Table of Contents

Advertisement

Operator

Manual

/ Manuel

de Fop6rateur

/ Manual

del operador

m

_E,_d_s_,

Single

Stage,

Beff

Drive,

E_ectric

Air

Compressors

_Fi_,_h

Compresseurs

d'air 6_ectriques

a un etage a entrainement

par courroie

el6ctricos

de aire, de una sola etapa y accionamiento

por correa

_Engllsh

_IIWARNING:

Read and understand aH safety precautions in this manual before operating. Fairure to comply

with instructions in this manual courd resuk in persona! iniury, property damage, and/or voiding of your warranty.

The manufacturer

W_LL NOT be liable for any damage because of failure to follow these instructions.

I1_ IIFre_d_

AVERT_SSEMENT

: Lisez et veillez a bien comprendre toutes les consignes de s6curit6 de ce manuel avant

d'utiliser I'appareiL Toute derogation aux instructions contenues dans ce manue! peut entrainer I'annulation de la

garantie, causer des blessures et/ou des d6gSts mat6riels. Le fabricant NE SAURA 6tre tenu responsable de

dommages r6sultant de I'inobservation de ces instructions.

ADVERTENCIA:

Lea y comprenda todas las precauciones

de seguridad contenidas en este manual antes de

utilizar esta unidad. Si no cumple con las instrucciones de este manual podria ocasionar lesiones personales,

da5os a

la propiedad y/o la anulaci6n de su garantia. El fabricante NO SER.A responsable de ning0n daSo por no acatar estas

instrucciones.

Printedin

U.S.A.

200-2437

Rev A

12-04

Advertisement

Table of Contents

Summary of Contents for Kobalt Air compressor

-

Page 1: C_Blage 61Ectrique

Operator Manual / Manuel de Fop6rateur / Manual del operador _E,_d_s_, Single Stage, Beff Drive, E_ectric Compressors _Fi_,_h Compresseurs d'air 6_ectriques a un etage a entrainement par courroie el6ctricos de aire, de una sola etapa y accionamiento por correa _Engllsh _IIWARNING: Read and understand aH safety precautions in this manual before operating. -

Page 2: Table Of Contents

TABLE OF CONTENTS SAFETY GUIDELINES ......... Daily Startup ........OVERVIEW ......... Shutdown ........MAINTENANCE ........Basic Air Compressor Components ....ASSEMBLY ......... Draining the Tank ........ Assembling the Compressor ......Checking the Oil ......... COMPRESSOR CONTROLS ......Changing the Oil ......... ELECTRICAL POWER REQUIREMENTS .... -

Page 3: Safety Guidelines

m _E,,_g_s. SAFETY GUIDELINES The following information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please read the manual and pay attention to these sections. - A POTENTIAL HAZARD THAT WILL CAUSE SERIOUS INJURY OR LOSS OF LIFE. -

Page 4: Consignes De Securite

I_Fre,_;_, CONSIGNES DE SECURITE Les informations suivantes concement VOTRE SECURITE et LA PROTECTION DU MATERIEL CONTRE LES PANNES. Pour vous aider identifier Fanature de ces informations, nous utilisons les symboles suivants. Veuillez lire le manuel et prater attention _ ces sections. - DANGER POTENTIEL POUVANT... -

Page 5: Pautas De Seguridad

PAUTA8 DE SEGURmDAD La informaci6n que sigue se refiere a la protecci6n de SU SEGURIDAD y FaPREVENCI©N DE PROBLEMAS DEL EQUIPO. Como ayuda para reconocer esta informaci6n, usamos Fossiguientes simboFos. Lea por favor eFmanuaFy preste atenci6n a estas secciones. - UN POSIBLE RIESGO QUE CAUSARA LESIONES GRAVES O LA PE_RDIDA DE LA VIDA. - UN RIESGO POTENOIAL QUE PODRiA PROVOCAR GRAVES LESIONES O MUERTE. -

Page 6: Overview

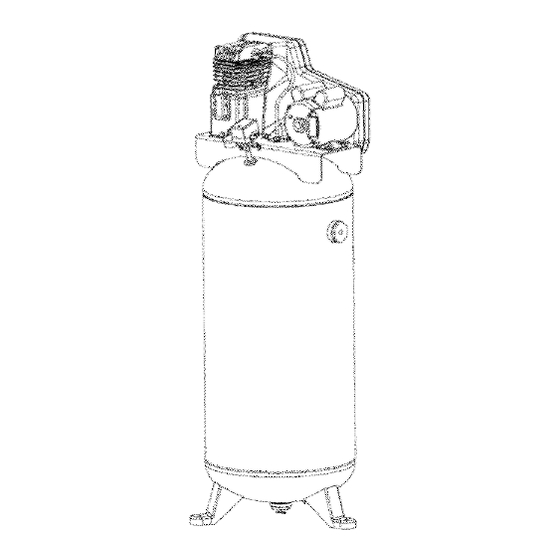

OVERVIEW \ VUE D'ENSEMBLE _ RESUMEN GENERAL I[iZ.:]_,_!_i_/_BASIC AiR COMPRESSOR COMPONENTS The basic components of the air compressor are the electric motor, pump, pressure switch and tank (see Fig. I). The electric motor (see A) powers the pump. The electric motor is equipped with an overload protector to help prevent... -

Page 7: Assembly

ASSEMBLY / ASSEMBLAGE ASSEMBLING THE COMPRESSOR Si cela est necessaire pour votre modele, installez la poignee (A) en inserant les extremites dans la base et en Unpack the air compressor. Inspect the unit for damage. If les fixant a I'aide des boulons (B) fournis (Fig. 2). Apriete the unit has been damaged in transit, contact the carrier los pernos contra la base con una Ilave de 1/2"... -

Page 8: Montaje

Recomendamos emplear almohadiJlas MONTAJE DEL COMPRESOR amortiguadoras de goma debaio de las patas Desembale eEcompresor de aire. Inspeccione Jaunidad (vea C) de Jas unidades fijas p/n (094-0021). En las para verificar que no sufri6 daSos. Si Eaunidad ha sido patas deI tanque hay orificios para empernarlo. daSada durante eEtransporte, comuniquese con Ea Co!oque las calzas entre las patas y las almohadillas... -

Page 9: Compressor Controls

COMPRESSOR CONTROLS / COIVIMANDES DU COMPRESSEUR CONTROLES DEL COMPRESOR COMPRESSOR CONTROLS d6passez iamais la pression Refer to Fig. 3. maximum nominale de I'outiL PRESSURE switch (see A) This switch turns on the compressor. Etis operated Tournez le bouton dans le sens des aiguilles d'une montre manually, but when in the ON position, it allows the compressor pour augmenter la pression et dans le sens inverse pour la reduire. -

Page 10: Electrical Power Requirements

ELECTRICAL POWER REQUIREMENTS SPECIFICATIONS DE L'AUMENTATION ELECTRIQUE REQUERIMIENTOS DE AUMENTACION ELC:CTRICA whether the product is properly grounded. Do not modify the ELECTRICAL WiRiNG plug provided; if it wil! not fit the outlet, have the proper outlet installed by a licensed electrician. Refer to the air compressor's serial label for the unit's FOR PERMANENTLY... -

Page 11: Instructions De Mise

SPECIFICATIONS DE L"AMMENTATION ELECTRIQUE REQUERtMIENTOS DE AUMENTACION ELECTRICA Como altemativa, intente utilizar una manguera de aire mas RALLONGES Continue larga para Ilegar a la zona donde se requiere aire, e! cable no debe Utilisez seulement une ral!onge a 3 fils munie d'une prise de tener una !ongitud mayor que 9.1 m (50 pies) y un alambre con terre a 3 lames et une prise de courant a 3 fentes dans laquelle la calibre minimo de 12 (AWG). -

Page 12: Motor

MOTOR RESET AND WIRING \ REMISE EN MARCHE ET CABLAGE DU MOTEUR RESTABLECLMHENTO Y CABLEADO DEL MOTOR MOTOR RESET SWITCH II-IIm _,i_ _NTERRUPTOR RESTABLECIMIENTO MOTOR Ensure that all guards and shrouds are in AsegOrese de que todos place before pressing the reset switch to restart the motor. -

Page 13: Break-In Of The Pump

BREAK4N OF THE PUMP _ RODAGE DE LA POMPE _ MARCHA DE LA BOMBA BREAK-IN OF THE PUMP Despu6s de aproximadamente 30 minutos, co!oque conmutador activado per presi6n en la posici6n Check the levee of oil in the pump with the sight glass. The APAGADO. -

Page 14: Operating Instructions

OPERATING INSTRUCTIONS \ MODE D'EMPLOI \ INSTRUCCIONES OPERATIVAS DAILY STARTUP Fig. 6 Every day check the sight @ass to ensure that the leveJ of A = Full oil in the pump is at the required revel The pump oiE level A = PJein must be between A and B (see Fig. -

Page 15: Instrucc!Ones Operativas

MODE D'EMPLOI \ INSTRUCCIONES OPERATIVAS ARRET Fig° 6 A = Full Placer Eemanocontacteur en position ARRI_T (C). A = Ptein D6branchez le cordon d'alimentation. A = Ueno R6duisez la pression darts le r6servoir par Forifice de B = Add sortie du tuyau. Vous pouvez egaEement tirer sur I'anneau B = Ajoutez de la soupape de decharge (G) et Eamaintenir ouverte B = Agregor... -

Page 16: Maintenance

MAINTENANCE _ ENTRETJEN \ MANTENIMIENTO Retirez le bouchon d'event (E) avant de faire I'appoint d'huile. MAINTENANCE Aioutez de I'huile iusqu'a ce que le niveau, te! qu'indique par le voyant (D), se situe entre les marques FULL (plein) (A) et ADD To avoid personal iniury, always shut off and (aiouter) (B). -

Page 17: Belt Tension And Pulley Alignment

MAmNTENANCE _ ENTRETIEN \ MANTENIMIENTO BELT TENSION AND PULLEY ALIGNMENT avoid personar injury, always shut off and unplug the compressor and rerieve al! air pressure from the system before performing any service on the air compressor. NOTE: Drive belt tensioning and pulley arignment done at the same... - Page 18 MAINTENANCE _ ENTRETIEN \ MANTENIMIENTO PULLEY ALIGNMENT To check pulley arignment, remove the beetguard and place a straightedge (see A) against the pump flywheeJ (see B) (See Fig..9). Measure and record the distance from the straightedge to the edge of the drive belt at point C. Then measure the distance from the straightedge to the edge of the drive belt again at points D and E.

-

Page 19: Cleaning The Air Filter

MAINTENANCE _ ENTRETIEN \ MANTENIMIENTO CLEANING THE AiR FILTER [11_11Fi,_'_,c_ ENTREPOSAGE Avant d'entreposer le compresseur pour une pOriode A dirty air filter will reduce the compressor's performance prolong6e, utilisez une soufflette pour nettoyer toute la and life. To avoid any internal contamination of the pump, the poussiere et tousles debris du compresseur. -

Page 20: Service Interval

I [_:_E,._,_,, SERVICE iNTERVAL Perform the following maintenance at the intervars indicated below, inspect and clean air filter ..........Daily Check pump oil level ........... Daily Change pump oil ........Every t00 operating hours Operate the pressure relief valves ........Daily Check belt... -

Page 21: Troubleshooting Chart

TROUBLESHOOTING CHART Note: Troubleshooting problems have similar causes and solutions, PROBLEM POSSIBLE CAUSE SOLUTION Excessive current draw Low voltage/motor ovedoad Check that power suppEy is adequate and that compressor is on a trips circuit breaker dedicated circuit. If using extension cord, try using without. -

Page 22: Depannage

Remarque : Les problemes de depannage peuvent avoir des causes et des solutions simHaires, PROBL#ME CAUSE POSSIBLE SOLUTION Tension insuffisante/surcharge V6rifiez que !'alimentation est ad6quate et que le compresseur est Le preJ_vement e×cessif du moteur de Courant cause branche sur un circuit s6pare. V6rifiez que le compresseur est d_elenchement branche sur son propre circuit. -

Page 23: Cuadro De Deteccion De Fallos

CUADRO DE DETECCI6N DE FALLOS Nota: Los probJemas de detecci@l de faJlos pueden tener causas y soJuciones simiJares. CAUSA POSIBLE SOLUCION PROBLEMA Volaje bajo/sobrecarga del motor Consumo e×cesivo de la Ve@que que el suministro de energia sea el adecuado y que el compresor se encuentre conectado en un circuito exdusivo. -

Page 24: Glossary Of Terms

GLOSSARY OFTERMS ASME Cubic feet per minute; a unit of measure of air flow, American Society of Mechanicar Engineers. Indicates that the components are manufactured, tested and inspected to the specifications set by ASME. Pounds per square inch; a unit of measure of air pressure. Kick=in pressure Factory set low pressure point that starts the compressor to repressurize the tank to a higher pressure.

Need help?

Do you have a question about the Air compressor and is the answer not in the manual?

Questions and answers