing press however as described previously. Operating Manual - PlateWriter 2500/3000 1347...

- Page 65 Finally the Top Margin box will be available for you to enter the gripper plus the • plate bend on the printing press. Both the Left Margin and Right Margin boxes will be greyed out, as the job will au- • tomatically be centred by the RIP. 1347 Operating Manual - PlateWriter 2500/3000...

- Page 66 In the Effects section set Rotate to the required rotation that matches depending on • the PostScript or PDF file and if you have a portrait or landscape press. Click the Save As… button. • Operating Manual - PlateWriter 2500/3000 1347...

- Page 67 ...click the OK button to exit. " If you click “Cancel” at any point including to exit the Page Setup Manager above, then any changes you made or new Page Setups will be lost! 1347 Operating Manual - PlateWriter 2500/3000...

-

Page 68: Duplicating And Editing Existing Page Setups

Editing a Page Setup is easy, but remember that it will alter the Page Setup you choose to edit. We recommend that you duplicate/copy the Page Setup you want to base your new Page Setup upon, then change this duplicate and leave the original Page Setup untouched. Operating Manual - PlateWriter 2500/3000 1347... - Page 69 From the list in the Page Setup Manager dialogue… • ...select the Page Setup you wish to base your new Page Setup upon, in this case se- lect the SM52 Standard Page Setup and click Copy... to create a duplicate Page Setup. 1347 Operating Manual - PlateWriter 2500/3000...

- Page 70 In this case plate width is 511 mm and plate length is 400 mm. Set the new Top Margin if this press has a different Gripper requirement. Click OK. You will be returned to the New Page Setup window. • Operating Manual - PlateWriter 2500/3000 1347...

- Page 71 Click Save As... to save your new page setup with the new plate size. Give your new Page Setup a name to reflect the setting you have selected. • In this example name the Setup GTO52 CMYK Standard. Click Save. 1347 Operating Manual - PlateWriter 2500/3000...

-

Page 72: Printing A Job Using The Rip

Using the Print File command When you select Print File from the Navigator RIP menu, the dialogue box shown below appears. Ensure you choose an appropriate Page Setup for printing the files, from the Page Setup drop-down list. Operating Manual - PlateWriter 2500/3000 1347... -

Page 73: Printing Several Files

" The list of files to print can include files other than PostScript language, PDF files, TIFF 6.0, and TIFF/IT-P 1. The RIP ignores types of files that it cannot print. 1347 Operating Manual - PlateWriter 2500/3000... -

Page 74: Automating Job Input To The Rip

RIP accept input from any Mac application that prints to the printer(s) broadcast by the RIP. However we do not recommend using the built-in AppleTalk on the RIP. If print sharing is necessary for Mac OS, then please use the supplied application ExtremeZ-IP. Operating Manual - PlateWriter 2500/3000 1347... -

Page 75: Managing Input Plugins

When you have finished making changes in the Input Controller, you can keep it visible as a way of monitoring which inputs are submitting jobs or close it either by using the Navigator RIP -> Input Controller menu option or by clicking the tool bar button. 1347 Operating Manual - PlateWriter 2500/3000... -

Page 76: Turning On The Input System

To add a new input source to the list: Click the New button in the Input Controller window. The RIP displays an Input • Channel Edit dialogue box, allowing you to fill in the details for this source. Operating Manual - PlateWriter 2500/3000 1347... -

Page 77: Copying An Input Plugin

Select the entry in the Input Controller and click the Edit button. • Double-click the entry in the Input Controller. • The RIP displays an Input Channel Edit dialogue box, allowing you to edit the details for the selected plugin. 1347 Operating Manual - PlateWriter 2500/3000... -

Page 78: Configuring An Input Plugin

To make enabled inputs active, choose Navigator RIP -> Start Inputs or click the Green Traffic Light tool bar button. To stop all enabled inputs, choose Navigator RIP -> Start Inputs again or click the Red Traffic Light tool bar button. Operating Manual - PlateWriter 2500/3000 1347... -

Page 79: Using The Spoolfolder Input Folder

RIP is started, or if a very large number of files have been queued, the RIP determines the order of those jobs by the date stamps on the files. 1347 Operating Manual - PlateWriter 2500/3000... -

Page 80: Creating And Configuring A Spoolfolder Input Source

Controller menu option or by clicking the tool bar button. The Input Controller dialogue box will appear. • Click New. The RIP displays the Input Channel Edit dialogue box. • Choose SpoolFolder from the Type drop-down list. • Operating Manual - PlateWriter 2500/3000 1347... - Page 81 Give your input queue a Name (try to use names that reflect the Page Setup you are • sending it to, to make editing queues later a little easier). Click on the Configure button to open the Spool Folder Configuration window. • 1347 Operating Manual - PlateWriter 2500/3000...

- Page 82 Warn if spool folders do not exist Select this box if you want the RIP to issue a warning if a folder named as a spool, error, or completion folder does not exist. Operating Manual - PlateWriter 2500/3000 1347...

- Page 83 If a file successfully prints, the RIP moves it to the location specified in the text field beside this button unless the Delete on completion box is checked. Click the Complete Folder button to change this location using the standard file browsing dialogue box. 1347 Operating Manual - PlateWriter 2500/3000...

- Page 84 “Configure”. Now you only need to change the “Spool” folder, to reflect a new folder to act as the source for your new queue. Operating Manual - PlateWriter 2500/3000 1347...

-

Page 85: Using More Than One Method

Windows. This utility can also be installed by the RIP installer. It has to be installed on each Windows workstation where printing to the RIP is done. For details of the ExtremeZ-IP application please refer to the manual which can be opened via the Windows Start->Programs->ExtremeZ-IP folder. 1347 Operating Manual - PlateWriter 2500/3000... -

Page 86: Calibrating

“Actual Press” calibration, we can then add an intended press calibration curve, thus enabling a print shop with multiple presses to create a more consistent and even calibration across all its work. Start the Navigator RIP. • Operating Manual - PlateWriter 2500/3000 1347... - Page 87 Choose a page setup and click on Print uncalibrated press target. The calibration • target will be ripped and written to disk. You should get four separations. Load a plate. • In the Output Controller/Monitor window select Uncalibrated target in the Active • Queue 1347 Operating Manual - PlateWriter 2500/3000...

- Page 88 Check that the Media Width, Media Length and Margins are correct for your plate. • (The calibration target is rather small, but you should check to ensure the margins will put it inside your printing area). Operating Manual - PlateWriter 2500/3000 1347...

- Page 89 It is not unusual for each ink to achieve a differ- ent gain characteristic, so you will need to separately measure each colour printed. 1347 Operating Manual - PlateWriter 2500/3000...

- Page 90 Once you have entered the Cyan data select the Magenta channel and enter the data • measure for the magenta output. Repeat the above for the remaining colours. • Click OK in this window and in the Calibration Manager window to save your pro- • file. Operating Manual - PlateWriter 2500/3000 1347...

-

Page 91: Including The Press Calibration In Page Setups

Actual Press calibration list. Leave the Tone Curves and the Intended Press curve set to (None). • Save the edited Page Setup by clicking OK in this window and in the Page Setup • Manager window. 1347 Operating Manual - PlateWriter 2500/3000... -

Page 92: Why Use Intended Press Or Tone Curves

Save the edited Page Setup by clicking OK in this window and in the Page Setup • Manager window. You can confirm if the output of your intended curves achieves the results you re- • quired by printing calibrated press target. Operating Manual - PlateWriter 2500/3000 1347... -

Page 93: Backup & Restore Your Navigator Rip Configuration For Windows

CD, print the Glunz & Jensen factory default file which you have backed up instead. Follow the instructions to configure the RIP memory and dongle passwords. Your entire configuration will then be restored, and you can resume work. 1350 Operating Manual - PlateWriter 2500/3000... - Page 94 Using the RIP 4-56 Backup & restore your Navigator RIP configuration for Windows Operating Manual - PlateWriter 2500/3000 1347...

-

Page 95: Part 5: Troubleshooting

To change a fuse, switch off all power to the machine first. Always ensure that the new fuse is of the correct size and rating according to the electrical diagram placed in the Spare Parts Manual. 1206 Operating Manual - PlateWriter 2500/3000... -

Page 96: Problems With The Finishing Unit

Power the unit off, replace bulb, then power the unit on again. RED - 4 FLASHES Motor regulation error - motor/conveyor is blocked. BUZZER SOUNDS Power the unit off, remove obstacle, then power the unit on again. Operating Manual - PlateWriter 2500/3000 1350... -

Page 97: Problems With The Registration System/Print Head

If the contact of the print head with the plate causes blocking the print head then the printer displays PAPER JAM error. " These errors cannot be handled by closing the printer front cover. They have to be handled as stated below. In case of FRONT COVER OPEN error: 1350 Operating Manual - PlateWriter 2500/3000... - Page 98 Feed rollers are automatically opened by the printer. • Remove the plate from the printer. • Turn the printer off and on. This will reset the error and release the front cover • switch. Operating Manual - PlateWriter 2500/3000 1350...

Need help?

Do you have a question about the PlateWriter 2500 and is the answer not in the manual?

Questions and answers