Table of Contents

Advertisement

Installation, Operation, and Maintenance

Blower Coil Air Handler

Single Zone Air Handler, 400 to 4000 CFM

Models BCHE, BCVE and later design sequence

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-conditioning equipment

can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that are attached to the equipment.

June 2022

SAFETY WARNING

BCX-SVX002A-EN

Advertisement

Table of Contents

Troubleshooting

Summarization of Contents

Installation, Operation, and Maintenance

Blower Coil Air Handler

Details on blower coil air handler units for single zone applications.

Models BCHE, BCVE and later design sequence

Identifies specific blower coil unit models covered in the manual.

Introduction

Warnings, Cautions, and Notices

Defines and explains safety advisories used throughout the manual.

Follow EHS Policies!

Instructs personnel to follow Environmental, Health, and Safety policies.

Model Number Description

Digit 1, 2, 3, 4 — Unit Model

Defines codes for BCHE (Horizontal) and BCVE (Vertical) unit models.

Digit 5, 6, 7 — Unit Size

Specifies unit size codes from 12 (1 Ton) to 120 (10 Ton).

General Information

Horizontal blower coil (BCHE model)

Provides general information and diagram for horizontal blower coil units.

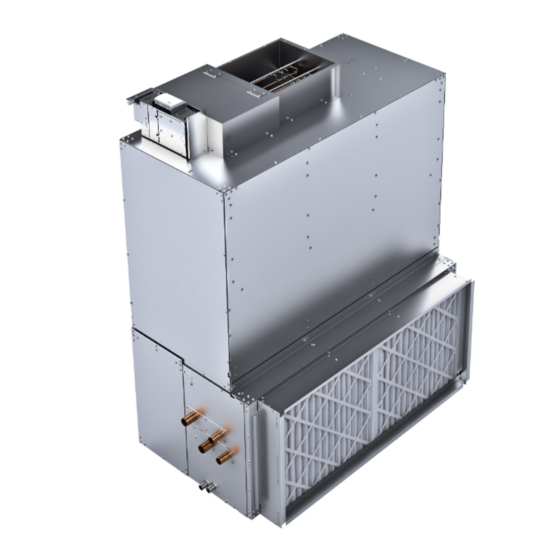

Vertical blower coil BCVE size 24-60

Illustrates the vertical blower coil unit and its components.

Pre-Installation

Receiving and Handling

Instructions for inspecting, handling, and receiving unit shipments.

Site Preparation

Details required site preparation, including weight support and space.

Dimensions and Weights

Service Clearances

Provides recommended service clearance diagrams for unit installation.

Table 1. Service requirements (inches)

Table detailing service clearance dimensions (A and B) by unit size.

Dimensions and Weights

Horizontal Blower Coil

Diagram and details for the BCHE horizontal blower coil unit.

Table 2. BCHE horizontal blower coil dimensions (inches) and weights (lb)

Table of dimensions and weights for BCHE horizontal blower coils.

Dimensions and Weights

Vertical Blower Coil

Diagram for BCVE vertical blower coil, size 24-60.

Table 3. BCVE 24 to 60 vertical blower coil dimensions (inch) and weights (lb)

Table of dimensions and weights for BCVE 24-60 vertical units.

Options

Angle Filter and Mixing Box

Details on angle filter and mixing box options and their dimensions.

Bottom/Top Access Filter Box

Diagram for bottom/top access filter box option.

Return and Discharge Attenuators

Diagrams for return and discharge attenuator options.

Electric Heat

Figure 18. BCHE/BCVE blower coils with electric heat section

Diagrams showing electric heat sections for BCHE/BCVE units.

Table 11. BCHE/BCVE blower coils with electric heat section dimensions (inches) and weights (lb)

Table of dimensions and weights for electric heat sections.

Coil Connections

Table 15. BCHE hydronic coil connection sizes, OD (inches)

Table of hydronic coil connection sizes for BCHE units.

Table 17. BCHE DX coil connection sizes, OD (inches) (continued)

Continuation of BCHE DX coil connection size table.

Sample Piping Schematics

Illustrates typical piping schematics for 2-way valves.

Dimensions and Weights

Valve and Actuator Operation

Explains operation of valves and actuators, excluding specific Cv values.

Valve Stroke Time

Provides stroke time data for various valve selections.

Installation Mechanical

Lifting and Rigging

Safety warnings and procedures for lifting and rigging the unit.

General Lifting Considerations

Guidelines for estimating center of gravity and using proper rigging methods.

Figure 31. Ceiling mounted horizontal unit

Diagram showing ceiling mounting of horizontal units with suspension rods.

Installation Mechanical

Figure 32. Add nut and flat washers to threaded rod

Illustrates attaching nuts and washers to threaded rods for mounting.

Vertical Unit (Model BCVE) Installation

Procedures for installing vertical BCVE units on the floor.

Accessory Installation — Mix Box, Angle Filter, Bottom Access Filter, and Attenuators

Instructions for installing various unit accessories.

Installation Mechanical

Figure 36. Mix box install

Diagram illustrating the installation of a mix box accessory.

Installation Mechanical

Duct Connections

Standards and recommendations for connecting ducts to the unit.

Installation Mechanical

Condensate Drain Connections

Guidelines for sizing and installing condensate drain lines and traps.

Figure 42. BCXE drain pan removal

Diagram showing the removal process for the BCXE drain pan.

Piping and Connections

Connection Leaks!

Notice regarding potential leaks at coil headers and connection points.

General Recommendations

Recommendations for proper installation, piping, and trapping of coils.

Drain Pan Trapping (Models BCHE/BCVE)

Instructions for drain pan trapping, especially for negative pressure applications.

Piping and Connections

Water Coil Piping

Information on water coil self-venting and combinations for minimum velocity.

Refrigerant Coil Piping

Guidance on refrigerant coil piping and split-system component arrangement.

Piping and Connections

Liquid Lines

Details on liquid line sizing, routing, and insulation.

Components

Lists necessary liquid-line refrigerant components and their sequence.

Piping and Connections

Suction Lines

Guidance on suction line sizing, routing, and insulation.

Piping and Connections

R-410A Refrigerant under Higher Pressure than R-22!

Warning about R-410A refrigerant's higher pressure and required equipment.

Expansion Valves

Information on expansion valves for metering refrigerant into evaporator coils.

Piping and Connections

Field-Installed Evaporator Piping

Illustrates typical piping for single-circuit evaporator coils.

Installation - Controls

Control Options

Lists available control options: CSTI, Thermostat, and UC400-B.

Customer Supplied Terminal Interface (CSTI)

Details the CSTI interface for field-supplied thermostats or controllers.

Cooling

Describes how the CSTI changeover function provides cooling.

Installation - Controls

Heating

Explains how the CSTI changeover function provides heating.

Installation - Controls

Thermostat

Information on wall-mounted, field-installed thermostats and their control.

Figure 55. Thermostat wiring diagram

Illustrates wiring diagrams for various thermostat system configurations.

Installation - Controls

Communication Wire Specifications

Details specifications for BACnet MS/TP link wiring.

Tracer® UC400-B Controller

Overview of the UC400-B controller for VAV control applications.

Installation - Controls

MAC Address

Explanation of MAC Address requirements for BACnet operation.

BACnet Device ID

Explanation of BACnet Device ID requirements for network operation.

Installation - Controls

BACnet networks with a Tracer® SC system controller

How Device ID is soft set with a Tracer SC system controller.

Installation - Controls

WARNING Hazardous Voltage!

Warning about hazardous voltage when working with controllers.

WARNING Proper Ground Connection Required!

Emphasizes the need for proper ground connection for controllers.

Installation - Controls

Air-Fi® Wireless Communications Systems

Information on Air-Fi Wireless Communication systems and devices.

Air-Fi® Wireless Communications Interface (WCI)

Details the WCI for wireless communication between Trane SC and unit controllers.

Installation - Controls

Wireless Zone Sensors

Information on Trane wireless zone sensors and their communication.

Wired Zone Sensors

Information on using wired zone sensors with WCI.

Installation - Controls

Zone Sensor Options

Overview of available wall-mounted zone sensors for design flexibility.

Zone Sensor Installation

Steps for installing zone sensors.

Location Considerations

Guidelines for selecting optimal locations for zone sensors.

Installation - Controls

Location Considerations for Wireless Zone Sensors

Placement criteria for wireless zone sensors to ensure signal strength.

Height Requirements

Recommended mounting height requirements for zone sensors.

Installation - Controls

Figure 67. Mounting zone sensor base plate

Diagram for mounting the zone sensor base plate.

Receivers

Information on receiver installation and removal.

Installation - Controls

Zone Sensor Settings

Process for establishing communication between receiver and sensor.

Address Setting

Procedure for setting rotary address switches for receiver and sensor.

Installation - Controls

Figure 72. Receiver conducts 20 second channel scan

Diagram showing receiver channel scan process.

Associating Sensor to Receiver

Steps for associating wireless sensors with their receivers.

Installation - Controls

Sensor Operations

Details sensor operations like temporary occupancy and end-of-range values.

Receiver Power-up Sequence

Describes the sequences that occur when power is applied to the receiver.

Installation - Controls

Transmission Variables

Lists transmission time variables for wireless sensors.

Wireless Sensor Specifications

Table of technical specifications for wireless sensors.

Installation - Controls

Wireless Display Sensor (WDS)

Procedure for configuring wireless display sensors.

Installation - Controls

Displaying Setpoint or Temperature

How to configure the sensor to display temperature or setpoint.

Locking or Unlocking Settings

Procedure to lock or unlock sensor settings like setpoint or fan speed.

Installation - Controls

WDS Operating Mode

How to operate the wireless display sensor (WDS) in different modes.

Changing Room Temperature

Steps to adjust the room temperature setting on the sensor.

Installation - Controls

Changing Heating/Cooling Settings

How to change heating/cooling settings on the thermostat.

Changing Fan Settings

How to change fan settings on the thermostat.

Installation — Electrical

Unit Wiring Diagrams

Information on obtaining and using unit wiring diagrams.

Supply Power Wiring

Guidelines for proper supply power wiring, including warnings.

MCA and MOP Calculations

Calculations for Minimum Circuit Ampacity and Maximum Overcurrent Protection.

ECM Overview and Setup

Trane Electronically Commutated Motor (ECM)

Overview of Trane's ECM motor technology and its benefits.

VelociTach™ Motor Control Board

Details the VelociTach motor control board functions and features.

ECM Overview and Setup

Status Display

Explanation of the motor control board's status display and characters.

ECM Overview and Setup

Safety Requirements

Essential safety recommendations for ECM motor and control board setup.

ECM Overview and Setup

User Interface

Description of the VelociTach motor control board's on-board user interface.

ECM Overview and Setup

Table 31. Button actuation levels

Table detailing button functions and actuation levels for the user interface.

ECM Overview and Setup

Configuration Examples

Examples demonstrating how to view and change motor control board parameters.

ECM Overview and Setup

Error codes

Table listing error codes generated by the motor control board.

Adjustments

Adjustments needed for motor control board commissioning.

ECM Overview and Setup

Adjusting Variable Speed Inputs

Instructions for calibrating variable speed inputs (VSP) on the system.

ECM Overview and Setup

VSP Setup Examples

Examples illustrating VSP setup configurations for optimal performance.

ECM Overview and Setup

Adjusting Optional Auto-Changeover Function on CSTI Units

How to adjust the auto-changeover function on CSTI units.

ECM Overview and Setup

Motor Control Board Settings

Details motor control board functions and unit-specific settings.

ECM Overview and Setup

Table 33. Configuration settings of the motor control board (for reference only)

Table of motor control board configuration settings and their descriptions.

ECM Overview and Setup

Fan Speed Response Verification

Procedure to verify fan speed response after commissioning.

Start-Up

Pre-Startup Checklist

Checklist to verify installation procedures before unit startup.

General Checklist

A general checklist to ensure all installation steps are complete.

Start-Up

Thermostat

Information on thermostat configuration and operation.

Thermostat Operation

How the thermostat operates in auto fan mode and other modes.

Start-Up

Button Functions

Description of thermostat buttons and their functions.

Operating Modes

Explanation of the four possible operating modes for the thermostat.

Start-Up

Tracer® UC400-B Controller

Overview of the Tracer UC400-B controller for VAV control.

Analog Sensors

Information on thermistor sensors used for temperature measurements.

Start-Up

Zone Sensor

Details zone sensor inputs and setpoint adjustments.

Fan Switch

How the zone sensor fan switch controls fan operation.

Start-Up

UC400-B Stand-Alone Operation

Procedure for operating the UC400-B controller in stand-alone mode.

UC400-B Operation

Overview of controller operation, including fan modes.

Start-Up

Occupancy Modes

Explanation of different occupancy modes: Occupied, Unoccupied, Standby, Bypass.

Timed Override Control

How to use timed override buttons for temporary occupancy.

Start-Up

Zone Temperature Control

Methods for controlling zone temperature: Cascade, Simplified, Discharge Air.

Discharge Air Tempering

Function to temper discharge air during cooling mode.

Start-Up

Water Temperature Sampling Function

Function for sampling entering water temperature for hydronic systems.

Fan Operation

Details fan operation modes: continuous, AUTO, and manual.

Start-Up

Exhaust Control

How exhaust control is achieved via binary output and its coordination.

Valve Operation

Explains controller support for modulating and two-position valves.

Start-Up

Economizing (Free Cooling)

How the controller supports economizing or free cooling.

Electric Heat Operation

Details operation of staged and modulating electric heat.

Start-Up

Dehumidification Operation

Conditions under which the controller supports space dehumidification.

Unit Protection Strategies

Strategies to protect the unit or building from damage.

Smart Reset

Automatic restart procedure for units locked out by diagnostics.

Start-Up

Freeze Avoidance

Protection against freezing during low ambient temperatures when fan is OFF.

Freeze Protection (Discharge Air Temperature Low Limit)

Protection against freezing by monitoring discharge air temperature.

Routine Maintenance

Hazardous Service Procedures!

Safety precautions for technicians performing maintenance.

Rotating Components!

Warning about hazards associated with rotating components during servicing.

Routine Maintenance

Fans

Information on inspecting and cleaning fan sections.

Fan Motors

Periodic inspection of fan motors for vibration or temperature.

Routine Maintenance

Coils

General recommendations for keeping coils clean for maximum performance.

Water Coils

Safety warnings and procedures for cleaning water coils.

Routine Maintenance

Refrigerant Coils

Safety warnings and procedures for cleaning refrigerant coils.

Coil Winterization

Procedures for water coil winterization to prevent freeze-up.

Routine Maintenance

Cleaning Non-Porous Surfaces

Procedures for cleaning non-porous insulating surfaces.

Cleaning Porous Surfaces

Procedures for cleaning porous insulating surfaces.

Drain Pans

Safety warnings and procedures for cleaning condensate drain pans.

Diagnostics and Troubleshooting

Hazardous Service Procedures!

Safety precautions for troubleshooting procedures.

Table 43. Troubleshooting recommendations

Table of common symptoms, probable causes, and recommended actions.

Diagnostics and Troubleshooting

Receiver Diagnostics

Explanation of receiver LED states and their diagnostic meanings.

Diagnostics and Troubleshooting

Sensor Diagnostics

Explanation of sensor LED states and error codes shown on the WDS.

Testing Signal Strength

Procedure to test signal strength between sensors and receivers.

Diagnostics and Troubleshooting

Testing Battery Status

Procedure to test battery status for wireless sensors and receivers.

Diagnostics and Troubleshooting

24 V Power Status Indicator

Indicator for normal 24V power status on the receiver.

Check Signal Strength on a Site

Steps to check signal strength on-site for wireless systems.

Diagnostics and Troubleshooting

Manual Association

Procedure for manually associating receivers and sensors.

Disassociation

Conditions and procedures for disassociating sensors from receivers.

Diagnostics and Troubleshooting

Servicing and Testing Tools

Tools and procedures for servicing and testing wireless sensor systems.

Procedure for Testing Zone Sensor

Steps to test zone sensors when they are not working as expected.

Diagnostics and Troubleshooting

Measuring Output Resistance

Procedure to measure receiver output resistance for diagnostics.

Cleaning the Sensor

Instructions for cleaning sensors without causing damage.

Diagnostics and Troubleshooting

Tracer® UC400-B Controller

Description of LED activity for the Tracer UC400-B controller.

Diagnostics and Troubleshooting

Overriding Outputs

How to safely override controller outputs for testing or commissioning.

Diagnostics

Explanation of diagnostic messages and their effect on controller operation.

Diagnostics and Troubleshooting

Table 54. Diagnostics generated by UC400-B controller

Table listing UC400-B controller diagnostics, causes, consequences, and types.

Diagnostics and Troubleshooting

Fans with UC400-B Controller

Troubleshooting fan issues when using UC400-B controller.

Diagnostics and Troubleshooting

Valves with UC400-B Controller

Troubleshooting valve issues when using UC400-B controller.

Diagnostics and Troubleshooting

DX Coils or Electric Heat with UC400-B Controller

Troubleshooting DX coils or electric heat with UC400-B controller.

Outdoor Air Dampers with UC400-B Controller

Troubleshooting outdoor air damper issues with UC400-B controller.

Diagnostics and Troubleshooting

ECM Motors

General information and warnings related to ECM motors.

General Information

Overview of VelociTach motor control board monitoring and speed requests.

Diagnostics and Troubleshooting

Troubleshooting Tips

Tips for troubleshooting VelociTach motor control board and ECM motor issues.

Table 61. Motor does not spin, spins too slowly

Troubleshooting table for motor spin issues.

Diagnostics and Troubleshooting

Replacing ECM Components

Guidelines and warnings for replacing ECM motor components.

Diagnostics and Troubleshooting

Replacement Checklist

Checklist to ensure proper replacement of ECM components.

Circuit Module Replacement

Procedure for replacing circuit modules on the control board.

Diagnostics and Troubleshooting

Application Notes

Notes on ECM motor differences and application considerations.

RPM Mode

Explanation of RPM mode operation for ECM motors.

Diagnostics and Troubleshooting

Troubleshooting Other Unit Functions

How ECM operation may interact with other system components.

Wiring Diagrams

Table 63. Wiring diagram matrix

Matrix listing available wiring diagrams by number and description.

Layout and Control Box Diagrams

Figure 109. Left-hand control box with motor, electric heat, condensate overflow, low-limit switch, discharge air temperature, and angle filter/ mixing box actuator

Diagram of the left-hand control box and its components.

Layout and Control Box Diagrams

Figure 110. Right-hand control box with motor, condensate overflow, low-limit switch, and discharge air temperature

Diagram of the right-hand control box and its components.

Layout and Control Box Diagrams

Figure 111. Size 24 to 60 BCVE unit with condensate overflow, low-limit switch, and discharge air temp

Diagram of BCVE 24-60 unit showing key components in the control box.

Layout and Control Box Diagrams

Figure 112. Control box for Tracer® UC400-B controller

Diagram of the control box for the Tracer UC400-B controller.

Figure 113. Control box for CSTI with 2-stage EH and DX coil

Diagram of the control box for CSTI with 2-stage EH and DX coil.

Need help?

Do you have a question about the BCVE and is the answer not in the manual?

Questions and answers