Table of Contents

Advertisement

Quick Links

MC-1, MC-2, MC-3 and ME-1, ME-2, ME-3 Series

1.

GENERAL INTRODUCTION ................................................... 1

1.1. Document Purpose ............................................................... 1

1.2. Product Purpose ................................................................... 1

1.3. Product Mounting and Location ............................................ 1

2.

PRODUCT DESCRIPTION ....................................................... 2

3.

INSTALLATION ...................................................................... 10

3.1. Inspecting the Product ........................................................ 10

3.2. Following and Using Safety Precautions.............................. 10

3.3. Obtaining Tools and Equipment .......................................... 10

3.4. Preparing the Installation Site ............................................. 10

3.5. Lifting the MC-x/ME-x ........................................................ 11

3.6. Mounting the MC-x/ME-x ................................................... 11

3.7. MC-x/ME-x Wiring and Equipment...................................... 13

3.8. Modular Expansion Units ................................................... 18

3.9. Add-on Battery Chamber Kits.............................................. 21

3.10. Conduit Seals ..................................................................... 22

3.11. Verifying the Installation ..................................................... 22

4.

PERIODIC MAINTENANCE .................................................. 22

5.

TECHNICAL ASSISTANCE AND REPAIR SERVICE .......... 22

6.

WARRANTY & CUSTOMER SERVICE ................................. 22

7.

SPECIFICATIONS ................................................................... 22

7.1. Regulatory Specifications .................................................... 22

7.2. Product Specifications ........................................................ 23

7.3. Available Options ............................................................... 24

7.4. Configuration Weights ........................................................ 25

1. GENERAL INTRODUCTION

1.1.

Document Purpose

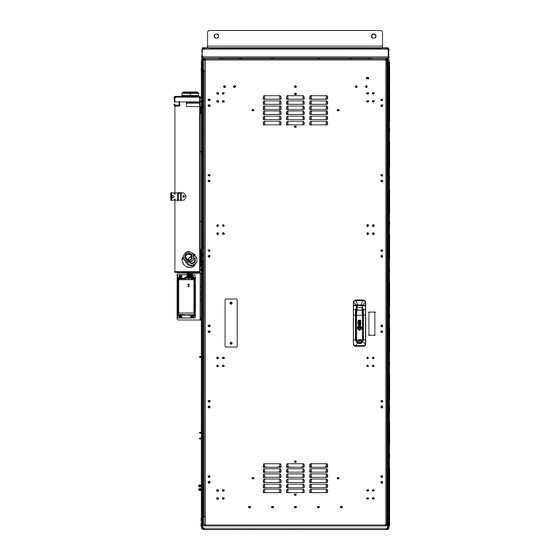

This document provides general information for the MC-1, MC-2, and MC-3 series of the Charles Industries' Modular Cabinets, as well as

the ME-x Modular Expansion units. Figure 1 shows an example of an MC-3 series cabinet.

Hereafter, the Charles MC-1, MC-2, and MC-3 Series Modular Cabinets will be referred to as the "MC-x." The ME-1, ME-2, and ME-3

1.2.

Product Purpose

The MC-x/ME-x consists of a protective enclosure for an integrated system of electronic components and equipment that can serve fiber

and copper interfaces. This series is part of Charles Industries' line of Modular Cabinets. The modular enclosures can combine multiple

bays to support a variety of applications. Bays can be added in the factory or in the field, creating a versatile solution that can grow with

changing applications. If purchasing units for field expansion, order the ME-x series.

1.3.

Product Mounting and Location

This enclosure is suitable for outside plant-type (OSP) locations and those that may require NEC compliance. The outdoor, weather-

resistant MC-x/ME-x is to be mounted on a concrete or composite pad (Charles CPAD). The installer connects the power, fiber, and copper

connections. Detailed mounting and installation information is covered in Section 3.

ME-x cabinets are very similar to the MC-x bays, except that the ME-x bays do not have side panels. See Section 3.8.

©Copyright 2024 Charles Industries LLC. All rights reserved.

Availability of features and technical specifications herein are subject to change without notice.

Charles is a registered trademark of Charles Industries.

Charles Modular Cabinet

General Description and Installation

Modular Expansion units will be referred to collectively as the "ME-x."

Figure 1

-NOTE-

LT-MCX

7

th

Printing, February 1, 2024

Front View of an MC-3 Bay

Page 1 of 25

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Amphenol Charles MC-1 Series

-

Page 1: Table Of Contents

LT-MCX Printing, February 1, 2024 Charles Modular Cabinet MC-1, MC-2, MC-3 and ME-1, ME-2, ME-3 Series General Description and Installation GENERAL INTRODUCTION ........... 1 1.1. Document Purpose ............... 1 1.2. Product Purpose ..............1 1.3. Product Mounting and Location ..........1 PRODUCT DESCRIPTION ............ -

Page 2: Product Description

LT-MCX 2. PRODUCT DESCRIPTION The MC-x can contain multiple bays. The series has multiple bay types, and these bays can have thermal and incoming power distribution units mounted on the cabinet exterior. See section 7.3 for a full description of the available options. The MC-1, MC-2, and MC-3 differ in their external dimensions. - Page 3 LT-MCX 7.82 97.31 17.90 7.82 32.00 36.00 73.96 (3) Ø1.75/2.50 KNOCKOUTS 26.50 (2) Ø2.50/3.60 KNOCKOUTS (8) Ø0.88 KNOCKOUTS 20.50 4.54 15.46 (4) Ø0.75 MOUNTING HOLES Figure 3 MC-2/ME-2 Equipment Bay, Single Bay Dimensions (in inches) This example includes no thermal or incoming power distribution unit mounted on the exterior. This option has front and rear doors.

- Page 4 LT-MCX 7.82 97.31 17.90 7.82 32.00 36.00 82.70 (3) Ø1.75/2.50 KNOCKOUTS 26.50 (2) Ø2.50/3.60 KNOCKOUTS (8) Ø0.86 KNOCKOUTS 16.50 4.54 15.46 (4) Ø0.75 MOUNTING HOLES Figure 4 MC-3/ME-3 Equipment Bay, Single Bay Dimensions (in inches) This example includes no thermal or incoming power distribution unit mounted on the exterior. This option has front and rear doors.

- Page 5 LT-MCX Bay Type Height (X) No. Battery Trays No. of Rack Rails Battery Bay MC-1 61.80 MC-2 74.10 MC-3 82.70 66.89 Battery Bay with Rack Rail Space MC-1 61.80 MC-2 74.10 MC-3 82.70 32.00 36.00 (4) Ø0.75 MOUNTING HOLES 25.00 4.54 15.50 22.00...

- Page 6 LT-MCX (2) LIFTING BRACKETS SOLAR SHIELD HVAC TWIST LOCK (IF EQUIPPED) GFCI OUTLET DOOR ALARM AND HVAC CUTOFF SWITCHES (IF EQUIPPED WITH HVAC) 3PT LATCH, 216 STYLE PADLOCKABLE DOOR HANDLE (BOTH DOORS) WIND LATCH (BOTH DOORS) ALARM TERMINAL (2) 2x8 GROUND BARS BLOCK (NOT VISIBLE IN THIS VIEW) DOOR MOUNTED...

- Page 7 LT-MCX (2) LIFTING BRACKETS SOLAR SHIELD ALARM TERMINAL BLOCK OVERHEAT THERMOSTAT BUS BARS TOP: -48VDC POWER BATTERY BOTTOM: RETURN BREAKER ALARMS BREAKERS FOR LIGHT DOOR ALARM AND AND THERMAL HVAC CUTOFF SWITCHES SYSTEMS (IF EQUIPPED WITH HVAC) 3PT LATCH, 216 STYLE PADLOCKABLE DOOR HANDLE BATTERY...

-

Page 8: Fiber Management

LT-MCX DOOR ALARM SWITCH (ALL DOORS) (2) LIFTING BRACKETS LGX PANELS MODULAR ALARM PANEL 19”/23” ADJUSTABLE RACK RAILS (FRONT AND REAR) FIBER MANAGEMENT SOLAR SHIELD 3 PT LATCH 216 STYLE PADLACKABLE DOOR HANDLE WIND LATCH (ALL DOORS) Figure 8 MC-x Fiber Bay Components Front and rear doors shown. - Page 9 LT-MCX (2) LIFTING BRACKETS SOLAR SHIELD POWER SHELF (IF EQUIPPED) BATTERY RETAINER BRACKETS BATTERY DISCONNECT BREAKERS BATTERY TRAYS WIND LATCH DOOR ALARM SWITCH VENTS ON REAR BATTERY BREAKER ALARM PANEL DOOR MOUNTED 23” HORIZONTAL THERMAL RACK MOUNT SPACE SYSTEM (NO. OF RU (IF EQUIPPED, DEPENDS ON BAY THERMOSIPHON...

-

Page 10: Installation

LT-MCX 3. INSTALLATION 3.1. Inspecting the Product The MC-x/ME-x is shipped mounted upright on a skid. Remove the bolts, unpack the unit, and dispose of the packaging material. -INSPECTION NOTE- Visually inspect the unit for damages prior to installation. If the equipment was damaged in transit, immediately report the extent of the damage to the transportation company. -

Page 11: Lifting The Mc-X/Me-X

LT-MCX 3.5. Lifting the MC-x/ME-x See section 7.3.1 for MC-x/ME-x weights. Use the formula in section 7.3.1 to calculate the maximum SLING weight of customer supplied equipment that can be added to the MC-x/ME-x prior to lifting. Charles ANGLE recommends the following procedure for lifting the MC-x/ME-x. >... - Page 12 LT-MCX 3.6.2. Constructing a New Pad Use only concrete for new pad construction. Do not use substitute materials since they lack the rigidity for MC-x/ME-x • placement. • Observe local building practices for pad construction. Charles recommends that the pad should extend a minimum of 8” beyond the MC-x/ME-x base on all sides.

-

Page 13: Mc-X/Me-X Wiring And Equipment

LT-MCX 3.6.3. Mounting the MC-x/ME-x on a Pad Four customer supplied, corrosion resistant, 1/2”-13 hex head bolts with anchors are required for mounting each MC-x/ME-x bay to the concrete pad. Note: if mounting a battery bay, then use 5/8” Grade 8 bolts and washers with the mounting hardware. - Page 14 LT-MCX 3.7.2. AC Voltage Connection The MC-x equipment bay is available with an AC load center (multiple position options available). If a load center is selected, then incoming 208/240A voltage is connected to the main circuit breaker. The maximum wire size is 2/0AWG (or 250kcmil for 200A load centers).

- Page 15 LT-MCX 3.7.5. Available Thermal Systems These are listed in section 7.3 under Item D, Bay Thermal. In that configuration matrix, each thermal unit is given a code. Codes from the configuration matrix are shown here for reference. Code 2: 2000BTU 48VDC HVAC The 2000BTU DC powered HVAC compressor and fans are PID (proportional integral derivative) controlled.

- Page 16 LT-MCX Code C: 12000BTU 48VDC HVAC The 12000BTU DC powered HVAC compressor and fans are PID (proportional integral derivative) controlled. The compressor turns on at C at low speed and will increase/decrease speed as needed to maintain this temperature. The compressor turns off when the internal °...

- Page 17 LT-MCX Code J: 4000BTU 120VAC HVAC and Code U/Code Y: 10000BTU 240VAC HVAC The 4000 and 10000 BTU AC powered HVAC is driven by a built-in controller and temperature sensor. The factory cooling cycle turns on at 30°C and off at 27 C.

-

Page 18: Modular Expansion Units

LT-MCX Avoid placing items in front of the thermosiphon’s return and supply vents. Maintain a minimum of 6” clearance to enable proper air flow. 3.7.6. Alarm Block Connections A 10-position, labeled alarm block monitors components in the equipment compartment. See the electrical diagram on the inside of the MC-x/ME-x front door for information about alarm connections. - Page 19 LT-MCX 3.8.2. Mounting the ME-x Bay Views in this section have all doors hidden for clarity. The side panel on the MC-x installation is held in place by nuts on the inside of the cabinet. Remove the side panel from the MC- x bay by removing these nuts (Figure 19).

- Page 20 LT-MCX Mount the ME-x bay as described in the Mounting section of this document. Use the (18) 1/4-20 hex screws, washers, and nuts that ship with the ME-x bay to secure the two bays together (Figure 21). Position hardware so that the screws and washers are inside the ME-x bay and the nuts are inside the MC-x bay.

-

Page 21: Add-On Battery Chamber Kits

LT-MCX 3.9. Add-on Battery Chamber Kits An add-on battery chamber kit can be ordered with the MC-x/ME-x cabinets. The battery kit is a chamber with a single battery tray, removable front and rear access panels, and a 100W, thermostat-controlled heater pad. All chambers also include a 100A battery disconnect breaker. -

Page 22: Conduit Seals

LT-MCX 3.10. Conduit Seals All internal and external conduit openings on the MC-x/ME-x must be completely sealed with a duct seal compound to prevent moisture from entering enclosure. Battery bays (if present) must be internally sealed from the equipment bays to prevent outgassing from the batteries into the equipment BEFORE bays. -

Page 23: Product Specifications

LT-MCX 7.2. Product Specifications Physical Dimensions MC-1/ME-1: 62”Hx32”Wx32”D (single bay) MC-2/ME-2: 74”Hx32”Wx36”D (single bay) MC-3/ME-3: 84”Hx32”Wx36”D (single bay) 19”/23” Equipment Rack Space and Hole MC-1: 54.25” (31RU) rack spacing Spacing (Adjustable) MC-2: 64.75” (37RU) rack spacing MC-3: 75.25” (43RU) rack spacing All with tapped EIA #12-24 mounting holes on front and rear rails Maximum Supported Weight Equipment Bays: 11 lbs. -

Page 24: Available Options

LT-MCX 7.3. Available Options For Values A through E, choose desired option from the corresponding column below. A. Series D. Bay Thermal E. Power 1 = 62”H x 32”W x 32”D 2 = 2000 BTU 48VDC HVAC C = 12 Position AC Load Center 2 = 74”H x 32”W x 36”D 5 = 6000W Thermosiphon (CTMS) D = 30 Position AC Load Center,... -

Page 25: Configuration Weights

LT-MCX 7.4. Configuration Weights To calculate the approximate weight of a configuration, use the individual component weights shown below. Component Weight (lbs.) Bay Styles E, MC-1 Equipment Bay E, MC-2 Equipment Bay E, MC-3 Equipment Bay B, MC-1 Battery Bay B, MC-2 Battery Bay B, MC-3 Battery Bay D, MC-2 Battery Trays with Rack Space Above...

Need help?

Do you have a question about the Charles MC-1 Series and is the answer not in the manual?

Questions and answers