Table of Contents

Advertisement

Quick Links

Minarc

Evo 150

EN

Operating manual • English

FI

Käyttöohje • Suomi

SV

Bruksanvisning • Svenska

NO

Bruksanvisning • Norsk

DA

Brugsanvisning • Dansk

DE

Gebrauchsanweisung • Deutsch

NL

Gebruiksaanwijzing • Nederlands

FR

Manuel d'utilisation • Français

ES

Manual de instrucciones • Español

PL

Instrukcja obsługi • Polski

RU

Инструкции по эксплуатации • По-русски

PT

Manual de utilização • Português

IT

Manuale di istruzioni • Italiano

Advertisement

Table of Contents

Summary of Contents for Kemppi Evo 150

- Page 1 Minarc Evo 150 Operating manual • English Käyttöohje • Suomi Bruksanvisning • Svenska Bruksanvisning • Norsk Brugsanvisning • Dansk Gebrauchsanweisung • Deutsch Gebruiksaanwijzing • Nederlands Manuel d’utilisation • Français Manual de instrucciones • Español Instrukcja obsługi • Polski Инструкции по эксплуатации • По-русски...

- Page 3 OPERATING MANUAL English...

-

Page 4: Table Of Contents

CONTENTS PREFACE ..................General ............................Product introduction . -

Page 5: Preface

2.6 "Connecting cable connections" later in this manual. Minarc Evo 150 tolerates fluctuations in input voltage, and it is suitable for on-site work using power generators and long power cables. The power source utilises PFC technology to ensure optimum usage on a single phase power supplies. -

Page 6: Before You Start Using The Unit

High rates of harmonic current may cause losses and disturbance to some equipment. Minarc Evo 150 complies with IEC 61000-3-12. SERIAL NUMBER The serial number of the unit is marked on the rating plate. The serial number makes it possible to trace product manufacturing series. -

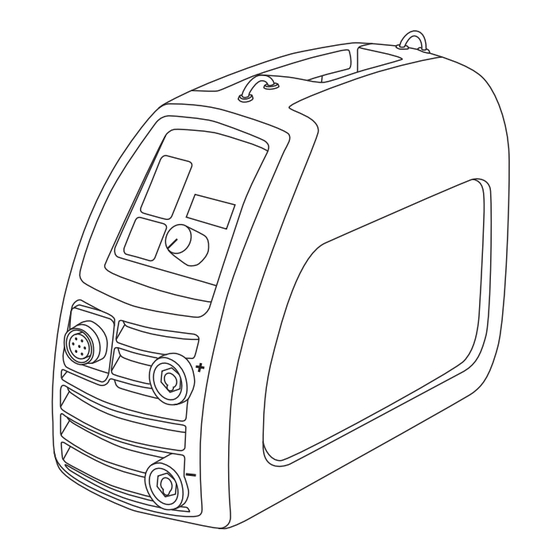

Page 7: General View Of The Machine

GENERAL VIEW OF THE MACHINE Machine case ON/OFF power switch Welding current display Positive and negative welding circuit connection sockets Electrode holder and welding cable Earth return cable and clamp Connection socket for remote control of welding current CABLE CONNECTIONS Connection to the mains The machine is equipped with a 3 m long supply voltage cable and plug. -

Page 8: Operating Functions

OPERATING FUNCTIONS Welding current adjustment knob Welding process selection button Welding current meter display Indicator lights, machine 'ON' , (VRD: 'VRD safe ON') Overheating indicator Remote control ON/OFF button Main switch and 'ON' indicator When you turn the main switch to position I, the indicator light is illuminated and the unit is ready for welding. -

Page 9: Use

Welding fumes may be dangerous to your health. Ensure that there is ample ventilation NOTE! during welding! Never look at the arc without a face shield specifically designed for arc welding! Protect yourself and your surrounding area from the arc and hot welding spatter! PREPARE TO WELD Always wear protective clothing, gloves, face and eye shields suitable for welding. -

Page 10: Mma Welding

When removing the slag coating, ensure you protect your eyes and face with suitable equipment. For more info, visit www.kemppi.com > Welding ABC. 3.2.1 Filler materials and equipment Minarc Evo can be used with all electrode types suitable for DC welding. Electrode sizes for the unit are listed in Technical data section later in this manual. -

Page 11: Tig Welding

TIG WELDING Minarc Evo 150 can also be used for basic TIG welding and remote current control. The TIG arc is started by the touch and lift ignition technique. Order numbers for the additional equipment required for TIG welding and/or remote current control devices can be found in Ordering codes section later in this manual. -

Page 12: Dc Tig Welding

Argon shielding gas is used in DC TIG welding. Your dealer will give you advice on choosing the correct gas, supplier, and supporting equipment. Open the gas valve on the Kemppi TTM 15V TIG torch. When the gas starts to flow, ignite the arc. The arc is activated by lightly touching the work piece with the tungsten electrode and lifting away. -

Page 13: Using The Shoulder Strap

The length of arc is regulated by holding the tungsten electrode tip at a suitable distance from work piece. A suitable arc length is usually about the diameter of the tungsten electrode. When the arc is burning, move the electrode slowly forwards to the start of the weld, tilting the torch to approximately 10-15°... -

Page 14: Maintenance

• If the machine’s duty cycle has been exceeded, wait for indicator to turn off. In certain circumstances, this light may also indicate irregularity in the supply voltage. Too low or high supply voltage. If the machine’s malfunction is not eliminated with the above measures, contact Kemppi service. STORAGE Store the unit in a clean and dry place. -

Page 15: Disposal Of The Machine

The owner of the equipment is obliged to deliver a decommissioned unit to a regional collection centre, per the instructions of local authorities or a Kemppi representative. By applying this European directive you will improve the environment and human health. -

Page 16: Technical Data

TECHNICAL DATA Minarc Evo 150 Connection voltage 1 ~ 50/60 Hz 230 V ± 15 % Rated power at max. current 35 % ED MMA 140 A/4.5 kVA 35 % ED TIG 150 A/3.2 kVA Supply current 35 % ED I 19.7 A... - Page 18 78681 EPONE CEDEX myynti.fi@kemppi.com info.ru@kemppi.com FRANCE Tel +33 1 30 90 04 40 KEMPPI SVERIGE AB KEMPPI, TRADING (BEIJING) COMPANY, Telefax +33 1 30 90 04 45 LIMITED Box 717 sales.fr@kemppi.com Room 420, 3 Zone, Building B, S-194 27 UPPLANDS VÄSBY No.12 Hongda North Street,...

Need help?

Do you have a question about the Evo 150 and is the answer not in the manual?

Questions and answers