Subscribe to Our Youtube Channel

Summary of Contents for FULTON FBZ Series

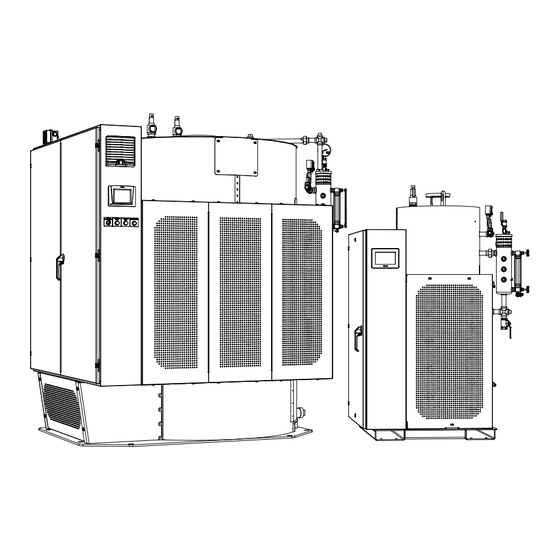

- Page 1 INSTALLATION, OPERATION, AND MAINTENANCE MANUAL FBZ Series Electric Steam Boiler 90kW - 1300kW VIEW1 Serial/ National Board Number Model Fulton Order Owner Site Name Date FBZ-IOM-2024-0927...

- Page 3 THE WATER COLUMN AND WATER GAUGE GLASS ..............2-14 Installing Electric Elements ................2-16 System Piping Testing ..................2-18 Assembly of Fulton Multi-Skid Engineered Systems ......... 2-18 Before Leaving The Installation ................2-19 Operation Start-Up Preparation & Installation Review ............3-2 Start-Up Service ....................

- Page 4 TABLE OF CONTENTS FBZ-IOM-2024-0927 © Fulton Group N.A., 2024...

- Page 5 INTRODUCTION INTRODUCTION INSTALLATION OPERATION MAINTENANCE & TROUBLESHOOTING WARRANTY Questions? Please Contact Your Local Manufacturer’s Representative...

- Page 6 Label all wires prior to disconnecting when servicing controls. Wiring errors can cause of your Fulton equipment, and should be read in its entirety and be made improper and dangerous operation. permanently available to the staff responsible for the operation of the boiler. It...

- Page 7 INTRODUCTION SECTION 1 FBZ-IOM-2024-0507 WARNING Receiving Inspection After checking controls by manual adjustment, always ensure they are reset The customer should examine the equipment for any damage. It is the to their proper settings. responsibility of the installer to ensure all parts supplied with the equipment are fitted in a correct and safe manner.

- Page 8 No shutoff of any kind shall be placed between the safety relief To ensure that your Fulton equipment is operating safely and valve and the equipment or in the discharge pipe between such efficiently, follow the maintenance procedures set forth in this valve and the atmosphere.

- Page 9 Never operate the pump with a closed discharge Competent personnel in accordance with all applicable local valve. codes should carry out the installation of the Fulton equipment. “Factory-Trained Personnel” refers to someone who has attended a Fulton Service School specifically for the equipment covered in this manual.

- Page 10 INTRODUCTION SECTION 1 FBZ-IOM-2024-0507 THIS PAGE LEFT INTENTIONALLY BLANK © Fulton Group N.A., 2024...

- Page 11 INSTALLATION INTRODUCTION INSTALLATION OPERATION MAINTENANCE & TROUBLESHOOTING WARRANTY Questions? Please Contact Your Local Manufacturer’s Representative...

- Page 12 7. Never allow weight to bear on the jacket, control panel, trim, burner, fuel installation to ensure no damage has occurred during shipment, handling, or train or fan housing of any Fulton boiler. Use only lifting eyes or fork holes storage. for movement.

- Page 13 INSTALLATION SECTION 2 FBZ-IOM-2024-0927 WARNING Table 1 - Minimum Clearances Around the Boiler All information in this manual is for Unit Size Panel Rear/Sides Element Removal reference and guidance purposes, (kW) inch (mm) inch (mm) inch (mm) and does not substitute for required professional training, conduct, and strict 36 (915) 24 (610)

- Page 14 Solids that enter with the feedwater will concentrate in the boiler. A regular schedule of boiler blowdown (see Maintenance section of this manual) must be maintained to prevent high solid concentrations from corroding the vessel or forming deposits. © Fulton Group N.A., Inc. 2024...

- Page 15 Poor quality feedwater requires and cause high general corrosion rates. increased blowdown and increased chemical treatment costs The Fulton Warranty does not cover damage or failure that to prevent boiler corrosion and scaling. can be attributed to excessive corrosion, scale or fouling.

- Page 16 If oil is present foam will result. Often oil in boiler water will originate in the condensate. This contaminated condensate should be directed to the sewer until the source of the oil is determined and corrective steps taken. © Fulton Group N.A., Inc. 2024...

- Page 17 INSTALLATION SECTION 2 FBZ-IOM-2024-0927 WARNING Iron (oxides): Iron in any of its oxide or complex forms is undesirable in boiler water. Iron in its various forms can originate in the raw water makeup, All information in this manual is for condensate return water, or form directly in the boiler as a result of corrosion.

- Page 18 ++ If there is no preheat in the feedwater tank, feedwater piping between the feedwater tank and the boiler should be sch 80, SA 106B. +++ Welded/flanged pipe (3” and greater) may be sch. 40. © Fulton Group N.A., Inc. 2024...

- Page 19 INSTALLATION SECTION 2 FBZ-IOM-2024-0927 WARNING 3. All piping and piping components used should be suitable for the design Assure all electrical connections are temperatures, pressure and fluid used in the system. powered down prior to attempting 4. During the installation, ensure that no dirt, water, or residue from welding replacement or service of electrical is left in the system.

- Page 20 TUBING FOR SIGHT GLASS DRAIN WATER SAMPLE PORT SURFACE BLOWDOWN SURFACE BLOWDOWN DRAIN SHUT OFF CHECK VALVE VALVE FAST OPENING BLOWDOWN VALVE VALVE FIGURE 1 - NEAR BOILER PIPING (CONTINUED ON NEXT PAGE) 2-10 © Fulton Group N.A., Inc. 2024...

- Page 21 G-17-100003.2 INSTALLATION SECTION 2 FBZ-IOM-2024-0927 VENT TO ATMOSPHERE CONDENSATE RETURNS OVERFLOW VENT TO ATMOSPHERE FEEDWATER SIGHT MAKEUP TANK GLASS WATER SUPPLY COOLING WATER INLET STEAM PREHEAT CONNECTION THERMOMETER TEE FOR CHEMICAL BLOWDOWN QUILL INJECTION TANK THROTTLING THERMOMETER GLOBE VALVE SHUT OFF CHECK VALVE VALVE...

- Page 22 2. Do not use the feedwater pump as a support for the feedwater piping. This could add undue strain to the pump head. Use proper piping supports as necessary to support feedwater piping. 2-12 © Fulton Group N.A., Inc. 2024...

- Page 23 INSTALLATION SECTION 2 FBZ-IOM-2024-0927 WARNING 3. Do not use stainless steel within the Boiler External Piping (BEP) boundary. After the appropriate system tests have 4. Ensure all piping is done in compliance with all applicable codes. been satisfactorily completed, all hot pipework and vessels must be adequately 5.

- Page 24 10. Do not support discharge piping with the safety valve. Discharge piping must be supported adequately by appropriate means. 11. Fulton recommends the use of a drip pan elbow, as this provides the needed drainage and isolation from expansion as required.

- Page 25 INSTALLATION SECTION 2 FBZ-IOM-2024-0927 WARNING 6. Remove the glass packing nut, friction washer and glass packing from the fittings and place them in the same order on either end of the water gauge All information in this manual is for glass.

- Page 26 No warranty is implied or given by Fulton related to the use of this information. This information is to be used at the equipment owner’s risk.

- Page 27 Insulation resistance shall be measured utilizing 500 volts direct current (VDC). Individual circuits shall be greater than 5 megaohm. If measuring individual elements, insulation resistance shall be greater than 20 megaohm. If the electric heating element has a low megaohm reading, contact Fulton for factory repair. 2-17...

- Page 28 Assembly of Fulton Multi-Skid Systems Adhere to the following for multi-skid engineered systems: CAUTION 1. Refer to the Fulton mechanical/electrical drawings during assembly. Equipment damage can occur if proper precautions are not taken. 2. Ensure that equipment orientation allows for operation interface and maintenance.

- Page 29 INSTALLATION SECTION 2 FBZ-IOM-2024-0927 WARNING 9. If a header is supplied, mount the header as shown in the mechanical drawing. All information in this manual is for reference and guidance purposes, – NOTE: For piping supplied in sections, make up and connect hand tight until all and does not substitute for required professional training, conduct, and strict sections are in place to ensure sections align properly.

- Page 30 INSTALLATION SECTION 2 FBZ-IOM-2024-0927 THIS PAGE LEFT INTENTIONALL BLANK 2-20 © Fulton Group N.A., Inc. 2024...

- Page 31 OPERATION INTRODUCTION INSTALLATION OPERATION MAINTENANCE & TROUBLESHOOTING WARRANTY Questions? Please Contact Your Local Manufacturer’s Representative...

- Page 32 In addition to commissioning the boiler, the service technician will also familiarize boiler room personnel with the operation of all Fulton equipment. Personnel must be qualified to understand the basic operation and function of controls.

- Page 33 Consequently, if boil out is not accomplished prior to system operation, erratic professional codes and regulations. water level control and surging may occur. Fulton strongly recommends that a boiler chemical specialist be consulted for the purchase of chemicals for boiler cleaning.

- Page 34 Standard low water cutoff devices are Fulton level probes. Alternate cutoff devices are MM-150, MM-157, MM-193-7b. Fulton probe type low water cutoff devices have a built in 3 second time delay feature. Float type low water cutoff controllers have a 30-second delay. Test as...

- Page 35 ƒ High Limit Pressure Switch This information is for reference purposes Perform the following to test: only. Fulton Companies is not responsible for this product, including (but not limited 1. With electrial elements on and the boiler under pressure, lower the set to) its accuracy, reliability, and safety.

- Page 36 OPERATION SECTION 3 FBZ-IOM-2024-0927 THIS PAGE LEFT INTENTIONALLY BLANK © Fulton Group N.A., 2024...

- Page 37 MAINTENANCE INTRODUCTION INSTALLATION OPERATION MAINTENANCE & TROUBLESHOOTING WARRANTY Questions? Please Contact Your Local Manufacturer’s Representative...

- Page 38 CUT OFF LOW WATER by a qualified and knowledgeable CUT OFF* individual, such as a Fulton representative, qualified installer, service agency or gas supplier. Any potential warranty issues that arise after an unqualified individual has manipulated boiler parameters will not be considered.

- Page 39 MAINTENANCE & TROUBLESHOOTING SECTION 4 FBZ-IOM-2024-0927 WARNING 4. Check to be sure feedwater pump is working. Only qualified, trained electrical personnel 5. For float type water level control, blow down the float chamber. shall perform any activity on energized equipment. Lockout /tagout shall always 6.

- Page 40 3. If the feedwater is being treated by chemical compounds, make sure that this treatment is carried out carefully and according to the chemical supplier’s instructions. NOTE: Fulton recommends that the feedwater chemical treatment should be – added between the pump and the boiler. 4. Check water level in sight glass.

- Page 41 MAINTENANCE & TROUBLESHOOTING SECTION 4 FBZ-IOM-2024-0927 Recommended Semi-Annual 10. Replace hand hole gaskets as follows: » Remove the hand hole assembly using a 1-1/4” Maintenance Schedule tee handle wrench or 1-1/4” 1/2” drive socket wrench. See Figure The following steps should be carried out semi-annually: »...

- Page 42 Guidelines below are for the vessel only. For additional information regarding the steam boilers, control panels and accessories, please contact Fulton. ƒ Waterside Protection The best corrosion-control program of operating boilers and ancillary equipment can be completely offset by neglect during outages, as metal surfaces are often attacked and damaged by oxygen during shut-downs.

- Page 43 MAINTENANCE & TROUBLESHOOTING SECTION 4 FBZ-IOM-2024-0927 CAUTION The choice between wet and dry lay-up depends on the length of time a boiler If the gasket leaks while pressure is being and ancillary equipment will be out of service. Wet lay-up is recommended for built up, tighten only enough to stop short outages (30 days or less);...

- Page 44 5. Test the boiler water bi-monthly during the outage to ensure proper control levels are being maintained. 6. If a piece of equipment is not able to be isolated and airtight, a dry layup of that equipment may be necessary. © Fulton Group N.A., Inc. 2024...

- Page 45 MAINTENANCE & TROUBLESHOOTING SECTION 4 FBZ-IOM-2024-0927 Troubleshooting Refer to table below for troubleshooting. Problem Remedy Cause If a break is detected, shut off power and remove fuse. Replace with a Fuse new fuse of same voltage and amps. Turn power on. Trace wiring diagram through each component to verify power in each Voltage stage.

- Page 46 High dissolved solids Blowdown schedule High alkalinity in boiler water Poor Steam High organics in boiler water Adequate blowdown schedule or over feeding of water treatment Quality chemicals. High total dissolved solids in boiler water 4-10 © Fulton Group N.A., Inc. 2024...

- Page 47 WARRANTY INTRODUCTION INSTALLATION OPERATION MAINTENANCE & TROUBLESHOOTING WARRANTY Questions? Call (315) 298-5121, or visit us online at www.fulton.com...

- Page 48 Fulton be liable for any consequential, incidental, special, punitive, or other indirect damages arising in any way including, but not limited to, loss of profits or business, even if Fulton has been advised of the possibility of such damages.

- Page 49 WARRANTY SECTION 5 FBZ-IOM-2024-0927 PAGE LEFT INTENTIONALLY BLANK Questions? Call (315) 298-5121, or visit us online at www.fulton.com...

- Page 50 Fulton Group N.A., Inc. Fulton Thermal Corporation is part of Fulton Group N.A., Inc., a global manufacturer of steam, hot water and thermal fluid heat transfer systems. ...

Need help?

Do you have a question about the FBZ Series and is the answer not in the manual?

Questions and answers