Thermal Dynamics CutMaster 50 Service Manual

Plasma cutting power supply

Hide thumbs

Also See for CutMaster 50:

- Operating manual (44 pages) ,

- Instruction manual (90 pages) ,

- Operating manual (48 pages)

Summary of Contents for Thermal Dynamics CutMaster 50

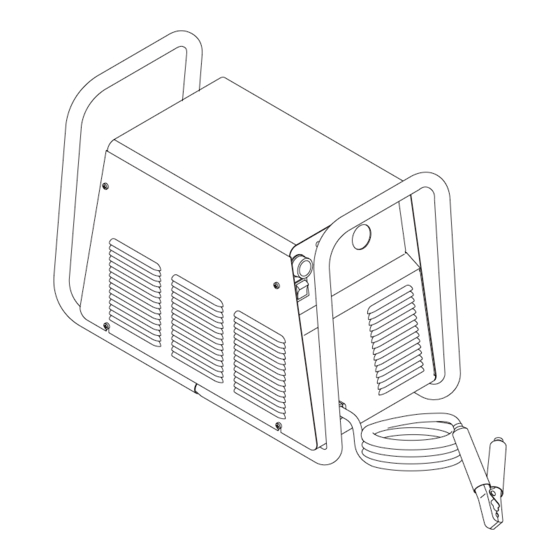

- Page 1 Plasma Cutting Power Supply CutMaster™ 50 A-02766 Service Manual April 21, 2003 Manual No. 0-2806...

- Page 3 While the information contained in this Manual represents the Manufacturer's best judgement, the Manufacturer assumes no liability for its use. Plasma Cutting Power Supply CutMaster™ 50 Service Manual Number 0-2806 Published by: Thermal Dynamics Corporation 82 Benning Street West Lebanon, New Hampshire, USA 03784 (603) 298-5711 www.thermal-dynamics.com Copyright 2000 by Thermal Dynamics Corporation All rights reserved.

-

Page 4: Table Of Contents

TABLE OF CONTENTS SECTION 1: GENERAL INFORMATION ....................1-1 1.01 Notes, Cautions and Warnings ..............1-1 1.02 Important Safety Precautions ............... 1-1 1.03 Publications ....................1-2 1.04 Note, Attention et Avertissement ..............1-3 1.05 Precautions De Securite Importantes ............1-3 1.06 Documents De Reference ................ - Page 5 TABLE OF CONTENTS (continued) SECTION 6: PARTS LISTS ........................6-1 6.01 Introduction ....................6-1 6.02 Ordering Information ..................6-1 6.03 Major External Replacement Parts ............... 6-2 6.04 Front Panel Replacement Parts ..............6-3 6.05 Left Side Internal Replacement Parts ............6-4 6.06 Right Side Internal Replacement Parts ............

- Page 6 TABLE OF CONTENTS (continued) APPENDIX 10-A: MAIN PC BOARD WIRING (208/230-Volt units with Boards Rev. G or earlier) ..................A-21 APPENDIX 10-B: MAIN PC BOARD WIRING (208/230-Volt units with Boards Rev. H and I) . A-22 APPENDIX 10-C: MAIN PC BOARD WIRING (208/230-Volt units with Boards Rev. J) ... A-23 APPENDIX 10-D: MAIN PC BOARD WIRING (for 400-Volt and 460-Volt units) ......

-

Page 7: General Information

SECTION 1: GASES AND FUMES GENERAL INFORMATION Gases and fumes produced during the plasma cutting process can be dangerous and hazardous to your health. 1.01 Notes, Cautions and Warnings • Keep all fumes and gases from the breathing area. Throughout this manual, notes, cautions, and warnings Keep your head out of the welding fume plume. -

Page 8: Publications

• Wear dry gloves and clothing. Insulate yourself from the work piece or other parts of the welding PLASMA ARC RAYS circuit. • Repair or replace all worn or damaged parts. Plasma Arc Rays can injure your eyes and burn your skin. •... -

Page 9: Note, Attention Et Avertissement

6. ANSI Standard Z49.2, FIRE PREVENTION IN THE USE ATTENTION OF CUTTING AND WELDING PROCESSES, obtain- able from American National Standards Institute, 1430 Broadway, New York, NY 10018 Toute procédure pouvant résulter l’endommagement du matériel en cas de non- 7. AWS Standard A6.0, WELDING AND CUTTING CON- respect de la procédure en question. - Page 10 • Eloignez toute fumée et gaz de votre zone de respira- • Ne touchez jamais une pièce “sous tension” ou “vive”; tion. Gardez votre tête hors de la plume de fumée portez des gants et des vêtements secs. Isolez-vous provenant du chalumeau. de la pièce de travail ou des autres parties du circuit de soudage.

-

Page 11: Documents De Reference

ultra-violets très forts. Ces rayons d’arc nuiront à vos 1.06 Documents De Reference yeux et brûleront votre peau si vous ne vous protégez pas correctement. Consultez les normes suivantes ou les révisions les plus récentes ayant été faites à celles-ci pour de plus amples •... - Page 12 9. Norme 70 de la NFPA, CODE ELECTRIQUE NA- TIONAL, disponible auprès de la National Fire Pro- tection Association, Batterymarch Park, Quincy, MA 02269 10. Norme 51B de la NFPA, LES PROCÉDÉS DE COUPE ET DE SOUDAGE, disponible auprès de la National Fire Protection Association, Batterymarch Park, Quincy, MA 02269 11.

-

Page 13: Declaration Of Conformity

Rigorous testing is incorporated into the manufacturing process to ensure the manufactured product meets or exceeds all design specifications. Thermal Dynamics has been manufacturing products for more than 30 years, and will continue to achieve excellence in our area of manufacture. -

Page 14: Statement Of Warranty

None Warranty repairs or replacement claims under this limited warranty must be submitted by an authorized Thermal Dynamics® repair facility within thirty (30) days of the repair. No transportation costs of any kind will be paid under this warranty. Transportation charges to send products to an authorized warranty repair facility shall be the responsibility of the customer. -

Page 15: Introduction

This manual provides service instructions for the Ther- Maintenance work should be accomplished in a timely mal Dynamics CutMaster 50 Plasma Cutting Power Sup- manner. If problems are encountered, or the equip- ply. Information in this manual is particularly applicable... - Page 16 INTRODUCTION Manual 0-2806...

-

Page 17: Description

2. Front Panel LED Indicators SECTION 3: DESCRIPTION • AC TEMP • GAS 3.01 Scope 3. Rear Panel Features The purpose of this section is: • Primary Input Power Cable (with Molded Plug, on • To familiarize the service technician with the capa- 208/230V units only) bilities and limitations of the equipment, •... -

Page 18: Power Supply Options And Accessories

7. Pilot Circuitry D. Hand Pendant Control (for machine applications only) Capacitive Discharge (CD), Ignition DC Pilot A hand pendant control with 25 ft (7.6 m) cable which 8. Weight provides ON/OFF signals to the power supply. Power Supply w/Input Cable & Work Lead, Torch & E. -

Page 19: Service Troubleshooting Diagnostics

INV ON signal is given and the DC indicator on the Front Panel turns ON. The CutMaster 50 Power Supply is available for several input voltages. This Service Manual covers all types. When the torch is activated (press torch switch, send... -

Page 20: Common Operating Problems

The purpose of the swirl is to maintain a smooth col- umn of gas. The swirl effect results in one side of a e. Non-Genuine Thermal Dynamics parts used cut being more square than the other. Viewed along 4. Short Torch Parts Life the direction of travel, the right side of the cut is more square than the left. -

Page 21: Troubleshooting Guide - General Information

6. Repair as needed being sure to verify that unit is fully operational after any repairs. A. General Information NOTES The CutMaster 50 Operating Manual describes basic troubleshooting and parts replacement procedures. Many signals are transferred between Printed Cir- cuit Board Assemblies on Cables. If these cables... -

Page 22: Main Input And Internal Power Problems

B. Main Input and Internal Power Tests This completes the Main Arc Test. If the equipment op- erates as described, proceed to Subsection 4.07. If prob- 1. Connect main AC power to the unit. lems still persist then contact Technical Services. 2. - Page 23 8. Faulty ON/OFF switch (refer to Appendix 11, 28 V AC D. System will not pilot; AC indicator ON, TEMP Circuit Diagram). indicator ON Measure for 28VAC between J3-5 and J3-6 on the 1. Air flow through unit is restricted Main Power PC Board.

-

Page 24: Pilot Arc Problems

2. Faulty Pressure Switch Measure for 12 vdc from wire #9 to wire #10 at the Gas Pressure Switch, located on the right side of the unit. a. If voltage is present and pressure is above 50 psi (3.4 bar), replace Gas Pressure Switch/ Solenoid Assembly. - Page 25 C. No arc in torch; No arc at spark gap on CD PC Board; AC indicator ON; TEMP indicator off; Gas flows; GAS and DC indicators ON; CD enable indicator ON 1. Faulty CD PC Board J28-1 NOTE J28-2 Check the size of the CD PCB. Power Supplies with 4"...

-

Page 26: Main Arc Problems

8. Faulty PCR Relay For 208/230V units with Rev H or later Main PC Boards, and all 400V and 460V units: Install a jumper between wires on PCR Relay as indicated below. Try piloting again. Arc shuts off during operation; Arc will not re- start when torch switch is activated. - Page 27 7. Excessive pressure can damage printed circuit board. C. Diode Testing Basics Use only minimal pressure and gentle movement Testing of diode modules requires a digital volt/ohm- when disconnecting or connecting printed circuit meter that has a diode test scale. Remember that even board plugs.

- Page 28 AC voltage at the main power source. D. Input Diode Test Check Input Diode for shorted input diode. CutMaster 50 Input Contactor Voltage Ranges Input Voltage Remove AC power and with an ohmmeter set on the di-...

- Page 29 400V and 460V Power Supply Input Contactor: CutMaster 50 Logic PCB Indicators INV ON CD Enable Rev. AA Logic PCB Connections to To E2 Rev AB+ Logic PCB Main PCB To E3 • If the INV ON indicator does not turn ON, then To E1 replace the Logic PCB.

- Page 30 • After two seconds INV ON indicator on the Logic PCB should turn ON. If indicator does This completes the test procedures. not turn ON, replace Logic PCB. CutMaster 50 Logic PCB Indicators INV ON CD Enable Rev. AA Logic PCB Rev AB+ Logic PCB d.

-

Page 31: Repairs & Replacement Procedures

3. Attach the copper foil to a convenient and exposed electrical ground. This section describes parts replacement procedures and all repairs which may be performed on the CutMaster 50 4. Connect the equipment primary cable ground to Power Supply. the same electrical ground as the wrist strap. -

Page 32: Major External Parts Replacement

B. Tube Handle Replacement 5.04 Major External Parts Replacement 1. Remove the cover per Subsection 5.04-A. 2. Remove the four bolts and star washers securing Refer to Section 6.03 for Major External Replacement Parts the tube handles to the base of the unit. and overall detailed drawing. -

Page 33: Left Side Internal Parts Replacement

B. ON/OFF Switch Replacement D. POT/LED PC Board Replacement 1. Remove the cover per Subsection 5.04-A. Follow the antistatic procedures in Subsection 5.02. 2. Disconnect the four wires on the rear of the ON/ 1. Remove the cover per Subsection 5.04-A. OFF Switch, noting the location and orientation of 2. - Page 34 B. Main Input Contactor Replacement C. Pilot Relay Assembly (PCR) 1. Remove the cover per Subsection 5.04-A. 1. Remove the cover per Subsection 5.04-A. 2. Label and disconnect all wiring leading to the con- 2. Carefully remove all wire connections to the Re- tactor.

- Page 35 E. IGBT Circuit Board, Input Diode, or Output For input diodes on 400 or 460-Volt units only: Diode Replacement a. Cut away one side of the round pad, about 1/4” (6 mm) at the widest, to accommodate Follow the antistatic procedures in Subsection 5.02. the Main PC board standoff on the chassis.

- Page 36 A: Present for input diodes only. B: Position pad with trimmed edge at bottom 4. Disconnect all wire and cable connections to the for CutMaster 50, 400-V and 460-V input Main PC Board, including the connections from diodes only. the three smaller PC Boards. Refer to the Main PC...

-

Page 37: Rear Panel Parts Replacement

For Power Supplies with Type B Filter/Regulator: 5.07 Rear Panel Parts Replacement a. Remove the nut securing the Filter/Regulator Refer to Subsection 6.07 for parts list and overall detailed Assembly to the Regulator Mounting Bracket. drawing. b. Remove the hardware securing the Bracket to the rear panel of the Power Supply. - Page 38 C. Standard Filter Element Replacement D. Optional Single-Stage Filter Element Replacement 1. Remove power from the power supply; turn off the gas supply. NOTES 2. Unscrew the bowl on the bottom of the Regula- The Power Supply shuts down automatically when tor/Filter Assembly.

- Page 39 E. Optional Two-Stage Filter Element F. Input Power Cable Replacement Replacement 1. Remove the cover per Subsection 5.04-A. NOTE 2. Label and disconnect the wires from the Main In- put Contactor. The Two-Stage Air Filter has two Filter Elements. When the Filter Elements become dirty the Power 3.

-

Page 40: Right Side Internal Parts Replacement

6. Install the replacement Pressure Switch/Solenoid 5.08 Right Side Internal Parts Assembly by reversing the above steps. Once in- Replacement stalled, the Solenoid Assembly should fit securely under the Fan Shroud and should not be move- Refer to Section 6.07 Right Side Internal Parts List and able. - Page 41 D. Main Transformer Replacement (T5) 12. Turn unit onto its left side. 13. Position the replacement Transformer as follows: CAUTION a. with the PC Board facing out from the unit; The Power Supplies use two types of Main Trans- b. the cables oriented to the right side; former.

- Page 42 4. Remove the front mounting screw securing the 6. Install the replacement CD Transformer as follows: Output Inductor Assembly to the unit base. 5. Remove grommet from Fan Shroud for better ac- WARNING cess to the Output Inductor Assembly rear mount- ing stud.

-

Page 43: Parts Lists

SECTION 6: PARTS LISTS 6.01 Introduction A. Parts List Breakdown The parts lists provide a breakdown of all replaceable components. The parts lists are arranged as follows: Section 6.03 Major External Replacement Parts Section 6.04 Front Panel Replacement Parts Section 6.05 Left Side Internal Replacement Parts Section 6.06 Right Side Internal Replacement Parts Section 6.07 Rear Panel Replacement Parts Section 6.08 Options and Accessories... -

Page 44: Major External Replacement Parts

6.03 Major External Replacement Parts Item # Description Catalog # Cover with labels 9-8535 Tube, roll handle 9-8520 Hardware: Screw, 10-32 x 1/2 PPH Swageform See Note 1 Washer, 1/4 External Star See Note 1 Screw, 1/4 - 20 x 3/4" Hex See Note 1 A-02819 NOTES... -

Page 45: Front Panel Replacement Parts

6.04 Front Panel Replacement Parts Item# Description Catalog # Knob, Fluted, Skirted, 0.250 I.D. 9-8527 On/Off Rocker Switch, DPST 8-3258 Run/Set Switch, Rocker, SPST 9-1042 Assembly, Pot/LED PCB 9-8004 Cable, Work, #6 awg with Clamp, 20 Ft (6.1 m) 9-8528 A-02850 NOTE Illustration may vary slightly from unit. -

Page 46: Left Side Internal Replacement Parts

6.05 Left Side Internal Replacement Parts Item # Description Catalog # Fuse 1/2A, 250V (For 208/230-Volt units) 9-6395 1/2A, 600V (For 400-Volt and 460-Volt units) 9-8110 Main Input Contactor For 208/230-Volt Units 9-8522 For 400-Volt and 460-Volt Units 9-8554 PCR Pilot Relay (May mount to front panel) 9-7508 PCB Assembly, Logic 9-8536... - Page 47 C, D A-02936 NOTE Illustration may vary slightly from unit. Manual 0-2806 PARTS LISTS...

-

Page 48: Right Side Internal Replacement Parts

6.06 Right Side Internal Replacement Parts Item # Description Catalog # Assembly, Pressure Switch/Solenoid 9-8563 Assembly, CD PCB For 208/230-Volt Units with 4" x 7" (102 mm x 178 mm) CD PCB 9-8541 For 208/230-Volt Units with 3.5" x 4" (89 mm x 102 mm) CD PCB 9-8552 For 400-Volt and 460-Volt Units 9-8552... - Page 49 C, G A, B A-02855 NOTE Illustration may vary slightly from unit. Manual 0-2806 PARTS LISTS...

-

Page 50: Rear Panel Replacement Parts

6.07 Rear Panel Replacement Parts Item # Description Catalog # Assembly, Regulator/Filter Regulator/Filter Assembly type A-1 incl. Bracket (Refer to Note 3) 9-8524 Regulator/Filter Assembly (only) 9-7514 Regulator Mounting Nut (only) 9-5804 Regulator Mounting Bracket (only) For Units with Type A Assembly 9-8521 For Units with Type A-1 Assembly 9-8606... -

Page 51: Options And Accessories

6.08 Options and Accessories Description Catalog # Single-Stage Filter Kit (Includes Filter And Hose) 7-7507 Replacement Filter Body 9-7740 Replacement Filter Element 9-7741 Replacement Filter Hose (Not Shown) 9-7742 Two-Stage Air Line Filter Kit (Includes Hose & Mounting Screws) 7-7500 Bracket, Filter Mounting (Not Shown) 9-7535 Two-Stage Air Filter Assembly... - Page 52 PARTS LISTS 6-10 Manual 0-2806...

-

Page 53: Appendix 1: Input Wiring Requirements

APPENDIX 1: INPUT WIRING REQUIREMENTS Input Power Input Current Input Suggested Sizes (See Notes) Voltage Freq. 1-Ph 3-Ph 1-Ph 3-Ph Fuse (Amps) Wire (AWG) Wire (Canada) (Volts) (Hz) (kVA) (kVA) (Amps) (Amps) 1-Ph 3-Ph 1-Ph 3-Ph 1-Ph 3-Ph 17.5 Line Voltages with Suggested Circuit Protection and Wire Sizes Based on National Electric Code and Canadian Electrical Code NOTES Refer to Local and National Codes or local authority having jurisdiction for proper wiring requirements. -

Page 54: Appendix 2: Sequence Of Operation (Block Diagram

APPENDIX 2: SEQUENCE OF OPERATION (BLOCK DIAGRAM) ACTION ACTION ACTION ACTION ON/OFF switch Close external RUN/SET RUN/SET switch to ON. disconnect switch. switch to RUN. to SET. RESULT RESULT RESULT RESULT AC indicator blinks for 8 Power to system. Gas flow stops. Gas solenoid open, seconds then steady on. -

Page 55: Appendix 3-A: Logic Pc Board Layout (For Rev Aa Logic Boards

APPENDIX 3-A: LOGIC PC BOARD LAYOUT (For Rev AA Logic Boards) TP10 TP1 TP4 A-02779 Pins P1-1 to P1-36 Logic Board Signals P1-1 +12vdc from Main PCB P1-26 Gate Drive B Return P1-2 +12vdc from Main PCB P1-27 Gate Drive B Signal P1-3 Ground P1-28... -

Page 56: Appendix 3-B: Logic Pc Board Layout (For Rev Ab Boards Or Later

APPENDIX 3-B: LOGIC PC BOARD LAYOUT (For Rev AB Boards or Later) A-02937 P1-1 to P1-36 TP10 Logic Board Signals P1-1 +12vdc from Main Power PCB P1-26 Gate Drive B Return P1-2 +12vdc from Main PCB P1-27 Gate Drive B Signal P1-3 Ground P1-28... - Page 57 This page left blank. Manual 0-2806 APPENDIX...

-

Page 58: Appendix 4-A: Main Power Pc Board Layout (For 208/230-Volt Units With Boards To Rev. G

APPENDIX 4-A: MAIN POWER PC BOARD LAYOUT (for 208/230-Volt units with Boards to Rev. G) TP18 TP10 INPUT DIODE OUTPUT DIODE IGBT CIRCUIT A-02767 Main Power PC Board Signals J1-1 +12vdc to Logic PCB J1-16 Logic Low = Pilot on Signal from Logic PCB J1-17 Logic Low = DC OK Signal from Logic PCB J1-2... - Page 59 J1-32 Not used. J1-33 Not used. J1-34 Not used. J1-35 Ground J1-36 Ground J2-1 Overtemp Signal from TS1 mounted on Heatsink J2-2 Overtemp Return J3-1 Pilot ON Signal Logic Low for Pilot ON J3-2 +18 vdc to PCR Pilot Relay J3-3 28VAC B from Auxilliary Transformer to On/OFF Switch J3-4...

-

Page 60: Appendix 4-B: Main Power Pc Board Layout (For 208/230-Volt Units With Boards Rev. H And I

APPENDIX 4-B: MAIN POWER PC BOARD LAYOUT (for 208/230-Volt units with Boards Rev. H and I) TP10 TP18 INPUT DIODE IGBT OUTPUT CIRCUIT DIODE A-03032 Main Power PC Board Signals J1-1 +12vdc to Logic PCB J1-16 Logic Low = Pilot on Signal from Logic PCB J1-17 Logic Low = DC OK Signal from Logic PCB J1-2... - Page 61 J1-32 Current Sense-A. J1-33 Current Sense-B. J1-34 Current Sense-B. J1-35 Ground J1-36 Ground J2-1 Overtemp Signal from TS1 mounted on Heatsink J2-2 Overtemp Return J3-1 Pilot ON Signal Logic Low for Pilot ON J3-2 +18 vdc to PCR Pilot Relay J3-3 28VAC B from Auxilliary Transformer to On/OFF Switch J3-4...

-

Page 62: Appendix 4-C: Main Power Pc Board Layout (For 208/230-Volt Units With Boards Rev. J

APPENDIX 4-C: MAIN POWER PC BOARD LAYOUT (for 208/230-Volt units with Boards Rev. J) R85 (Refer J27 (Refer to NOTE) to NOTE) TP10 E12 E11 TP18 J2 J23 E42 E43 E36 E37 E39 E38 E40 E41 E28 E29 A-03270 TP-13 TP-14 Main Power PC Board Signals J1-1... - Page 63 J1-28 Gate Drive A Return from Logic PCB J1-29 Gate Drive A Return from Logic PCB J1-30 Negative out J1-31 Current Sense-A J1-32 Current Sense-A. J1-33 Current Sense-B. J1-34 Current Sense-B. J1-35 Ground J1-36 Ground J2-1 Overtemp Signal from TS1 mounted on Heatsink J2-2 Overtemp Return J3-1...

-

Page 64: Appendix 4-D: Main Power Pc Board Layout (For 400-Volt And 460-Volt Units

APPENDIX 4-D: MAIN POWER PC BOARD LAYOUT (for 400-Volt and 460-Volt units ) TP18 TP10 Assembly No. 19x1743 AA TP13 TP14 A-03043 Main Power PC Board Signals J1-16 Logic Low = Pilot on Signal from Logic PCB J1-1 +12vdc to Logic PCB J1-17 Logic Low = DC OK Signal from Logic PCB J1-2... - Page 65 J1-32 Current Sense-A. J1-33 Current Sense-B. J1-34 Current Sense-B. J1-35 Ground J1-36 Ground J2-1 Overtemp Signal from TS1 mounted on Heatsink J2-2 Overtemp Return J3-1 Pilot ON Signal Logic Low for Pilot ON J3-2 +18 vdc to PCR Pilot Relay J3-3 28VAC B from Auxilliary Transformer to On/OFF Switch J3-4...

-

Page 66: Appendix 5-A: Cd Pc Board Layout (For 208/230-Volt Units Through Unit Rev Al

APPENDIX 5-A: CD PC BOARD LAYOUT (for 208/230-Volt units through Unit Rev AL) J11-1 J11-3 J11-4 J11-5 A-03329 CD PC Board Signals J11-1 Approx 36 VAC from Main Switching Transformer. Refer to NOTES. J11-2 Return J11-3 Approx 36 VAC from Main Switching Transformer. Refer to NOTES. J11-4 Logic Low CD Enable Signal from Logic Board (J5-4) J11-5... -

Page 67: Appendix 5-B: Cd Pc Board Layout (For 400-Volt And 460-Volt Units, And 208/230-Volt Units Rev Am And Later

APPENDIX 5-B: CD PC BOARD LAYOUT (for 400-Volt and 460-Volt units, and 208/230-Volt units Rev AM and later) A-03086 CD PC Board Signals J28-1 +12 vdc J28-2 Logic Low CD Enable J28-3 Not Used J28-4 Not Used J28-5 Approx 36VAC from Main Switching Transformer (see NOTES) J28-6 Not Used J28-7... -

Page 68: Appendix 6: Led/Pot Pc Board Layout

APPENDIX 6: LED/POT PC BOARD LAYOUT A-01206 Pot/LED PC Board Signals J14-1 +10 vdc from Logic PC Board (J22-1) Pot High J14-2 Current Control to Logic PC Board (J22-2) Pot Wiper J14-3 Return for Current Control from Logic PC Board (J22-3) Pot Low J14-4 12vdc (J22-4) J14-5... -

Page 69: Appendix 7: Igbt Circuit Pc Board Layout

APPENDIX 7: IGBT CIRCUIT PC BOARD LAYOUT TP13 TP14 A-02851 Manual 0-2806 A-17 APPENDIX... -

Page 70: Appendix 8-A: Input Diode Pc Board Layout For 208/230-Volt Units

APPENDIX 8-A: INPUT DIODE PC BOARD LAYOUT for 208/230-Volt units A-02852 APPENDIX A-18 Manual 0-2806... -

Page 71: Appendix 8-B: Input Diode Pc Board Layout For 400-Volt And 460-Volt Units

APPENDIX 8-B: INPUT DIODE PC BOARD LAYOUT for 400-Volt and 460-Volt units Assembly No. 19x1743 AA A-03088 Manual 0-2806 A-19 APPENDIX... -

Page 72: Appendix 9: Output Diode Pc Board Layout

APPENDIX 9: OUTPUT DIODE PC BOARD LAYOUT A-02853 APPENDIX A-20 Manual 0-2806... -

Page 73: Appendix 10-A: Main Pc Board Wiring (208/230-Volt Units With Boards Rev. G Or Earlier

APPENDIX 10-A: MAIN PC BOARD WIRING (208/230-Volt units with Boards Rev. G or earlier) To Thermistor on Heatsink To Thermal Protection Device on To Input Output M1 Fan Solenoid/Pressure ON/OFF Contactor Inductor Harness Switch Wire Harness RUN SET Main PC Board Wire Harness LED/PCB Wire... -

Page 74: Appendix 10-B: Main Pc Board Wiring (208/230-Volt Units With Boards Rev. H And I

APPENDIX 10-B: MAIN PC BOARD WIRING (208/230-Volt units with Boards Rev. H and I) To Thermal Protection Solenoid/Pressure Device on Output To Input Switch Wire Harness To Thermistor ON/OFF Inductor Contactor M1 Fan RUN/SET on Heatsink Harness Wire harness LED/PCB Wire Harness INPUT... -

Page 75: Appendix 10-C: Main Pc Board Wiring (208/230-Volt Units With Boards Rev. J

APPENDIX 10-C: MAIN PC BOARD WIRING (208/230-Volt units with Boards Rev. J) To Thermal Protection Device on Output J27 (Refer to NOTE) Solenoid/Pressure Inductor ON/OFF Switch Wire Harness To Thermistor R85 (Refer RUN/SET To Input M1 Fan on Heatsink to NOTE) Wire harness Contactor Harness... -

Page 76: Appendix 10-D: Main Pc Board Wiring (For 400-Volt And 460-Volt Units

APPENDIX 10-D: MAIN PC BOARD WIRING (for 400-Volt and 460-Volt units) To Thermal Protection M1 Fan Device on Output Inductor To Input ON/OFF Harness Contactor Solenoid/Pressure RUN/SET To Thermistor Switch Wire Harness Wire Harness on Heatsink Auxiliary Transformer to Pot/LED Input Diode To Main... -

Page 77: Appendix 11: 28Vac Circuit Diagram

APPENDIX 11: 28VAC CIRCUIT DIAGRAM Line Voltage 0.5A Fuse 3 4 5 6 ON/OFF Switch 1 2 5 6 primary Auxiliary Transformer Voltage Protection CRT/+12 Regulator +12vdc Main Power PC Board A-02770 Manual 0-2806 A-25 APPENDIX... -

Page 78: Appendix 12: Maintenance Schedule

APPENDIX 12: MAINTENANCE SCHEDULE This schedule applies to all types of non-liquid cooled plasma cutting systems. Some systems will not have all the parts listed and those checks need not be performed. NOTE The actual frequency of maintenance may need to be adjusted according to the operating environment. Daily Operational Checks or Every Six Cutting Hours: Check torch consumable parts, replace if damaged or worn. - Page 79 This page left blank. Manual 0-2806 A-27 APPENDIX...

-

Page 80: Appendix 13-A: System Schematic (208/230-Volt Units With Main Pc Boards Rev. G Or Earlier

APPENDIX 13-A: SYSTEM SCHEMATIC (208/230-Volt units with Main PC Boards Rev. G or earlier) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 A-02943 APPENDIX A-28... - Page 81 24 25 26 27 28 29 30 31 32 33 34 35 36 24 25 26 27 28 29 30 31 32 33 34 35 36 A-02943 Manual 0-2806 A-29 APPENDIX...

-

Page 82: Appendix 13-B: System Schematic (208/230-Volt Units With Main Pc Board Rev. H Or I

APPENDIX 13-B: SYSTEM SCHEMATIC (208/230-Volt units with Main PC Board Rev. H or I) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 A-03031 APPENDIX A-30... - Page 83 24 25 26 27 28 29 30 31 32 33 34 35 36 24 25 26 27 28 29 30 31 32 33 34 35 36 A-03031 Manual 0-2806 A-31 APPENDIX...

-

Page 84: Appendix 13-C: System Schematic (208/230-Volt Units With Main Pc Board Rev. J Or Later

APPENDIX 13-C: SYSTEM SCHEMATIC (208/230-Volt units with Main PC Board Rev. J or later) A-03269 APPENDIX A-32 Manual 0-2806... - Page 85 A-03269 Manual 0-2806 A-33 APPENDIX...

-

Page 86: Appendix 13-D: System Schematic (400-Volt And 460-Volt Units

APPENDIX 13-D: SYSTEM SCHEMATIC (400-Volt and 460-Volt units) A-02967 APPENDIX A-34 Manual 0-2806... - Page 87 A-02967 Manual 0-2806 A-35 APPENDIX...

Need help?

Do you have a question about the CutMaster 50 and is the answer not in the manual?

Questions and answers