Table of Contents

Advertisement

Available languages

Available languages

Operator's

Manual

CRAFTSMAN °

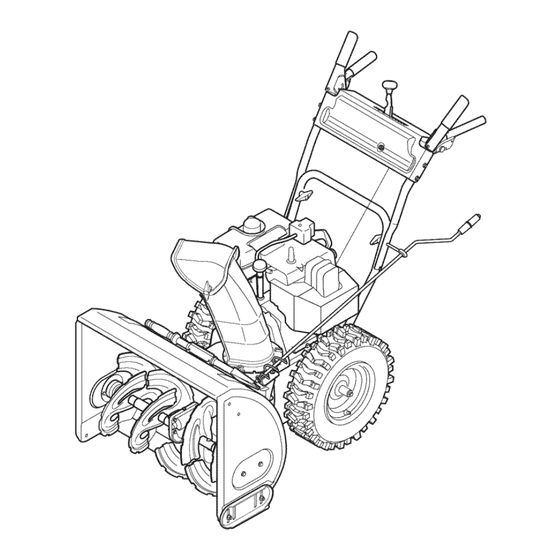

28" SNOW THROWER

Model No. 247.881900

CAUTION:

Before

using

this product,

read this

manual

and follow

all

safety

rules

and operating

instructions.

• SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LiST

ESPAI_OL

Sears, Roebuck

and Co., Hoffman

Estates,

IL 60179, U.S.A.

Visit our website:

www, craftsrnan.corn

FORMNO.769-01909D

7/5/2007

Advertisement

Table of Contents

Summary of Contents for Craftsman 247.881900

- Page 1 Operator's Manual CRAFTSMAN ° 28" SNOW THROWER Model No. 247.881900 • SAFETY ASSEMBLY OPERATION MAINTENANCE PARTS LiST CAUTION: Before using ESPAI_OL this product, read this manual and follow safety rules and operating instructions. Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

- Page 2 PartsList......Pages 26-37 Assembly ......Pages 8-11 Espa_ol ......Page 40 Operation ......Pages 12-15 Two -YearWarranty on Craftsman Snow Thrower This equipment iscovered by atwo-year warranty, provided that i tismaintained, lubricated, and tuned u paccording tothe instructions inthe operator's manual.

- Page 3 Congratulations on makinga smartpurchase.YournewCraftsman® Purchase a RepairProtectionAgreementnowand protectyourself productis designedand manufactured for yearsof dependableopera- from unexpectedhassleand expense. tion. But likeall products,it mayrequirerepairfrom time to time.That's Onceyou purchasethe Agreement,a simplephonecall is all that it whenhavinga RepairProtectionAgreementcansave you moneyand takesfor you toscheduleservice.Youcan call anytimeday or night, or aggravation.

- Page 4 This machine was built t obeoperated according totherules f or safe operation inthis manual. Aswith any type ofpower equipment, which, ifnot f ollowed, could e ndanger the personal This symbol points out i mportant safety i nstructions carelessness orerror onthe part o fthe operator can result inserious safety and/or property ofyourself and others.

-

Page 5: Operation

OPERATION MAINTENANCE & STORAGE Do not put hands or feet near rotatingparts, in the auger/impeller Nevertamperwith safetydevices.Checktheir properoperation housingor chuteassembly.Contactwiththe rotatingparts can amputate regularly.Referto the maintenanceandadjustmentsectionsof this handsand feet. manual. The auger/impellercontrol leveris a safetydevice.Neverbypassits Beforecleaning, repairing,or inspectingmachinedisengageall control operation.Doingso makesthe machineunsafeand maycause personal leversand stop the engine.Wait until the auger/impellercome to a injury. - Page 6 This page left intentionally blank.

- Page 7 1. KEEP AWAY FROMROTATING IMPELLER ANDAUGER. C ONTACT WITHIMPELLER OR AUGER CANAMPUTATE HANDS ANDFEET. 2. USECLEAN-OUT TOOL TOUNCLOG DISCHARGE C HUTE. 3. DISENGAGE CLUTCH L EVERS, STOP ENGINE, ANDREMAIN BEHIND HANDLES U NTIL ALL MOVING PARTS HAVE STOPPED BEFORE UNCLOGGING ORSERVICING MACHINE. 4.

-

Page 8: Removing From Carton

NOTE:References to rightor left sideof the snow throwerare determined from behindthe unit in the operatingposition(standing directlybehindthesnow thrower,facing the handlepanel). REMOVING FROM CARTON Cut the cornersof thecarton and lay the sidesflat on the ground. Removeand discardall packinginserts. Movethe snowthrowerout of thecarton. Makecertainthe carton hasbeen completelyemptiedbefore discardingit. - Page 9 Positionthechute assemblyoverthe base. See Figure3. Closethe flangekeepersto securethe chuteassemblyto the chute base.See Figure4. The flangekeeperswill click into place whenproperlysecure. NOTE:If theflangekeeperswill noteasily click intoplace,use the palmof your handto applyswift,firm pressureto the backof each. Removetheflat washerand hairpinclipfrom the end of the chutedirectionalcontrol.

- Page 10 SET-UP Chute Clean=Out Tool A chute clean-out tool is fastenedto the top of the augerhousing with a mountingclip. See Figure6.The tool is designedto cleara chuteassemblyof ice and snow.This item is fastenedwith a cabletie at the factory.Cut the cabletie beforeoperatingthe snowthrower. Chute Clean-out Tool bever useyourhandsto cleara cloggedchuteassembly.Shutoff...

- Page 11 Chute Assembly The distancesnowis throwncan be adjustedby changingthe angleof the chuteassembly.Todo so: Stopthe engineby removingthe ignitionkeyand loosenthe plasticwingknobfoundon the left sideof thechute assembly. Pivotthe chute upwardor downwardbeforeretightening the wing knob. See Figure8. Auger Control Priorto operatingyoursnowthrower,carefullyreadand follow all instructionsbelow.Performall adjustmentsto verify yoursnow throweris operatingsafelyand properly.

- Page 12 get Control ElectricStart Button Chute Assembly DirectionalControl EnGine Controls RecoilStarter Handle ElectricStarterOutlet / Ignition /_/' Figure10 [GNITION Now that youhavesetupyoursnow thrower,it's importantto become acquainted with its controlsand features.Referto Figure10. The ignitionkey is a safety device.It mustbe fully insertedin order for the engineto start.

-

Page 13: Throttle Control

THROTTLE CONTROL DRIVE CONTROL/AUGER CONTROL LOCK The throttlecontrolis locatedon the rear of theengine. DRIVE It regulatesthe speedof the engineand willshut off the enginewhenmovedintothe STOPposition. CONTROL RECOIL STARTER HANDLE This handleis usedto manuallystart theengine. ELECTRIC STARTER BUTTON Pressingthe electricstarterbuttonengagesthe engine's electricstarterwhen pluggedintoa 120Vpowersource. ELECTRIC STARTER OUTLET... -

Page 14: Clean-Out Tool

CLEAN-OUT TOOL NOTE:A plasticdust cap maybe found insidethe fuel fill opening. Removeand discard,if present. Alwaysfill thefuel tank outdoorsand usea funnelor spout to Neveruseyourhandsto cleara cloggedchuteassembly.Shut preventspilling. off engineand remainbehindhandlesuntil all movingparts have Fillfuel tank with clean,fresh,unleadedgasoline. stopped beforeunclogging. Neverfill thefuel tank completely.Fillthe tank to within 1/2" from the top to providespace forexpansionof fuel. -

Page 15: To Engage Augers

Oncethe engine starts,releasestarterbutton. NOTE: Whenselectinga Drive Speed,usethe slowerspeedsuntil you are comfortableand familiarwith theoperationof the snow As the enginewarms,slowlyrotatechokecontrolto theOFF thrower. position.If the enginefalters,quicklyrotatechoke controlback to FULL 14D"I t henslowlyintothe OFF positionagain. Squeezethe drivecontrolagainstthe handlethe snowthrower Whendisconnecting the extensioncord, alwaysunplugthe end will move.Releaseit and drivemotionwill stop. -

Page 16: Engine Maintenance

ENGINE MAINTENANCE --,, Beforelubricating,repairing,or inspecting,disengageall controls land stop engine.Wait untilall movingparts havecome to a complete |stop. FULL Maintain Oil Level Checking Engine Between FULL and ADD Be sureengine is uprightand level. Unscrewoil fill capfrom oil fillertube and wipedipstickclean. Screwoil fill capback into oil filler tube.Tightensecurely. Unscrewand removeoil fill cap from oil filler tube. - Page 17 Checking Spark Plug Checksparkplug yearlyor every 100operatinghours Cleanarea aroundspark plug. Remove and inspectspark plug. Replace spark plug if porcelainis crackedor if electrodesare pitted,burnedor fouledwith deposits Checkelectrodegap with a feelergaugeand set gap to .030 (0.76ram)if necessary.See Figure14. Reinstall spark plugand tightensecurely. NOTE:A resistorsparkplug must be usedfor replacement.

-

Page 18: Shave Plate And Skid Shoes

SHAVE PLATE AND SKID SHOES Theshaveplateand skid shoes on the bottomof the snowthrowerare subjectto wear.They shouldbe checkedperiodicallyand replaced whennecessary. Toremoveskid shoes: Removethe four carriagebolts and hexflangenuts whichsecure themto thesnow thrower. Reassemble newskid shoes with the fourcarriagebolts(two on eachside) and hexflangenuts.Referto Figure17. Toremoveshave plate: Removethe carriageboltsand hexnuts whichattach it to the snowthrowerhousing. -

Page 19: Belt Replacement

Chute Bracket --,, If thespiral at the bottomof the chute directionalcontrolis not fully engagingwith the chute assembly, t he chute bracketcan be adjusted. To do so: Loosenthe two nuts which securethechute bracketand reposi- tion it slightly.See Figure20. Retightenthenuts. Auger Control Referto the Assemblysectionfor instructionson adjustingthe auger controlcable. - Page 20 Removethe frame coverfrom the undersideof the snow thrower by removingfourself-tappingscrewswhich secureit. See Figure Removethe beltas follows.Referto Figure24. Loosenand removetheshoulderscrewwhich actsas a belt keeper. Unhookthesupport bracketspringfrom theframe. Removethe beltfrom aroundthe augerpulley,and slip the belt betweenthesupport bracketand the augerpulley.See Figure25. Reassemble auger beltby followinginstructionsin reverseorder. NOTE:Do NOTforgetto reinstallthe shoulderscrewand reconnect the springto theframe after installinga replacementaugerbelt.

-

Page 21: Friction Wheel Removal

Removethe beltas follows.Referto Figure26. Rollthe auger beltoff theengine pulley. Use a wrenchto pivotthe idler pulleytowardthe right. Lift the drive beltoff enginepulley. Carefullypivotthe snowthrowerup and forwardso that it restson the auger housing. Removethe framecoverfrom the undersideof thesnow thrower by removingfour self-tappingscrewswhich secureit. Referto Figure23. - Page 22 Carefullyremovethe hex nutand washerwhichsecuresthe hex shaftto the snowthrowerframeand lightlytap the shaft'send to dislodgethe ball bearingfrom the rightside of theframe.See Figure29. NOTE:Be carefulnot to damagethe threadson the shaft. Carefullypositionthe hexshaft downward and to the left before carefullyslidingthe frictionwheelassemblyoff the shaft. See Figure30.

-

Page 23: Maintenance

MAINTENANCE SCHEDULE Beforeperforming anytypeof maintenance/service, disengage all Followthe maintenance schedulegivenbelow•This chart describes controlsandstoptheengine. W aituntilall movingpartshavecometo serviceguidelinesonly•Usethe ServiceLog columnto keeptrackof a complete stop.Disconnect sparkplugwireandgroundit against t he completedmaintenance tasks•To locate the nearest Sears Service enginetoprevent u nintended starting. A lwayswearsafetyglassesduring Center or to schedule service,simplycontactSears at 1-800-4-MY-HOME®. -

Page 24: Preparing Engine

If the snowthrowerwill notbe usedfor 30 days or longer,or if it is the end of the snowseasonwhenthe last possibilityof snow isgone,the equipmentneedsto be stored properly.Followstorageinstructionsbelowto ensuretop performancefromthe snow throwerfor many moreyears. PREPARING SNOW THROWER PREPARING ENGINE Whenstoringthe snowthrowerin an unventilatedor metalstor- Short=Term Storage age shed, careshouldbe taken to rustproofthe equipment.Using... - Page 25 Before performing anytypeof maintenance/service, disengage all controlsandstoptheengine. W aituntilall moving partshavecometo a complete stop.Disconnect sparkplugwireandgrounditagainstthe engineto prevent u nintended starting. A lwayswearsafetyglassesdurin( operation or whileperforming anyadjustments or repairs. Thissectionaddressesminor service issues,To locatethe nearestSears Service Center or to scheduleservice,simply contactSears at 1-800-4-MY-HOME®. Enginefails to start Chokecontrolnot in ONposition Movechoke controlto ON position.

- Page 26 Craftsman Snow Thrower Model 247.881900...

- Page 27 Craftsman Snow Thrower Model 247.881900 731-2635 SnowRemoval T oolMount 684-04268 HousingAssembly,Auger 28" 684-04057A 684-04107 ImpellerAssembly,12"Dia. SpiralAssembly,LH 710-0347 Hex Screw,3/8-16, 1.75,Gr5 684-04108 SpiralAssembly,RH 710-0451 Bolt,Carriage,5/16-18,.750Grl 731-04870 Spacer,1.25OD x .75ID x 1.00 710-04484 Screw, 5/16-18,0.750 736-0188 Washer,Flat, .76x 1.49x .06 710-0703 741-0493A Screw,Carriage,1/4-20,.750,Gr5...

- Page 28 Craftsman Snow Thrower Model 247.881900...

- Page 29 Craftsman Snow Thrower Model 247.881900 738-04122 631-04133A Screw,Shoulder,.43x 1.3, 1/4-20 HandleAssembly,ClutchLock,LH 731-04869 631-04134B i Chute,FlangeKeeper HandleAssembly,ClutchLock,RH 746-04397 684-04111B i Cabe, SpeedSelector HandleAss'y,Engage,Black,LH 749-04142A 684-04112B I Handle,Upper,LH HandleAss'y,Engage,Black,RH 750-04831 74004263 EyeBolt,ChuteCrank Spcr.,.254x .442x .625 Lg. 790-00313 Shift Lever 710-04326 Screw,#8-16x .50...

- Page 30 Craftsman Snow Thrower Model 247.881900...

- Page 31 Craftsman Snow Thrower Model 247.881900 656-04025A 731-04873 Disc Assembly,FrictionWheel Spacer,1.25x .75x 3.0 684-04153 738-04168 Axle, .75x 22" FrictionWheelAssembly,5.50D 684-04154 741-0919 SupportBracket,FrictionWheel Ball Bearing 684-04156A 710-0809 Shift Assembly,Rod Hex Screw,1/4-20,1.25,Gr5 710-0627 710-0191 Hex Screw,5/16-24,.750,Gr5 Hex Screw,3/8-24, 1.25,Gr8 710-0788 710-0672 Screw,1/4-20,1.000 Hex Screw,5/16-24,1.25,Gr5...

- Page 32 Craftsman Engine IVlodel LH318SA=156587 For Snow Thrower IVlodel 247.881900 ,/89...

- Page 33 Craftsman Engine Model LH318SA-156587 For Snow Thrower Model 247.881900 lli lll ll l =- , ," lmlB =- , , 37587 GovernorShaft 35385 Cylinder 27652 DowelPin 651080 Washer 650820 Screw,1/4-20x 0.5" 37588 GovernorGear Ass'y.(Incl.81) 30969 ExtensionCap 30588A GovernorSpool 28277 Washer...

- Page 34 Craftsman Engine IVlodel LH318SA-156587 For Snow Thrower IVlodel 247.881900 300. 34186A 30088A Screw,1/4-28x 1" FuelTank(Incl.292 & 301) 183. 34587A Choke Bracket 301. 35355 FuelCap 311. 35942 184. 33263 CarburetorTo IntakePipeGasket Oil FillPlug 314. 650873 185. 33877 IntakePipe Screw,1/4-20x 3/4" 186.

- Page 35 Craftsman Engine Model LH318SA=156587 For Snow Thrower Model 247.881900 640052 Carburetor 631776A ThrottleShaft & LeverAssembly 631970 ThrottleReturnSpring 631778 ThrottleShutter 650506 ShutterScrew 632112 Choke Shaft& LeverAssembly 632174 Choke Shutter 630735 Choke Positioning Spring 632164 FuelFitting 650417 ThrottleCrackScrew/IdleSpeedScrew 630766 TensionSpring 640016 IdleRestrictorScrew...

- Page 36 Craftsman Engine IVlodel LH318SA=156587 For Snow Thrower IVlodel 247.881900 590749 RewindStarter 590599A SpringPin (Incl. 4) 590600 Washer 590679 Retainer 590601 Washer 590678 BrakeSpring 590680 StarterDog 590412 DogSpring 590682 Pulley& RewindSpringAssembly 590750A StarterHousingAssembly 590535 StarterRope(Length98"x 9/64" dia.) 590574 MittenGrip Handle(optional) 590733 RewindStarter 11..__...

- Page 37 Craftsman Engine Model LH318SA=156587 For Snow Thrower Model 247.881900 33329E ElectricStarter110Volt (optional) 33451 DustCover 33842 RetainerRing 33430 SpringRetainer 33431 Anti-DriftSpring 37050 Gear & Nut (Incl•2) 35449 Drive EndCap Assembly 35450 "0" Ring 35915 Armature 35451B HousingAssembly 35452A BrushCardAssembly 35911 ThrustWasher...

- Page 38 (This pageapplicablein the U.S.A.and Canadaonly.) Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARB) and the United States Environmental Protection Agency (U.S. EPA) Emission ControJ System Warranty Statement (Owner's Defect Warranty Rights and ObJigations) EMISSIONCONTROL WARRANTYCOVERAGE ISAPPLICABLE TO CERTI- YEAR 1997AND LATERENGINES WHICHARE PURCHASED AND USED FlED ENGINESPURCHASEDIN CALIFORNIA IN 1995ANDTHEREAF- ELSEWHERE INTHE UNITEDSTATES (ANDAFTERJANUARY1,2001 IN...

- Page 39 Look For Relevant Emissions Durability Period and Air index information On Your Engine Emissions Label Engines that are certified to meet the California Air Resources Board (CARB) Tier 2 Emission Standards must display information regarding the Emissions Durability Period and the Air Index. Sears, Roebuck and Co., U.S.A. makes this information available to the consumer on our emission labels.

- Page 40 Craftsman Este equipoest,. cubiertopor una garanfiade dosahos, siempreque se mantenga,lubriquey ajustede acuerdocon las instrucciones del presentemanualdel operador.Duranteel aho de garanfia,si este equiposufrecualquierfalla producidapor defectosen materialeso manode obra,DEVUELVALO A SUCENTRODE PARTES& REPARACION SEARSM_,SCERCANO, y SearsIo reparar_t sin ningOn cargo.El serviciode garanfiaa domicilioester disponibleperose aplicar_t u n cargode traslado.

- Page 41 Felicitaciones por haberrealizadouna adquisici6ninteligente.El tecnicode Searspara los productosque requierenreparaci6n productoCraftsman@ que ha adquiridoest,. disehadoy fabricado a domicilio,adem_ts de una programaci6n convenientepara la parabrindar muchosahosde funcionamiento confiable.Perocomo reparaci6n todos losproductosa vecespuederequerirde reparaciones. E sen Unavez adquiridoel Acuerdo,puede programarel serviciocon ese momentocuandoel disponerde un Acuerdode protecci6npara tan s61orealizaruna Ilamadatelef6nica.Puede Ilamaren cualquier reparaciones le puedeahorrardineroy problemas.

- Page 42 Esta maquinafue construidapara ser operadade acuerdocon las reglas de seguridadcontenidasen este manual.AI igual quecon cualquiertipo instruccionesimportantesde seguridadquese deben de equipo motorizado,un descuidoo error por partedel operadorpuede respetarpara evitar poneren peligro su seguridad La presenciade este simbolo indicaque setrata de producirlesionesgraves.Estamaquinaes capazde amputarmanosy pies personaly/o materialy lade otraspersonas.

-

Page 43: Mantenimiento

OPERACION MANTENIMIENTO Y ALMACENAMIENTO • No pongalas maneso los piescerca de las piezas rotatorias,en la caja Nuncamanipulelosdispositivosde seguridadde manera imprudente. de labarrena/ motoro en el montajedel canal de descarga.El contacto Controleperi6dicamente que funcionende formaadecuada.Remftasea con las piezas rotatoriaspuedeproducirla amputacionde manosy pies. las seccionesde mantenimientoy ajustede este manual. -

Page 44: Montaje

NOTA:las referencias al ladoderechoo y ciertosde la m_tquina quitanievesedeterminandesdela parteposteriorde la unidaden posici6nde operaci6n(permaneciendo directamente detras de la m_tquina quitanieve,mirandohaciael panelde la manija). EXTRACCJON DE LA UNIDAD DE LA CAJA Corte lasesquinasde la caja de cart6ny extiendalaen el piso Quitey descartetodos los insertosde empaque. Saquela maquinaquitanievede la caja. - Page 45 SitOeel montajedel canalsobrela base.Vea la figura3. Cierrelos fijadoresde la brida para asegurarel montajedel canal a la basedel canal. Yea la figura4. Losfijadoresde la brida emiten un chasquidocuandoest_tnbien asegurados. NOTA:si los fijadoresde la brida no seajustan en su lugarfgtcilmente, utilice la palmade su manopara aplicaruna presi6nr_tpida y firme en la parte posteriorde cadauno.

- Page 46 CONFIGURACION " " Herramienta de Limpieza del Canal Hay una herramienta de limpiezadel canal iajustadaa la parte superiorde la caja de la barrenacon un pasadorde ensamblado.Vea la figura6. La herramientaest,.disehadapara limpiarel hieloy la nievedel montajede un canal.Este productose sujeta medianteuna Herrarnienta uni6nde cableen la f_.brica.

- Page 47 Ajuste del montaje del canal Es posibleajustar ladistanciaa la cualse arroja lanievecambiandoel _mgulo del montajedel canal. Parahacerlo: Detengael motorquitandola Ilavede encendidoy aflojela perilla a mariposade pl_tstico que se encuentraen el ladoizquierdodel montajedel canal. Gire el canal haciaarriba o haciaabajoantes de apretarla perilla a mariposa.Vea la figura8.

-

Page 48: Palanca De Cambios

Haydos velocidadesde retroceso(R). La uno (1) es la m_.slenta,y la carburadory se ayudaa encenderel motor. dos (2) es la m_.sr_.pida. Cumple con los est_ndares de seguridad de ANSI Lasm_.quinas quitanievede Craftsman cumplen conlosestandares de seguridad del instituto estadounidense d e est_.ndares nacionales (ANSI). - Page 49 CONTROL DEL ESTRANGULADOR CONTROL DE LA BARRENA El control del estrangulador estfi ubicadoen el motor. Regulala velocidaddel motor,y Io apagacuandomuevael CONTROL LA BARRENA controla la posici6nSTOR MANIJA DEL ARRANCADOR RETROCESO Esta manijase utiliza para arrancarel motormanualmente. BOTON BEL ARRANCABOR EL#CTRICO Si oprimeel bot6ndel arrancadorelectricose engranael arrancadorelectricodel motorcuandose Ioenchufaa una El controlde la barrenaest,.

- Page 50 CONTROL DIRECCIONAL DEL CANAL Aceite El motorse envi6con aceiteen el motor.Controleel nivelde aceite /CONTROL DIRECCIONAL DEL CANAL antes de cada operaci6npara asegurarsede que hayaaceite suficienteen el motor.Paraobtenerm_tsinstrucciones, r emflasea los pasosque aparecenen la p_tgina 52. DESCARGA JZQUIERDA Saquela varilladel nivelde aceitedel orificio de Ilenadode aceite.

- Page 51 NOTA:talvez sea necesarioun cebadoadicionalsi la temperaturaes inferiora 15° Fahrenheit. El arrancadorelectricoopcionalest,. equipadocon un cable de ali- mentaci6ny un enchufede tres terminalesconectadosa tierray ester Tome la manijadel arrancadorde retrocesoy tire de la cuerda disehadopara operarcon corrientedom_sticade 120voltios.Debe haciaafueralentamente. E n el momentoen el quese haga serutilizadocon un recept_.culo de tres terminalescorrectamente levementem_.sdificil tirarde la cuerda,permitaque la misma retrocedalentamente.

- Page 52 Antesde realizartareasde lubricaci6n,reparaci6no inspecci6n, desengranetodoslos controlesy detengael motor.Esperea que se ldetengantodas as p ezas m6v es. Mantenga el nivel MANTENIMIENTO DE MOTOR FULL de aceite entre Control del aceite del motor AsegOrese de que el motorestAverticaly nivelado. (lleno) y ADD (agregue) Desenrosque el tap6nde Ilenadode aceitedel tubo de Ilenadode aceitey limpiela varillade nivelde aceite.

- Page 53 Controleel espaciodel electrodocon un calibradorde sepa- racionesy ajustedichoespacioa 0,030pulg (0,76mm) si es necesario.Vea la figura13. Vuelvaa instalarla bujiay ajustebien. NOTA:Parael reemplazose debe utilizaruna bujfade resistor. Contactecon un centro de partesy reparaci6nSearspara una bujia de repuesto. Carburador Si creeque su carburadornecesitaun ajuste,consultecon un centro de partes y reparaci6nSears.El desempehodel motorno debeverse 1.

- Page 54 PLACA DE RASPADO Y ZAPATAS ANTIDESLIZANTES La placade raspadoy laszapatasantideslizantes ubicadasen la base de la m_.quina quitanieveestgm sujetasa desgaste.Peri6dicamente deberfacontrolarlospernosy reemplazarlos cuandosea necesario. Para retirarlas zapatasantideslizantes: Quitelos cuatropernosdel carroy lastuercasde bridahexago- nalesque los asegurana la mgtquina quitanieve. Montelas nuevaszapatasantideslizantes concuatrospernos de carro (dosen cada lado)y las tuercasde brida hexagonales.

-

Page 55: Reemplazo De La Correa

Ubiquela m_nsulahaciaarribapara brindarm_ts juego (o hacia abajopara aumentarla tensi6ndel cable). Vuelvaa apretarla tuercahexagonal s uperior. Soporte del canal Si la espiralsituadaen la parteinferiordel controldireccionaldel canal no se enganchacompletamente conel montajedel canal,es posible ajustarel soporte del canal. Parahacerlo: Aflojelas dostuercasque sujetanel soportedel canaly cambie su posici6nligeramente. - Page 56 Saquela cubierta del marcodesdedebajode la mgtquina quitanieveretirandoloscuatro tornillosautorroscantes que la aseguran.Vea la figura22. Aflojey retireel tornilloconrebordeque actOacomoguarda de la correa.Vea la figura23. Desenganche el resortede la m6nsulade soportedel marco. Retire la correade alrededorde la poleade la barrenay deslice la mismaentre la m6nsulade soportey la polea de la barrena. Vea la figura24.

- Page 57 Saquela correade la barrenade la poleadel motor. Tome la polea Iocay girela haciala derecha.Vea la figura Levantela correade la barrenapara sacarlade la polea del motor. 4. Girecon cuidadola m_tquina quitanievehaciaarriba y hacia delantede maneraque quedeapoyadasobrela cajade la barrena. 5. Saquela cubiertadel marcodesdedebajode la m_tquina quita nieveretirandoloscuatro tornillosautorroscantes que la aseguran.Veala figura22.

- Page 58 Retirecon cuidadola tuercahexagonal y la arandelaque sujetan el eje hexagonal a l marcode la maquinaquitanieve,y golpee suavemente el extremodel eje paradesplazarel cojinetede bolasdel ladoderechodel marco.Vea la figura28. NOTA:Tengacuidadode no dahar lasroscasdel eje. Con cuidado,ubiqueel eje hexagonal h aciaabajo y haciala izquierdaantesde deslizarcon precauci6nel montajede la rueda de fricci6nfueradel eje.Vea la figura29.

- Page 59 8ARRENAS Las barrenasest_majustadasal eje espiralcon dospasadoresde cuchillay pasadores de chaveta.Si la barrenagolpeaun objeto extrahoo una barrade hielo,la m_.quina quitanieveester disehadade maneraque los pasadoresse puedencortar.Si las barrenasno giran, verifiquesi los pasadores se cortaron.Vea la figura 31. NUNCAcambie lospasadoresde cuchillade las barrenaspor otra cosa que los pasadoresde cuchillade repuestodel fabricantedel equipooriginal,NO de pieza738-04124A.

- Page 60 Si no sevaa utilizael equipodurante 30 diaso mAs,o si esel finalde la temporada de nieveyya no existeposibilidad de quenieve,esnecesario almacenar e l equipode manera adecuada. S igalas instrucciones de almacenamiento quese indicana continuaci6n paragarantizar e l rendimiento mAximo de la mAquina quitanieve durantemuchos ahos. PREPARACION DE LA MAQUINA QUITANIEVE PREPARACION DEL MOTOR...

- Page 61 luier tipodel mantenimiento/servicio, sueltetodos los mandosy pare el motor.Esperehastaque todas las partesde Ilevepuestoscristalesinastillablesdurantela operaci6no realizandocualquierajuste o reparaciones. Esta secci6nse dirigea cuestione$de serviciomenores, Localizarel mac cereanoChamuscael Centrode Servicio o programarel servicio,simplemente ponerseen contactoChamusca en 1-800-4-MY-HOME®. = II • El motor no arranca /a palanea de obturacidn no estfi en la Pongael interruptor en la posici6nCHOKE(obtura- posici6nON (encendido)

- Page 62 (Esta p_tginase aplica s61oen EE.UU. y CanadA). Sears, Roebuck and Co., LI.S.Ao (Sears), el Coneejo de Recureoe Ambientalee de California (CARB) y la Agencia de Protecci6n Ambiental de los Eetados Unidoe (EPA) Declaracion de garant[a del sieterna de control de emisionee (derechoe y obmigacionee de la garant[a de defectoe del propi-...

- Page 63 Busque el periodo de duracion de emisiones importantes yla informaci6n de clasificacion de aire en la etiqueta de emisiones de su motor Los motores cuyo cumplimiento con los est&ndares de emisi6n Tier 2 de la Comisi6n de Recursos Ambientales de California (CARB) est6 certificado deben exhibir la informaci6n relacionada con el periodo de duraci6n de las emisiones y la clasificaci6n de aire.

- Page 64 Your Home For repair - in your home - of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! For the replacement parts, accessories owner's manuals that you need to do-it-yourself. For Sears professional installation of home appliances and items like garage door openers and water heaters.

Need help?

Do you have a question about the 247.881900 and is the answer not in the manual?

Questions and answers