Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Carimali MYA ULTRA

- Page 1 MYA ULTRA Service Manual www.carimali.com...

-

Page 3: General Safety Warnings

The weighted, equivalent sound pressure level is below 70 dB. After unpacking the machine, verify its integrity. In case of damage or doubts about the packaging contents, please contact the CARIMALI Service Centre. Handle the machine with care to prevent the risk of impacts or falls that may cause damage. - Page 4 Keep packaging parts (box, inner protections, etc.) out of reach of children since they are potentially dangerous. Do not dump those parts into the environment, but dispose them according to applicable regulations. This symbol on the product or on the packaging indicates that the product shall not be treated as household waste, as it shall delivered to an authorised waste collection point for recycling of electric and electronic devices.

- Page 5 Do not pull the power cord to unplug the machine from the electric socket. WARNING The machine can be used by children aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they have been given supervision or instruction concerning use of the appliance in a safe way and understand the hazards involved.

- Page 6 Once the machine is no longer in use or idle for any length of time, it is necessary to drain the boiler tanks. Contact a qualified service engineer or the CARIMALI Service Centre. When required and in case of operations not described in this...

- Page 7 2. INTRODUCTION This manual is a basic component for the use of the machine. It contains instructions and information about handling and usage of the machine in safety. 2.1 Symbols used in the manual Personal injury and Risk of electrical shock safery instructons Risk of scalding Risk of pinching hands...

- Page 8 2.2 Intended use This machine was designed and manufactured for dispensing: ● Coffee ● Cappuccino ● Milk ● Hot water ● Steam The machine is intended for professional use, such as: ● Refreshment areas in shops, office and environments ● Holiday farms ●...

-

Page 9: Description Of The Machine

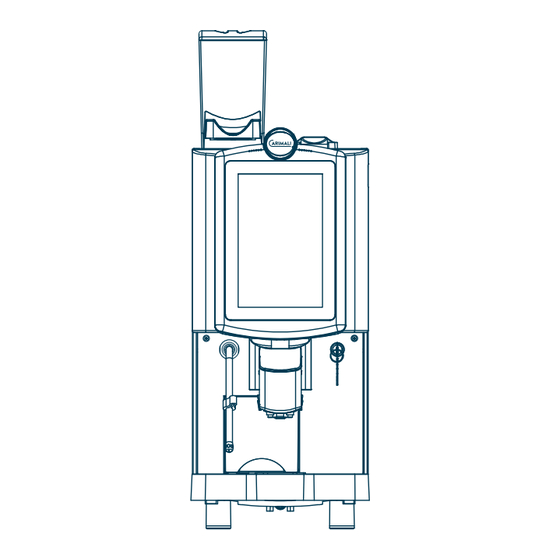

3. DESCRIPTION OF THE MACHINE 3.1 General description: Coffee hopper Decaf door Touch screen display Front door Milk tube Door lock Adjustable delivery noozles Steam wand Ground drawer Dip Tray 3.2 Identification: Type Voltage .... - Page 10 3.3 User interface (SAMPLE PAGE) time Wi-fi connection Alarm 1:40 Info bar SELECT DRINK Info menu Language page number 1:40 SELECT DRINK Espresso 2 Espresso Scroll up/down in certain pages Latte Milk Cappuccino Steam Scroll left/right (only in the select drink page)

-

Page 11: Installation

– The connection to water mains must be done by a skilled technician in compliance with applicable regulations. Use the certified CARIMALI HOSE (95.01889). -To prevent damages to the hydraulic circuit, the optimal range of the water inlet from the mains is between 10 and 15 FrenchDegrees (60/80 Mg/l Ca). - Page 12 30-70% not condesating -Reserve a space for the machine In closed 5°C< <30°C environments with temperature between 200mm 5°C - 30°C. Considering the dimensions listed in the previous page the minimum distance from walls or other objects must be 20 mm, to facilitate ventilation. Surface myst be Horizontal, flat and stable, at a minimum height above 950 mm.

- Page 13 In case of prolonged storage at a temperature below 2 °C, empty the machine hydraulic system. Do not switch the machine on be fore having reconditioned it for at least 1 hour at a suitable room temperature. If it is installed in WARNING areas with room temperature above 30 °C, malfunctioning may occur.

- Page 14 U s e O N L Y t h e certified CARIMALI WARNING hose. water drain WARNING Water inlet The water mains pressure must not exceed 6 bar (0.6 Mpa). If the mains pressure exceeds such limit, install a pressure reducer.

- Page 15 4.5 Dip tray assembling Hold the dip tray with 2 hands and push it inside its seat as per the picture. 4.6 Coffee hopper assembling Insert the metal tongue in the hole and then push down the hopper. Fix tightly the screw on the hopper and check it cannot be removed by hand.

-

Page 16: First Start-Up

5. FIRST START-UP 1:40 Power On Setup Help Remove the ground drawer, The following screen will appear. press the ON/Off switch. Wait Refer as “power on” page. for the software to load. 5.1 Machine configuration set-up From the “Power On” page press “SETUP”, the technician password is required. - Page 17 Machine configuration Insert the serial number of the machine, you can Machine model Mya 10p find it on the carton box or on the data albel Serial number sticked on the machine. 0000000000000 Installation date Insert the date of the installation at user place. 2016.01.01 Main power Select the mains voltage...

- Page 18 After the machine is finish press the “back” icon to go back to the “power on” page. 5.2 Boiler filling After the water main is connected and the valve is open press “ Power On” on the display. 1:40 1:40 After you “Power Machine heating, please wait...

- Page 19 At the end of the first filling of the hydraulic circuit, empty the boiler and fill it again. This procedure allows to remove any dirt from the inner part of the circuit. For further information about the emptying of the boiler, HINT see the relevant paragraph.

- Page 20 5.5 Products filling Risk of injury If objects find their way into the bean hopper or grinder, splinters may be ejected, leading to injury. Never put any objects in the coffee bean hopper or grinder. WARNING For a better result the milk temperature must be below 4°C. HINT With additional fridge unit Coffee hopper...

-

Page 21: Operation

6. OPERATION When dispensing beverages and steam, hot liquid comes out of the spouts. The adjacent surfaces and spouts become hot. When dispensing beverages and steam, do not reach beneath the spouts. Do not touch the spouts immediately after dispensing. CAUTION Always place a suitable cup under the spout before dispensing beverages. - Page 22 Second product Preparing your drink... Abort delivery selection Espresso Delivery progress Delivering drink Preparing your drink... If you press the second product selection machine will go bank to drink selection and will show which products Espresso are available for dispensing together Steam (for Example Steam or Hot water).

- Page 23 6.1.1 Self service To turn on and off it is necessary to insert a password. In self-service mode the steam delivery is disable. Second product delivery is disable. Product abort is disable. Decaf door is disable. After the product is delivered display will show “Enjoy your drink” 6.1.2 Self service + MDB payment system To turn on and off it is necessary to insert a password.

-

Page 24: Beverage Setting

6.3 Switching OFF To switch off the machine acces to the info menu (see paragraph 5.4) and select “switching off the machine”. On the display the “power on” button will appear. If machine is set in Self-service mode a password is needed to confirm the operation After switching off from the software machine still have electrical connection to main parts. - Page 25 The setting page for each drink is made of several tab depending the type of drink you are going to set. First tab is general, the following tabs are for setting each ingredient and they are activate or de-activate accordingly the drink type.

- Page 26 Drink name Can be set any name for the drink by using the Cappuccino touch keyboard on the display. Change the icon of the product, multiple choices Drink icon are available. Set the price of drink (any currencies). Price € 0.00 Deliver a drink as per the settings.

- Page 27 Enable/disable the possibility to use the decaf Decaffeinated door for this drink. Set how many times the machine will deliver this Repetitions ingredient any time the drink is selected. For example, if repetitions is set at 2 the coffee will be delivered 2 times following the parameter in this tab, including extra-water.

- Page 28 7.1.3 Milk This tab is available if Drink selection is “Milk” or “ Coffee+milk” and it is used for setting the milk. This tab is divided in two parts, first (Pre) is for the milk delivered before or together the coffee, the second part (Post) is for the milk dispensed after the coffee.

- Page 29 Steamed milk (pre or post) Quantity of hot milk (no foam) to be delivered defined by the seconds the milk pump is on. Pump speed (%) Pump speed is how fast the pump turn and it is define of percentage on the maximum speed pump. Quantity of the milk foam to be delivered defined by Foamed milk (pre or post)

- Page 30 7.1.4 Water This tab is available if Drink selection is “Hot water”. Setting for button XX Water time (s) General Water Quantity of Hot water delivered set as Water Water time (s) time (sec). 7.1.5 Steam This tab is available if Drink selection is “Steam”. Setting for button XX Steam time (s) General...

- Page 31 7.2 Manual settings Manual regulation of the machines are four, grinder setting, coffee flow settings, froth regulation and hot water mixing regulation. Grinder Hot water mixing Coffee flow Froth regulation 7.2.1 Grinding settings To set the coarseness of the coffee open the front door and regulate it by turning the knob clockwise for more coarse and anti-clockwise for more...

- Page 32 7.2.2 Flow control of coffee dispensing To set flow of the coffee adjust the nut on the output assembled on the group. Rotate clockwise to reduce speed or counter-clockwise to increase it. 7.2.3 Froth regulation The regulator increase/decrease the quantity of air going to the milker.

-

Page 33: Machine Cleaning

8. MACHINE CLEANING Inadequate cleaning can result in food residues accumulating in the machine and at the spouts, there by contaminating products. Do not use the machine unless it WARNING has been cleaned according to the instructions. OPERATION TYPE OF OPERATION FREQUENCY Display cleaning Manual... - Page 34 8.1.2 External machine surfaces cleaning Do not use solvents, chlorine-based products or abrasive agents to carry out this operation. Do not clean the machine with direct water jets. Never immerse the CAUTION machine in water or other liquids. Some parts of the machine may be hot. WARNING Proceed with the daily external cleaning of the machine using a cloth dampened with water and dry thoroughly.

- Page 35 To remove the hopper open the screw (1), close the hopper door (2) and then lift it up from front (3) and then move it out . Clean with a solution of hot water and sanitizing product. Rinse and dry thoroughly.

- Page 36 8.2 Functional parts cleaning To access to the cleaning menu of the machine press the info icon Choose manual cleaning from the info menu Manual cleaning Display_cleaning START SKIP The cleaning menu will be Power cleaner SKIP START shown, you can start or skip the suggested cleaning.

- Page 37 Press “Start” on the POWER CLEANER, follow the instructions on the display. Insert the milk hose support on the dip tray Remove the milk tube from the container and place in the support on the dip tray. After you perform this operation press “NEXT”...

- Page 38 Right after you select the ALL IN ONE the machine will ask you if you want turn off the machine when the cleaning is complete. Press (YES) to switch the machine back on at the Power On screen at the end of washing, or press (NO) to switch the machine on at the drinks selection screen.

- Page 39 Follow the instruction on the display : 1- Prepare the cleaning solution in 600ml of water (check the cleaner instruction for the dilution); 2- Press “next”, machine will perform the cleaning; 3- Replace the cleaner solution with clean water and press “next”; Wait for the process to finish.

-

Page 40: Configurations Menu

9. CONFIGURATIONS MENU CONFIGURATIONS From the “power on” page press setup and insert correct password to access the “configuration menu”. Read doses data System data System clock Service Alarm history Display regulation According to the password Machine parameters Change password Group movement level some items may be not available. - Page 41 Reset counter A as per the name will reset the counter A, select this item and confirm the reset of the doses counter A. 9.2 System data This menu shows the number of cleaning performed . Counters can be reset by pressing the “Reset” button and confirming the operation.

- Page 42 Clock managment Scroll down to access to the Automatic Enable auto start-up start-up settings. This function will turn on Set auto switch on time: 7:04 and off the machine accordingly to the time 8:05 set. 9:06 Switch off the machine: 7:04 To enable this function set “Enable auto 8:05...

- Page 43 9.4 Service This menu is related to the cleaning and service of the machine. Can be set a fixed time for the cleaning, set auto- rinse frequency of the group and milker. Service 9.4.1 Clean-rinse Clean rinse settings Cleaning time Clean-rinse Cleaning time 1 For better drinking results...

- Page 44 Example: if I set the “cleaning time” at 3p.m. and “Cleaning cycles alarm” to zero means that at 3 p.m. no any product can be delivered is the cleaning is not performed. If “Cleaning cycles alarm” is set to 10 means that if after 3 p.m. you can deliver other 10 drinks before the machine stop to deliver and cleaning must be performed.

-

Page 45: Alarm History

Set the reminder of the inspection. A warning will be Machine service inspection Service check By date shown on the display when the date is reach. It can be Next inspection 2021.05.27 disable by pressing on service check and choose disable. -

Page 46: Machine Parameters

Screen-saver, video fro delivery, pictures and background are pre-set files saved in the media library of the software. From this menu’ is only possible to Enable/disable those items. To change then see the related section. 9.7 Machine parameters Menu’ where to set most of the important parameters of the machine such as temperature, payment and additional units Machine parameters... - Page 47 9.7.3 Temperature Machine parameters Measure unit ºC or ºF can be set General Temperature unit °C Prices Steam boiler temperature (preset at 124ºC) Steam temperature Temperature °C Temperature Energy saving Energy saving will reduce the temperature of the boiler in Milker ENERGY SAVER 1 Time-out (m)

- Page 48 9.7.5 Unit plus Machine parameters Parameter settings for additional units. Fridge General In order to activate this tab the additional unit Fridge temperature °C Prices must be first set in the “machine Fridge alarm temperature °C Temperature Fridge alarm temperature time-out (m) configuration”, see the related paragraph.

-

Page 49: Actuator Test

Press the buttons to move the selected part of the group. Group movement Higher motor DOWN Visualization field of the electrical pulses and the Pulses:30 movement direction. Direction: DOWN Espeller LEFT RIGHT Direction: LEFT Lower motor DOWN Pulses:29 Direction: UP Lower motor pulse regulation. -

Page 50: Machine Configuration

Actuator test Actuator test Actuators 3 Rotation direction Milk pump Steam heating of the milk pump Charge Direction Milk solenoid valve Speed Air solenoid valve Press here to test Milker rinsing solenoid valve the actuator. Filling up solenoid valve Milk pump speed Steam noozle solenoid valve Power cleaner solenoid... - Page 51 Machine configuration Insert the serial number of the machine, you can Machine model Mya 10p find it on the carton box or on the data albel Serial number sticked on the machine. 0000000000000 Installation date Insert the date of the installation at user place. 2016.01.01 Main power Select the mains voltage...

- Page 52 9.13 Preset configuration Preset all the parameters accordingly to the type of preset chosen. Preset configuration The preset of parameters can be performed at Preset: different levels: Please select preset type • SERVICE: It resets the accessible parameters Factory with pass word of level 3. Technician •...

-

Page 53: Preset Configuration

10. LANGUAGE SELECTION AND HELP MENU’ 10.1 Preset configuration To set the language from the “Power on” page press the flag icon on the top right. 1:40 1:40 Italiano English Deutsch A menu’ will the available Mexican languages will appear. Select one of the available Power On Power On... - Page 54 11 SOFTWARE UPGRADE - DATA DOWNLOAD/UPLOAD 11.1 USB pendrive connection Turn Off the machine, open the door and connect the USB pendrive to the USB port 11.2 Software upgrade Copy the software folder in a blank USB. Do not rename the folder, it must be something similar to this: U:\Carimali7SW391_master206.

- Page 55 Coffee service Wait the machine to perform the software System upgrading upgrade, one it is finish machine will reboot, disconnect the USB drive. Master board statu upgrading STATUS: Entering in boot mode.. 11.3 Data download/upload Connect a blank USB to the machine (see section 11.1). Wait for the software to load and insert the technician password.

-

Page 56: Password Level

12 PASSWORD LEVEL 12.1 Access level with password LEVEL USER DEFAULT PASSWORD Waiter 11111 Roaster 22222 Service 33333 Technician 44444 12.2 Function accessible according to the level password CONFIGURATION MENU TABS READ DOSES DATA Dose counter A Dose counter B Reset dose counter A SYSTEM DATA SYSTEM CLOCK... - Page 57 13 OPERATIONAL ALARM If any alarm occur the icon on the Info bar will switch red. press that icon to see error details 1:40 SELECT DRINK 13.1 Error code list 10 HIGHER MOTOR PULSES Causes: the upper motor encoder has not received pulses for 3 seconds, since the motor is not running Result: the machine is switched OFF.

- Page 58 Check the following: Gear motor defective Gear motor not aligned with the brewing chamber Faulty master card. 13 LOWER MOTOR ERROR 13 Causes: a mechanical shutdown occurred to the gear motor or the lower piston encoder is not reading the impulses correctly Result: the machine is switched OFF.

- Page 59 Check the following: Level probe (SLC) is dirty, so isolated from the water (the complete filling of the boiler is checked) no water from mains low water pressure faulty motor pump faulty filling solenoid valve incorrect electrical connections (level probe -SLC- misconnected wire).

- Page 60 leakage from the by-pass solenoid valve. leakage from the tubes of the coffee hydraulic circuit leakage from the no-return valve 38 STEAM BOILER TEMPERATURE ALARM This alarm is visualised on display by code 38 First case: the temperature inside the steam boiler has reached the limit value of 129°C (264.2°F) or more.

- Page 61 clogged group piston filters (coffee is not dispensed) faulty group solenoid valve (coffee is not dispensed) clogged inlet filters (coffee is not dispensed) blocked flowmeter (coffee is not dispensed) or faulty flowmeter (coffee dispensed continuously) faulty electrical connection (coffee dispensed continuously). Note: If the coffee is dispensed continuously, use the machine as if it were manual: press the required key to start up the dose, then press the same key to stop the dose being dispensed, after checking the amount...

-

Page 62: Clock Error

Solution: Carry out “PRESET CONFIGURATION DATA” procedure Insert new software by means of P.C. 63 CLOCK ERROR Check the following: run down battery faulty master board 65 MOTOR BLOCK Causes: a mechanical block occurred to the Mixer Result: the machine is switched OFF Check the following: Mixer motor defective Master board defective... -

Page 63: Sim Card Error

80 SIM CARD ERROR Only for machine with GSM Modem KIT Check the following : SIM card not inserted into GSM Modem faulty SIM card SIM card not properly inserted faulty GSM Modem 81 GSM : OFF Only for machine with GSM Modem KIT Check the following : check the power supply of the GSM modem installed in the coffee machine... -

Page 64: Group Maintenance

91 GROUP MAINTENANCE Cause: the group has reached the number of programmed cycles (see Service chapter). Result: none. Solution: check the group and cancel the alarm following the procedure of the chapter info reset. 92 MAINTENANCE Cause: the machine has reached the number of programmed cycles or the inspection date (see Service chapter). -

Page 65: Decommissioning And Disposal

8. DECOMMISSIONING AND DISPOSAL Should you decide not to use the machine any longer, unplug it and then make it inoperative by cutting off the power cord. CAUTION The disposal of the machine is not responsibility of the Manufacturer and must be carry out in compliance with the applicable regulations. - Page 66 Carimali Catering Equipment (Suzhou) Co. Ltd., 1801# Pangjin RD, Building T2, Wujiang Suzhou China 215200.

Need help?

Do you have a question about the MYA ULTRA and is the answer not in the manual?

Questions and answers