Perkins 4.236 Series User Handbook Manual

Hide thumbs

Also See for 4.236 Series:

- Workshop manual (169 pages) ,

- Operator's manual (72 pages) ,

- Service data (66 pages)

Table of Contents

Advertisement

Perkins 4.236 Series

Models 4.236, T4.236, 4.248, 4.2482

USER'S HANDBOOK

4 cylinder diesel engines for automotive, agricultural and

industrial use

Publication TPD 1291E, Issue 2.

© Proprietary information of Perkins Engines Company Limited, all rights reserved.

The information is correct at the time of print.

Published in 1998 by Technical Publications,

Perkins Engines Company Limited, Peterborough PE1 5NA England

i

This document has been printed from SPI². Not for Resale

Advertisement

Table of Contents

Summary of Contents for Perkins 4.236 Series

- Page 1 4 cylinder diesel engines for automotive, agricultural and industrial use Publication TPD 1291E, Issue 2. © Proprietary information of Perkins Engines Company Limited, all rights reserved. The information is correct at the time of print. Published in 1998 by Technical Publications, Perkins Engines Company Limited, Peterborough PE1 5NA England This document has been printed from SPI².

- Page 2 This publication is written in Perkins Approved Clear English This publication is divided into six chapters: 1 General information 2 Engine views 3 Operation instructions 4 Preventive maintenance 5 Engine fluids 6 Fault diagnosis The following pages contain a detailed table of contents...

-

Page 3: Table Of Contents

4.236 Series Contents 1 General information Introduction ................... 1 Safety precautions ................... 2 How to care for your engine ... - Page 4 4.236 Series How to start a cold engine with manually operated ptart pilot ....... 17 How to start a cold engine with KBi or electrically operated start pilot ..... 18 How to stop the engine ...

- Page 5 4.236 Series 5 Engine fluids Fuel specification ................. . 41 Lubricating oil specification ............... 42 Coolant specification ...

- Page 6 This page is intentionally blank This document has been printed from SPI². Not for Resale...

-

Page 7: General Information

General information Introduction The 4.236 Series is a family of automotive, industrial and agricultural engines with power outputs from 76,0 to 37,5 kW (102,0 to 50,5 bhp). More than sixty years of diesel production experience, together with the latest technology, have been applied to the manufacture of your engine to give you reliable and economic power. -

Page 8: Safety Precautions

Turbochargers operate at high speed and at high temperatures. Keep fingers, tools and debris away from the inlet and outlet ports on the turbocharger and prevent contact with hot surfaces. Fit only genuine Perkins parts. User’s Handbook, TPD 1291E, Issue 2... -

Page 9: How To Care For Your Engine

Renew the filter elements and lubricating oil regularly in order to ensure that the inside of your engine remains clean. Ensure that all adjustments and repairs are done by personnel who have had the correct training. Perkins distributors have this type of personnel available. You can also obtain parts and service from your Perkins distributor. -

Page 10: Engine Preservation

Note: If protection against frost is not necessary and a corrosion inhibitor is to be used, it is recommended that you consult the Service Department, Perkins International Limited, Peterborough. 7 Operate the engine for a short period in order to circulate the lubricating oil and the coolant in the engine. -

Page 11: Parts And Service

If the engine protection is done correctly according to the above recommendations, no corrosion damage will normally occur. Perkins are not responsible for damage which may occur when an engine is in storage after a period in service. -

Page 12: Powerpart Consumable Products

4.236 Series POWERPART consumable products Perkins have made available the products indicated below in order to assist in the correct operation, service and maintenance of your engine and your machine. The instructions for the use of each product are given on the outside of each container. - Page 13 4.236 Series POWERPART Liquid Gasket To seal flat faces of components where no joint is used. Especially suitable for aluminium components. Currently Loctite 518. Part number 21820518. POWERPART Threadlock (pipe) To retain and seal pipe connections with coarse threads. Pressure systems can be used immediately.

-

Page 14: Engine Identification

4.236 Series Engine identification The 4.236 Series family consists of four engines; the naturally aspirated 4.236, 4.248 and 4.2482 engines and the turbocharged T4.236 engine. The engine number is stamped on a label which is fastened to the left side of the cylinder block (A1). On some applications, the label is fastened to the right side of the cylinder block (B1). -

Page 15: Engine Data

4.236 Series Engine data Number of cylinders - 4.236, T4.236 ............... . 4 - 4.248, 4.2482 . - Page 16 This page is intentionally blank This document has been printed from SPI². Not for Resale...

-

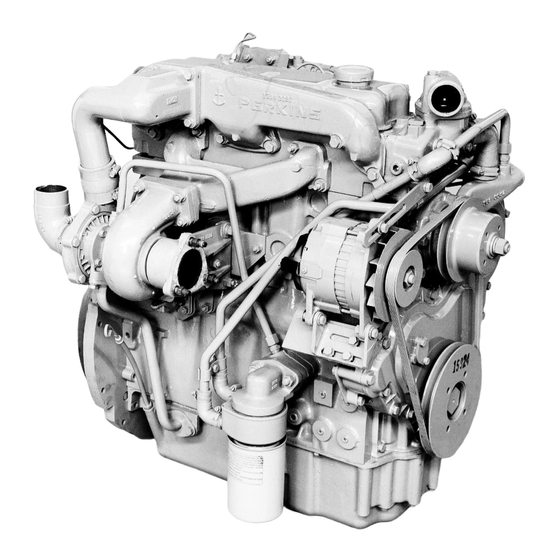

Page 17: Engine Views

4.236 Series Engine views Introduction Perkins engines are built for specific applications and the views which follow do not necessarily match your engine specification. Location of engine parts Front and left side of 4.236 engine 1 Filler cap for lubricating oil... - Page 18 4.236 Series Rear and right side of T4.236 engine 14 Induction manifold 21 Lubricating oil sump 15 Fuelled starting aid 22 Drain plug for lubricating oil 16 Exhaust manifold 23 Flywheel housing 17 Alternator 24 Flywheel 18 Turbocharger 25 Fuel lift pump...

-

Page 19: Operation Instructions

Diesel engines need a cold starting aid if they are to start in very cold conditions. Normally, your machine will be fitted with the correct equipment for your region of operation. Perkins engines can be equipped with various cold starting systems. For the 4.236 Series engines these systems are: Fuelled starting aid: An electrically operated device which ignites a specific amount of diesel fuel in the induction manifold in order to heat the induction air. -

Page 20: How To Start A Warm Engine

4.236 Series How to start a warm engine 1 If the engine is equipped with a manual stop control, ensure that it is in the "run" position. 2 Adjust the engine speed control to the quarter open position. 3 Turn the start key to the "HS" or "S" position (A) to engage the starter motor. -

Page 21: How To Start A Cold Engine Without Starting Aids

4.236 Series How to start a cold engine without starting aids 1 If the engine is equipped with a manual stop control, ensure that it is in the "run" position. 2 Adjust the engine speed control to the maximum speed position. -

Page 22: How To Start A Cold Engine With The Fuelled Starting Aid

4.236 Series How to start a cold engine with the fuelled starting aid 1 If the engine is equipped with a manual stop control, ensure that it is in the "run" position. 2 Turn the start key to the "H" position (A) and keep it there for 15 seconds. -

Page 23: How To Start A Cold Engine With Manually Operated Ptart Pilot

4.236 Series How to start a cold engine with manually operated ptart pilot Do not use the hand pump until the starter motor is engaged. The amount of fluid which is necessary for an engine start will be found by experience. -

Page 24: How To Start A Cold Engine With Kbi Or Electrically Operated Start Pilot

4.236 Series How to start a cold engine with KBi or electrically operated start pilot If necessary, renew the screw type canister. Ensure that the sealing washer remains in position when the new canister is fitted. Each container has a safety valve. -

Page 25: How To Stop The Engine

The idle or maximum speed settings must not be changed by the engine operator because this can damage the engine or transmission. The warranty of the engine can be affected if the seals on the fuel injection pump are broken during the warranty period by a person who is not approved by Perkins. Running-in A gradual running-in of a new engine or POWER EXCHANGE engine is not necessary. -

Page 26: Turbocharged Engines

Information for turbocharged engines can be obtained from Perkins. Changes to the settings of the fuel injection pump must be made by a Perkins distributor or by an approved distributor for the fuel injection pump. -

Page 27: Preventive Maintenance

4.236 Series Preventive maintenance Preventive maintenance periods These preventive maintenance periods apply to average conditions of operation. Check the periods given by the manufacturer of the equipment in which the engine is installed. If necessary, use the shorter periods. When the operation of the engine must conform to the local regulations these periods and procedures may need to be adapted to ensure correct operation of the engine. -

Page 28: Schedules

4.236 Series Schedules The schedules which follow must be applied at the interval (kilometers, miles, hours or months) which occurs first. First service at 800/1600 km (500/1000 miles) 25/50 hours Every day or every 8 hours Every 7500 km (5000 miles) 250 hours or 4 months... -

Page 29: How To Drain The Cooling System

4.236 Series How to drain the cooling system Caution: Do not drain the coolant while the engine is still hot and the system is under pressure because dangerous hot coolant can be discharged. 1 Ensure that the machine is on level ground. -

Page 30: How To Check The Drive Belt(S)

4.236 Series How to check the drive belt(s) Renew a belt if it is worn or damaged. If twin belts are fitted, they must be renewed together. To check the deflection, press down the belt with the thumb at the centre of the longest free length and check the deflection (A). -

Page 31: How To Clean The Gauze Strainer Of The Fuel Lift Pump

4.236 Series How to clean the gauze strainer of the fuel lift pump 1 Remove the cover and joint (A1) from the top of the fuel lift pump (A2) and remove the gauze strainer (A3). 2 Carefully wash all the sediment from the lift pump body. -

Page 32: Fuel Pre-Filter

8 Eliminate the air from the fuel filter, see "How to eliminate air from the fuel system" on page 29. Caution: It is important to use only the genuine Perkins fuel filter element. The use of a wrong element can damage the fuel injection pump. -

Page 33: Atomiser Fault

4.236 Series Atomiser fault Warnings! Ensure that the fuel does not spray onto your skin. Keep away from moving parts during engine operation. Some moving parts cannot be seen clearly while the engine runs. An atomiser fault can cause an engine misfire. -

Page 34: How To Renew An Atomiser

4.236 Series How to renew an atomiser Warning! Do not allow dirt to enter the fuel system. Before a connection is disconnected, clean thoroughly the area around the connection. After a component has been disconnected, fit a suitable cover to all open connections. -

Page 35: How To Eliminate Air From The Fuel System

4.236 Series How to eliminate air from the fuel system There are two methods to eliminate air from the fuel system according to the type of pump fitted: Standard method: This method is used on the Lucas DPA fuel injection pump. Vent screws (A1 and A2) are fitted to this pump. - Page 36 4.236 Series How to eliminate air from the fuel system (standard method) 1 Loosen the banjo connection bolt which is fitted on the top of the filter (A1). 2 Operate the priming lever on the fuel lift pump (B) until fuel, free from air, comes from the filter vent point.

- Page 37 4.236 Series 8 Loosen the union nuts of the high-pressure pipes (E1) at two of the atomisers. Operate the starter motor until fuel, free from air, comes from the pipe connections. Tighten the high- pressure pipe connections. 9 The engine is now ready to start.

- Page 38 4.236 Series How to eliminate air from the fuel system (self-vent method) If the engine has been stopped by air in the fuel system ensure that fuel has been added to the tank or that the leakage has been corrected.

-

Page 39: How To Renew The Lubricating Oil

4.236 Series How to renew the lubricating oil 1 Operate the engine until it is warm. 2 Stop the engine, remove the sump drain plug (A1) and its washer and drain the lubricating oil from the sump. Ensure that the washer is not damaged. Fit the drain plug and its washer and tighten the plug to 34 Nm (25 Ibf ft) 3,5 kgf m. -

Page 40: How To Renew The Canister Of The Lubricating Oil Filter

Caution: The canister contains a valve and special tube to ensure that lubricating oil does not drain from the filter. Therefore, ensure that the correct Perkins POWERPART canister is used. User’s Handbook, TPD 1291E, Issue 2... -

Page 41: Air Cleaner

4.236 Series Air cleaner A typical wet type air cleaner is shown at (A). The wet type air cleaner must be drained at a suitable interval. The container and element (A1) must be cleaned with kerosene or with another suitable fluid. Do not use gasolene. Check that the seal (A2) is not damaged and renew it, if necessary. -

Page 42: Air Filter

4.236 Series Air filter Environmental conditions have an important effect on the frequency at which the air filter needs service. Certain air filters have a separate dust bowl (A1) which must be cleaned at intervals. The amount of dust in the bowl shows if it has been removed at the correct time for the conditions of operation. -

Page 43: Restriction Indicator

4.236 Series Restriction indicator The restriction indicator for these engines must work at a pressure difference of 508/558 mm (20/22 in) of water gauge. It is fitted on the air filter outlet or between the air filter and the induction manifold. -

Page 44: How To Clean The Engine Breather Valve

4.236 Series How to clean the engine breather valve Note: A breather valve is fitted only to 4.2482 engines. 1 Disconnect the hose clips and remove the pipe between the induction manifold and the breather valve (A). 2 Release the clamp screw and remove the breather valve from the rocker cover. -

Page 45: How To Check The Valve Tip Clearances

4.236 Series How to check the valve tip clearances These are checked between the top of the valve stem and the rocker lever (A). The correct clearances are 0,25 mm (0.010 in) for inlet and exhaust valves with the engine hot or cold. - Page 46 This page is intentionally blank This document has been printed from SPI². Not for Resale...

-

Page 47: Engine Fluids

These fuels can be used but they can affect engine performance. It is recommended that you consult the Perkins Technical Service Department at Peterborough, especially if JP4 fuel is to be used. These fuels are more flammable than diesel fuel and need careful storage and careful management. -

Page 48: Lubricating Oil Specification

4.236 Series Lubricating oil specification Use only a good quality lubricating oil to the relevant specification as shown in the table below. Caution: The type of lubricating oil to be used may be affected by the quality of the fuel which is available. -

Page 49: Coolant Specification

1 If it is possible, use clean soft water in the coolant. 2 If an antifreeze mixture, other than Perkins POWERPART, is used to prevent frost damage, it must have an ethanediol base (ethylene glycol) with a corrosion inhibitor. It is recommended that the corrosion inhibitor is of the sodium nitrite or sodium benzoate type. - Page 50 This page is intentionally blank This document has been printed from SPI². Not for Resale...

-

Page 51: Fault Diagnosis

4.236 Series Fault diagnosis Problems and possible causes Possible causes Problem Checks by the workshop Checks by the user personnel The starter motor turns the engine too slowly 1, 2, 3, 4 The engine does not start 5, 6, 7, 8, 9, 10, 12, 13,... -

Page 52: Code List Of Possible Causes

4.236 Series Code list of possible causes 1 Battery capacity low. 2 Bad electrical connections. 3 Fault in starter motor. 4 Wrong grade of lubricating oil. 5 Starter motor turns engine too slowly. 6 Fuel tank empty. 7 Fault in stop control. - Page 53 4.236 Series 47 Lubricating oil pump is worn. 48 Relief valve does not close. 49 Relief valve does not open. 50 Relief valve spring is broken. 51 Fault in suction pipe of lubricating oil pump. 52 Piston is damaged. 53 Piston height is incorrect.

- Page 54 This page is intentionally blank This document has been printed from SPI². Not for Resale...

Need help?

Do you have a question about the 4.236 Series and is the answer not in the manual?

Questions and answers

Hi, I have a 4.236 perkins diesel powered utility tractor built in Italy in 1981. I **** confused as to which engine oil to use. Can you please help me figure out which viscosity oil I need and what is the MF specification required for this oil. I **** looking at your chart and it states a whole range of oils including a 0W which I have never seen not even for gas engines. How reliable is this chart you have? please advise.

The recommended viscosity for engine oil in a Perkins 4.236 Series diesel engine depends on the ambient temperature. The viscosity grades include 0W, 5W20, 10W30, 15W40, 20W50, 20, 30, and 40. The oil specification should meet API CC/SE, API CD/SE, ACEA E1, or ACEA E2 standards.

This answer is automatically generated