Advertisement

7.1 - GENERALITIES

Before carrying out any maintenance activity it is necessary to:

Disconnect the plug from the electrical outlet to completely isolate the machine

from the rest of the system.

7.2 - BELT

The belt does not need any adjustments. Ususally, after 3/4 years it must be repla-

ced, in this case call the "ASSISTANCE CENTER".

7.3 - FEET

The feet could deteriorate with time, thus reducing the stability of the machine.

Therefore they must be replaced.

7.4 - FEEDING CABLE

Periodically check the wear of the cable and call the "ASSISTANCE CENTER"

to replace it.

CHAP. 8 - DISMANTLING

8.1 - PUTTING IT OUT OF WORK

If for some reason it is decided to put the machine out of work make sure that it

cannot be used by anyone: unplug the electrical connections.

8.2 - DISPOSAL

Once it has been put out of work the machine can be eliminated. To correctly di-

spose of the machine get information from any company responsible for such a

service and take careful note of the materials used for the various components.

ASSISTANCE CENTER

AUTHORIZED RETAILER

16

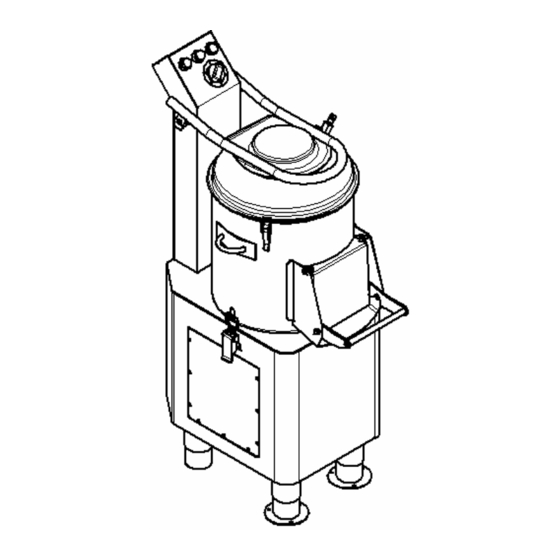

Potato peeler: PPJ 10-20 CE

Mussel cleaner: LCJ 10 CE

INSTRUCTIONS FOR USE AND MAINTENANCE MANUAL

1

Advertisement

Table of Contents

Summarization of Contents

Machine Maintenance Generalities

Belt Maintenance

Belt does not need adjustment, requires replacement after 3-4 years. Contact Assistance Center.

Feet Maintenance

Feet may deteriorate over time, reducing machine stability and requiring replacement.

Feeding Cable Maintenance

Periodically check the feeding cable for wear and call the Assistance Center for replacement.

Machine Dismantling

Putting Machine Out of Work

Ensure the machine cannot be used by unplugging all electrical connections.

Machine Disposal

Obtain disposal information from a service company and note component materials.

Routine Cleaning Procedures

General Cleaning Guidelines

Disconnect power before cleaning. Clean daily, focus on food contact parts. Avoid harsh cleaners and high-pressure jets.

Machine Information and Safety

General Precautions

Use by trained personnel only. Disconnect power before maintenance or cleaning.

Installed Safety Devices

Conforms to EN norms; equipped with a control card for safety features.

Machine Description

General Description

Designed for maximum safety, hygiene, robustness, and silence.

Constructive Features

Constructed from AISI 304 steel, polished aluminum, plastic cover, and aluminum work plate.

Technical Data

Dimensions, Weight, Characteristics

Table detailing measurements and technical features for various models.

Electrical Connections

Single-Phase Motor Connection

Connect to 230V/50Hz using a CEI plug and magnetothermic-differential switch.

Three-Phase Motor Connection

Connect to 400V/50Hz, check rotation, and adapt for 230V if needed.

Receiving and Installation

Shipping Details

Machine is packaged in a box with a pallet, manual, and CE certificate.

Package Inspection

Inspect package for damage upon arrival and report issues within 3 days.

Package Disposal

Package materials are solid urban waste; dispose according to local regulations.

Machine Placement

Position machine on a stable, level surface near a faucet and drain.

Machine Use

Controls Overview

Location and function of START, STOP, OUT pushbuttons, and timer.

Loading and Working Product

Procedure for loading and running the product, including safety precautions.

Electrical Diagrams

Single-Phase Electrical Diagram

Shows the electrical wiring for the single-phase system.

Three-Phase Electrical Diagram

Shows the electrical wiring for the three-phase system.

Need help?

Do you have a question about the PPJ10 and is the answer not in the manual?

Questions and answers