Table of Contents

Advertisement

Operator

Manual

/ Manuel

de Fop rateur

/ Manual

del operador

_E._,_

OiHess,

Single

Stage,

Direct

Drive,

Electric

Air

Compressors

_Fr_ct,

Sans

I'huile,

d'une

seul

etape,

a prise

directe,

compresseurs

d'air

electriques

_Jllspa_,i_, Sin aciete,

de una sola

etapa,

de mando

directo,

compresores

de aire electricos

_Engllsh

_IIWARNING:

Read and understand aH safety precautions in this manual before operating. Failure to comply

with instructions in this manual could result in persona! iniury, property damage, and/or voiding of your warranty.

The manufacturer

WiLL NOT be liable for any damage because of failure to follow these instructions.

Ii_

IIFre_cfl

AVERTISSEMENT

: Lisez et veillez a bien comprendre toutes les consignes de s6curit6 de ce manuel avant

,&

d'utiliser I'appareiL Toute derogation aux instructions contenues dans ce manue! peut entrainer I'annulation de la

garantie, causer des blessures et/ou des d6gSts mat6riels. Le fabricant NE SAURA 6tre tenu responsable de

dommages r6sultant de I'inobservation de ces instructions.

_Spaz#sh

_

ADVERTENClA:

Lea y comprenda todas las precauciones

de seguridad contenidas en este manual antes de

utilizar esta unidad. Si no cumple con las instrucciones de este manual podria ocasionar lesiones personales,

dados a

la propiedad y/o la anulaci6n de su garantia. El fabricante NO SER.& responsable de ningOn da_o por no acatar estas

instrucciones.

Printedin

U.S.A.

200-2430

Rev A

12-04

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Kobalt Air compressor

- Page 1 Operator Manual / Manuel de Fop rateur / Manual del operador _E._,_ OiHess, Single Stage, Direct Drive, Electric Compressors _Fr_ct, Sans I'huile, d'une seul etape, a prise directe, compresseurs d'air electriques _Jllspa_,i_, Sin aciete, de una sola etapa, de mando directo, compresores de aire electricos...

-

Page 2: Table Of Contents

TABLE OF CONTENTS SAFETY GUIDELINES ......Daily Start.up ......OVERVIEW ........Shutdown ......... Basic Air Compressor Components ..... MAINTENANCE ....... ASSEMBLY ........Draining the Tank ......Assembling the Compressor ....Checking the Relief Valve ....COMPRESSOR CONTROLS ...... Testing for Leaks ...... -

Page 3: Safety Guidelines

1_E,,_h SAFETY GUmDELINES The following information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please read the manual and pay attention to these sections. - A POTENTIAL HAZARD THAT WiLL CAUSE SERIOUS iNJURY OR LOSS OF LIFE. - A POTENTIAL HAZARD THAT COULD CAUSE SERIOUS _NJURY OR LOSS OF UFE. -

Page 4: Consignes De Si_Curite

CONSIGNES DE SECURITE Les informations suivantes concernent VOTRE SECURITE et LA PROTECTION DU MATERIEL CONTRE LES PANNES. Pour vous aider identifier la nature de ces informations, nous utilisons les symboles suivants. Veuillez lire le manuel et pr6ter attention _ ces sections. - DANGER POTENTIEL POUVANT ENTRAi'NER DE GRAVES BLESSURES OU LA MORT. -

Page 5: Pautas De Seguridad

PAUTAS DE SEGURIDAD La informaci6n que sigue se refiere a la protecciOn de SU SEGURIDAD y la PREVENCION DE PROBLEMAS DEL EQUIPO. Como ayuda para reconocer esta informaci6n, usamos los siguientes simbolos. Lea por favor el manual y preste atend6n a estas secciones. - UN POSIBLE RIESGO QUE OAUSARA LESlONES GRAVES O LA PC:RDIBA DE LA VIDA. -

Page 6: Overview

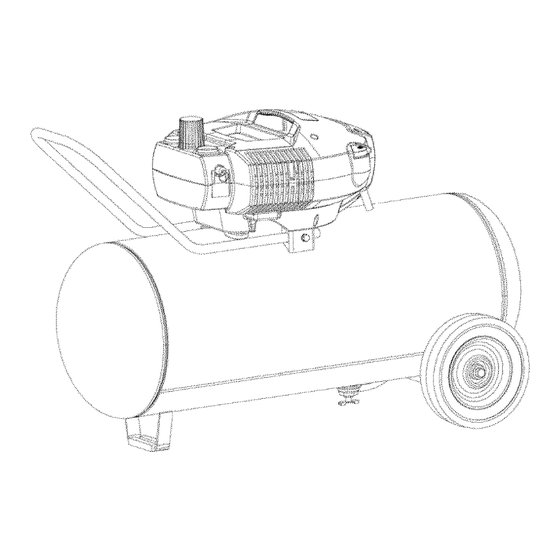

OVERVIEW \ VUE D'ENSEMBLE \ RESUMEN GENERAL F_E,_!;_i,_ BASIC AiR COMPRESSOR COMPONENTS OiHess air compressors are factory lubricated for life and do not require any oil A&B The basic components of the air compressor are the electric motor, pump, pressure switch, and tank. The electric motor (see A) powers the pump. -

Page 7: Assembly

ASSEMBLY JASSEMBLAGE ASSEMBUNG THE COMPRESSOR ,& _:La palette d'exp6dition n'est pas Unpack the air compressor. Inspect the unit for damage. If con_ue pour servir de base & un compresseur the unit has been damaged in transit, contact the carrier marche. and complete a damage claim. -

Page 8: Compressor Controls

COMPRESSOR CONTROLS / COMMANDES DU COMPRESSEUR CONTROLES DEL COMPRESOR Sortie d'air (voir F) COMPRESSOR CONTROLS Raccorder le tuyau pneumatique NPT de 6.35 mm (1/4 po) PRESSURE switch (see A) cette sortie. This switch turns on the compressor. Etis operated manually, but when in the ON position, it allows the compressor to start up or shut down automatically, without warning, upon air demand. -

Page 9: Electrical Power Requirements

ELECTRICAL POWER REQUIREMENTS SPECIFICATIONS DE L'AUMENTATION €:LECTRIQUE REQUERIMIENTOS DE ALJMENTACI6N ELC:CTRICA ELECTRICAL WIRING Check with a licensed electrician if the grounding instructions are not completely understood, or if in doubt as to whether the Refer to the air compressor's serial label for the unit's product is properly grounded. -

Page 10: Rallonges

SPC:CIFICATIONSDE L'ALIMENTATION E_LECTRtQUEREQUERIMIENTOS DE ALIMENTACION ELECTRJCA Como alternativa, intente utiJizaruna manguera de aire m_s RALLONGES Continue larga para Ibgar a la zona donde se requiere aire, el cable no debe UtiEisez seulement une rallonge a 3 fils munie d'une prise de tener una Iongitud mayor que 30 m (100 pies) y un alambre con terre a 3 lames et une prise de courant a 3 fentes dans laqueHe Ea... -

Page 11: Break-In Of The Pump

BREAK-IN OF THE PUMP _ RODAGE DE LA POMPE _ MARCHA DE LA BOMBA BREAKoIN OF THE PUMP Turn the pressure switch to the OFF position (see A). Open the petcock (see B). Turn in the counterclockwise direction. Plug in the power cord. Turn the pressure switch to the ON position (see C). -

Page 12: Operating Instructions

OPERATING INSTRUCTIONS \ MODE D'EMPLOI \ INSTRUCCIONES OPERATWAS DAILY STARTUP Turn the pressure switch to the OFF position (see A). Close the tank petcock (see D). Turn in the clockwise direction. Hug in the power cord. _High temperatures are generated by the electric motor and the pump. -

Page 13: Instrucciones Operativas

MODE D'EMPLOI _ INSTRUCCIONES OPERATIVAS ARR_T Placer le manocontacteur en position ARRI_T (A), D6branchez le cordon d'alimentation. Reduisez la pression dans le r6servoir par Forifice de sortie du tuyau. Vous pouvez 6gabment tirer sur Fanneau de la soupape de decharge (E) et la maintenir ouverte pour lib@er la pression dans le r6servoir. -

Page 14: Maintenance

MAINTENANCE _ ENTRETIEN \ MANTEN_MIENTO MAINTENANCE _,_h VERIFICATION DE LA SOUPAPE DE D#CHARGE] Tirez chaque jour sur la soupape de decharge pour vous avoid personal injury, always shut off and assurer qu'elle fonctionne correctement et 61iminer toutes les unplug the compressor and relieve al! air pressure from obstructions 6ventuelles. -

Page 15: Service Interval

SERVmCE iNTERVAL Perform the following maintenance at the intervals indicated below, Operate the pressure relief valve ......... Daily Drain tank ............Daily ENTRET_EN PERRODHQUE Effectuez I'entretien suivant aux intervalles indiqu6s ci-dessous, Faites fonctionner -soupapes de d_charge .......... Chaque jour Vidangez te r_servoir .......... -

Page 16: Troubleshooting Chart

I [@Z_,_ TROUBLESHOOTmNG CHART Note: Troubleshooting problems may have similar causes and solutions. PROBLEM POSSIBLE CAUSE SOLUTION Low pressure or not Tank petcock is open Close petcock enough air Prolonged excessive use of air Decrease amount of air used. Compressor does not Compressor not large enough... - Page 17 TROUBLESHOOTNNG CHART Note: Troubleshooting problems may have similar causes and solutions. PROBLEM POSSIBLE CAUSE SOLUTION Pressure relief valve Contact authorized service center. Tank pressure exceeded normal opens operating pressure Contact authorized service center. Pressure switch stuck Motor will start automaticallY when tank pressure drops below Motor will not run Tank...

-

Page 18: De_Pannage

Remarque : Les prob[_mes de d_pannage peuvent avoir des causes et des solutions simi[aires. PROBL#:ME CAUSE POSSIBLE SOLUTION Robinet de reservoir ouvert Fermer le robinet Faib[e pression manque d'air Usage excessif d'air Reduire I'utilisation d'air comprime. Compresseur pas assez Verifier le debit d'air requis pour [es accessoires. S'il est superieur compresseur fonctionnant... - Page 19 Remarque : Lea probJ_mes de d_pannage peuvent avoir des causes et des soJutions similaires. PROBL#ME CAUSE POSSIBLE SOLUTION La soupape de s_ret_ La pression du r6servoir Contacter un centre d'entretien agr66. a'ouvre d6passe la limite normale Manocontacteur bloqu6 Le moteur ne d_marre La pression du r6servoir...

- Page 20 CUADRO DE DETECC[ON DE FALLOS Nota: Los prob[emas de detecci6n de fa[[os pueden tener causas y so[uciones simHares. PROBLEMA CAUSA POSBLE SOLUCJON Presi6n baja o E! grifo de desagOe del tanque Cierre el grifo de desagOe insuficiente cantidad est_ abierto aire.

-

Page 21: Cuadro De Deteccion De Fallos

II-Im_,,_ _, CUADRO DE DETECCL6N DE FALLOS Nota: Los problemas de detecci6n de fallos pueden tenet causas y soluciones similares. PROBLEMA CAUSA POSIBLE SOLUCION Sobrecalentamiento Ventilaci6n deficiente Reubique el compresor en un _rea donde haya aire fresco, seco y con buena circulaci6n. Superficies de enfriamiento Limpie minuciosamente todas las superficies de enfriamiento de la... -

Page 22: Glossary Of Terms

GLOSSARY OFTERMS ASME Cubic feet per minute; a unit of measure of air flow. American Society of Mechanical Engineers. Indicates that the components are manufactured, tested and inspected to the specifications set by ASME. Pounds per square inch; a unit of measure of air pressure. Kick-in pressure Factory set low pressure point that starts the compressor to...

Need help?

Do you have a question about the Air compressor and is the answer not in the manual?

Questions and answers