Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Parweld XTI 200 AC/DC P

- Page 1 XTI 200 AC/DC P INVERTER WELDER Instructions for use ISSUE 3...

- Page 2 XTI 200 AC/DC INVERTER – USER INFORMATION WARNING Operation and maintenance of arc welding equipment can be dangerous and hazardous to your health. FIRE AND EXPLOSION Fire and explosion can be caused by hot slag, sparks, or the To prevent possible injury, read, understand and follow all arc weld.

- Page 3 CONNECTION OF POWER SUPPLY CABLE Warning: Parweld advises that this equipment be electrically connected Vow voltage light. Indicates when the input power is by a qualified electrician. under voltage. Fault light This indicates a fault or over temperature Connect the power supply cable to the required voltage.

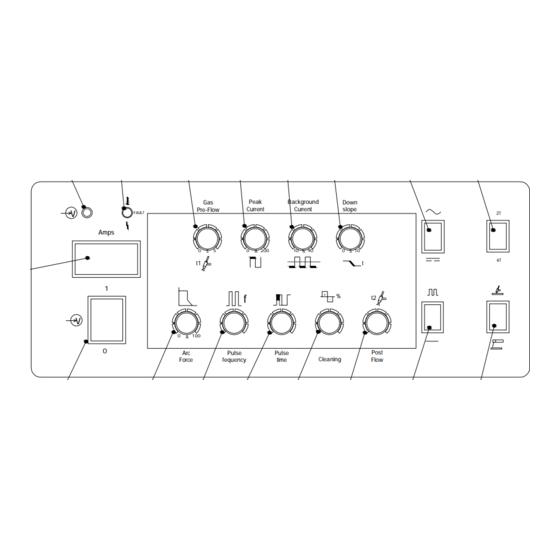

- Page 4 16) Pulse selector. Switches DC pulsing on or off when MMA WELDING GUIDE in DC TIG welding mode. 17) Process selector switch Switches the machine Electrode polarity between TIG welding and MMA welding mode. Note: MMA electrodes are generally connected to the torch terminal the power output is latched on when in MMA mode and the work lead to the work piece terminal so it should only be changed over when all output...

- Page 5 BASIC TIG WELDING GUIDE Guide for selecting filler wire diameter Tig welding cable connection Filler wire diameter dc current range Connect the TIG torch to the Negative terminal and the work 1/16” (1.6 mm) 20 - 90 lead to the Positive terminal for direct current straight polarity. 3/32”...

- Page 6 excessive work/torch leads to leads are not penetration in butt the right connected to the joint welding terminals right welding terminals Uneven leg length Wrong placement Re-position filler in fillet joint of filler rod (b) Torch lead is (b) Connect it to disconnected the ‘.’...

- Page 7 failure of the weld current is too low welding current (f) Wrong (f) Use electrodes metal to fill the electrode for designed for root of the weld (b) Electrode too (b) Use smaller position position in which large for joint. diameter in which welding is welding is...

- Page 8 The remedies of the purchaser set forth herein are exclusive and the liability of Parweld with respect to any contract, or anything done in Type: XTI 200 AC/DC , XTI 200 AC/DC-DV connection therewith such as the performance or breach...

Need help?

Do you have a question about the XTI 200 AC/DC P and is the answer not in the manual?

Questions and answers