Subscribe to Our Youtube Channel

Summary of Contents for Sirman PPJ 10 SC

- Page 1 Potato peeler: PPJ 10-20 SC Mussel cleaner: LCJ10-20 SC CE INSTRUCTIONS FOR USE AND MAINTENANCE MANUAL...

- Page 2 INTRODUCTION This manual has been written to provide the client with all information concerning the machine and the norms pertaining to it, apart from the use and maintenance instructions which enable it to be used in the best way possible, therefore maintaining its efficiency through time. This manual must be given to all personnel who will use or do maintenance on the machine.

- Page 3 CHAP. 7 - MAINTENANCE page 14 - GENERALITIES - BELT - FEET - FEEDING CABLE CHAP. 8 - DISMANTLING page 14 - PUTTING IT OUT OF WORK - WEEE Waste of Electric and Electronic Equipment...

-

Page 4: General Precautions

CHAP. 1 - MACHINE INFORMATION 1.1 - GENERAL PRECAUTIONS • The machine must only be used by trained personnel who are perfectly aware of the safety norms contained in this manual. • If there is a turnover of staff, promptly provide proper training for new personnel. •... -

Page 5: Description Of The Machine

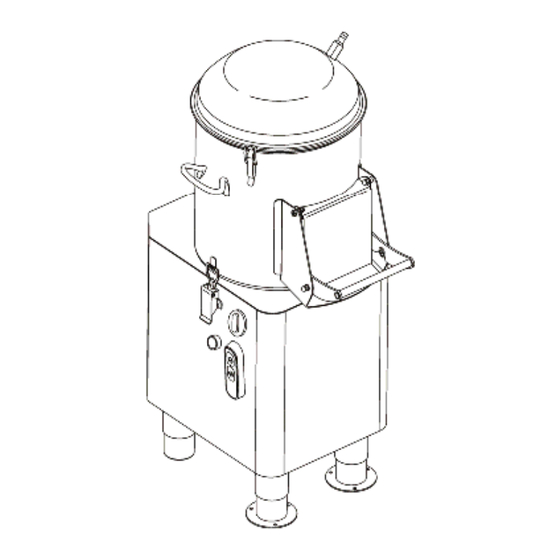

- controlling the unloading of the product; - controlling the safety micros; a micro, which causes the machine to stop in case the cover or discharge door opens (see FIG. n°1), does not allow the machine to turn on if it is not in the closed position; an N.V.R. - Page 6 1.3.3 - Machine makeup FIG. n°1 - General view of the machine KEY: 1. Hopper 2. Cover block hinge 3. Pan 4. Pan block hinge 5. Feet 6. Controls 7. Flanged feet 8. Structure 9. Discharge door 10. Cover 11. Water inlet 12.

-

Page 7: Chap. 2 - Technical Data

CHAP. 2 - TECHNICAL DATA 2.1 - DIMENSIONS, WEIGHT, CHARACTERISTICS ... FIG. n°2 - Drawings of dimensions TAB. n°1 - MEASUREMENTS AND TECHNICAL FEATURES u. u Model PPJ10 SC LCJ10 SC PPJ20 SC LCJ 20 SC 230- 230-400V/5 Power source A x B 203x282 203x282... - Page 8 CHAP. 3 - RECEIVING THE MACHINE 3.1 - SHIPPING THE MACHINE (see FIG. n°3) The machine leaves our warehouses correctly packaged, such a package consists of: a) an external box in robust cardboard and a wooden pallet; b) ) the achine; c) ) is manual;...

-

Page 9: Chap. 4 - Installation

3.2 - CHECKING THE PACKAGE UPON RECEIPT When the package is received, if there is no external damage, open the package and check that all the material is inside (see FIG. n°3). If the package shows signs of mishandling, bumps or falls upon delivery, the shipping company must be made aware of the damage within 3 days of the delivery date indicated on the documents, and a detailed report must be written on the damage to the machine. -

Page 10: Electrical Connections

4.2 - ELECTRICAL CONNECTIONS 4.2.1 - PPJ/LCJ SC with single-phase motor The machine is outfitted with a feeding cable with a cross section area of 3x1.5 mm 2 , length 1.5m. Connect the machine to 230V./50Hz by means of a blue CEI plug, interposing a magnetothermic- differential switch of 10A, ∆... -

Page 11: Electrical Diagrams

4.3 - ELECTRICAL DIAGRAMS 4.3.1 - Diagram of the electrical system single-phase FIG. n°6 4.3.2 - Diagram of electrical system three-phase FIG. n°7... -

Page 12: Operational Check

4.4 - OPERATIONAL CHECK Before proceeding to testing make sure the upper cover and the discharge door are well-blocked, then check the running of the machine with the following procedure: 1 check that the upper cover and the discharge door are closed well; 2 press the START ‘I’... - Page 13 5.2 - LOADING AND WORKING THE PRODUCT (see FIG. n°10) NB: The goods to be worked are loaded gradually on the cap from the upper cover when the motor is off. Adhere to the following procedure: 1 load the product from the upper cover, making sure that the discharge door is closed well;...

-

Page 14: Chap. 7 - Maintenance

Cleaning and maintenance operations are carried out only when the machine is off and the feeding cable is unplugged. 6.1 - GENERALITIES Before cleaning the machine the feeding plug must be disconnected from the network to completely isolate the machine. The machine must be cleaned at the end of every work day and all the parts of the machine (completely removable) which come into direct or indirect contact with the worked foodstuff must be carefully cared for. - Page 15 8.2 - WEEE Waste of Electric and Electronic Equipment Directive 2002/95/EC, 2002/96/EC and 2003/108/EC on the restriction of the use of certain hazardous substances in electrical and electronic equipment, and waste electrical and electronic equipment This symbol, crossed out wheelie bin, on the product or on its packaging indi-cates that this product must not be disposed of with your other household waste.

- Page 16 ASSISTANCE CENTER AUTHORIZED RETAILER...

- Page 17 CHAP. 3 - RECEIVING THE MACHINE 3.2 - CHECKING THE PACKAGE UPON RECEIPT When the package is received, if there is no external damage, open the package and check that all the material is inside (see FIG. n°3). 3.1 - SHIPPING THE MACHINE (see FIG. n°3) If the package shows signs of mishandling, bumps or falls upon delivery, the The machine leaves our warehouses correctly packaged, such a package consists shipping company must be made aware of the damage within 3 days of the...

Need help?

Do you have a question about the PPJ 10 SC and is the answer not in the manual?

Questions and answers