Advertisement

7.1 - GENERALITIES

Before carrying out any maintenance activity it is necessary to:

Disconnect the plug from the electrical outlet to completely isolate the machine

from the rest of the system.

7.2 - BELT

The belt does not need any adjustments. Ususally, after 3/4 years it must be repla-

ced, in this case call the "ASSISTANCE CENTER".

7.3 - FEET

The feet could deteriorate with time, thus reducing the stability of the machine.

Therefore they must be replaced.

7.4 - FEEDING CABLE

Periodically check the wear of the cable and call the "ASSISTANCE CENTER"

to replace it.

CHAP. 8 - DISMANTLING

8.1 - PUTTING IT OUT OF WORK

If for some reason it is decided to put the machine out of work make sure that it

cannot be used by anyone: unplug the electrical connections.

8.2 - DISPOSAL

Once it has been put out of work the machine can be eliminated. To correctly di-

spose of the machine get information from any company responsible for such a

service and take careful note of the materials used for the various components.

ASSISTANCE CENTER

AUTHORIZED RETAILER

16

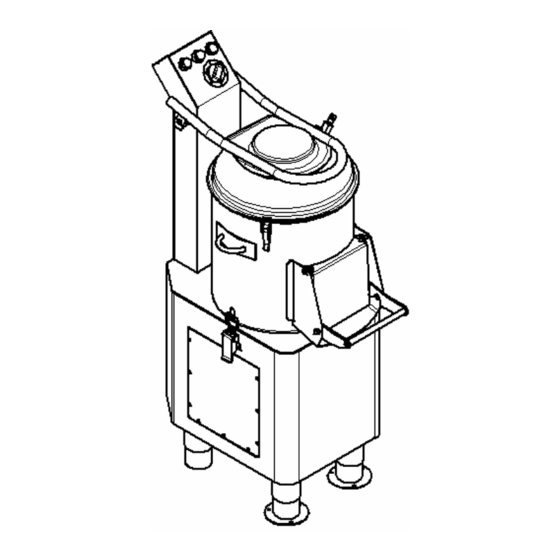

Potato peeler: PPJ 10-20 CE

Mussel cleaner: LCJ 10 CE

INSTRUCTIONS FOR USE AND MAINTENANCE MANUAL

1

Advertisement

Table of Contents

Summary of Contents for Sirman PPJ10 2V-PP/PC

- Page 1 Potato peeler: PPJ 10-20 CE 7.1 - GENERALITIES Mussel cleaner: LCJ 10 CE Before carrying out any maintenance activity it is necessary to: Disconnect the plug from the electrical outlet to completely isolate the machine from the rest of the system. 7.2 - BELT The belt does not need any adjustments.

-

Page 2: Chap. 7 - Maintenance

INTRODUCTION CHAP. 6 - ROUTINE CLEANING • This manual has been written to provide the client with all information Before starting this chapter it is important to point out that: concerning the machine and the norms pertaining to it, apart from the use and The line of professional PPJ/LCJ is outfitted with normative measures for the e- maintenance instructions which enable it to be used in the best way possible, lectrical and mechanical protections both in the working phase and the cleaning... -

Page 3: Index Of Drawings

AND WORKING THE PRODUCT (see FIG. CHAP. 7 - MAINTENANCE page 16 n°10) - GENERALITIES NB: The goods to be worked are loaded gradually - BELT on the cap from the upper cover when the motor is - FEET off. - FEEDING CABLE Adhere to the following procedure: 1 load the product from the upper cover, making... - Page 4 CHAP. 1 - MACHINE INFORMATION 4.4 - OPERATIONAL CHECK Before proceeding to testing make sure the upper cover and the discharge door are well-blocked, then check the running of the machine with the following 1.1 - GENERAL PRECAUTIONS • The machine must only be used by trained personnel who are perfectly aware procedure: 1 check that the upper cover and the discharge door are closed well;...

-

Page 5: Description Of The Machine

4.3.2 - Diagram of three-phase electrical system - controlling the unloading of the product; - controlling the safety micros; • a micro, which causes the machine to stop in case the cover or discharge door opens (see FIG. n°1), does not allow the machine to turn on if it is not in the closed position;... -

Page 6: Electrical Diagrams

4.3 - ELECTRICAL DIAGRAMS 1.3.3 - Machine makeup 4.3.1 - Diagram of the single-phase electrical system KEY: FEED Pushbutton strip Hopper Cover block hinge TENSION CHANGE Pan block hinge Maintenance door Feet Flanged feet Structure Discharge door Cover Feeding tap Handle Stand Sieve... -

Page 7: Electrical Connections

TAB. n°1 - MEASUREMENTS AND TECHNICAL FEATURES Model u.m. PPJ10 PPJ20 LCJ10 LCJ20 PPJ10 2V PPJ10 2V - PP/PC - PP/AV 230 V. / 50 Hz Power source 400V/50Hz 4.2 - ELECTRICAL CONNECTIONS 230 - 400 V. -

Page 8: Chap. 4 - Installation

CHAP. 3 - RECEIVING THE MACHINE 3.2 - CHECKING THE PACKAGE UPON RECEIPT When the package is received, if there is no external damage, open the package and check that all the material is inside (see FIG. n°3). 3.1 - SHIPPING THE MACHINE (see FIG. n°3) If the package shows signs of mishandling, bumps or falls upon delivery, the The machine leaves our warehouses correctly packaged, such a package consists shipping company must be made aware of the damage within 3 days of the...

Need help?

Do you have a question about the PPJ10 2V-PP/PC and is the answer not in the manual?

Questions and answers