Summarization of Contents

Introduction

2.01 How to Use This Manual

Guide on how to effectively use the owner's manual for safe and correct operation of the equipment.

2.02 Equipment Identification

Information on identifying the welding unit by its specification, model, and serial number for reference.

2.03 Receipt of Equipment

Instructions for checking the received equipment against the invoice and inspecting for any shipping damage.

Arc Welding Safety Instructions and Warnings

1.02 Declaration of Conformity

Formal statement of the equipment's compliance with applicable regulations and standards for quality and safety.

1.03 Limited Warranty

Details the terms, conditions, and limitations of the manufacturer's warranty for the welding equipment.

Electromagnetic Compatibility

3.01 Installation and use - Users Responsibility

Defines the user's responsibility for ensuring proper installation and resolving any detected electromagnetic disturbances.

3.02 Assessment of Area

Guidance on assessing the surrounding area for potential electromagnetic interference before installation.

3.03 Methods of Reducing Electromagnetic Emissions

Provides methods to reduce electromagnetic emissions from the welding equipment, including mains supply and cable management.

General Information

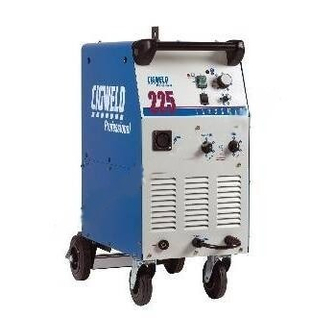

4.01 TRANSMIG 225, 255 MIG Power Source, 255 2R Wirefeeder

Overview of the TRANSMIG 225/255 MIG Power Source and 255 2R Wirefeeder, highlighting features and intended use.

4.02 User Responsibility

Outlines the user's responsibility for correct installation, operation, maintenance, and unauthorized modifications.

4.03 Duty Cycle

Explanation of the duty cycle rating for the welding power source and its implications for operation.

Safe Practices For The Use Of Welding Equipment

5.01 Precautions to be Taken by Operators

Essential safety precautions for operators to prevent electrical shock and other hazards during welding.

5.02 Personal Protection

Details necessary personal protective equipment (PPE) like gloves, clothing, and face shields for welding safety.

Resuscitation For Electric Shock Victims

6.01 Resuscitation

Step-by-step instructions for performing resuscitation on victims of electric shock, including CPR.

Specifications

7.01 TRANSMIG 225, 255 MIG Power Source Specifications

Detailed technical specifications for the TRANSMIG 225 and 255 MIG Power Sources, including ratings and dimensions.

7.02 Optional Accessories

List of available optional accessories for the TRANSMIG welding equipment, including part numbers.

Installation Recommendations

8.01 Environment

Guidelines for suitable operating environments, considering hazards like electric shock and conductive elements.

8.02 Location

Recommendations for locating the welding unit, considering factors like moisture, dust, and ventilation.

8.03 Ventilation

Emphasis on ensuring adequate ventilation in the welding area to remove harmful fumes and gases.

8.04 Mains Supply Voltage Requirements

Specifies the mains supply voltage requirements, fuse sizes, and lead sizes for optimal performance and safety.

Set up for the TRANSMIG 225, 255 MIG Power Source

9.01 Power Source Connections

Steps for connecting the power source, including work lead and gas cylinder setup.

9.02 Wirefeeder Connections (Remote models only)

Instructions for connecting the wirefeeder to the power source for remote operation.

9.03 Wirefeeder Connections (Compact models only)

Instructions for connecting the wirefeeder integrated into the power source for compact operation.

9.04 Common Connections

Procedure for threading electrode wire through the wire feeder system and into the MIG torch.

9.05 Drive Roller Pressure Adjustment

Guidance on adjusting the drive roller pressure for satisfactory wire feeding without slippage or excessive wear.

9.06 Wire Reel Brake

Instructions for adjusting the wire reel brake to prevent spool unwinding and tangling.

9.07 Wire Reel Hub Assembly

Details the assembly components of the wire reel hub, including part numbers for identification.

Power Source and Wirefeeder Controls, Indicators and Features

10.01 Standby switch with in-built Indicator Light

Description of the standby switch and indicator light, showing mains power connection status.

10.02 Wirespeed Control

Explains the wirespeed control knob's function in regulating welding current via electrode wirefeed rate.

10.03 Output Voltage Control Switch (Coarse)

Details the coarse voltage control switch for adjusting welding voltage in larger increments.

10.04 Output Voltage Control Switch (Fine)

Details the fine voltage control switch for adjusting welding voltage in smaller increments.

10.05 Torch Polarity Lead (Compact models only)

Explains the torch polarity lead for selecting welding voltage polarity for different electrode wires.

10.06 Positive Welding Terminal

Description of the positive welding terminal for connecting the welding current output.

10.07 Negative Welding Terminal

Description of the negative welding terminal for connecting the welding current output.

10.08 Torch Connector (Compact models only)

Location where the MIG torch connects to the compact power source.

10.09 Thermal Overload

Information on the thermal overload protection feature and its indication on the power source.

10.10 Spot Selector Switch

Switch for selecting the spot welding mode for joining two plates at a specific location.

10.11 Spot Timer

Control knob for setting the duration of a single spot weld when the spot selector is engaged.

10.12 Wirefeeder Control Socket (Remote model only)

Details the 7-pin receptacle for connecting a wirefeeder to the power source circuitry.

250A TWECO MIG Torch OTWX212/3035 (where supplied)

11.01 MIG Torch Components

List and identification of the various components that make up the 250A TWECO MIG Torch.

11.02 MIG Torch Contact Tips

Table listing part numbers for MIG torch contact tips corresponding to different wire sizes.

11.03 MIG Torch Conduits

Table listing part numbers for MIG torch conduits for hard and soft electrode wires.

11.04 Installing a new Wire Conduit

Step-by-step instructions for installing a new wire conduit into the MIG torch cable assembly.

11.05 MIG Torch Maintenance

Recommended weekly maintenance for the MIG torch conduit to prevent wire feeding issues.

Basic Welding Technique

12.01 Setting of the Power Source & Wirefeeder

Guidance on balancing wirespeed and voltage controls for optimal welding current and arc length.

12.02 Position of MIG Torch

Explanation of how the MIG torch angle affects the weld width during the welding process.

12.03 Distance from the MIG Torch Nozzle to the Work Piece

Recommended stick-out distance for the electrode wire from the MIG torch nozzle to the workpiece.

12.04 Travel Speed

Information on how travel speed influences the weld bead width and penetration.

12.05 Electrode Wire Size Selection

Factors to consider when selecting electrode wire size and shielding gas for different applications.

Routine Maintenance & Inspection

13.01 Cleaning the Feed Rolls

Instructions for cleaning the drive rolls and grooves to ensure proper wire feeding performance.

Basic Troubleshooting

14.02 Solving Problems Beyond the Welding Terminals - Porosity

Troubleshooting guide for weld porosity, identifying causes related to gas supply and contamination.

14.03 Solving Problems Beyond the Welding Terminals – Inconsistent Wire Feed

Troubleshooting guide for inconsistent wire feed issues, covering spool brake, rollers, and liner problems.

14.04 Welding Problems

Common welding problems like undercut, lack of penetration, and weld cracking, with their causes and remedies.

14.05 Power Source / Wirefeeder Problems

Troubleshooting issues related to the power source and wirefeeder operation, including indicator lights and trigger functions.

Need help?

Do you have a question about the 255 and is the answer not in the manual?

Questions and answers