Table of Contents

Advertisement

Quick Links

Instructions – Parts List

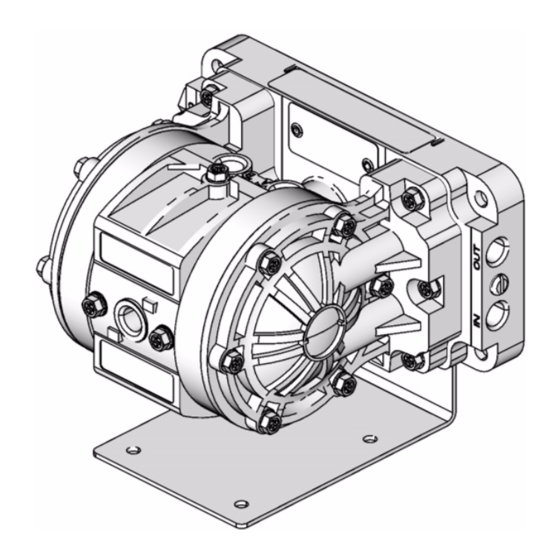

Husky ™ 205 Air-Operated

Diaphragm Pumps

100 psi (0.7 MPa, 7 bar) Maximum Incoming Air Pressure

100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure

Important Safety Instructions.

Read all warnings and instructions in this manual.

Save these instructions.

Part No. D120XX

Polypropylene Pump with Air-Operated Motor

Part No. D110XX* and DM10XX*

Acetal Pump with Air-Operated Motor

Part No. D150XX and DM50XX

PVDF Pump with Air-Operated Motor

Part No. D220XX

Polypropylene Pump with Solenoid Ports

Part No. D210XX*

Acetal Pump with Solenoid Ports

Part No. D250XX

PVDF Pump with Solenoid Ports

These models are certified:

*

II 2 GD

Ex h IIC 66°C...135°C Gb

Ex h IIIC T135°C Db

ATEX T-code rating is dependent on the temperature

of the fluid being pumped. Fluid temperature is limited

by the materials of the pump interior wetted parts.

See Technical Data for the maximum fluid operating

temperature for your specific pump model.

308652ZAP

EN

ti10660a

Advertisement

Table of Contents

Summarization of Contents

Warnings

Equipment Misuse Hazard

Details hazards from improper equipment use, modification, or incompatible fluids, emphasizing safety precautions.

Hazardous Fluids

Outlines risks associated with handling hazardous fluids and required safety measures for protection.

Fire and Explosion Hazard

Explains risks of static electricity and ignition sources, detailing prevention measures.

Installation

Tightening Threaded Fasteners

Instructions for checking and retorquing pump fasteners before and after initial use.

Grounding

Procedures for grounding the pump and system to prevent static discharge and ensure safety.

Air Exhaust Ventilation

Guidance on safely venting pump exhaust, especially when handling hazardous fluids.

Mountings

Instructions for securing the pump using mounting brackets and ensuring stability.

Air Lines

Details on connecting air lines, including master air valves and filters.

Fluid Lines

Guidelines for connecting fluid inlet and outlet hoses for proper pump priming.

Typical Installation

Examples of common system configurations for pump installation.

Operation

Pressure Relief Procedure

Steps to safely relieve pressure before servicing or moving the pump.

Flushing the Pump Before First Use

Procedure for flushing the pump with water or solvent before initial operation.

Starting and Adjusting the Pump

Steps for safely starting, priming, and adjusting pump operation.

Pump Shutdown

Procedures for safely shutting down the pump at the end of operations.

Maintenance

Lubrication

Information on lubricating the air valve and air inlet for optimal performance.

Tightening Threaded Connections

Guidelines for checking and tightening threaded connections to prevent leaks.

Flushing and Storage

Procedures for flushing the pump before storage to prevent damage.

Service

Service Kits

Information on ordering and identifying service kits for air valve and fluid sections.

Servicing the Air Valve

Step-by-step instructions for disassembling and servicing the air valve assembly.

Replacing Diaphragms

Detailed procedure for removing and installing new diaphragms.

Replacing Check Valves

Steps for removing, replacing, and reinstalling check valves.

Parts Identification and Listing

Parts Matrix

A matrix to determine the pump model based on material construction.

Service Kit Matrix

A matrix to identify the correct service kit based on pump materials.

Air Motor Section Parts

Lists and diagrams for parts related to the air motor assembly.

Fluid Section Parts

Lists and diagrams for parts related to the fluid section assembly.

Check Valve Parts

Lists and diagrams for check valve components.

Diaphragm Parts

Lists and diagrams for diaphragm components.

Torque Sequence

Valve Cover Torque

Specifies torque values and sequence for valve cover screws.

Fluid Cover Torque

Specifies torque values and sequence for fluid cover screws.

Manifold to Center Section Torque

Specifies torque values and sequence for manifold-to-center section screws.

Performance Charts

Fluid Outlet Pressure Charts

Graphs showing fluid outlet pressure vs. flow rate at different air pressures.

Air Consumption Charts

Graphs showing air consumption vs. flow rate at different air pressures.

Need help?

Do you have a question about the D150a1 and is the answer not in the manual?

Questions and answers