Table of Contents

Advertisement

Quick Links

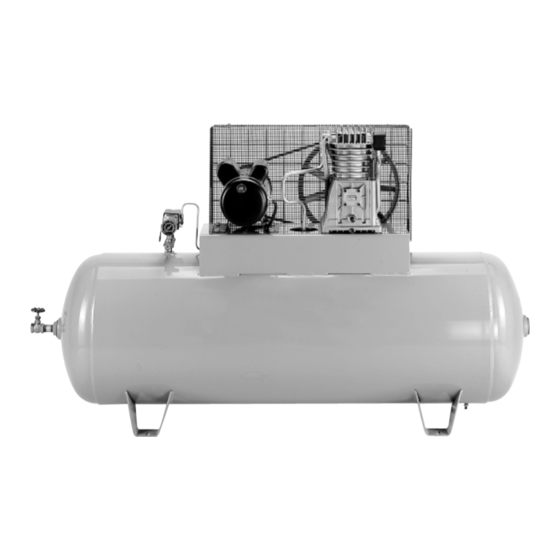

TWIN CYLINDER AIR COMPRESSORS

SAFETY GUIDELINES ....................................................... 1

WARRANTY STATEMENT ................................................. 2

WARNING CHART ......................................................... 3-4

GLOSSARY ........................................................................ 5

DUTY CYCLE ..................................................................... 5

GENERAL INFORMATION ................................................ 5

ON-RECEIPT INSPECTION .............................................. 5

DESCRIPTION OF OPERATION ....................................... 6

ASSEMBLY (PORTABLE UNITS) ...................................... 6

Tools Needed for Assembly ......................................... 6

Rubber Foot Strip ......................................................... 6

PROCEDURES .............................................................. 7-9

Location of Air Compressor ........................................ 7

This manual contains information

that is important for you to know

and understand. This information

relates to protecting YOUR

SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To

help you recognize this informa-

tion, we use the symbols to the

right. Please read the manual and

pay attention to these sections.

Call our Toll Free Number 1-800-888-2468, Ext 2, then 1, to obtain the location of the nearest Authorized Service

Center for ordering repair parts and for warranty repairs.

When ordering repair parts from your local Authorized Service Center, always give the following information:

• Model number of your compressor

• Part number and description of the item you wish to purchase

Retain Original Sales Receipt as Proof of Purchase for Warranty Repair Work.

MG7-OFTWIN REV. 11/5/98

GENERAL MANUAL FOR

PERMANENTLY LUBRICATED

TABLE OF CONTENTS

SAFETY GUIDELINES - DEFINITIONS

URGENT SAFETY INFORMATION - A HAZARD

THAT WILL CAUSE SERIOUS INJURY OR LOSS

OF LIFE.

IMPORTANT SAFETY INFORMATION - A

HAZARD THAT MIGHT CAUSE SERIOUS

INJURY OR LOSS OF LIFE.

Installation for Stationary Unit .................................... 7

Lubrication and Oil ..................................................... 7

Extension Cords ......................................................... 7

Voltage and Current Protection .................................. 8

Piping ......................................................................... 8

Grounding Instructions - (Portable) ........................... 8

Additional Regulators & Controls ............................... 8

Break-in Procedures ................................................... 8

Wiring Instructions-(Stationary) ................................. 9

Grounding Instructions (Stationary) ........................... 9

OPERATING PROCEDURES ........................................... 9

Daily Start-up Checklist .............................................. 9

MAINTENANCE ................................................................ 10

Air Filter - Inspection and Replacement ...................... 10

Safety Valve - Inspection ............................................ 10

Motor .......................................................................... 10

Check Valve Replacement ........................................... 10

STORAGE .......................................................................... 11

TROUBLESHOOTING GUIDE .................................... 12-13

DeVilbiss Air Power Company • 213 Industrial Drive • Jackson, TN 38301-9615

Information for preventing damage to

equipment.

Information that you should pay spe-

cial attention to.

Advertisement

Table of Contents

Summary of Contents for DeVilbiss MG7-OFTWIN

-

Page 1: Table Of Contents

• Model number of your compressor • Part number and description of the item you wish to purchase Retain Original Sales Receipt as Proof of Purchase for Warranty Repair Work. MG7-OFTWIN REV. 11/5/98 GENERAL MANUAL FOR TABLE OF CONTENTS Removal of Shipping Boards and Installation for Stationary Unit ... -

Page 2: Limited Warranty

45 days from the date of purchase. An air compressor that pumps air more than 50% during a one hour period is considered misuse because the air compressor is undersized for the required air demand. Maximum compressor pumping time per hour is 30 minutes. -

Page 3: Important Safety Instructions

VAPORS, THEY MAY IGNITE, CAUSING FIRE OR EXPLOSION. RESTRICTING ANY OF THE COMPRESSOR VENTILATION OPENINGS WILL CAUSE SERI- OUS OVERHEATING AND COULD CAUSE FIRE. YOUR AIR COMPRESSOR IS POWERED BY RISK OF ELECTRICITY. LIKE ANY OTHER ELECTRICALLY ELECTRICAL SHOCK POWERED PROPERLY IT MAY CAUSE ELECTRIC SHOCK. - Page 4 HAZARD REPAIRS ATTEMPTED BY UNQUALIFIED PER- RISK OF SONNEL CAN RESULT IN SERIOUS INJURY OR ELECTRICAL SHOCK DEATH BY ELECTROCUTION. (cont’d) ELECTRICAL PROVIDE ADEQUATE GROUNDING TO THIS PRODUCT INJURY OR DEATH FROM ELECTROCUTION. SEE GROUNDING INSTRUCTIONS. THE COMPRESSED AIR STREAM CAN CAUSE RISK FROM SOFT TISSUE DAMAGE TO EXPOSED SKIN AND FLYING OBJECTS...

-

Page 5: Glossary

This air compressor requires no oil. Now you can enjoy all the benefits of having an air compressor without ever having to purchase, add or change oil. -

Page 6: Description Of Operation

This filter must always be clean and ventilation openings free from obstructions. See "Maintenance". Air Compressor Pump: To compress air, the piston moves up and down in the cylinder. On the downstroke, air is drawn in through the air intake valves. The exhaust valve remains closed. -

Page 7: Installation And Break-In Procedures

INSTALLATION AND BREAK-IN PROCEDURES Location of the Air Compressor Locate the air compressor in a clean, dry and well ventilated area. The air filter must be kept clear of obstructions which could reduce air flow to the air compressor. The air compressor should be located at least 12"... -

Page 8: Voltage And Current Protection

This air compressor must be properly grounded. The air compressor is equipped with a cord having a grounding wire with an appropriate grounding plug. The plug must be used with an outlet that has been installed and grounded in accordance with all local codes and ordinances. -

Page 9: Wiring Instructions-(Stationary)

5. Open the regulator by turning it clockwise. Adjust the regulator to the correct pressure setting. Your compressor is ready for use. 6. Always operate the air compressor in well-ventilated areas; free of gasoline or other solvent vapors. Do not operate the compressor near the spray area. -

Page 10: Routine Maintenance Schedule

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE DONE BY To ensure efficient operation and longer life of the air compressor outfit, a routine maintenance schedule should be prepared and followed. The following routine maintenance schedule is geared to an outfit in a normal working environment operating on a daily basis. -

Page 11: Storage

Before you store the air compressor, make sure you do the following: 1. Review the “Maintenance” and "Operating Procedures" sections and perform maintenance as necessary. Be sure to drain water from the air tank. STORAGE Protect the electrical cord and air hose from damage (such as being stepped on or run over). -

Page 12: Troubleshooting Guide

SCFM or pressure supplied by your air compressor, you need a larger compressor. Clean or replace air intake filter. Do not operate the air compressor with the filter removed. See page 8. Check and replace if required. Remove and clean, or replace. - Page 13 PROBLEM CAUSE Motor will not run or restart. Motor overload protection switch has tripped. Tank pressure exceeds pressure switch “cut-in” pressure. Wrong gauge wire or length of exten- sion cord. Check valve stuck open. Loose electrical connections. Possible defective motor or capacitor. Paint spray on internal motor parts.

- Page 14 SERVICE NOTES NOTAS DE SERVICIO NOTES SUR LE SERVICE 14 — ENG...

- Page 15 SERVICE NOTES NOTAS DE SERVICIO NOTES SUR LE SERVICE 15 — ENG...

-

Page 16: Service Notes

GENERAL MANUAL FOR PERMANENTLY LUBRICATED TWIN CYLINDER AIR COMPRESSORS SERVICE NOTES DeVilbiss Air Power Company • 213 Industrial Drive • Jackson, TN 38301-9615...

Need help?

Do you have a question about the MG7-OFTWIN and is the answer not in the manual?

Questions and answers