Table of Contents

Advertisement

Quick Links

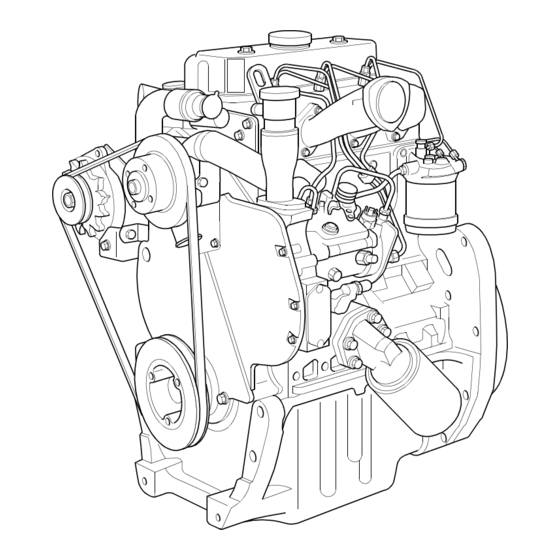

Perkins 900 Series

Models CP and CR

WORKSHOP MANUAL

3 cylinder, naturally aspirated, and turbocharged diesel

engines for agricultural and industrial use

Publication, TPD 1345, Issue 3.

© Proprietary information of Perkins Engines Company Limited 2000, all rights reserved.

The information is correct at the time of print.

Published in June 2001 by Technical Publications.

Perkins Engines Company Limited, Peterborough, PE1 5NA, England.

i

This document has been printed from SPI². Not for Resale

Advertisement

Table of Contents

Summarization of Contents

1 General Information

Introduction

Overview of the workshop manual for Perkins 900 Series engines.

Engine Identification

Details on how to identify the Perkins 900 Series engine number and labels.

Safety Precautions

Important safety guidelines for operating and servicing the engine.

Engine Lift Equipment

Guidance on using appropriate equipment for lifting engine components safely.

Viton Seals

Information and warnings regarding the handling of Viton seals, especially when burned.

POWERPART Recommended Consumable Products

List of recommended consumable products for engine service and maintenance.

2 Specifications

Data and Dimensions

Technical specifications and dimensions for basic engine data.

Thread Sealant

Recommendations for using sealant on setscrews and studs for engine assembly.

Standard Torque Tensions

Standard torque values for various types of fasteners used on the engine.

Special Torque Tensions

Specific torque values for setscrews and nuts in different engine assemblies.

Compression Test Data

Information and guidelines for performing engine compression tests.

3 Cylinder Head Assembly

General Description

Overview of the cylinder head assembly and its components.

Rocker Cover

Procedure for removing and fitting the rocker cover.

Rocker Assembly

Procedures for removing, dismantling, and inspecting the rocker assembly.

Valve Tip Clearances

Procedure for checking and adjusting valve tip clearances.

Cylinder Head Assembly

Procedures for removing and fitting the cylinder head assembly.

4 Piston and Connecting Rod Assembly

General Description

Overview of pistons, connecting rods, and their features.

Big End Bearing

Procedures for removing and fitting big end bearings.

Piston Rings

Procedures for removing, fitting, and inspecting piston rings.

5 Crankshaft Assembly

General Description

Overview of the crankshaft, its materials, and balance weights.

Crankshaft Pulley

Procedures for removing and fitting the crankshaft pulley.

Rear Oil Seal Assembly

Procedures for removing and fitting the rear oil seal assembly.

Main Bearings

Procedures for removing and fitting main bearings with the crankshaft in position.

Crankshaft

Procedures for removing and fitting the crankshaft, and checking its condition.

6 Timing Case and Drive Assembly

General Description

Overview of the timing case, gears, and their drive mechanism.

Timing Case Cover

Procedure for removing and fitting the timing case cover.

Front Oil Seal

Procedures for removing and fitting the front oil seal.

Timing Case

Procedure for removing and fitting the timing case.

7 Cylinder Block Assembly

General Description

Description of the cylinder block construction, liners, and camshaft journals.

Cylinder Block

Procedures for dismantling and inspecting the cylinder block.

Cylinder Liner

Procedure for fitting cylinder liners.

8 Engine Timing

General Description

Overview of engine timing gears and fuel injection pump timing.

To Set the Engine to Top Dead Centre (TDC)

Procedure for setting the engine to TDC on the compression stroke.

To Check the Valve Timing

Procedure for checking the engine valve timing.

9 Aspiration System

General Description

Overview of the turbocharger and its function.

Turbocharger

Procedures for removing and fitting the turbocharger.

Turbocharger Faults

Chart of common turbocharger problems and their possible causes.

Closed Breather System

Procedure for renewing the engine breather valve.

10 Lubrication System

General Description

Explanation of the engine lubrication system and oil flow.

Filter Canister

Procedure for renewing the oil filter canister.

Sump

Procedures for removing and fitting the engine sump.

Lubricating Oil Pump

Procedure for removing the lubricating oil pump.

11 Fuel System

Fuel Filter Types

Description of the two types of fuel filters used on the engine.

To Renew the Element Type Filter

Procedure for renewing the element type fuel filter.

Atomisers

Information on atomiser faults and how to identify a defective atomiser.

Fuel Lift Pump

Procedures for removing and fitting the fuel lift pump.

Delphi Fuel Injection Pumps

Procedures for removing and fitting Delphi fuel injection pumps.

To Adjust

Procedure for adjusting the fuel injection pump idle and maximum speeds.

To Eliminate Air from the Fuel System

Procedure for bleeding air from the fuel system.

12 Cooling System

General Information

Overview of the engine cooling system and coolant flow.

How to Fill the Cooling System

Procedure for filling and venting the cooling system.

Coolant Pump

Procedures for removing and fitting the coolant pump.

13 Flywheel and Flywheel Housing

General Description

Description of the flywheel and flywheel housing construction.

Flywheel

Procedures for removing and fitting the flywheel.

Flywheel Housing

Procedures for removing and fitting the flywheel housing.

14 Electrical Equipment

To Check the Drive Belts

Procedure for checking the condition and tension of drive belts.

To Remove and to Fit the Alternator

Procedures for removing and fitting the alternator.

Alternator Fault Diagnosis

Guide for diagnosing common alternator faults and their causes.

Starter Motors

Procedures for removing and fitting the starter motor.

Cold Starting System

General description of the cold starting system.

Starting Aid

Procedures for removing and fitting a fuelled starting aid.

15 Auxiliary Equipment

Not Used

This section is not used in this manual.

16 Special Tools

List of Special Tools

List of special tools available for engine service and maintenance.

Need help?

Do you have a question about the CP and is the answer not in the manual?

Questions and answers