Table of Contents

Advertisement

Quick Links

Instructions – Parts List

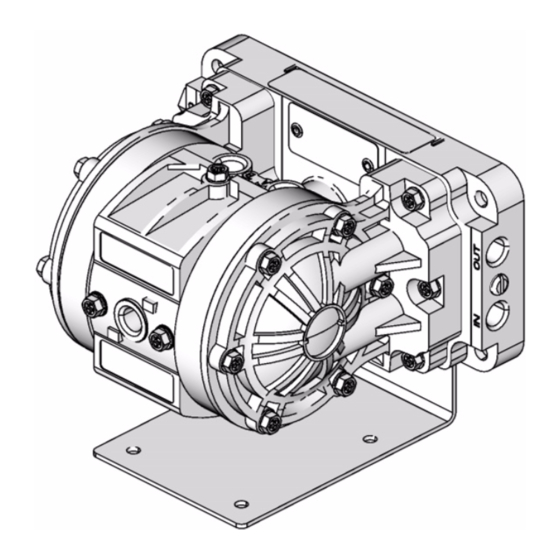

Husky ™ 205 Air-Operated

Diaphragm Pumps

100 psi (0.7 MPa, 7 bar) Maximum Incoming Air Pressure

100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure

Important Safety Instructions.

Read all warnings and instructions in this manual.

Save these instructions.

Part No. D120XX

Polypropylene Pump with Air-Operated Motor

Part No. D110XX* and DM10XX*

Acetal Pump with Air-Operated Motor

Part No. D150XX and DM50XX

PVDF Pump with Air-Operated Motor

Part No. D220XX

Polypropylene Pump with Solenoid Ports

Part No. D210XX*

Acetal Pump with Solenoid Ports

Part No. D250XX

PVDF Pump with Solenoid Ports

These models are certified:

*

II 2 GD

Ex h IIC 66°C...135°C Gb

Ex h IIIC T135°C Db

ATEX T-code rating is dependent on the temperature

of the fluid being pumped. Fluid temperature is limited

by the materials of the pump interior wetted parts.

See Technical Data for the maximum fluid operating

temperature for your specific pump model.

308652ZAP

EN

ti10660a

Advertisement

Table of Contents

Summarization of Contents

Installation

Tightening Threaded Fasteners Before First Use

Instructions for checking and retorquing all external fasteners before first use and periodically.

Grounding

Ensuring proper grounding of the pump and system to prevent static sparking and fire hazards.

Air Exhaust Ventilation

Properly venting pump exhaust air to a safe place, away from people and food handling areas.

Mountings

Guidelines for securely mounting the pump using the provided bracket and ensuring support.

Air Lines

Connecting air lines, installing air control accessories, and ensuring proper air supply.

Fluid Lines

Connecting fluid-in and fluid-out lines, ensuring the OUT port is mounted upwards for priming.

Typical Installation

Guidance on typical system installations, including solenoid operation and PLC integration.

Operation

Pressure Relief Procedure

Steps to safely relieve pressure before checking, adjusting, cleaning, moving, or repairing the pump.

Flushing the Pump Before First Use

Procedure for flushing the pump with water or a compatible solvent to prevent contamination or damage.

Starting and Adjusting the Pump

Steps for properly grounding, checking fittings, and starting the pump to prime it.

Pump Shutdown

Procedure for safely shutting down the pump and relieving pressure at the end of operation.

Maintenance

Lubrication

Information on air valve lubrication and cautions against over-lubrication.

Tightening Threaded Connections

Instructions for checking hose wear, damage, and retorquing threaded connections.

Flushing and Storage

Steps for flushing the pump before storage to prevent fluid drying or freezing and damage.

Service

Service Kits

Information on ordering and identifying service kits for air valve and fluid section repairs.

Servicing the Air Valve

Step-by-step procedure for servicing the air valve, including component replacement.

Replacing Diaphragms

Detailed instructions for safely removing and installing new diaphragms for the pump.

Replacing Check Valves

Procedure for replacing the check valves, ensuring correct orientation and clean seat areas.

Parts Matrix

Service Kit Matrix

Matrix for determining the correct service kit model number based on pump construction materials.

Parts

Air Motor Section (matrix column 2)

Parts list and descriptions for the air motor section of the pump.

Fluid Section (matrix column 3)

Parts list and descriptions for the fluid section of the pump.

Check Valve (matrix column 5)

Parts list and descriptions for the check valves used in the pump.

Diaphragm (matrix column 6)

Parts list and descriptions for the diaphragms used in the pump.

Performance Charts

Husky 205 Fluid Outlet Pressure

Chart showing fluid outlet pressure versus fluid flow at different air pressures.

Husky 205 Air Consumption

Chart showing air consumption versus fluid flow at different air pressures.

Graco Standard Husky Pump Warranty

Graco Information

Contact and website information for Graco products, patents, ordering, and support.

Need help?

Do you have a question about the D12091 and is the answer not in the manual?

Questions and answers