Summarization of Contents

Important information

Protection and standards

Lists directives (CE, ROHS, ATEX) and harmonized Ex-standards applied to the sensors.

Disposal instructions for electronic equipment

Instructions for proper disposal of old electronic devices.

Software upgrades and updates

Importance of installing software upgrades and liability for non-compliance.

Preface

Technical data and documentation

Information that data sheets are available on the Kistler website.

Principle of operation

Explains how piezoresistive sensors work using Wheatstone bridge, DCE, media-separated, and block technology.

Media compatibility

Details media compatibility for DCE sensors and media-separated sensors.

Requirements to cooling

Specifies requirements for Kistler cooling system Type 2621G, including temperature, flow rate, pressure, and composition.

Precautions for water cooling

Advises on precautions for water cooling, including system activation and temperature management.

Operation

Operation in non-hazardous areas

Specifies that non-Ex-certified sensors can be used in non-hazardous areas.

Operation in hazardous areas

Outlines the procedures and conditions for operating sensors in hazardous areas.

Instructions for operation in hazardous areas

Lists rules for using Ex-certified sensors in hazardous areas, specifically zone 2.

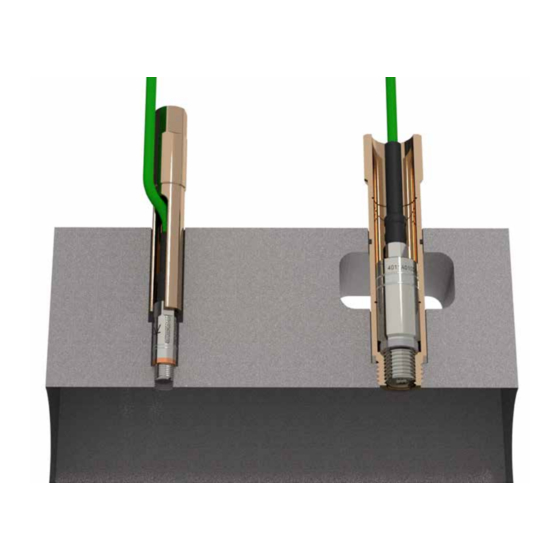

Installation of the Sensor (Ex-ec) for operation in zone 2

Illustrates and explains the installation of Ex-certified sensors in Zone 2 areas.

Installation of the piezoresistive sensor

General information

Emphasizes accuracy depends on careful installation, bore machining, and torque.

Direct installation

Describes direct installation, space-saving benefits, and risks of repeated mounting/dismounting.

Installation with sleeve

Explains installation using a mounting sleeve for accessing measurement points via galleries.

Installation examples

Shows examples of sleeve mounting, direct mounting, and pipe mounting.

Machining the mounting bore

Details requirements for machining the sensor bore, focusing on concentricity and sealing surface.

Mounting the water hose on the cooling pipe

Describes the procedure for mounting the FPM hose onto the sensor's cooling pipe.

Protector heat screen for water cooled sensor

Discusses cleaning or replacing the protector heat screen for water-cooled sensors.

Check points before installation

Lists checks for water leakage, cable condition, sensor seal ring, and mounting bore.

Installing the sensor into the bore

Details the process of feeding the cable and installing the sensor into the bore, including lubrication.

Zero-point correction

Procedure of zero-point adjustment for sensors installed with cooled switching adapters

Details the zero-point adjustment procedure for sensors with cooled switching adapters.

Dismounting and maintenance

Dismounting

Outlines the steps for safely dismounting the sensor, in reverse order of installation.

Maintenance

Covers visual inspection, cleaning of sensors, and handling precautions for the diaphragm.

Removing the cooling pipes

Lists materials and procedures for removing cooling pipes.

Installing the cooling pipes

Lists materials and procedures for installing cooling pipes, including Loctite application.

Need help?

Do you have a question about the 4011 Series and is the answer not in the manual?

Questions and answers