Table of Contents

Advertisement

Quick Links

Perkins Phaser and 1000 Series

WORKSHOP MANUAL

Phaser

1000 Series

Publication TPD 1312E, Issue 1.

(c) Perkins Group Limited 1995, all rights reserved.

Published 1 April 1995 by Technical Publications,

Perkins International Limited, Peterborough PE1 5NA, England

Perkins Phaser/1000 Series, April 1995

4 and 6 cylinder diesel engines for

automotive applications

4 and 6 cylinder diesel engines for

agricultural and industrial application

Contents

Contents

EXIT

EXIT

Contents

Contents

EXIT

EXIT

00.01

Advertisement

Chapters

Table of Contents

Summarization of Contents

General information

Introduction

This workshop manual provides assistance in the service and overhaul of Perkins Phaser and 1000 Series engines.

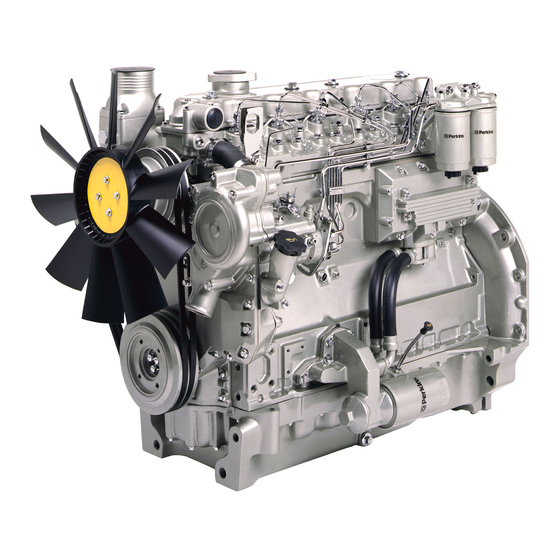

Engine views

Provides visual representations of engine components and their arrangement for identification.

Engine identification

Explains the system for identifying Phaser and 1000 Series engines using code letters and numbers.

Safety precautions

Lists essential safety precautions for operating and servicing the engines.

Powerpart consumable products

Lists and describes Perkins Powerpart products recommended for engine maintenance.

Safety

Engine lift equipment

Details on recommended lift equipment capacity and procedures for safely lifting engines.

Asbestos joints

Precautions and procedures for handling engine joints containing asbestos.

Viton seals

Safety precautions regarding Viton seals, particularly if burned.

Specifications

Basic engine data

Provides fundamental technical data and specifications for the engines.

Recommended torque tensions

Lists recommended torque values for various engine components and fasteners.

CYLINDER HEAD ASSEMBLY 12

General description

Provides an overview of the cylinder head assembly and its function.

Rocker cover

Instructions for removing and fitting the rocker cover.

Rocker assembly

Procedures for removing, fitting, dismantling, and assembling the rocker assembly.

Valve tip clearances

Method for checking and adjusting valve tip clearances.

Valve springs

Instructions for changing valve springs with the cylinder head fitted.

Valves and valve springs

Procedures for removing, fitting, inspecting, and correcting valves and valve springs.

Valve guides

Instructions for inspecting valve guides for wear.

Cylinder head

Procedures for inspecting and correcting the cylinder head.

Data and dimensions

Provides detailed dimensions and data for cylinder head components.

PISTON AND CONNECTING ROD ASSEMBLIES 13

General description

Overview of pistons and connecting rods used in Phaser and 1000 Series engines.

Big end bearing

Instructions for removing, fitting, and inspecting big end bearings.

Piston and connecting rod assembly

Procedures for removing, fitting, dismantling, and assembling piston and connecting rod assemblies.

Piston rings

Instructions for removing, fitting, and inspecting piston rings.

Connecting rod

Procedures for inspecting connecting rods for distortion and wear.

Piston cooling jets

Instructions for removing, fitting, and checking the alignment of piston cooling jets.

Data and dimensions

Provides detailed dimensions and data for pistons and connecting rods.

CRANKSHAFT ASSEMBLY 14

General description

Describes the construction and function of the crankshaft and its components.

Crankshaft pulley

Instructions for removing and fitting the crankshaft pulley on four-cylinder engines.

Crankshaft pulley and damper

Procedures for removing and fitting the crankshaft pulley and damper on six-cylinder engines.

Rear oil seal assembly - engines which have the standard seal

Instructions for removing and fitting the rear oil seal assembly with a standard seal.

Rear oil seal assembly - engines which have a flywheel housing that is oil filled

Procedures for removing and fitting the rear oil seal assembly for engines with an oil-filled flywheel housing.

Thrust washers

Method for checking crankshaft end-float and fitting thrust washers.

Main bearings

Instructions for removing, fitting, and inspecting main bearings.

Crankshaft

Procedures for removing and fitting the crankshaft.

Balancer unit

Instructions for removing, fitting, dismantling, assembling, and inspecting the balancer unit.

Data and dimensions

Provides specifications and dimensions for crankshaft components.

TIMING CASE AND DRIVE ASSEMBLY 15

General description

Describes the construction and function of the timing case and drive components.

Timing case cover

Instructions for removing and fitting the timing case cover.

Front oil seal

Procedures for removing and fitting the front oil seal.

Idler gear and hub

Instructions for removing, fitting, and inspecting the idler gear and hub.

Compressor idler gear (Bendix)

Procedures for removing and fitting the compressor idler gear for Bendix compressors.

Fuel pump gear

Instructions for removing and fitting the fuel pump gear.

Camshaft gear

Procedures for removing and fitting the camshaft gear.

Crankshaft gear

Instructions for removing and fitting the crankshaft gear.

Timing case

Procedures for removing and fitting the timing case.

Camshaft and tappets

Instructions for removing and fitting the camshaft and tappets.

Data and dimensions

Provides specifications and dimensions for timing case and drive assembly components.

CYLINDER BLOCK ASSEMBLY 16

General description

Describes the construction and function of the cylinder block.

Cylinder block

Procedures for dismantling and assembling the cylinder block.

Cylinder liner

Instructions for inspecting cylinder liners for wear and damage.

Data and dimensions

Provides specifications and dimensions for cylinder block components.

Engine timing 17

Bosch EPVE fuel injection pumps

Details on setting and checking engine timing for Bosch EPVE pumps.

Bosch MW in-line fuel injection pumps

Information regarding engine timing for Bosch MW in-line fuel injection pumps.

Lucas DPA and DPS fuel injection pumps

Procedures for setting and checking engine timing for Lucas DPA/DPS pumps.

Lucas DP200 Series fuel injection pump

Details on engine timing for Lucas DP200 Series fuel injection pumps.

Stanadyne fuel injection pump

Information on setting and checking engine timing for Stanadyne fuel injection pumps.

ASPIRATION SYSTEM 18

General description

Explains the function and operation of the turbocharger system.

Turbocharger

Instructions for removing and fitting the turbocharger.

Engine breather systems

Procedures for cleaning and maintaining open and closed engine breather systems.

Data and dimensions

Provides specifications and dimensions for turbocharger components and waste-gate pressure.

LUBRICATION SYSTEM 19

General description

Overview of the engine lubrication system, including oil flow and components.

Filter canister

Instructions for renewing the fuel filter canister.

Filter head

Procedures for removing and fitting the fuel filter head.

Sump

Instructions for removing and fitting the engine oil sump.

Oil strainer and suction pipe

Procedures for removing, fitting, inspecting, and correcting the oil strainer and suction pipe.

Lubricating oil pump

Instructions for removing, fitting, and inspecting the lubricating oil pump.

Relief valve

Procedures for removing, fitting, dismantling, assembling, and inspecting the relief valve.

Flexible oil pipes

Instructions for removing, fitting, and inspecting flexible oil pipes.

Data and dimensions

Provides specifications and dimensions for lubrication system components.

Fuel system 20

Bosch EPVE fuel injection pumps

Details on general description, fuel filter, atomisers, fuel lift pump, and fuel injection pump for Bosch EPVE.

Bosch MW in-line fuel injection pump

Information on general description, fuel filter, fuel lift pump, and fuel injection pump for Bosch MW.

Lucas DPA and DPS fuel injection pumps

Details on general description, fuel filter, atomisers, fuel lift pump, and fuel injection pump for Lucas DPA/DPS.

Lucas DP200 Series fuel injection pump

Information on general description, fuel filter, fuel lift pump, and fuel injection pump for Lucas DP200 Series.

Stanadyne fuel injection pump

Details on general description, fuel filter, atomisers, fuel lift pump, and fuel injection pump for Stanadyne.

COOLING SYSTEM 21

General description

Explains the engine cooling system operation and component flow.

Thermostats

Instructions for removing, fitting, testing, and data for thermostats.

Coolant pump

Procedures for removing, fitting, dismantling, and assembling coolant pumps (gear, belt, auxiliary).

Fan

Instructions for removing and fitting the fan.

Fan drive

Procedures for removing, fitting, checking, and adjusting fan drive belts.

Lubricating oil cooler

Instructions for removing, fitting, dismantling, and assembling lubricating oil coolers.

Cooler by-pass valve

Procedures for removing, fitting, and checking the cooler by-pass valve.

Intercooler

Instructions for removing, fitting, cleaning, and inspecting the intercooler.

Data and dimensions

Provides specifications and dimensions for cooling system components.

FLYWHEEL AND FLYWHEEL HOUSING 22

General description

Describes the construction and function of the flywheel, starter ring, and flywheel housing.

Flywheel

Instructions for removing, fitting, checking flywheel run-out, and alignment.

Ring gear

Procedures for removing and fitting the flywheel ring gear.

Flywheel housing

Instructions for removing, fitting, checking concentricity, and alignment of the flywheel housing.

Data and dimensions

Provides limits for flywheel housing run-out and alignment.

ELECTRICAL EQUIPMENT 23

Alternators

General description, precautions, drive belt procedures, and alternator fault diagnosis.

Starter motors

General description, removal/fitting, maintenance, and testing procedures for starter motors.

Starting aid

Information on fuelled starting aids and port heaters, including removal, fitting, and checks.

AUXILIARY EQUIPMENT 24

Compressors

General description, procedures for Wabco and Bendix compressors, and their drive assemblies.

Power steering pump

Instructions for removing, fitting, dismantling, and assembling the power steering pump.

Exhauster

Procedures for removing and fitting the exhauster.

LIST OF SPECIAL TOOLS 25

List of special tools

Lists special tools required for engine service with descriptions and part numbers.

Need help?

Do you have a question about the Phaser Series and is the answer not in the manual?

Questions and answers