Table of Contents

Advertisement

Quick Links

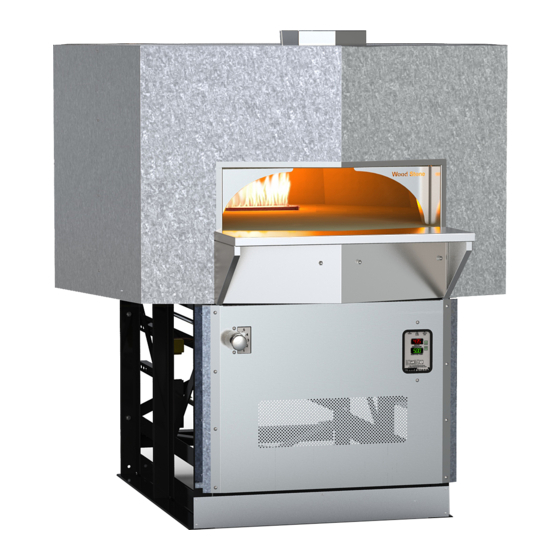

MOUNTAIN SERIES

Stone Hearth Oven

Dual Burner, Gas-Fired Models

wood stone corporation

1801 w. bakerview rd.

bellingham, wa 98226 usa

Installation and

Operation Manual

MT. CHUCKANUT

WS-MS-4-RFG-IR, RFG-IR

MT. ADAMS

WS-MS-5-RFG-IR, RFG-IR

MT. BAKER

WS-MS-6-RFG-IR, RFG-IR-(NAP)

MT. RAINIER

WS-MS-7-RFG-IR, RFG-IR

tf. 800.988.8103

t. 360.650.1111

f. 360.650.1166

woodstone-corp.com

Revised September 2014

Doc no: M0033.02

Advertisement

Table of Contents

Summarization of Contents

CAUTIONS AND WARNINGS

Essential Safety Precautions

Critical warnings about gas, flammables, power failures, and proper installation to prevent fires.

Read and Follow All Instructions

Emphasizes the critical need to read and follow all installation instructions to prevent fires.

Installation & Maintenance Warnings

Warnings about improper installation, adjustment, service, and the importance of reading the manual.

Clearance and Material Safety

Highlights fire risks from clearance failures and warnings about handling materials like glasswool.

Product Certifications

Information on ETL listing and approval by Intertek Testing Services for safety standards.

UNLOADING AND MOVING

Lifting the Oven Safely

Procedures for safely unloading and moving the oven using a crane or forklift.

Using a Pallet Jack

Instructions and safety warnings for moving the oven with a pallet jack.

Delivery Notes and Support

Important notes regarding delivery confirmation and seeking factory technical support.

INSTALLATION CLEARANCES

Minimum Clearance Requirements

Details minimum 1" side and 14" top clearances to combustibles.

Facade and Floor Clearances

Specifies non-combustible facade materials and non-combustible floor surface requirements.

Stucco Application Clearances

Notes that stucco-ready appliances follow similar clearances with specific stucco mix requirements.

Critical Installation Warnings

Emphasizes fire risks from improper installation and warnings about insulation in air spaces.

Clearance Diagram and Details

Provides a visual diagram illustrating top, side, and facade clearances for Wood Stone ovens.

FACADE DETAILS

ETL Sanitation Listing and Model Specifics

Explains the ETL Sanitation listing and how it applies to exposed surfaces and cooking.

Facade Construction Guidelines

Details requirements for facade materials, access for exhaust hoods, and service panels.

Facade Wall Material Requirements

Specifies that facade walls 6" to either side of the doorway and above must be non-combustible.

OUTDOOR INSTALLATION

Outdoor Installation Requirements

Outlines ETL approval for outdoor use and enclosure requirements, maintaining clearances.

Area Clearance for Combustibles

Mandates keeping the area around and beneath the oven clear of grass, leaves, and other combustibles.

Enclosure Options

Mentions available Wood Stone options for enclosing the area beneath the oven.

GAS SPECIFICATIONS

Gas Connection and Testing

Details the 3/4" NPT gas connection and testing procedures, advising against flame tests.

Burner Control Valves (SV-1 & SV-2)

Identifies SV-1 for IR burner and SV-2 for radiant burner, with test port locations.

Manifold Pressure Specifications

Provides factory-specified manifold pressures for Natural Gas and Propane models.

Altitude and Pressure Notes

Notes no altitude modifications are needed and the maximum inlet gas pressure.

Hourly Input Rates (BTU/hr)

Lists hourly input rates for Natural Gas and Propane models.

Gas Code Limitations

Outlines requirements for installation, pressure testing, and isolation from gas supply piping.

ELECTRICAL SPECIFICATIONS

Power Connection and Voltage Verification

Details connecting power to the terminal strip and verifying oven voltage (120 VAC or 240 VAC).

Electrical Ratings and Code

Lists electrical ratings (120/240 VAC) and grounding requirements per local and national codes.

VENTING

Venting Recommendations and Options

Manufacturer's recommendations for venting, prohibiting "B vent" and requiring grease duct material.

Venting Option 1: Direct Connection

Details direct connection via chimney or field-built grease duct, requiring specific static pressure.

CFM Requirements for Venting

Lists required CFM for different oven models to achieve specified static pressure.

Flue Adapter Information

Information on the flue adapter for round duct connection and MS-4 collar details.

Venting Option 2: Type 1 Hood

Describes using a Listed Type 1 exhaust hood and its installation requirements.

Venting Option 3: Combined Exhaust

Explains combining oven exhaust with other equipment under specific conditions and duct requirements.

Venting Prohibitions and Recommendations

Prohibits "B vent" and recommends consulting engineers and local authorities for venting plans.

Fire Suppression Requirements

Details fire suppression requirements, Type 1 hood usage, and fusible link ratings.

FLUE ADAPTER

Flue Adapter Installation

Instructions for attaching the flue adapter for round duct connection to the oven exhaust outlet.

MS-4 Collar and Duct Attachment

Notes MS-4 models have a standard 8" collar and may not need an adapter; duct must be grease-rated.

VENTING DO'S AND DON'TS

General Venting Rules and Guidelines

Covers basic rules for airflow, intake, and exhaust to ensure proper operation and prevent damage.

Direct Connect Venting Examples

Illustrates acceptable and unacceptable direct connect venting scenarios with diagrams.

Hood Installation Procedures and Clearances

Details hood mounting, facade requirements, and clearance specifications from pages 22-25.

ASSEMBLY

Oven Assembly Steps

Instructions for mounting the mantle, toe kick, and service/intake panel on the oven stand.

Service Panel Access Note

Highlights the service panel as the sole access for components and the need to maintain airflow.

Stucco Finish Oven Assembly

Specific instructions for stucco application on ovens ending with "-S", requiring 1-inch thickness.

MANTLE MOUNTING

Mantle/Bracket Installation

Steps for installing threaded studs, positioning the mantle/bracket, and securing with cap nuts.

Silicone Sealant Application

Instructions for filling gaps with high-temperature silicone sealant for a secure fit.

Granite Mantle Installation

Steps for applying silicone adhesive and seating granite stone onto the mantle bracket.

FRONT PANEL ASSEMBLY

Standard Front Panel & Toe Kick Instructions

Details assembly of the front panel and toe kick, including screw types.

Transformer Box and Connections

Identifies the transformer box location and notes the need for a licensed electrician for connections.

Service Panel Throttle Assembly

Describes the throttle knob assembly and its adjustable position for flame height control.

EXTENSION PANEL ASSEMBLY

Optional Lower Extension Assembly

Instructions for attaching the lower extension assembly to the oven legs.

Throttle Rod and Controller Assembly

Steps for removing the throttle rod assembly and attaching the controller to the extension.

Connecting Throttle Rod Extension

Details passing the EMT throttle rod through brackets and securing it with a cotter pin.

Final Throttle Rod & Panel Attachment

Instructions for passing the throttle rod, clamping, and securing the front panel to the bracket.

Calibrating the Pointer

Steps to loosen pointer collar set screws and position the pointer to "5" on the Flame Height Index Scale.

STUCCO APPLICATION

Stucco Application Overview

Depicts stucco application and notes minimum clearances and coating thickness.

Traditional Stucco Mix

Provides the traditional stucco mix ratio (1 part cement, 1 part regular cement, 5 parts sand).

Minimum Stucco Thickness

Specifies a minimum stucco application thickness of 1 inch over exposed metal lathing.

CONTROLLER

Controller Functions Overview

Explains the functions of the power, dome flame, and hearth heat indicator lights.

Display and Button Functions

Details the Hearth Temperature/Set Point displays and the On/Off button functionality.

Arrow Buttons and Unit Selector

Describes the arrow buttons for temperature adjustment and the unit selector for °F/°C.

INITIAL START-UP

Oven Start-Up Procedure

Outlines the critical initial start-up procedure to drive out moisture and prevent cracking.

Pre-Start Checks

Ensures main gas supply is on, control valves are ON, and venting is tested and approved.

First Day Firing Schedule

Details a step-by-step firing schedule for the first day, including flame height adjustments.

Turning Off the Oven

Instructions for turning off the oven and notes regarding restarting and oven cracks.

DAILY OPERATION

Oven Operation Overview

Provides a general overview of daily oven operation, noting it's not for solid fuel.

Adjusting Hearth Set Point

Instructions for setting the Hearth Set Point and adjusting the radiant flame for desired temperatures.

Adjusting Radiant (Dome) Flame

Explains how to adjust the radiant flame intensity using the Flame Height Control Knob.

Turning Off the Oven

Steps for turning off the oven and notes about restarting and condensation.

FLAME HEIGHT CONTROL

Determining Appropriate Flame Height

Explains how flame height relates to floor temperature and factors influencing it.

Using the Flame Height Indicator Scale

Details settings for Heat Up, Holding, and Cooking flames using the indicator scale.

Cooking Flame Purposes

Outlines the two main purposes of the cooking flame: top baking and heat replacement.

MAINTENANCE

Cleaning the Oven

Recommendations for cleaning oven debris using brushes and damp rags, avoiding chemicals.

Burner Area Warnings

Critical warnings against placing items in or above the flame or sweeping debris into the burner.

Oven Floor Cleaning Warning

Strict warning against using water or cleaning chemicals on the oven floor to prevent severe damage.

Night Heat Retention Doors

Explains the use of doors for heat retention and warns against operating the oven with them in place.

PERIODIC THERMAL CLEANING

Establishing a Thermal Cleaning Schedule

Guidance on when thermal cleaning is needed based on oven operating temperatures and buildup.

Thermal Cleaning Procedure

Steps for removing grease buildup by using the radiant flame at high settings to reach 600°F.

TROUBLESHOOTING GUIDE

Controller Not Turning On

Solutions for power issues, including checking breakers, wall switches, and interlocks.

Radiant Flame Not Lighting

Troubleshooting steps for the radiant flame not lighting, including gas supply and debris checks.

Underfloor Burner Operation

Addresses the "Hearth Heat" light being off and the underfloor burner not firing.

Hearth Temperature Status

Explains normal hearth temperature readings and the role of the radiant burner vs. set point.

"Chec" Display on Controller

Troubleshooting for the underfloor IR burner not firing when the floor temperature drops below the set point.

Service and Support Contact

Provides contact information and hours for service and technical support from Wood Stone.

OPERATION SEQUENCE

Burner Operation Sequence Overview

Details the sequence of operations for the RFG-IR oven with a Type 2 controller.

Power On and Pilot Ignition

Describes the initial steps of powering on, SV-2 valve operation, and pilot ignition sequence.

Burner Firing and Temperature Control

Explains the firing of burners based on floor temperature relative to the Hearth Set Point.

120 VAC ELECTRICAL DIAGRAM

RFG-IR 120 VAC Model Wiring

Provides the wire diagram for RFG-IR 120 VAC models with a Type 2 controller.

Temperature Controller Connections

Details connections for the temperature controller, including thermocouple and terminal blocks.

SV1 and SV2 Component Wiring

Shows wiring for the SV1 Infrared and SV2 Radiant components.

240 VAC ELECTRICAL DIAGRAM

RFG-IR 240 VAC Model Wiring

Presents the wire diagram for RFG-IR 240 VAC models with a Type 2 controller.

Transformer and Controller Wiring

Illustrates the wiring of the transformer, temperature controller, and SV components for 240V.

INTERLOCK DIAGRAM

Oven Control to Exhaust Fan Interlock

Explains the connection to interrupt oven power until the exhaust fan is turned on.

DPST Switch Functionality

Details the function of the Double Pole, Single Throw (DPST) switch for safety interlock.

LIMITED WARRANTY

Warranty Service and Contact Information

Outlines the warranty period, service requirements, and contact details for Wood Stone.

Warranty Exclusions

Lists specific instances where the provided warranty does not apply, such as improper installation or use.

Limitations of Liability

States limitations on Wood Stone's liability and the purchaser's rights regarding claims.

Need help?

Do you have a question about the MT. ADAMS WS-MS-5-RFG-IR and is the answer not in the manual?

Questions and answers