Summarization of Contents

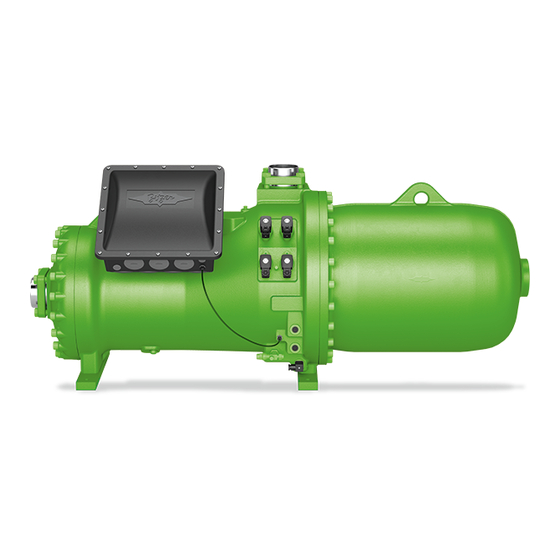

Technical Features

Balanced Product Range

Offers 8 basic models with tight performance graduation for optimal selection.

Space-Saving Design & Piping

Features shortest installed length and convenient piping with rotatable connections.

Universal Applications

Suitable for R134a, R407C, R22 refrigerants, with or without economiser.

High-Efficiency Profile

Incorporates advanced geometry, high stiffness, and patented manufacturing for peak performance.

Optional Accessories

Suction Shut-Off Valve

Optional accessory for suction line isolation.

Oil Level Switch

Optional accessory for monitoring oil level.

Economiser/Liquid Injection Adapter

Adapter for economiser operation and liquid injection.

External Oil Cooler Adapter

Adapter for connecting an external oil cooler.

Vibration Dampers

Optional components to reduce vibration.

Performance Data Explanation

Basis for Data

Performance data are based on European Standard EN 12900 and 60 Hz operation.

Dew Point vs. Mean Temperature

Explains differences in data for zeotropic blends like R407C due to dew point reference.

Pressure Reference Points

Connection Positions

Specifies connection positions 1 (HP) and 3 (LP) for reference, excluding pressure drops.

Type Designation Explained

CSH Series Code Breakdown

Explains the CSH designation: Series, Housing Size, Displacement, Execution, Motor Size/Design, Oil Type.

Application Limit Charts

R134a Standard & ECO Limits

Graphical representation of application limits for R134a, Standard and ECO modes.

R407C Standard & ECO Limits

Graphical representation of application limits for R407C, Standard and ECO modes.

R22 Standard & ECO Limits

Graphical representation of application limits for R22, Standard and ECO modes.

Legend for Application Charts

Explanation of symbols and terms used in the application limit charts.

R134a Standard Performance Data

Standard Operation Data

Performance data without liquid subcooling for standard operation.

Economiser Operation Data

Performance data with liquid subcooling for economiser operation.

Motor Version 2 Data

Data valid for compressors with motor version 2; version 1 may be required for higher temps.

R134a Oil Requirement

Requires Polyolester oil BSE170 for R134a operation.

R134a Economiser Performance Data

Economiser Operation Data

Performance data with liquid subcooling for economiser operation on R134a.

R134a Oil Requirement

Requires Polyolester oil BSE170 for R134a operation.

R407C Standard Performance Data

Standard Operation Data

Performance data without liquid subcooling for standard operation with R407C.

R407C Oil Requirement

Requires Polyolester oil BSE170 for R407C operation.

R407C Economiser Performance Data

Economiser Operation Data

Performance data with liquid subcooling for economiser operation on R407C.

R407C Oil Requirement

Requires Polyolester oil BSE170 for R407C operation.

R22 Standard Performance Data

Standard Operation Data

Performance data without liquid subcooling for standard operation with R22.

R22 Oil Requirement

Requires Complex Ester oil B320SH for R22 operation.

R22 Economiser Performance Data

Economiser Operation Data

Performance data with liquid subcooling for economiser operation on R22.

R22 Oil Requirement

Requires Complex Ester oil B320SH for R22 operation.

Technical Data Overview

Compressor Type Designation Explained

Details the meaning of each part of the compressor type designation, e.g., CSH6551-50Y.

Connection Size Information

Specifies pipe connection sizes for discharge and suction lines in mm and inch.

Capacity Control Options

Explains infinite or 4-step capacity control and its implications.

Electrical Considerations

Notes on selecting contactors, wiring, and fuses based on max. working current.

Accessories and Oil Charge Data

Oil Heater Specifications

Details oil heater voltage, wattage, and its function in maintaining oil lubricity during standstill.

Oil Heater Usage Conditions

Specifies when the oil heater must be used, e.g., outdoor installation, long shutdowns.

Capacity Control Module

Information on the capacity control module and its voltage/frequency rating.

Oil Charge Types

Lists oil charge types (BSE170, B320SH) for different refrigerants.

Dimensional Drawing - CSH65

Connection Position Details

Diagram showing connection positions 1-13 with their respective types and sizes.

Dimensional Drawing - CSH75

Connection Position Details

Diagram showing connection positions 1-14 with their respective types and sizes.

Dimensional Drawing - CSH85

Connection Position Details

Diagram showing connection positions 1-14 with their respective types and sizes.

CAD Drawing Information

DXF Format Availability

CAD drawings available on BITZER software CD-ROM and website.

3D Model Formats

Three-dimensional models available in VRML, STEP, or IGES formats upon request.

Connection Positions List

High Pressure Connections

Details HP connections (1, 2) and LP connection (3).

Oil & Service Connections

Lists oil sight glass (4), oil service valve (5), oil drain (6), and oil charge (7).

Optional & Accessory Connections

Covers oil level switch (8), oil heater (9), oil pressure (10), external oil cooler (11), PTC sensor (12), economiser/injection (13), pipe support (14).

Need help?

Do you have a question about the CSH6561-60Y and is the answer not in the manual?

Questions and answers