Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

User's

Manual

Y okogawa Electric Corporation

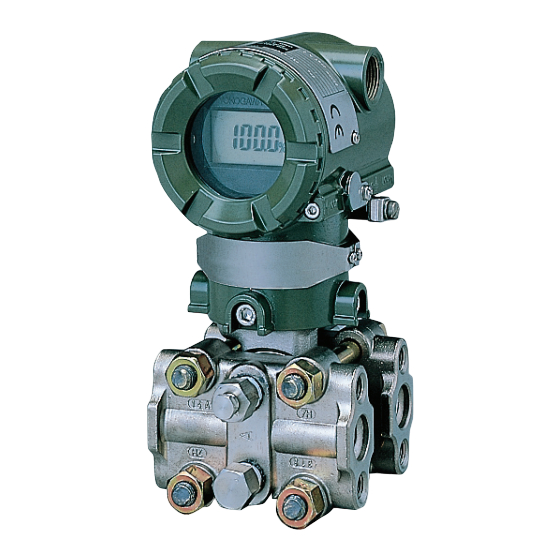

EJA Series Differential Pressure and

Pressure Transmitters

Installation Manual

1.

1.1

1.2

1.3

2.

2.1

2.2

2.3

2.4

2.5

2.6

2.7

3.

3.1

3.2

3.3

3.4

3.5

3.6

4.

4.1

4.2

4.3

5.

5.1

5.2

5.3

5.4

5.5

6.

6.1

6.2

7.

8.

CD-ROM included

IM 01C22A01-01E

For Safe Use of Product ..............................................2

Warranty ......................................................................2

ATEX Documentation ..................................................4

Model and Specifications Check .................................5

Selecting the Installation Location ..............................5

Pressure Connection ..................................................6

Installation of Explosion Protected Type .....................6

EMC Conformity Standards ..................................... 13

PED (Pressure Equipment Directive) ...................... 13

Low Voltage Directive ............................................... 14

Mounting................................................................... 15

Mounting the Diaphragm Seals ............................... 15

Diaphragm Seals Installation Consideration ............ 16

Affixing the Teflon Film ............................................. 17

Rotating Transmitter Section .................................... 18

Changing the Direction of Integral Indicator............. 18

Impulse Piping Installation Precautions ................... 19

Impulse Piping Connection Examples ..................... 21

Process Piping Installation Precautions ................... 22

Wiring Precautions ................................................... 23

Wiring ....................................................................... 23

Grounding ................................................................ 25

Power Supply Voltage and Load Resistance ........... 25

Preparation for Starting Operation ........................... 26

Zero Point Adjustment .............................................. 27

IM 01C22A01-01E

1st Edition

1

2

3

4

5

6

7

8

Advertisement

Table of Contents

Summary of Contents for YOKOGAWA Dpharp vigilantplant EJA Series

-

Page 1: Table Of Contents

User’s Manual EJA Series Differential Pressure and Pressure Transmitters Installation Manual CD-ROM included IM 01C22A01-01E Introduction For Safe Use of Product ..........2 Warranty ..............2 ATEX Documentation ..........4 Handling Cautions 2.1 Model and Specifications Check .........5 2.2 Selecting the Installation Location ......5 Pressure Connection ..........6 Installation of Explosion Protected Type .....6 EMC Conformity Standards ........ -

Page 3: Regarding This Manual

• All rights reserved. No part of this manual may be explanations, maintenance, troubleshooting, and fieldbus reproduced in any form without Yokogawa’s written communication operating procedures, both F OUNDATION permission. Fieldbus and PROFIBUS PA. For the items which are • Yokogawa makes no warranty of any kind with regard not covered in this manual, see the applicable user’s to this manual, including, but not limited to, implied manuals in the CD-ROM attached to this manual as listed warranty of merchantability and fitness for a particular in Table 1.1. purpose. ● Installation manual (this document) • If any question arises or errors are found, or if any EJA series common manual information is missing from this manual, please inform the nearest Yokogawa sales office. -

Page 4: Introduction

2.4 (Installation of an Explosion Protected in this manual when handling this instrument. In case Instrument) of this manual. the instrument is handled in contradiction to these • The use of this instrument is restricted to those who instructions, Yokogawa does not guarantee safety. have received appropriate training in the device. Please give your attention to the followings. • Take care not to create sparks when accessing the instrument or peripheral devices in a hazardous (a) Installation location. • The instrument must be installed by an expert (f) Modification engineer or a skilled personnel. The procedures • Yokogawa will not be liable for malfunctions or described about INSTALLATION are not permitted for damage resulting from any modification made to this operators. instrument by the customer. • In case of high process temperature, care should be taken not to burn yourself because the surface of body and case reaches a high temperature. Warranty • The instrument installed in the process is under • The warranty shall cover the period noted on the pressure. Never loosen the process connector bolts quotation presented to the purchaser at the time of to avoid the dangerous spouting of process fluid. purchase. Problems occurred during the warranty • During draining condensate from the pressure... - Page 5 <1. Introduction> • Responsible party for repair cost for the problems shall be determined by Yokogawa based on our investigation. • The Purchaser shall bear the responsibility for repair costs, even during the warranty period, if the malfunction is due to: - Improper and/or inadequate maintenance by the purchaser. - Failure or damage due to improper handling, use or storage which is out of design conditions. - Use of the product in question in a location not conforming to the standards specified by Yokogawa, or due to improper maintenance of the installation location. - Failure or damage due to modification or repair by any party except Yokogawa or an approved representative of Yokogawa. - Malfunction or damage from improper relocation of the product in question after delivery. - Reason of force majeure such as fires,...

-

Page 6: Atex Documentation

<1. Introduction> ATEX Documentation This is only applicable to the countries in European Union. IM 01C22A01-01E... -

Page 7: Handling Cautions

<2. Handling Cautions> Handling Cautions When the transmitter is delivered, visually check them Bolt to make sure that no damage occurred during shipment. Process connector Also check that all transmitter mounting hardware shown Process connector Gasket in Figure 2.1 is included. If the transmitter was ordered U-bolt without the mounting bracket or without the process connector, the transmitter mounting hardware is not Mounting bracket included. (Flat type) Table 2.1 Applicable Model Code for Mounting Mounting bracket Hardware (L type) U-bolt nut Applicable Transmitter mounting bolt Suffix code Part name model... -

Page 8: Pressure Connection

(d) Installation of Explosion-protected Transmitters undertaken by the customer, intrinsically safe Explosion-protected transmitters can be installed construction or explosionproof construction is damaged in hazardous areas according to the types of and may cause dangerous condition. Please contact gases for which they are certified. See Subsection Yokogawa for any repair or modification required to the 2.4 “Installation of Explosion Protected Type instrument. Transmitters.” NOTE Pressure Connection For F Fieldbus and PROFIBUS PA OUNDATION... - Page 9 • Intrinsically Safe for Class I, Division 1, Groups A, Note 4. Maintenance and Repair B, C & D. Class II, Division 1, Groups E, F & G and • The instrument modification or parts replacement by Class III, Division 1 Hazardous Locations. other than authorized representative of Yokogawa • Nonincendive for Class I, Division 2, Groups A, B, C & Electric Corporation is prohibited and will void Factory D. Class II, Division 2, Groups E, F & G and Class III, Mutual Intrinsically safe and Nonincendive Approval.

-

Page 10: Wiring

* Associated apparatus (CSA certified barriers) • Take care not to generate mechanical sparking when Maximum output voltage (Voc) ≤ 30 V accessing to the instrument and peripheral devices in Maximum output current (Isc) ≤ 165 mA a hazardous location. Maximum output power (Pmax) ≤ 0.9 W Note 4. Maintenance and Repair Note 3. Installation • The instrument modification or parts replacement by • All wiring shall comply with Canadian Electrical Code other than authorized representative of Yokogawa Part I and Local Electrical Codes. Electric Corporation is prohibited and will void Factory • The instrument modification or parts replacement by Mutual Explosionproof Approval. other than authorized representative of Yokogawa Electric Corporation and Yokogawa Corporation of America is prohibited and will void Canadian FM Intrinsically Safe Type/FM Standards Intrinsically safe and nonincendive Explosionproof Type Certification. - Page 11 • Take care not to generate mechanical sparking when particular type of protection is selected, any accessing to the instrument and peripheral devices in other type of protection cannot be used. The a hazardous location. installation must be in accordance with the Note 4. Maintenance and Repair description about the type of protection in this • The instrument modification or parts replacement by instruction manual. other than authorized representative of Yokogawa Note 2. In order to avoid confusion, unnecessary Electric Corporation and Yokogawa Corporation marking is crossed out on the label other of America is prohibited and will void Canadian than the selected type of protection when the Standards Explosionproof Certification. transmitter is installed. Non-Hazardous Hazardous Locations Division 1 IECEx Intrinsically Safe Type / type n...

- Page 12 • In any safety barrier used output current must be limited by a resistor 'R' such that Io=Uo/R. [type n] • The safety barrier must be IECEx certified. Hazardous Location Non-hazardous Location • Input voltage of the safety barrier must be less than Group IIC, Zone 2 250 Vrms/Vdc. • The instrument modification or parts replacement by IECEx Certified EJA Series Pressure other than authorized representative of Yokogawa Equipment [nL] Transmitters Electric Corporation and will void IECEx Intrinsically safe and type n certification. Supply – – • The cable entry devices and blanking elements for Not Use type n shall be of a certified type providing a level of Safety Barrier ingress protection of at least IP54, suitable for the F0208.ai...

- Page 13 • Take care not to generate mechanical sparking when [Installation Diagram] accessing to the instrument and peripheral devices in a hazardous location. Hazardous Location Non-hazardous Location Transmitter Note 4. Maintenance and Repair • The instrument modification or parts replacement by Safety Barrier *1 Supply other than authorized representative of Yokogawa – – Electric Corporation is prohibited and will void IECEx Certification. 2.4.4 CENELEC ATEX (KEMA) Certification F0209.ai *1: In any safety barriers used the output current must be limited by a resistor “R” such that Imaxout-Uz/R. (1) Technical Data CENELEC ATEX (KEMA) Intrinsically Safe...

- Page 14 <2. Handling Cautions> Note 5. Maintenance and Repair [Installation Diagram] • The instrument modification or parts replacement by Hazardous Location Non-hazardous Location other than authorized representative of Yokogawa (Zone 2 only) Electric Corporation is prohibited and will void KEMA Transmitter Flameproof Certification. Supply Power Supply – – CENELEC ATEX (KEMA) Intrinsically Safe Type/CENELEC ATEX (KEMA) Flameproof Type/CENELEC ATEX Type n F0210.ai Model EJA-A Series pressure transmitters with Ratings of the Power Supply as follows; Maximum Voltage: 30 V...

-

Page 15: Emc Conformity Standards

*1: The third figure from the last shows the last one figure of the year of production. For example, the production year of the product engraved in “NO.” column on the name plate as follows is 2001. (5) Maintenance and Repair 12A819857 WARNING The year 2001 The instrument modification or parts replacement by *2: “180-8750” is a zip code which represents the following address. other than authorized Representative of Yokogawa Electric Corporation is prohibited and will void the 2-9-32 Nakacho, Musashino-shi, Tokyo Japan certification. EMC Conformity Standards (6) Name Plate EN61326, AS/NZS CISPR11 Name plate CAUTION This instrument is a Class A product, and it is designed for use in the industrial environment. Please use this instrument in the industrial environment only. : Refer to USER'S MANUAL... -

Page 16: Low Voltage Directive

<2. Handling Cautions> (2) Technical Data Low Voltage Directive • Models without /PE3 Applicable standard : EN61010-1 Article 3, Paragraph 3 of PED, denoted as Sound Engineering Practice (SEP) . (1) Pollution Degree 2 • Models with /PE3 "Pollution degree" describes the degree to which Module: H a solid, liquid, or gas which deteriorates dielectric Type of Equipment: Pressure Accessory - Vessel strength or surface resistivity is adhering. " 2 " applies Type of Fluid: Liquid and Gas to normal indoor atmosphere. Normally, only non- Group of Fluid: 1 and 2 conductive pollution occurs. Occasionally, however, temporary conductivity caused by condensation must PS-V Model V(L) Category* (bar) -

Page 17: Installation

<3. Installation> Installation IMPORTANT Adapter U-bolt (S) • When welding piping during construction, take care not to allow welding currents to flow through U-bolt nut (S) the transmitter. • Do not step on this instrument after installation. • For EJA430A, the atmospheric opening is located U-bolt nut (L) U-bolt (L) on the low pressure side cover flange. For EJA530A with Measurement span code A, B, and Mounting bracket 50 mm(2-inch) pipe C, the pipe is attached for the opening. These F0304.ai openings must not face upward. Figure 3.4 EJA510A and EJA530A Mounting Pipe Mounting the Diaphragm Zero-adjustment screw (Open to atmosphere) -

Page 18: Diaphragm Seals Installation Consideration

<3. Installation> 3.2.1 EJA210A and EJA220A Diaphragm Seals Installation The transmitter is mounted on a process using its Consideration high pressure side flange as shown in Figure 3.5. The IMPORTANT customer should prepare the mating flange, gasket, stud bolts and nuts. • When measuring the liquid level of the tank, the Stud bolt minimum liquid level (zero point) must be set to a Gasket level at least 50 mm above the center of the high pressure side diaphragm seal (see Figure 3.2.3). • Correctly install the diaphragm seals on the high and low pressure sides of the process, checking the label on each seal. • To avoid measuring error duets temperature difference between the two diaphragm seals, capillary tube must be bound together. The F0305.ai capillary tube must be securely fixed to the tank Figure 3.5 EJA210A and EJA220A Mounting wall to prevent movement by wind or vibration. -

Page 19: 3.4 Affixing The Teflon Film

<3. Installation> IMPORTANT pressure side The transmitter should be installed below the high pressure (HP) process connection to ensure a positive head pressure of fill fluid. The recommended height between the HP process connection and the transmitter is show in the following table. Pay special attention to vacuum applications. Model Height (h) EJA118 600 mm EJA438W Wetted parts material code S, (–) 700 mm T, U, EJA438N High EJA438W Wetted parts material code H 1,300 mm pressure side Wetted parts material code F0308.ai Figure 3.8 Example of Installation to Tank If it can not be installed below the HP process (Caution on Installation) connection with the recommended height above,... -

Page 20: Rotating Transmitter Section

<3. Installation> 4) After rotating the LCD, align both the LCD board Rotating Transmitter Section assembly and CPU assembly connectors and engage The transmitter section can be rotated in 90° segments. them. 5) Insert and tighten the two mounting screws. 1) Remove the two Allen screws that fasten the 6) Replace the cover. transmitter section and capsule assembly, using the Allen wrench. Also, remove the pipe for EJA530A CPU assembly with Measurement span code A, B, and C, using the slotted screwdriver. 2) Rotate the transmitter section slowly in 90° segments. Mounting screw Shrouding bolt 3) Tighten the two Allen screws to a torque of 5 N·m. IMPORTANT LCD board assembly F0311.ai Do not rotate the transmitter section more than 180°. Figure 3.11 Rotating Integral Indicator Pressure-detector section Rotate 90 or 180 segments Conduit connection... -

Page 21: Installing Impulse Piping

<4. Installing Impulse Piping> Installing Impulse Piping Impulse Piping Installation (3) Tightening the Process Connector Mounting Bolts Precautions After connecting the impulse piping, tighten the process The impulse piping that connects the process outputs connector mounting bolts uniformly. to the transmitter must convey the process pressure accurately. If, for example, gas collects in a liquid filled (4) Connecting the Transmitter and 3-Valve impulse piping, or the drain of a gas-filled impulse piping Manifold (EJA110A) becomes plugged, the impulse piping will not convey A 3-valve manifold consists of two stop valves to block the pressure accurately. Since this will cause errors process pressure and an equalizing valve to equalize in the measurement output, select the proper piping the pressures on the high and low pressure sides of the method for the process fluid (gas, liquid, or steam). Pay transmitter. Such a manifold makes it easier to disconnect careful attention to the following points when routing the the transmitter from the impulse piping, and is convenient impulse piping and connecting the impulse piping to the... -

Page 22: Routing The Impulse Piping

<4. Installing Impulse Piping> 4) Now tighten the nuts and bolts securely in the NOTE following sequence: Process connector bolts �� transmitter-end ball head �� transmitter-end ball head transmitter-end ball head • If the process fluid is a gas, the taps must be lock nuts �� 3-valve manifold ball head lock nuts �� �� 3-valve manifold ball head lock nuts �� 3-valve manifold ball head lock nuts �� �� vertical or within 45° either side of vertical. 3-valve manifold mounting bracket U-bolt nuts • If the process fluid is a liquid, the taps must be horizontal or below horizontal, but not more than ... -

Page 23: Impulse Piping Connection Examples

<4. Installing Impulse Piping> (5) Condensate Pots for Steam Flow Liguid Steam Measurement Orifice Condensate pot Tap valve If the liquid in the impulse piping repeatedly condenses Union or vaporizes as a result of changes in the ambient or or flange process temperature, this will cause a difference in the fluid head between the high pressure and low pressure sides. To prevent measurement errors due to these head differences, condensate pots are used when measuring steam flow. 3-valve (6) Preventing Wind Speed Effects in Very Low manifold Differential Pressure Measurement IMPORTANT Drain valve Drain plug... -

Page 24: Process Piping Installation Precautions

<4. Installing Impulse Piping> Process Piping Installation NOTE Precautions • If the process fluid is a gas, then as a rule the manifold must be located at the downside of the 4.3.1 Connecting Process Piping to the pressure-sensing assembly. Transmitter • If the process fluid is a liquid, then as a rule the manifold must be located at the upside of the (1) Confirming the Process Fluid Flow pressure-sensing assembly. Direction The mark “ ” on the manifold indicates the direction in (2) Pipe Size for Process Piping which the process fluid is flowed (from right to left). Use a 15 mm (1/2-inch) pipe for process piping When connecting the process piping to the process connection to the process connector. connector, confirm the process fluid flow direction. (3) Preventing Freezing Flow direction (from right to left) Orifice name plate... -

Page 25: Wiring

<5. Wiring> Wiring Connections of External NOTE Wiring to Terminal Box For F Fieldbus and PROFIBUS PA OUNDATION communication types, please refer to manuals in the 5.2.1 Power Supply Wiring Connection attached CD-ROM. Connect the power supply wiring to the SUPPLY + and – terminals. Transmitter terminal box Wiring Precautions Power supply – IMPORTANT • Lay wiring as far as possible from electrical noise F0502.ai sources such as large capacity transformers, Figure 5.1 Power Supply Wiring Connection motors, and power supplies. -

Page 26: Wiring Installation

<5. Wiring> 5.3.1 Loop Configuration Since the DPharp uses a two-wire transmission system, signal wiring is also used as power wiring. Flexible metal conduit DC power is required for the transmitter loop. The Apply a non-hardening transmitter and distributor are connected as shown below. Wiring metal sealant to the threads for conduit waterproofing. For details of the power supply voltage and load resistance, see Section 5.6. Drain plug (1) General-use Type and Flameproof Type F0506.ai Figure 5.5 Typical Wiring Using Flexible Metal Hazardous Location Non-hazardous Location Conduit... -

Page 27: Grounding

<5. Wiring> 2) Insert the cable through the union cover, the union Grounding coupling, the clamp nut, the clamp ring, the gland, Grounding is always required for the proper operation of the washer, the rubber packing, and the packing transmitters. Follow the domestic electrical requirements box, in that order. as regulated in each country. For a transmitter with builtin 3) Insert the end of the cable into the terminal box. lightning protector, grounding should satisfy ground 4) Tighten the union cover to grip the cable. When resistance of 10Ω or less. tightening the union cover, tighten approximately one turn past the point where the cable will no Ground terminals are located on the inside and outside of longer move up and down. the terminal box. Either of these terminals may be used. Proper tightening is important. If it is too tight, a circuit break in the cable may occur; if not tight WARNING enough, the flameproof effectiveness will be compromised. 5) Fasten the cable by tightening the clamp nut. For TIIS flameproof type and intrinsically safe, 6) Tighten the lock nut on the union cover. grounding should satisfy Class D requirements 7) Connect the cable wires to each terminal. (grounding resistance, 100Ω or less). Transmitter terminal box Apply a non-hardnening Ground terminal sealant to the threads for (Inside) -

Page 28: Operation

<6. Operation> Operation Output Status Setting at CPU Failure NOTE Set the burn-out direction as shown in the figures below. For F Fieldbus and PROFIBUS PA The direction is set to the H side for delivery unless option OUNDATION code /C1 is specified in the order. For option code /F1, the communication types and for the transmitter operating output signal for down-scale is -2.5%, 3.6 mA DC or less. confirmation and zeroing by any communication method, refer to manuals in the attached CD-ROM for ● BRAIN and HART except option code /F1 further information. Setting pin (CN4) Preparation for Starting Operation CPU assembly Setting Pin (CN4) Burn-Out Output at Confirming that Transmitter is Operating... -

Page 29: Zero Point Adjustment

<6. Operation> Zero Point Adjustment Adjust the zero point after operating preparation is completed. IMPORTANT Do not turn off the power to the transmitter immediately after a zero adjustment. Powering off within 30 seconds after a zero adjustment will return the adjustment back to the previous settings. Using the Transmitter Zero-adjustment Screw Use a slotted screwdriver to turn the zero-adjustment screw. Turn the screw clockwise to increase the output or counterclockwise to decrease the output. The zero point adjustment can be made with a resolution of 0.01% of the setting range. Since the degree of zero adjustments varies with the screw turning speed, turn the screw slowly for fine adjustment and quickly for coarse adjustment. Zero-adjustment Screw Zero-adjustment screw F0604.ai IM 01C22A01-01E... -

Page 30: Errors And Countermeasures

Errors and Countermeasures <7. > Errors and Countermeasures NOTE For F Fieldbus and PROFIBUS PA communication types, please refer to manuals in the attached CD-ROM. OUNDATION The table below shows a summary of error messages for BRAIN and HART protocols. Table 7.1 Error Message Summary Integral Indicator Description Cause Output Operation during Error Countermeasure Display None GOOD ERROR Capsule problem.* Outputs the signal according to Replace capsule.* Er. 01 CAP MODULE FAULT status of a burnout direction pin or switch (the signal can be set as “hold” for BRAIN protocol). -

Page 31: Parameter Summary

<8. Parameter Summary> Parameter Summary IMPORTANT NOTE If the transmitter is turned off within 30 seconds after For F Fieldbus and PROFIBUS PA OUNDATION parameters have been set, the set data will not be communication types, please refer to manuals in the stored and the terminal returns to previous settings. attached CD-ROM. HART Communication Menu Tree 1 PROCESS 1 Pressure Hot Key 1 Keypad Input 1 LRV VARIABLES 2 Percent Range 2 URV 3 Analog Output 3 Unit 4 Sensor Temperature 4 LSL... - Page 32 <8. Parameter Summary> BRAIN Communication Parameter List Instruments to which applicable: F: Differential pressure transmitters: E JA110A, EJA120A, EJA130A, EJA118W, EJA118N, EJA118Y, and EJA115 P: Pressure transmitters: EJA310A, EJA430A, EJA440A, EJA510A, EJA530A, EJA438W, and EJA438N L: Liquid level transmitters: EJA210A and EJA220A Applicability Rewrita- Item Description Remarks Default Value bility MODEL Model+capsule type — TAG NO. Tag number — 16 alphanumerics SELF CHECK Self-diagnostic result —...

- Page 33 <8. Parameter Summary> Applicability Rewrita- Item Description Remarks Default Value bility D23 DISP HRV Engineering range, higher –19999 to 19999 As specified when range value ordered. D30 TEMP UNIT Temperature setting units deg C/deg F deg C D31 STAT. P. UNIT Static pressure setting Selected from mmH As specified when —...

- Page 34 <Installation and Operating Precautions for TIIS Intrinsically Safe Equipment> Installation and Operating Precautions for TIIS Intrinsically Safe Equipment Apparatus Certified Under Technical Criteria (IEC-compatible Standards) and from “RECOMMENDED PRACTICES for Explosion-Protected Electrical Installations in General Industries,” published in 1979 1. General 3. Terminology The following describes precautions on electrical apparatus (1) Intrinsically safe apparatus: Electrical apparatus in which all of intrinsically safe construction (hereinafter referred to as the circuits are intrinsically safe circuits. intrinsically safe apparatus). (2) Associated apparatus: Electrical apparatus in which there Following the Labor Safety and Health Laws of Japan, an are both intrinsically safe circuits and non-intrinsically safe intrinsically safe apparatus must undergo type tests in order circuits that can affect the safety of intrinsically safe circuits.

- Page 35 <Installation and Operating Precautions for TIIS Intrinsically Safe Equipment> (1) A safety barrier which meets the combination requirements (a) refer to the equipment configuration diagram and make electrical wiring properly; by referring to its safety rating and combination parameters shall be selected. (b) prevent intrinsically safe wiring from being contacted with (2) For pressure transmitters, pH transmitters, temperature non-intrinsically safe wiring, and separate the intrinsically safe circuit from other electrical circuits; detectors and the like, safety barriers that can be combined are already specified. Other safety barriers cannot be used. (c) prevent intrinsically safe wiring from being electrostatically and magnetically affected by non-intrinsically safe wiring; Note 2: Testing Intrinsically Safe System An assembly (as a system) in which intrinsically safe apparatus (d) reduce wiring inductance and capacitance produced and safety barriers are combined is assessed to ensure that its between the intrinsically safe apparatus and safety barrier where possible, and use a shorter cable between the safety requirements are satisfied. A tested and certified system intrinsically safe apparatus and safety barrier than specified incorporates a certification number (intrinsically safe apparatus if the maximum permissible inductance of the cable is and safety barriers have the same certification number). specified as operating conditions;...

- Page 36 <Installation and Operating Precautions for TIIS Flameproof Equipment> Installation and Operating Precautions for TIIS Flameproof Equipment Apparatus Certified Under Technical Criteria (IEC-compatible Standards) 1. General (4) Path length of joint surface The following describes precautions on electrical apparatus of On a joint surface, the length of the shortest path through flameproof construction (hereinafter referred to as flameproof which flame flows from the inside to outside of the flameproof apparatus) in explosion-protected apparatus. enclosure. This definition cannot be applied to threaded joints. Following the Labour Safety and Health Laws of Japan, flameproof apparatus is subjected to type tests to meet either (5) Gaps between joint surfaces the technical criteria for explosionproof electrical machinery and The physical distance between two mating surfaces, or equipment (standards notification no. 556 from the Japanese...

- Page 37 Exercise great care not to damage the joints or shock the pipe or duct, apply sealing of the protective pipes in the enclosure. vicinity of individual boundaries, or fill the ducts with sand appropriately. (b) If any damage occurs in threads, joints or mating surfaces, • When branch connections of cables, or cable connections inspection windows, connections between the transmitter with insulated cables inside the conduit pipes are made, and terminal box, shrouds or clamps, or external wiring a flameproof or increased-safety connection box shall be connections which are essential in flameproofness, contact used. In this case, flameproof or increased-safety cable Yokogawa Electric Corporation. glands meeting the type of connection box must be used for cable connections to the box. CAUTION (2) Flameproof Metal Conduit Wiring • For the flameproof metal conduit wiring or insulated Do not attempt to re-process threaded connections or refinish wires shall be used as recommended by the USER’S joints or mating surfaces. GUIDELINES for Electrical Installations for Explosive Gas Atmospheres in General Industry, published in 1994. (c) Unless otherwise specified, the electrical circuitry and • For conduit pipes, heavy-gauge steel conduits conforming to internal mechanisms may be repaired by component JIS C 8305 Standard shall be used.

- Page 38 Revision Information Title : EJA Series Differential Pressure and Pressure Transmitters Installation Manual Manual No. : IM 01C22A01-01E Edition Date Page Revised Item Jan. 2008 New publication IM 01C22A01-01E...

- Page 39 WARNING: This CD contains software, and is for use in a computer only. Do not play this on an audio CD player, as the high volume may damage your hearing or audio speakers. Copyright © 2008 Yokogawa Electric Corporation. All Rights Reserved.

- Page 40 (Germany), Madrid (Spain), Runcorn (United Kingdom), Milano (Italy), Velizy Villacoublay (France), Roodeport (Republic of South Africa), Budapest (Hungary), Stockholm (Sweden) YOKOGAWA AMERICA DO SUL LTDA. Praca Acapulco, 31 - Santo Amaro. Sao Paulo/SP - BRAZIL Phone : 55-11-5681-2400 Fax : 55-11-5681-4434 YOKOGAWA ENGINEERING ASIA PTE.

Need help?

Do you have a question about the Dpharp vigilantplant EJA Series and is the answer not in the manual?

Questions and answers