Table of Contents

Advertisement

Advertisement

Table of Contents

Summarization of Contents

About this manual

1.1 Validity

Specifies the scope and applicability of the operating instructions.

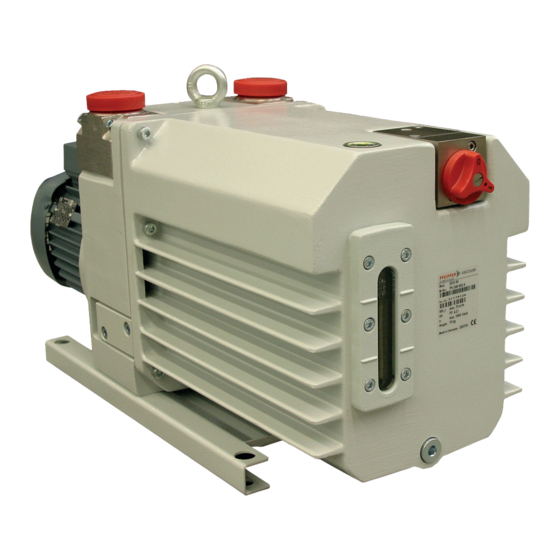

1.1.2 Variants

Details the different versions of the Uno/DuoLine series vacuum pumps.

1.3 Conventions

Explains conventions used in the manual, including abbreviations and symbols.

1.3.1 Abbreviations

Provides a list of abbreviations used in the document.

1.3.2 Pictographs

Explains the meaning of pictographs used to convey information.

1.3.3 Stickers in the product

Describes the stickers found on the product and their meanings.

Safety

2.1 General safety instructions

Introduces the risk levels and information levels used in the safety section.

2.2 Safety instructions

Details safety instructions based on risk assessment and life cycle phases.

2.3 Safety precautions

Provides essential safety precautions for handling the product.

2.4 Safety precautions for handling pumps with magnetic coupling

Specific safety measures for pumps equipped with magnetic couplings.

2.5 Limits of use of the product

Defines the operating limits, such as ambient and medium temperatures.

2.6 Proper use

Outlines the correct and intended uses of the vacuum pump.

2.7 Foreseeable improper use

Lists uses that are considered improper and may void warranty.

Product description

3.1 Product identification

Explains how to identify the product using information on the rating plate.

3.2 Scope of delivery

Lists the items included in the standard delivery package of the pump.

3.3 Functional description

Describes the basic functionality and design of the rotary vane pumps.

3.4 Operating principle

Details the working mechanism of the UnoLine and DuoLine rotary vane pumps.

Transportation and Storage

4.1 Transport

Provides safety warnings and instructions for transporting the pump.

4.2 Storage

Outlines the recommended procedures and conditions for storing the pump.

Installation

5.1 Installing the pump

Covers installation location, orientation, ambient conditions, and mounting guidance.

5.2 Connecting the vacuum side

Step-by-step guide for establishing the vacuum connection to the pump.

5.3 Connecting the exhaust side

Instructions for connecting the exhaust side of the pump, including safety warnings.

5.4 Establishing mains connection

Details on how to safely establish the electrical mains connection for the pump.

5.4.1 Three phase motor with 6-pin terminal board

Specific connection instructions for 3-phase motors with a 6-pin terminal board.

5.4.2 Three phase motor with 9-pin terminal board

Wiring diagrams and instructions for 3-phase motors with a 9-pin terminal board.

5.4.3 Checking the direction of rotation

Procedure for verifying the correct direction of motor rotation to prevent fluid escape.

5.4.4 Motor protection

Explains motor protection methods, including PTC thermistor sensors.

5.4.5 Motor control

Information on motor control options like frequency converters and soft start relays.

5.5 Refilling operating fluid

Step-by-step guide for refilling the pump's operating fluid, including safety warnings.

5.6 Connecting accessories

Guidance on connecting various accessories to the pump.

5.6.1 Solenoid valve for gas ballast valve (standard version)

Instructions for installing the solenoid valve conversion kit for the gas ballast valve.

5.6.2 Solenoid valve for gas ballast valve (C version)

Details on installing the solenoid valve conversion kit for C version pumps.

5.6.3 Process monitoring (option)

Explains the installation and function of optional process monitoring units.

5.6.4 Gas flushing device

Guidance on installing a gas flushing device to protect the operating fluid from contamination.

Operation

6.1 Commissioning

Steps to follow before the initial start-up of the vacuum pump.

6.2 Switching on

Procedure for switching the pump on and initial warm-up process.

6.3 Operation with gas ballast

Explains the function and use of the gas ballast for preventing condensation.

6.3.1 Gas ballast valve - standard version

Details on operating the gas ballast valve in its standard configuration.

6.3.2 Gas ballast valve with flushing gas connection (option)

Instructions for operating the gas ballast valve with an optional flushing gas connection.

6.3.3 Gas ballast valve with solenoid valve (option)

How to operate the gas ballast valve when controlled by an optional solenoid valve.

6.4 Operation with flushing gas

Guidance on operating the pump using a flushing gas supply.

6.5 Refilling operating fluid

Instructions for refilling operating fluid, including safety precautions.

6.6 Switching off the pump

Procedures for safely switching off the vacuum pump.

6.6.1 Venting the vacuum chamber

Procedure for safely venting the vacuum chamber after pump shutdown.

6.6.2 Maintaining the vacuum in the chamber

Methods to maintain vacuum in the chamber after the pump is switched off.

Maintenance

7.1 Maintenance instructions

General guidelines and safety warnings for performing maintenance on the pump.

7.2 Maintenance instructions for M or MC version magnetic coupling

Specific maintenance procedures for pumps with magnetic couplings.

7.3 Checklist for inspection and maintenance!

A table outlining inspection and maintenance tasks with recommended intervals.

7.4 Changing the operating fluid

Procedure for changing the pump's operating fluid, including safety and aging information.

7.4.1 Degree of aging of P3 operating fluid

Methods to determine the degree of aging for P3 operating fluid.

7.4.2 Draining the operating fluid

Step-by-step instructions for draining the used operating fluid from the pump.

7.4.3 Rinsing and cleaning

Procedure for rinsing and cleaning the pump for dirt drainage.

7.5 Cleaning the gas ballast valve

Instructions for cleaning the gas ballast valve.

7.5.1 Gas ballast valve - standard version

Instructions for removing and cleaning the gas ballast valve on standard versions.

7.5.2 Gas ballast valve – corrosive gas version

Procedure for removing and cleaning the gas ballast valve on corrosive gas versions.

7.5.3 Adjusting the gas ballast valve silencer

Guidance on cleaning and readjusting the gas ballast valve silencer.

7.6 Changing operating fluid type

Instructions on how to change between different types of operating fluid.

7.7 Checking the oil level in the oiler (C version pumps only)

Procedure for checking the oil level in the oiler for C version pumps.

Decommissioning

8.1 Shutting down for longer periods

Instructions for safely shutting down the pump for extended storage periods.

8.2 Recommissioning

Procedures to follow when recommissioning a pump after a long shutdown.

8.3 Disposal

Safety warnings and guidelines for the proper disposal of the pump and its fluids.

Spare parts

11.1 Spare parts packs

Overview of available spare parts packs for Uno/DuoLine pumps.

11.1.1 Set of seals

Details the contents of the seal set spare parts pack.

11.1.2 Maintenance kit 1 – maintenance level 1

Lists the components included in Maintenance Kit 1.

11.1.3 Overhaul kit and set of seals

Details the components included in the overhaul kit for pump servicing.

11.1.4 Set of vanes

Information on the set of vanes spare parts pack.

11.1.5 Coupling set

Details the contents of the coupling set spare parts pack.

Technical data and dimensions

12.1 General

Provides the basis for technical data and measurement standards for the pumps.

12.2 Technical data

Presents detailed technical specifications for Uno/DuoLine pumps.

12.3 Dimensions

Provides dimensional drawings and measurements for the Uno/DuoLine pumps.

Need help?

Do you have a question about the DUO 65 and is the answer not in the manual?

Questions and answers