Summary of Contents for Alfa Laval GLX

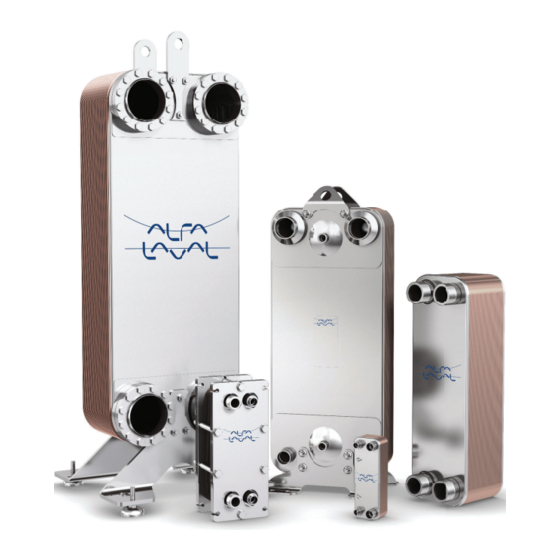

- Page 1 Brazed and Gas-to-liquid plate heat exchangers AC, AXP, CB, CD, DOC, GL, GLX Instruction Manual Lit. Code 200001565-1-EN-GB...

- Page 2 © Alfa Laval Corporate AB 2020-05 This document and its contents are subject to copyrights and other intellectual property rights owned by Alfa Laval Corporate AB. No part of this document may be copied, re-produced or transmitted in any form or by any means, or for any purpose, without Alfa Laval Corporate AB’s prior express written permission. Information and services provided in this document are made as a benefit and service to the user, and no representations or warranties are made about the accuracy or suitability of this information and these services for any purpose.

- Page 3 English Magyar Download local language versions of this instruction Az Ön nyelvére lefordított használati útmutatót manual from www.alfalaval.com/bhe-manuals or use letöltheti a www.alfalaval.com/bhe-manuals the QR code weboldalról, vagy használja a QR-kódot. български Italiano Изтеглете версиите на това ръководство за Scarica la versione in lingua locale del manuale di употреба...

- Page 4 Pусский Руководство пользователя на другом языке вы можете загрузить по ссылке www.alfalaval.com/bhe- manuals или отсканировав QR-код. Slovenski Prenesite različice uporabniškega priročnika v svojem jeziku s spletne strani www.alfalaval.com/bhe-manuals ali uporabite kodo QR. Slovenský Miestne jazykové verzie tohto návodu na používanie si stiahnite z www.alfalaval.com/bhe-manuals alebo použite QR kód.

-

Page 5: Table Of Contents

Contents 1 Preface ..........................7 Intended use......................7 Prior knowledge......................7 Warranty conditions....................7 Environmental compliance..................7 2 Safety ..........................9 Safety considerations....................9 Definitions of expressions..................9 Personal protective equipment................10 3 Description ........................11 Function........................11 Name plates......................11 4 Installation ........................13 Unpacking........................13 Lifting........................13 Requirements...................... -

Page 7: Preface

Unless altered by written agreement, Alfa Laval standard warranty applies. 1.4 Environmental compliance Alfa Laval endeavours to perform its own operations as cleanly and efficiently as possible. Environmental aspects are taken into consideration when developing, designing, manufacturing, servicing and marketing the company’s products. - Page 8 1 Preface Restricted substances All heat exchangers are in compliance with REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS Directive. 200001565-1-EN-GB...

-

Page 9: Safety

2.1 Safety considerations The plate heat exchanger shall be used and maintained in accordance with Alfa Laval’s instructions in this manual. Incorrect handling of the plate heat exchanger may result in serious consequences with injuries to persons and/or property damage. Alfa Laval will not accept responsibility for any damage or injury resulting from not following the instructions in this manual. -

Page 10: Personal Protective Equipment

2 Safety 2.3 Personal protective equipment Protective shoes A shoe with a reinforced toe cap to minimize foot injuries caused by dropped articles. Protective helmet Any helmet designed to protect the head from accidental injury. Protective goggles A pair of tight-fitting eyeglasses worn to protect the eyes from hazards. Protective gloves Gloves that protects the hand from hazards. -

Page 11: Description

3 Description 3.1 Function The heat exchanger consists of a pack of corrugated metal plates with portholes for the input and output of the two separate fluids. The heat transfer between the two fluids takes place through the plates. Figure 1: Function: Cover plate (1), corrugated plates (2), seal (3) and ports (4). 3.2 Name plates WARNING The mechanical design pressures and temperatures are marked on the... - Page 12 3 Description 200001565-1-EN-GB...

-

Page 13: Installation

4 Installation 4.1 Unpacking Carefully open the package containing the heat exchanger. Check that all items are included according to the specifications and that all parts are undamaged. Before installing the heat exchanger, remove the plastic plugs or caps in the connections. -

Page 14: Requirements

4 Installation WARNING Heat exchangers with large plate packs may be difficult to lift without lifting lugs because the center of gravity may cause the heat exchanger lean too much. If in doubt, use lifting lugs. 4.3 Requirements WARNING The heat exchanger must be installed and operated so that no risk of injury to personnel or damage to property. - Page 15 Installation 4 With reference to definitions in figure, the loads during installation should not exceed the limits specified in table below. Maximum recommended connection loads during installation Figure 4: Outer diameter of the connection (D). Table 1: Maximum recommended connection loads during installation Outer diameter, mm Tension force Bending moment...

-

Page 16: Mounting

4 Installation 4.4 Mounting It is recommended to mount the heat exchanger on the floor, on feet or on the wall. Larger heat exchangers should be secured with support mountings (ordered as accessory) intended for a specific heat exchanger, or be secured with straps or by means of mounting bolts. - Page 17 Installation 4 Recommendations for GL products It is recommended to mount the heat exchanger on the floor, on feet or on the wall. The heat exchanger can be installed horizontally or vertically. NOTE For condensing applications it is recommended to install the unit vertically with the gas flow from top to down.

-

Page 18: Installation In General

4 Installation NOTE An external casing is required for GLX units to achieve correct functionality. 4.5 Installation in general WARNING Safety valves must be installed according to pressure vessel regulations. NOTE Before connecting any piping, make sure all foreign objects have been flushed out of the system. - Page 19 Installation 4 Connections Threaded connections – Use a torque wrench when connecting the pipe and observe the specified limits. Refer to table “Maximum recommended connection loads during installation” in section Requirements on page 14 Brazed connections – Clean by rubbing down and degreasing the various surfaces.

-

Page 20: Installation As Evaporator Or Condenser

4 Installation 4.6 Installation as evaporator or condenser In applications where a phase change of media occurs, the heat exchanger must be installed vertically. For refrigeration applications – Figure A shows the installation of an evaporator, where the connections may be either on the front or on the rear. Figure B shows a condenser. -

Page 21: Leak Test

Installation 4 S4.2 S4.1 S4.2 S4.1 S3.1 S3.2 S3.1 S3.2 Figure 6: Dual circuit: A is parallel flow; B is diagonal flow. 1.Refrigerant inlet 2.Refrigerant outlet Water/Brine inlet and outlet are typically positioned on the rear side. 4.7 Leak test Perform leakage test of the connections before placing the heat exchanger in operation. - Page 22 4 Installation 200001565-1-EN-GB...

-

Page 23: Operation

5 Operation 5.1 Start-up NOTE If several pumps are included in the system, make sure you know which one should be activated first. NOTE Adjustments of flow rates should be made slowly in order to avoid the risk of water hammer. Water hammer is a short-lasting pressure peak that can appear during start-up or shut-down of a system, which causing liquids to travel along a pipe as a wave at the speed of sound. -

Page 24: Unit In Operation

Heat exchangers operating with freezing temperatures shall be properly insulated with the insulation tight to the surface of the heat exchanger to avoid humid air to freeze. Contact Alfa Laval representative for further clarification. NOTE To avoid damage due to freezing, the medium used must include an anti- freeze agent when operating conditions are below 5 °C (41 °F) and/or... - Page 25 WARNING The heat exchanger is not intended for cyclic processes, please contact an Alfa Laval Representative for advice. • Locate the temperature sensor as close as possible to the outlet from the heat exchanger. • Choose valves and regulation equipment which give stable temperatures/ pressures for the heat exchanger.

- Page 26 5 Operation Heating and cooling insulations are available as accessories. Be aware that temperature limits of insulation and the heat exchanger can be different. 200001565-1-EN-GB...

-

Page 27: Shut-Down

Operation 5 5.3 Shut-down NOTE If several pumps are included in the system, make sure you know which one should be stopped first. Slowly reduce the flow rate in order to avoid water hammer. When the valve is closed, stop the pump. Repeat steps 1–2 for the other medium/ media. - Page 28 5 Operation 200001565-1-EN-GB...

-

Page 29: Maintenance

This is dependent on exposure time and concentration of chlorine. In every case where the chlorination of the heat exchanger cannot be avoided, consult an Alfa Laval Representative for advice. 6.2 Cleaning-In-Place Cleaning-In-Place (CIP) equipment permits cleaning of the heat exchanger. - Page 30 6 Maintenance Consult an Alfa Laval representative for approriate advice on selecting CIP equipment. For detailed information regarding Cleaning liquids and procedure, refer to the Alfa Laval Cleaning procedures manual. Type of cleaning: • AlfaCaus cleaning removes organic deposits. During the process it is important to control the pH value and the recommended pH value is 7.5 -...

-

Page 31: Fault Tracing

7 Fault tracing 7.1 Pressure drop problems If the pressure drop has increased. Action 1. Check that all valves are open including non-return valves. • Measure the pressure and the flow rate directly in front of the inlet and after the outlet of the heat exchanger. -

Page 32: Heat Transfer Problems

7 Fault tracing 7.2 Heat transfer problems The heat transfer capacity is dropping. Action 1.Measure temperatures at inlets and outlets. Also measure flow rates on both me- dia, if possible. On at least one of the media, both temperatures and the flow rate must be measured. -

Page 33: Storage

8 Storage Alfa Laval delivers the heat exchanger ready for operation, unless agreed otherwise. Keep the plate heat exchanger in the packing box until it is ready to be installed. If there is any uncertainty with regard to the storage of the heat exchanger, please consult an Alfa Laval Representative.

Need help?

Do you have a question about the GLX and is the answer not in the manual?

Questions and answers