Summarization of Contents

Important Information

Protection and Standards

Compliance with CE and directives like ISO 9001, ROHS, ATEX.

Disposal Instructions

Guidance on proper disposal of electronic devices to avoid environmental harm.

Software Updates

Importance of installing software upgrades and liability for outdated software.

Preface

Technical Data and Documentation

Information on where to find technical data sheets for the sensors.

Principle of Operation

Explanation of how the piezoresistive sensor element works and different technologies used.

Media Compatibility

Information on compatible media for DCE and media-separated sensors.

Cooling Requirements

Specifications for coolant temperature, flow rate, pressure, and composition for sensor cooling.

Water Cooling Precautions

Safety guidelines for operating and maintaining the water cooling system for sensors.

Operation

Operation in Non-Hazardous Areas

Guidelines for using sensors without Ex-certification in safe environments.

Hazardous Area Operation Instructions

Rules for using Ex-certified sensors in Zone 2, including installation and modification restrictions.

Sensor Execution Types for Hazardous Areas

Specifies sensor types (4011AE, 4017AE, 4067EE) certified for hazardous area use.

Product Marking for Hazardous Areas

Details on ATEX and IECEx markings for Ex-certified sensors.

Zone 2 Sensor Installation (Ex-ec)

Guidance and conditions for installing Ex-ec certified sensors in Zone 2.

Installation of Piezoresistive Sensor

General Installation Information

Importance of careful installation for accuracy, bore machining, and torque specifications.

Direct Installation

Procedure for direct sensor installation, including thread lubrication and diaphragm protection.

Installation with Sleeve

Method for installing sensors using a mounting sleeve for sealing, particularly in galleries.

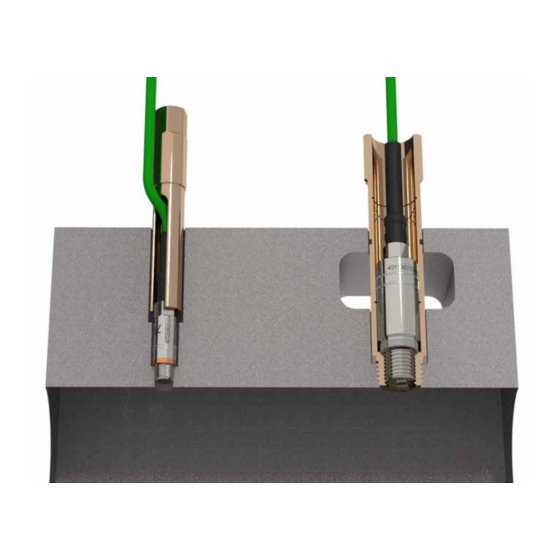

Installation Examples

Visual examples of different sensor installation methods: sleeve, direct, and pipe mounting.

Mounting Bore Machining

Requirements for machining the sensor bore, ensuring concentricity and a flat sealing surface.

Mounting Water Hose on Cooling Pipe

Procedure for fitting the FPM hose onto the sensor's cooling pipe using heat expansion.

Water Cooled Sensor Heat Screen

Maintenance of the protector screen for water-cooled sensors in exhaust applications.

Pre-Installation Checks

Checks for water leakage, cable condition, seal ring integrity, and mounting bore quality.

Installing Sensor into Bore

Steps for feeding the cable, fitting the mounting key, and lubricating threads before installation.

Setting Up Measuring Chain

Analog Compensated Sensors Setup

Procedure for parameterizing amplifiers for analog compensated sensors using calibration data.

Analog Sensors with V200S Extension

Connecting sensors with integrated TEDS and potential manual parameterization needs.

Digital Compensated Sensors Setup

Connecting digital sensors with TEDS; no parameterization needed for compatible amplifiers.

Zero-Point Correction

Zero-Point Correction (Without Cooling)

Steps for zero-point correction for sensors without cooling adapters, involving engine warm-up and barometric adjustment.

Zero-Point Correction (With Cooling)

Procedure for zero-point adjustment with cooled adapters during steady state measurements.

Dismounting and Maintenance

Dismounting Procedure

Step-by-step instructions for safely removing the sensor from the mounting bore.

Maintenance and Inspection

Guidelines for visual inspection, cleaning, and handling of sensors to maintain accuracy.

Need help?

Do you have a question about the 4065 Series and is the answer not in the manual?

Questions and answers