Table of Contents

Advertisement

Quick Links

TCI-W13, TCI-W23 Series Wall Mounted Universal Controller

Features

•

Universal PID and/or binary control for any analog

input/output signal and range.

•

Multiple auxiliary functions: heat-cool auto changeover,

automatic enable, setpoint compensation.

•

Differential, averaging, min and max functions

•

Cascading of control loops (-W23 type).

•

Alarm monitoring of low and high limits on all inputs.

•

Programmable reaction in case of alarm.

•

Feedback function for inputs and set points.

•

Functions for dehumidifying, set point shift, cascade

control.

•

Password protected programmable user and control

parameters.

•

Blue backlight.

TCI-W23 also includes

•

Power Cap protected real-time clock with 48hr power

backup.

•

Clock with up to 8 switching events

•

7-day programmable schedules, with options including

change of setpoints and direct position of manual outputs.

Applications

•

Fan coil units

•

Heat exchangers

•

Zoning

General

•

TCI-W13: 1 independent control loop, 1 internal temperature sensor, 1 universal input (analog/binary/temp),

1 binary/PWM output, 2 analog outputs

•

TCI-W23: 2 independent control loops, 8 time schedules, 1 internal temperature sensor, 1 universal input,

1 passive input, 1 binary/PWM output, 2 analog outputs

•

Internal temperature sensor standard. Add replaceable humidity element as required: AES3-HT-A2 (2%), AES3-

HT-A3 (3%), or AES3-HT-A5 (5%)

•

Flexible application configuration is made with a parameter-setting routine using the standard operation terminal.

Product Name

- W

T

C

I

2

Types and Ordering

Product

Product No.

Name

TCI-W13

40-10 0259

TCI-W13-H

40-10 0260

TCI-W23

40-10 0263

TCI-W23-H

40-10 0264

AES3-HT-A2

40-50 0102

AES3-HT-A3

40-50 0103

AES3-HT-A5

40-50 0104

Temperature sensors: Use Vector Controls NTC sensors to achieve maximum accuracy:SDB-Tn10-20 (duct), SRA-Tn10

(room), SDB-Tn10-20 + AMI-S10 as immersion sensor.

Actuators: Choose modulating actuators with an input signal type of 0-10 V DC or 4-20 mA (Min. and max. signal

limitations may be set with parameters.3-pointpoint actuators with constant running time are recommended.

Binary auxiliary devices (e.g. pumps, fans, on/off valves, humidifiers, etc): Do not directly connect devices that exceed

specified limits in technical specifications – observe startup current on inductive loads.

Doc: 70-00-0365C, V2.0, 20220523

Subject to alteration

•

VAV

•

Air handlers

•

Fan, Pump control

-

3

U

Housing

In/Outputs:

Control loops:

Mounting:

Series:

Temperature

Humidity

Loop

Sensor

Sensor

(internal)

(internal)

1

1

2

© Vector Controls GmbH, Switzerland

TCI-W13, TCI-W23 Universal Controller

•

Humidifiers

•

Dehumidifiers

•

Ventilation

Blank = square housing

See table below

1 = 1 control loop, 2 = 2 control loops

W = Wall mounted

TCI

Binary

UI

TI

Output

0

0

1

1

1

0

1

1

1

1

1

•

Radiant heating

•

Radiant cooling

•

Pressurization

Time

Analog

Schedules

Output

0

rH Sensor 3% acc.

2

Time schedules

8

rH Sensor 3% acc.

rH Sensor 2% acc.

rH Sensor 3% acc.

rH Sensor 5% acc.

O

VERVIEW

TCI-W13

TCI-W23

Option

Standard

Page 1-22

Advertisement

Table of Contents

Summarization of Contents

Overview

Features

Key capabilities of the universal controller, including PID control, auto changeover, and alarm monitoring.

Applications

Lists the various systems the controller can manage, such as fan coil units, VAV, and air handlers.

General Controller Information

Provides general specifications for the TCI-W13 and TCI-W23 controllers, including loop count and input/output details.

Technical Specifications

Electrical and Input Specifications

Details power supply requirements, signal input types, ranges, and accuracy for temperature/humidity sensors.

Output and Environmental Specifications

Describes signal outputs, environmental operating conditions, and transport/storage requirements.

Standards and Physical Characteristics

Covers relevant standards, materials, dimensions, weight, and product testing/certification information.

Wiring and Connection

Wiring Diagrams and Terminal Functions

Illustrates electrical connections and explains the function of each terminal on TCI-W13/W23 controllers.

Jumper Settings

Provides guidance on setting jumpers for input and output configurations on the controller.

Mounting and Installation

Mounting Location Recommendations

Recommends ideal locations for controller installation to ensure optimal performance and accessibility.

Installation and Dimension Details

Directs to specific installation sheets and displays physical dimensions for planning.

Display and Operation

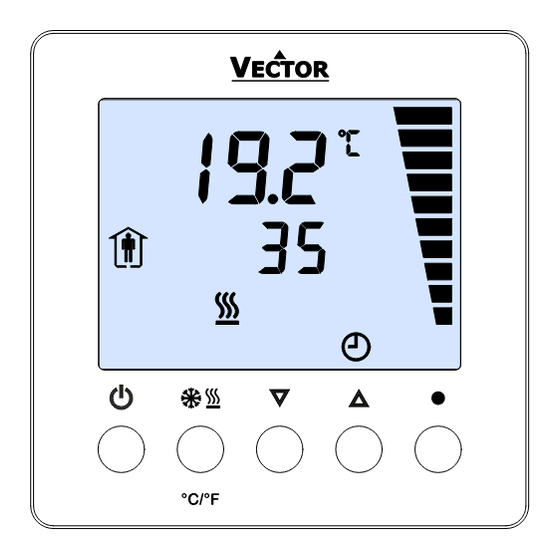

User Interface Element Descriptions

Details the function of each display element, from loop indication to large digits showing measured values.

Operational Modes and Status

Controller Modes and Operational States

Explains controller modes (Occupied, Cooling) and operational states like loop display and OFF mode.

Special Operational Scenarios

Covers special scenarios such as cascade control override, power failure, and alarm messages.

Error Messages and Manual Adjustments

Error Message Interpretation

Lists and explains error codes (Err1, Err3, Err4) and their corresponding conditions for troubleshooting.

Manual Mode Changes and Sensor Calibration

Details manual adjustments for heat/cool mode, input value display, and sensor calibration procedures.

Software Version Identification

Explains how to identify the controller's software version using button combinations.

Clock Operation and Time Schedules

Clock Setup and Management

Guides on setting up the clock, enabling/disabling time schedules, and managing schedule status.

Creating and Applying Time Schedules

Provides step-by-step instructions for creating and applying time schedules for mode changes and setpoints.

Parameter Configuration

Parameter Access and Levels

Defines two access levels for parameters: User/display (0009) and Control (00241).

Recommended Setup Procedure

Outlines the essential steps for setting up and configuring the controller, from jumpers to testing.

Parameter Modules and Modification

Lists parameter modules (UP, 1T/1H/1U/2U, etc.) and explains the process for parameter modification.

User and Display Parameter Details

User/Display Parameter Settings (UP)

Details user and display parameters (UP00-UP18) covering modes, display content, clock, and backlight settings.

Input Configuration

Internal and Universal Input Setup

Configures internal temperature/humidity sensors and universal inputs (1U, 2T) for signal type, range, and alarms.

Input Alarm Configuration

Sets up low/high limit alarms for inputs (ALA1-ALA8) and defines how alarms trigger and are managed.

Input Mathematical Functions

Explains how to calculate mathematical functions (average, min, max, differential) using input values.

Control Loop Configuration

Setpoint Manipulation and Limits

Configures setpoint limits, compensation, and dead zones for heating and cooling control loops.

Cascade Control Setup

Details how to configure cascade control sequences, linking primary and secondary loops for advanced control.

Setpoint Compensation

Explains how to use input values to automatically adjust setpoints for heating or cooling based on conditions.

PI and Integral Control Sequences

PI Control Sequence Parameters

Sets parameters for proportional band (P-band) and offsets for heating and cooling PI sequences.

Integral and Differential Control Setup

Configures integral gain (KI) and measuring intervals for stable temperature control and comfort.

Digital Control Sequences

Stage Actions and Switching Logic

Defines stage actions (cumulative, single, digital) and switching logic for multi-stage control applications.

Switching Hysteresis and Delay

Configures hysteresis and delay settings for digital outputs to manage switching cycles and prevent rapid changes.

Output Configuration

Analog Output Configuration

Configures analog outputs for control loops, special functions, manual positioning, and alarms.

Analog Output Scaling and Alarms

Sets output signal limits, scaling, and assigns alarms to analog output states.

Digital Output Configuration

Digital Output Type and Function Assignment

Selects output type (digital/PWM) and assigns control loop or special function to digital outputs.

Digital Output Alarms and Delays

Configures alarms, switch-off/on delays, and fan symbol display for digital outputs.

PWM Output Configuration

PWM Output Settings and Limits

Details PWM duty cycle limits, activation, and cycle time settings for precise digital output control.

PWM Output Alarms and Important Notes

Assigns alarms to PWM outputs and provides important notes regarding PWM cycle times and relay lifetime.

Auxiliary Functions

Summer/Winter Compensation

Configures temperature-based compensation for heating and cooling setpoints based on outdoor conditions.

Occupied/Unoccupied Mode Switching

Sets up automatic switching between occupied and unoccupied modes using inputs like sensors or key cards.

Enable/Disable Controller Functions

Input-Based Enable/Disable Control

Enables or disables the controller based on input values, with options for delays and limit ranges.

Input Limit Configuration for Control

Defines input limits (Limit 1, Limit 2) used for enabling or disabling controller functions based on input values.

Heating/Cooling Mode Changeover

Input-Driven Mode Switching Logic

Selects an input to drive heating/cooling mode changes, with options for delays and input limits.

Mode Changeover Recommendations

Provides suggested temperature setpoints for switching between heating and cooling based on supply media or outdoor air.

Need help?

Do you have a question about the 40-10 0263 and is the answer not in the manual?

Questions and answers