Table of Contents

Advertisement

Quick Links

OWNER' S GUIDE

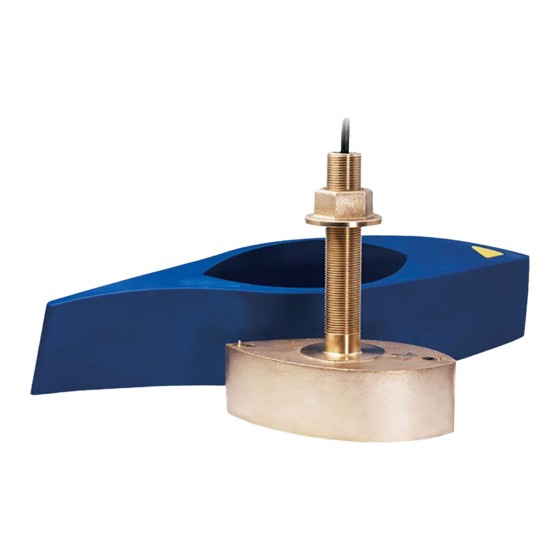

Thru - Hull, Metal Stem

Depth Transducer

Models: B45, B46, B258, B260,

SS258, SS260, SS261, SS270W, SS505, SS560

IMPORTANT : Please read the instructions completely

before proceeding with the installation. These

instructions supersede any other instructions in your

instrument manual if they differ.

CAUTION : NEVER USE SOLVENTS!

Cleaners, fuel, paint, sealants, and other products may

contain strong solvents, such as acetone, which attack

many plastics greatly reducing their strength.

Applications

• Bronze transducer recommended for fiberglass or wood hulls.

Never mount a bronze transducer in a metal hull, because

electrolytic corrosion will occur.

• Stainless steel transducer compatible with all hull materials.

Recommended for aluminum hulls to prevent electrolytic corrosion

provided the stainless steel transducer is isolated from the metal hull.

Caution : Installation requires using a fairing kit to isolate the

stainless steel transducer from a metal hull.

• Never install a metal transducer on a vessel with a positive

ground system .

Tools & Materials

Safety goggles

Dust mask

Electric drill

Drill bits:

Pilot hole

B45, B46, SS505

B260, SS260, SS261,

SS270W, SS560

B258, SS258

Sandpaper

Mild household detergent or weak solvent (such as alcohol)

File (installation in a metal hull)

Fairing (MANDATORY FOR SS261 AND SS560)

Angle finder or digital level (installation with a fairing)

Band saw or hand saw (installation with a fairing)

Rasp or power tool (installation with a fairing)

Marine sealant (suitable for below waterline)

Slip-joint pliers

Zip-ties

Water-based antifouling paint ( MANDATORY IN SALT WATER )

Installation in a cored fiberglass hull: (see page 4)

Drill bit for hull interior:

B45, B46, SS505

B260, SS260, SS261,

SS270W, SS560

B258, SS258

Cylinder, wax, tape, and casting epoxy

&

3mm or 1/8"

22mm or 7/8"

33mm or 1-5/16"

30mm or 1-3/16"

35mm or 1-3/8"

42mm or 1-5/8"

40mm, 41mm, or 1-5/8"

INSTALLATION INSTRUCTIONS

Record the information found on the cable tag for future reference.

PN:___________________Date___________Frequency________kHz

B45

High-Performance

Identify Your Model

The model name is printed on the cable tag.

About Fairings

Nearly all vessels have some deadrise angle at the mounting

location. If the transducer is mounted directly to the hull, the

sound beam will be tilted to the side at the same angle as the

deadrise. A fairing is strongly recommended if the deadrise angle

exceeds 10 ° .

• Orients the sound beam straight down by mounting the

transducer parallel to the water surface.

• Mounts the transducer deeper in the water for clean flow over

the transducer's face.

Made of a high-impact polymer with an integrated cutting guide,

an Airmar fairing is safer and easier to cut with a band saw and

shape with hand tools than custom fairings. It can be shaped to

accommodate a deadrise angle of up to about 25 ° . (For fairing

part numbers, see "Replacement Parts" on page 4.)

A backing block is mounted inside the hull to provide a level

surface for the hull nut to seat against (see Figure 2). It is

fabricated matching the interior deadrise angle of the boat. After

cutting an Airmar fairing, use the remaining section with the

cutting guide for the backing block.

High-Performance Fairing has a long streamlined shape for

excellent performance above 15kn (18MPH). (To order see

"Replacement Parts" on page 4.)

Mounting Location

• The water flowing across the hull must be smooth with a

minimum of bubbles and turbulence (especially at high speeds).

Caution : DO NOT MOUNT near water intake or discharge

openings or behind strakes, fittings, or hull irregularities.

• The transducer must be continuously immersed in water.

• The transducer beam must be unobstructed by the keel or

propeller shaft(s).

• Choose a location away from interference caused by power and

radiation sources such as: the propeller(s) and shaft(s), other

Standard

Fairing

Fairing

Advertisement

Table of Contents

Summary of Contents for Airmar B45

- Page 1 Made of a high-impact polymer with an integrated cutting guide, Dust mask an Airmar fairing is safer and easier to cut with a band saw and Electric drill shape with hand tools than custom fairings. It can be shaped to Drill bits: accommodate a deadrise angle of up to about 25 °...

- Page 2 fin keel 300–600mm (1–2'). Figure 2. Bedding and installing in a metal hull • Full keel sailboat —Locate amidships and away from the keel (B45 with Standard Fairing shown) at the point of minimum deadrise angle. Copyright © 2005, 2007 Airmar Technology Corp.

- Page 3 If the cable must be cut and 6. Shape the fairing to the hull as precisely as possible with a rasp spliced, use Airmar’s splash-proof Junction Box No. 33-035 and or power tool. follow the instructions provided. Removing the water-proof 7.

- Page 4 Figure 6. Preparing a cored fiberglass hull email: sales@airmareurope.com Copyright © 2005 Airmar Technology Corp. AIRMAR ® 35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA TECHNOLOGY CORPORATION www.airmar.com ■ Copyright © 2003, 2005, 2007 Airmar Technology Corp. All rights reserved.

Need help?

Do you have a question about the B45 and is the answer not in the manual?

Questions and answers