Table of Contents

Advertisement

To ensure safe usage and full performance of this product, please be sure to read through this manual com-

pletely.

To ensure immediate access whenever needed, store this manual in a safe location.

Unauthorized copying, quotation, or translation of this manual, in whole or in part, without the written approval

of Roland DG Corp., is prohibited.

The contents of this document and the specifications of this product are subject to change without notice.

Roland DG Corp. assumes no responsibility for any loss or damage relating to this product, regardless of any defect

in this product or this manual. Such loss or damage, whether direct or indirect, includes, but is not limited to, that

arising from the specifications or performance of this product, that due to failure of the product to perform, and

that arising from any article made using this product.

USER'S MANUAL

Advertisement

Table of Contents

Summary of Contents for Roland Metaza MPX-90

- Page 1 The contents of this document and the specifications of this product are subject to change without notice. Roland DG Corp. assumes no responsibility for any loss or damage relating to this product, regardless of any defect in this product or this manual. Such loss or damage, whether direct or indirect, includes, but is not limited to, that arising from the specifications or performance of this product, that due to failure of the product to perform, and that arising from any article made using this product.

-

Page 2: For California

For EU Countries Manufacturer: ROLAND DG CORPORATION 1-6-4 Shinmiyakoda, Kita-ku, Hamamatsu-shi, Shizuoka-ken, 431-2103 JAPAN The authorized representative in the EU: Roland DG Corporation, German Office Halskestr. 7, 47877 Willich, Germany Roland DG Corp. has licensed the MMP technology from the TPL Group. -

Page 3: Table Of Contents

Contents To Ensure Safe Use ..................4 Important Notes on Handling and Use...............9 About Operation Manuals .................10 Documentation Included with the Machine ................10 How to Display Help for Software ....................10 How to Display Help for METAZA Driver ................11 Chapter 1 Getting Started .................13 1-1 About the Machine ................14 Features ..............................14 1-2 Names and Functions ................15... - Page 4 Contents 3-4 Starting and Stopping Printing ..............52 Starting Printing ..........................52 Stopping Printing Operations ....................54 Chapter 4 More Advanced Operations .............57 4-1 Tips and Tricks for Image Layout ............58 Keeping Only the Required Portion of an Image (Trimming) ........58 Adjusting the Location, Size, or Angle of an Image ............59 Enclosing an Image in a Frame ....................62 4-2 Tips and Tricks for Text Layout..............64 Adjusting the Location, Size, or Angle of a Text ..............64...

- Page 5 System Requirements for USB Connection ................ 115 Windows® is a registered trademark or trademark of Microsoft® Corporation in the United States and/or other countries. Company names and product names are trademarks or registered trademarks of their respective holders. Copyright © 2009-2010 Roland DG Corporation http://www.rolanddg.com...

-

Page 6: To Ensure Safe Use

To Ensure Safe Use Improper handling or operation of this machine may result in injury or damage to property. Points which must be observed to prevent such injury or damage are described as follows. About WARNING and CAUTION Notices Used for instructions intended to alert the user to the risk of death or severe injury WARNING should the unit be used improperly. - Page 7 Continuing to use the machine may result electrical shock. If anything gets inside, in fire, electrical shock, or injury. Con- immediately disconnect the power cord tact your authorized Roland DG Corp. and contact your authorized Roland DG dealer. Corp. dealer.

- Page 8 To Ensure Safe Use Important notes about the power cord, plug, and electrical outlet Never allow to get wet. Never place any object on top or subject to damage. Never bend or twist with undue force. Never make hot. Never pull with undue force. Dust may cause fire.

- Page 9 To Ensure Safe Use The head area becomes hot WARNING Never touch the head immediately after printing has finished. Doing so may cause burns.

-

Page 10: Warning Label

To Ensure Safe Use Warning Label Warning label is affixed to make areas of danger immediately clear. The meaning of the label is as follows. Be sure to heed its warnings. Also, never remove the label or allow it to become obscured. Caution: High Temperature Never touch immediately after printing. -

Page 11: Important Notes On Handling And Use

Important Notes on Handling and Use This machine is a precision device. To ensure the full performance of this machine, be sure to observe the following important points. Failure to observe these may not only result in loss of performance, but may also cause malfunction or breakdown. This Machine is a Precision Device. -

Page 12: About Operation Manuals

Be sure to read it first. METAZA Driver Online Help Roland METAZAStudio Online Help Roland SFEdit2 Online Help Dr. Engrave Online Help You view this documentation on your computer screen. Installing the respective programs makes these avail- able for viewing. -

Page 13: How To Display Help For Metaza Driver

From [Start] menu, click [Control Panel] → [Hardware and Sound] → [Printers]. Windows XP From [Start] menu, click [Control Panel] → [Printers and Other Hardware] → [Printers and Faxes]. Right click [Roland MPX-90]. Click [Printing Preferences]. The setting window appears. Continue on the next page... - Page 14 About Operation Manual Click [Help]. METAZA Driver help appears.

-

Page 15: Chapter 1 Getting Started

Chapter 1 Getting Started 1-1 About the Machine ..............14 Features ..................14 1-2 Names and Functions ............15 This Machine ................15 1-3 Checking the Included Items ..........17... -

Page 16: About The Machine

1-1 About the Machine Features This machine is a metal printer. It prints images by striking detailed points using a marking pin mounted in a head. Chapter 1 Getting Started... -

Page 17: Names And Functions

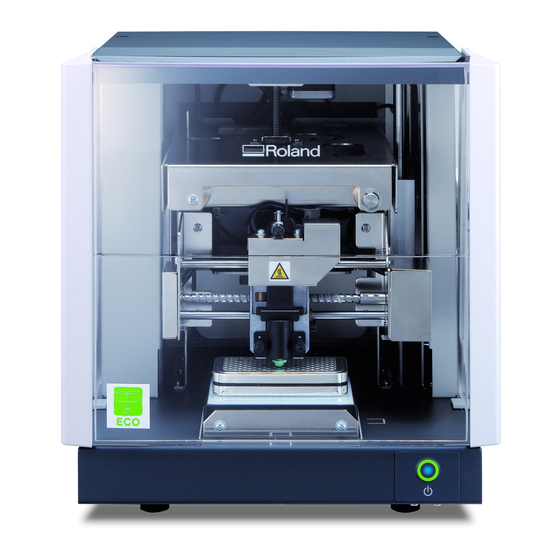

1-2 Names and Functions This Machine Main Unit Cover Close the cover when making print. Hold the middle area of the cover as shown in the figure below when opening it. Knob D e t e r m i n e t h e h e a d p o s i t i o n based on the sur- face height of the... - Page 18 1-2 Names and Functions Head (MPH-90) Printing is performed on material using with a marking pin. Diamond is attached to the tip of the marking pin. Since the head is a consum- able part, replace it at an appropriate timing. ...

-

Page 19: Checking The Included Items

(One installed on the unit by default) Center vise (1) Adhesive sheet (1) Table (1) USB cable (1) Roland Software Package Head (MPH-90) (1) CD-ROM (1) (Installed on the unit by default) Test-use printing material (4) User’s manual (1) Hexagonal wrench (1) -

Page 21: Chapter 2 Installation And Setup

Chapter 2 Installation and Setup 2-1 Installation ................20 Installation Environment ............20 Removing and storing the retainers...........21 2-2 Cable Connections ..............23 Connecting the machine to a power supply.......23 2-3 Installing the Software ............24 System Requirements ...............24 The Software You Can Install and Set Up .........24 Installing METAZA Driver ............25 Installing the Software ...............26 2-4 METAZAStudio Settings ............27... -

Page 22: Installation

2-1 Installation Installation Environment Install in a quiet, stable location offering good operating conditions. An unsuitable location can cause accident, fire, faulty operation, or breakdown. CAUTION Install in a location that is level and stable. Installation in an unsuitable location may cause an accident, including a fall or tip over. -

Page 23: Removing And Storing The Retainers

2-1 Installation Removing and storing the retainers Retaining materials are attached to protect the machine from vibration during shipment. Remove these after emplacement. Remove all Retaining materials. Any that remain may cause faulty operation or breakdown when the power is switched on. - Page 24 2-1 Installation Storing the retainers Keep the retaining materials by mounting them to the position shown in the figure. Chapter 2 Installation and Setup...

-

Page 25: Cable Connections

2-2 Cable Connections Connecting the machine to a power supply At this time, the connection to the computer must not be made yet. Failure to follow the correct procedure may make installation impossible. You make the connection to the computer when you install METAZA driver. ... -

Page 26: Installing The Software

(*2) The operation in the Windows XP mode has not been verified. For the latest information, see the Roland DG Corp. website (http://www.rolanddg.com). The Software You Can Install and Set Up This is a program for creating printing data. It enables you import... -

Page 27: Installing Metaza Driver

Before you start installation and setup, make sure the USB cable is NOT connected. Log on to Windows as “Administrators.” Insert the Roland Software Package CD-ROM into the computer. When the automatic playback window appears, click [Run menu.exe]. The install menu appears automatically. ... -

Page 28: Installing The Software

2-3 Installing the Software Click of the install menu window and setup guide win- dow. Installing the Software Procedure Display the window for the install menu of the software. Click [Install] of the program you want to install. ... -

Page 29: Metazastudio Settings

After you finish installing and setting up METAZAStudio, continue by making the setting for the printer. Be sure to make the setting before use. Procedure From [Start] menu, click [All Pro- grams] (or [Programs]) → [Roland METAZAStudio] → [METAZAStu- dio]. METAZAStudio starts. ... -

Page 31: Chapter 3 Making Prints

Chapter 3 Making Prints 3-1 Switching the Power On and Off ...........30 Switching On the Power ............30 Switching Off the Power ............31 3-2 Getting Ready ................32 The Printable Area ..............32 Head Caps ................32 Preparing Material to Print ............33 Loading Material Using the Adhesive Sheet ......36 Using the Center Vise ...............40 Loading Material Using the Center Vise ........41 3-3 Preparing Print Data (METAZAStudio) ........44... -

Page 32: Switching The Power On And Off

3-1 Switching the Power On and Off Switching On the Power Procedure Make sure that the stopper contacts the ring and the knob is tightened as shown in the figure In the case as shown in the figure , loosen the knob to make it into the state shown in the figure , and then tighten the knob. -

Page 33: Switching Off The Power

3-1 Switching the Power On and Off Description When the power is ON in the state shown in the figure , there are cases where the power lamp blinks and an error occurs immediately after the initial operation is completed. To clear the error, take the procedure and press the Power/Movement button. -

Page 34: Getting Ready

3-2 Getting Ready The Printable Area The machine's printable area is as follows. Top view of the table Printable Area 50mm × 50mm Center line Center line Maximum Printable Area (80mm × 80mm) The setting by METAZA Driver is required. If an image exceeds the printable area, the print result might become uneven in the outside of the printable area. -

Page 35: Preparing Material To Print

3-2 Getting Ready Preparing Material to Print Prepare material that meets all of the following conditions. Thickness *1 0.3 to 40 mm (0.012 to 1.5 in.) Size *1 When using the adhesive sheet: 100mm (3.9 in.) (W) × 200mm (7.9 in.) (L) or less, or 200mm (7.9 in.) (W)×... - Page 36 3-2 Getting Ready Cross-section of printing material When using an adhesive sheet or a center vice. There must be no unevenness on the print surface. *4 Not OK Not OK Edge of the material is L-shape too high. Materials that cannot be used are those of which unevenness comes into contact with the moving part of the machine when material is set or when printing is made.

- Page 37 3-2 Getting Ready Conditions for Material When Printing Curved Surfaces *5 The table and figure below show the printing-assured area and the area reached by the marking pin with respect to the diameter of the cylinder. Note, however, that the following conditions are assumed. ...

-

Page 38: Loading Material Using The Adhesive Sheet

3-2 Getting Ready Loading Material Using the Adhesive Sheet Procedure Switch on the power P.30, "Switching On the Power" Make sure that the stopper con- tacts the ring and the knob is Ring tightened as shown in the figure. Tighten the knob if it is loose. - Page 39 3-2 Getting Ready Affix the adhesive sheet to the table. Mount the material on the sheet. Press down lightly on the material to secure it in place. Mounting the Adhesive Sheet Place it straight, aligned with the scale marks on the table. ...

- Page 40 3-2 Getting Ready When material is too large to be placed within the table Place the material in a way that the center of the printing area comes to the center of the scale on the table. If the material tilts, place a support Adhesive sheet in order to keep the material hori-...

- Page 41 3-2 Getting Ready As shown in the figure, move the knob to the lowest position. Tighten the knob. Make sure the center of the knob is posi- tioned properly as pointed by the arrow located under the knob. Knob Stopper Adjust the position of the knob so that its center will come above this marking.

-

Page 42: Using The Center Vise

3-2 Getting Ready Using the Center Vise With the center vise, you secure material in place by clamping it in the vise. You can also vary the orienta- tion and front and back sides of the vise when using it. Use it in a way matched to the size and shape of the material. -

Page 43: Loading Material Using The Center Vise

3-2 Getting Ready Loading Material Using the Center Vise Procedure Switch on the power. P.30, "Switching On the Power" Make sure that the knob is tight- ened in the state shown in the Ring figure. If it is not in the state shown in the figure, Tighten loosen the knob, and then tighten it as it is in the state shown in the figure. - Page 44 3-2 Getting Ready Mount the center vise. Fit the tabs on the bottom of the center Fit the tabs here in the case of hori- vise into the holes in the table on the zontal mounting. unit. If the material tilts, place a support in order to keep the material horizontal.

- Page 45 3-2 Getting Ready Move the knob to the lowest position as shown in the figure. Tighten the knob. Make sure the center of the knob is posi- tioned properly as pointed by the arrow located under the knob. Knob Stopper Adjust the position of the knob so that its center will come above this marking.

-

Page 46: Preparing Print Data (Metazastudio)

3-3 Preparing Print Data (METAZAStudio) Starting METAZAStudio From the [Start] menu, click [All Programs] (or Program) → [Roland METAZAStudio] → [METAZAStudio]. METAZAStudio starts. P. 45, "METAZAStudio Screen" Chapter 3 Making Prints... -

Page 47: Metazastudio Screen

3-3 Preparing Print Data (METAZAStudio) METAZAStudio Screen Toolbar The toolbar is provided with buttons for Menu Bar running METAZAStudio commands such as [Material] and [Open]. Runs the various commands for METAZAStudio. METAZAStudio online help ("Commands" METAZAStudio online help ("Commands") >... -

Page 48: Step1 : Determine The Shape And Size Of Material

3-3 Preparing Print Data (METAZAStudio) Step1 : Determine the shape and size of material. This section explains the shape and size of material to be determined by METAZAStudio when using the plate as explained below. METAZAStudio has a number of different types of material preregistered. Use the material with the “tag”... - Page 49 3-3 Preparing Print Data (METAZAStudio) Click the icon with the “tag” name. Material window Click The [Material Size] dialog box appears. Enter the values for the size of the material. Click [OK]. The material you selected appears in the Edit window.

-

Page 50: Step2 : Import The Image

3-3 Preparing Print Data (METAZAStudio) Set “Margin” to “1 mm.” Click [OK]. For printing on a flat plate, make the margin at least one millimeter. Other- wise the marking pin may strike and damage the edge of the material. Step2 : Import the Image Here you import an image (such as photograph or drawing) for printing. - Page 51 3-3 Preparing Print Data (METAZAStudio) At [Look in], select the location of the file. At [Files of type], select either [Picture file] or [Adobe Illustrator file]. Select the file you want. Click [Open]. The specified image is imported and displayed with the margins you set.

-

Page 52: Step3 : Enter The Text

3-3 Preparing Print Data (METAZAStudio) Step3 : Enter the Text Here you type in the text to print. Procedure Click Click on the printing area. Type in the text. You can change the size and orientation of the typed text and fill it. ... - Page 53 3-3 Preparing Print Data (METAZAStudio) For [Save in], specify where to save the file. Type in a file name. Click [Save]. Chapter 3 Making Prints...

-

Page 54: Starting And Stopping Printing

P. 36, "Loading Material Using the Adhesive Sheet," p. 41, "Loading Material Using the Center Vise" Procedure Close the cover. Click The [Print] dialog box appears. Make sure [Roland MPX-90] is chosen as the printer name. Click [Properties]. Chapter 3 Making Prints... - Page 55 3-4 Starting and Stopping Print Click the [Image Correction] tab. Select [Material]. Select either the composition or the product code of the material. You can adjust and register the striking force. P. 92, "Registering a Composition and Adjusting the Striking Force" Select Print mode.

-

Page 56: Stopping Printing Operations

From [Start] menu, click [Control Panel] → [Hardware and Sound] → [Printers]. Windows XP From [Start] menu, click [Control Panel] → [Printers and Other Hardware] → [Printers and Faxes]. Double-click the [Roland MPX-90] icon. At the [Printer] menu, click [Can- cel All Documents] (or [Purge Print Documents]). - Page 57 3-4 Starting and Stopping Print If the message shown in the figure appears, click “Yes.” Chapter 3 Making Prints...

-

Page 59: Chapter 4 More Advanced Operations

Chapter 4 More Advanced Operations 4-1 Tips and Tricks for Image Layout ...........58 Keeping Only the Required Portion of an Image (Trimming) ..58 Adjusting the Location, Size, or Angle of an Image ....59 Enclosing an Image in a Frame ..........62 4-2 Tips and Tricks for Text Layout ..........64 Adjusting the Location, Size, or Angle of a Text ......64 Arranging a Text to a Fan Layout ..........66... -

Page 60: Tips And Tricks For Image Layout

4-1 Tips and Tricks for Image Layout Keeping Only the Required Portion of an Image (Trimming) METAZAStudio can cut an original image to remove unneeded areas and keep just the required portion. This operation is called “trimming. ” In this example, you use the printing data created from page 46 to 48. Procedure ... -

Page 61: Adjusting The Location, Size, Or Angle Of An Image

4-1 Tips and Tricks for Image Layout Adjusting the Location, Size, or Angle of an Image METAZAStudio can change the location, size, and angle of a placed image to achieve the layout you want. In this example, you use the printing data created at page 58, “Keeping Only the Required Portion of an Image (Trimming). - Page 62 4-1 Tips and Tricks for Image Layout Drag the handles at the four cor- ners of the image to adjust the size. Handles With the handles present at the four corners of the image, click the image a second time. The shape of the handles at the four corners changes to (●).

- Page 63 4-1 Tips and Tricks for Image Layout Drag to adjust the angle of the image. Holding down the keyboard’s SHIFT key as you drag makes the angle change by 45 degrees at a time. Using this method can be convenient at times such as when you want to perform rotation by precisely 90 degrees.

-

Page 64: Enclosing An Image In A Frame

4-1 Tips and Tricks for Image Layout Enclosing an Image in a Frame You can change the arrangement of printing data by placing a frame around an image. You use frames reg- istered in what’s called METAZAStudio’s “library. ” The library contains a number of preregistered frames, and you can also register new ones. - Page 65 4-1 Tips and Tricks for Image Layout Adjust the size and location of the frame. When the size of the frame is larger than that of material, the result becomes as shown in the figure. The adjustment methods are the same as the methods for adjusting the location and size of an image.

-

Page 66: Tips And Tricks For Text Layout

4-2 Tips and Tricks for Text Layout Adjusting the Location, Size, or Angle of a Text You can change the location, size, and angle of a placed text same as image. Procedure Arrange the text horizontally. P. 50, “Step3 : Enter the Text” Click Click the laid-out text. - Page 67 4-2 Tips and Tricks for Text Layout Click on the text and hold until the shape of the handles at the 4 corners changes to [●]. Line up the pointer with a handle. The shape changes to a pointer for rota- tion.

-

Page 68: Arranging A Text To A Fan Layout

4-2 Tips and Tricks for Text Layout Arranging a Text to a Fan Layout You can arrange a text to a fan layout. Procedure Enter text. P. 50, “Step3 : Enter the Text” Click The [Properties] dialog box appears. ... -

Page 69: Laying Out Text Along A Shape

4-2 Tips and Tricks for Text Layout Laying Out Text along a Shape Here you lay out text along a shape you have made using the drawing tools. Procedure Click a drawing tool. In this example you use In the editing window, create a shape on the material. -

Page 70: Filling Text

4-2 Tips and Tricks for Text Layout Enter text. P. 50, “Step3 : Enter the Text” The text is laid out along the shape. Important! Layout on an integrated polyline is not possible. METAZAStudio METAZAStudio online help (“Commands” > “[Object] menu” > “Convert to Polyline,“ “Integrate Polyline”... - Page 71 4-2 Tips and Tricks for Text Layout Procedure Enter the text. P. 50, “Step3 : Enter the Text” Click The [Properties] dialog box appears. Click the [Fill and Contour] tab. Select the [Fill] check box. Select [Fill] or [Island Fill]. When you select [Island Fill], you need to enter Pitch as well.

-

Page 72: Creating And Editing Line Text

4-3 Creating and Editing Line Text SFEdit2 is software to create and edit stroke character fonts. On METAZAStudio, you can use the stroke char- acter fonts that are created and edited by SFEdit2. SFEdit2 window Toolbar Menu Bar The toolbar is provided with buttons for running Runs the various commands for SFEdit2. -

Page 73: Creating A Stroke Character Font

4-3 Creating and Editing Line Text Creating a Stroke Character Font The method of creating and saving a stroke character font is explained below. Procedure Starting METAZAStudio. P. 44, “Starting METAZAStudio” Click [Edit] → [Stroke Font] → [Run SFEdit2…]. - Page 74 4-3 Creating and Editing Line Text Click [Save] dialog box appears. Enter a name of the created stroke character font. Click [OK]. The created stroke character font is saved. Click Chapter 4 More Advanced Operations...

-

Page 75: Changing Input Characters Into Stroke Characters

4-3 Creating and Editing Line Text Changing Input Characters into Stroke Characters This section explains the method of changing input characters into stroke characters using a stroke character font. To use a stroke character font, either of the following operations must be done in advance. ... -

Page 76: Editing Stroke Character

4-3 Creating and Editing Line Text Editing Stroke character Using SFEdit2, you can edit the shape of a created stroke character. The procedure to edit a stroke character using SFEdit2 is explained below. Procedure Change an input character to a stroke character. ... -

Page 77: Checking And Adjusting Finished Result Of An Image

4-4 Checking and Adjusting Finished Result of an Image Checking the Finished Results in the Preview Window Checking the Finished Results in the Preview Window Click Preview window appears. Preview window Chapter 4 More Advanced Operations... -

Page 78: Adjusting The Finished Result In The Preview Window

4-4 Checking and Adjusting Finished Result of an Image Adjusting the Finished Result in the Preview Window At the preview window, you can adjust the brightness, contrast, and gamma correction. An image with clearly defined light and dark areas produces attractive printed results. Brightness This adjusts the overall brightness. -

Page 79: Printing On A Curved Surface

4-5 Printing on a Curved Surface With this machine, using a head cap lets you perform printing on cylinders and other examples of material whose surface height is not uniform. This section describes how to create data, using printing on a cylindrical material like the one shown below as an example. - Page 80 4-5 Printing on a Curved Surface Set “Margin” to “0 mm.” When you’re printing on cylindrical material, set the margins to zero mil- limeters. When printing on cylindrical material, the makeable area is limited, and so a sufficient printing area must be ensured by making the margins zero millimeters in size.

- Page 81 4-5 Printing on a Curved Surface Make sure [Roland MPX-90] is chosen as the printer name. Click [Properties]. Click the [Material] tab. Set [Diameter] to 10 millime- ters. Select [Direction]. Make horizontal writing on portrait material. Vertical Horizontal In this example, select (vertical).

-

Page 82: Step2 : Make Horizontal Writing On Portrait Material

4-5 Printing on a Curved Surface Step2 : Make horizontal writing on portrait material. After the printing area is determined, place images and text on the area. This section explains the method of inputting characters horizontally on portrait material. Procedure ... - Page 83 4-5 Printing on a Curved Surface Click Press the <→> key on the keyboard. The result becomes as shown in the figure. Enter text remained. Move the text to any position of your preference. P. 64, “Adjusting the Location, Size, or Angle of a Text”...

-

Page 84: Register New Material

4-6 Register New Material How to Register Wide Variety of Material METAZAStudio includes preregistered material of four shapes. To print material not registered in METAZAStudio, first register it as a new material. This prevents the printing area from being limited and the marking pin from being damaged as the result of hitting the edge of material. -

Page 85: Metaza Driver Settings

Windows XP From [Start] menu, click [Control Panel] → [Printers and Other Hardware] → [Printers and Faxes]. Right-click [Roland MPX-90]. Click [Printing Preferences]. The setting window for METAZA Driver appears. Going to the METAZAStudio [File] menu and clicking [Print Setup], then, in the [Print Setup] window, clicking [Properties], displays the same window as the one that appears using “Displaying the Setting... -

Page 86: About Dr. Engrave

4-8 About Dr. Engrave What is Dr. Engrave? Dr. Engrave is printing software for plate materials. It can read a text file in which data is separated by commas or tabs into the character field. You can use the files created with spreadsheet software and database software which have the text write function. For more information, see Help of Dr. -

Page 87: More Advanced Other Operations

4-9 More Advanced Other Operations More Advanced Other Operations You Can Accomplish with METAZAStudio METAZAStudio has some further useful functions, which are not explained in this document. Major functions are given below. For more information on how to operate METAZAStudio, refer to the online help for the program. -

Page 89: Chapter 5 Maintenance And Adjustment

Chapter 5 Maintenance and Ad- justment 5-1 Daily Care ................88 Points to Note on Daily Care .............88 Cleaning the Adhesive Sheet ............88 Cleaning the Body and Cover ...........89 Cleaning of the Head Cap ............89 5-2 Adjusting the Marking Pin ............90 Checking the State of the Marking Pin ........90 Adjusting the Striking Force of the Pin ........91 5-3 Composition Registration and Striking-force Adjustment..92... -

Page 90: Daily Care

5-1 Daily Care Points to Note on Daily Care WARNING Never use gasoline, alcohol, thinner, or any other flammable material. Doing so may cause fire. CAUTION Never touch the heads immediately after printing has finished. Doing so may cause burns. ... -

Page 91: Cleaning The Body And Cover

5-1 Daily Care Cleaning the Body and Cover Use a cloth moistened with water then wrung well, and wipe gently to clean. The surface of the cover is easily scratched, so use a soft cloth. Cleaning of the Head Cap Detach the head cap mounted on the machine and remove dirt and dust inside the head cap. -

Page 92: Adjusting The Marking Pin

5-2 Adjusting the Marking Pin Checking the State of the Marking Pin MPX-90 Head Manager indicates the amount of pin usage. When the indicator is shown in red, replace the head with a new one. Even when the indicator is not displayed in red, if the print quality is not satisfactory or the unevenness of the printed image persists, replace the head with a new one. -

Page 93: Adjusting The Striking Force Of The Pin

5-2 Adjusting the Marking Pin Adjusting the Striking Force of the Pin You can adjust the striking force of the pin by using MPX-90 Head Manager. Pin adjustment involves striking the pattern shown in the figure. Prepare a piece of test-use printing material (brass) or other material measur- ing about 60 mm (2.3 in.) by 60 mm (2.3 in.). -

Page 94: Composition Registration And Striking-Force Adjustment

From [Start], click [Control Panel] → [Hardware and Sound] → [Printers]. Windows XP From [Start], click [Control Panel] → [Printers and Other Hardware] → [Printers and Faxes]. Right-click [Roland MPX-90]. Click [Printing Preferences]. Setting Window for METAZA driver ap- pears. ... - Page 95 5-3 Composition Registration and Striking-force Adjustment Enter a name for the composi- tion you’re registering. Enter [Speed/Impact] The printing results vary according to the hardness of the material. Adjust to match the material. METAZA Driver online help ("[Correction] tab"...

- Page 96 5-3 Composition Registration and Striking-force Adjustment Click [OK]. METAZA Driver setting window closes. This is the end of registration of a material and the striking force suitable for it. To obtain printing results of higher quality, repeat to perform test print or to strike a same material, and adjust the value of print impact, etc.

-

Page 97: Adjustment Of The Origin-Point Location

5-4 Adjustment of the Origin-point Location Adjusting the Location of the Machine's Origin Point The origin point of the machine must be the center of the scale on the table. You can check the origin-point location by printing calibration data. Adjust the origin point if it is displaced. Prepare a plate-shaped material larger than 20 millimeters square. - Page 98 Windows XP From [Start] menu, click [Control Panel] → [Printers and Other Hardware] → [Printers and Faxes]. The [Printers] folder opens. Right-click [Roland MPX-90]. Click [Printing Preferences]. The setting window of METAZA Driver appears. Chapter 5 Maintenance and Adjustment...

- Page 99 5-4 Adjustment of the Origin-point Location Click the [Material] tab. In the width and length fields for [Offset], enter the displace- ment values you noted in step In the case of the figure in step , enter -0.5 in [Width] and 0.5 in [Length].

-

Page 100: The Replacement Of The Head Cap

5-5 The Replacement of the Head Cap The Replacement Cycle for the Head Cap When the head cap becomes worn away as shown in the figure below, it is time for replacement. Replace the head cap with a new one appropriately. The degree of wear may vary according to printing conditions. -

Page 101: Head Replacement

A General Guide of Head Life About 4,000 plates can be printed under the following conditions. Conditions of Use Material used : MD-NI (Roland nickel-plated plate) Printing area : 30 mm (1.1 in.) X 23 mm (0.9 in.) Print Mode : Photo... -

Page 102: How To Replace The Head

(brass), which is supplied with a replacement head (MPH-90), or a material equal to or larger than 60 mm (2.3 in.) x 60 mm (2.3 in.). A replacement head is sold separately. Consult your authorized Roland DG Corp. dealer. Do not stop the replacement operation halfway. - Page 103 5-6 Head Replacement When you have finished, click The window closes. Chapter 5 Maintenance and Adjustment...

-

Page 105: Chapter 6 Appendix

Chapter 6 Appendix 6-1 What to Do If ................104 The power supply light is blinking..........104 The machine doesn't run even when printing data is sent..104 The printed location isn't where desired ........104 Striking is performed, but nothing is printed......105 The printed image is unattractive. -

Page 106: What To Do If

6-1 What to Do If The power supply light is blinking. Do you set a material without using the supplied table (or the center vise)? Do you turn ON the power as the head position Turn OFF the power. Stop printing if it is underway. is set? If you set a material of which surface height is low without If the power is turned ON as the head position is set, the... -

Page 107: Striking Is Performed, But Nothing Is Printed

6-1 What to Do If The printed image is unattractive. P. 36, "Loading Material Using the Adhesive Sheet," p. 41, "Loading Material Using the Center Vise" Are the settings for the material in the driver's setting window correct? Is the origin point of the machine displaced? Choose the composition of the loaded material. -

Page 108: The Image Is Uneven

P. 36, "Loading Material Using the Adhesive Sheet" METAZA Driver online help ([Material] tab) 2. Go into the [Printers] folder. 3. Right-click the [Roland MPX-90] and open the Is the marking pin worn? setting screen for METAZA driver. Click [Printing Attractive printing may be impossible if the marking Preferences]. -

Page 109: Installation For Metaza Driver Is Impossible

6-1 What to Do If Installation for METAZA driver is Impossible Back If installation quits partway through, or if the wizard does not appear when you make the connection with a USB cable, take action as follows. Windows 7 1.Connect the machine with the computer via a USB cable, and turn on the machine. -

Page 110: Uninstalling Metaza Driver

D:\Drivers\WIN7X64 (64-bit version) 7. Go to the [Action] menu, and click [Unin- D:\Drivers\WIN7X86 (32-bit version) stall]. If you're not using the CD-ROM, go to the Roland DG Corp. 8. In "Confirm Device Uninstall" window, click website (http://www.rolanddg.com/) and download the [OK]. - Page 111 [Printer]. D:\Drivers\WINVISTAX86 (32-bit version) [Printer] folder opens. If you're not using the CD-ROM, go to the Roland DG Corp. 4. Click the model name’s icon you are using. website (http://www.rolanddg.com/) and download the From the [Organize] menu, click [Delete]. The...

- Page 112 6-1 What to Do If the folder where you want to expand the downloaded file. Chapter 6 Appendix...

-

Page 113: When Moving The Machine

6-2 When Moving the Machine Attach the retaining materials to the machine. When moving the machine, be sure to attach the retaining materials. Moving the machine without attaching the retaining materials may result in damage to the machine. Procedure Switching on the power. - Page 114 6-2 When Moving the Machine Hold down the Power/Movement button for ten seconds or longer. The head moves as shown in the figure. Power / Movement button Loosen the knob Loosen Knob Lift up the head. Tighten the knob as lifting the head.

- Page 115 6-2 When Moving the Machine Unplug the cables. Attach the retaining materials. The machine is to be secured at three points (with 5 screws). Attach all the retainers and wind up the screws with the provided hexagonal wrench. Hexagonal wrench Screw Screws...

-

Page 116: Locations Of The Power Rating And Serial Number Labels

6-3 Locations of the Power Rating and Serial Number Labels Serial Number This is required when you seek mainte- nance, servicing, or support. Never peel off the label or let it get dirty. Power Rating Use an electrical outlet that meets the requirements for voltage, frequency, and amperage given here. -

Page 117: Specification

6-4 Specification Main Unit Specifications MPX-90 Printable material Gold, silver, copper, platinum, brass, aluminium, iron, stainless steel, etc. (Vickers hardness [HV] of the printing surface must be 200 or less.) Loadable material size Maximum 100 mm (width) x 200 mm (length) x 40 mm (thickness), or 200 mm (width) x 100 mm (length) x 40 mm (thickness) (3.9 in. -

Page 120: Software License Agreement

Please read this Agreement before unpacking the media. Software license agreement Roland DG Corporation (hereinafter referred to as the “Company”) shall grant you a non-transferable, nonexclusive right to use the Software supplied with this Agreement, on the condition that you agree to the following provisions.

Need help?

Do you have a question about the Metaza MPX-90 and is the answer not in the manual?

Questions and answers