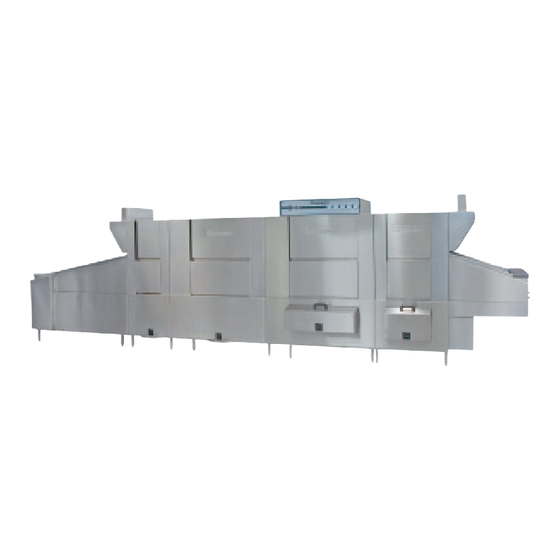

Champion EUCC Series User Manual

E series high temperature upright conveyor dishwasher

Hide thumbs

Also See for EUCC Series:

Table of Contents

Advertisement

Installation and Service Guide with Service Replacement Parts

Beginning with Serial No. J2089 and above

EUCCW-8 / EUCC-8

EUCCW-6 / EUCC-6

EUCCW-4 / EUCC-4

www.championindustries.com

P.O. Box 4149

Winston-Salem, NC 27115

336/661-1556 Fax: 336/661-1660

Toll-free: 800.858.4477

2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Toll-free: 800.263.5798

E series

High Temperature

Upright Conveyor Dishwasher

Models:

EUCCW

29" wide conveyor with a 4', 6',or 8'

center section

EUCC

24" wide conveyor with a 4', 6',or 8'

center section

Dishwasher serial no.

Issue Date: 5.09.07

Manual P/N 114254 rev. A

For machines beginning with S/N J2089 and above

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Champion EUCC Series

- Page 1 Installation and Service Guide with Service Replacement Parts Beginning with Serial No. J2089 and above E series High Temperature Upright Conveyor Dishwasher EUCCW-8 / EUCC-8 Models: EUCCW 29" wide conveyor with a 4', 6',or 8' center section EUCC 24" wide conveyor with a 4', 6',or 8'...

- Page 2 For future reference, record your dishwasher information in the box below. Model Number__________________________ Serial Number_______________________ Voltage________________Hertz_____________ Phase__________________ Champion Service Agent __________________________________ Tel:______________________ Champion Parts Distributor _________________________________ Tel:______________________ For all models: The data plate mounts to one side of the top-mounted control cabinet.

-

Page 5: Revisions To This Manual

Revisions to this manual Revision Revised Serial Number Revision Date Pages Effectivity Description 3.16.07 J2089 Released first edition 7.06245 3.22.07 J2089 Rev. parts list format 7.03226... - Page 6 This manual covers two models: EUCCW Electric high temperature flight-type conveyor dishwasher with built-in EUCC electric booster in 40° F/22° C rise or an optional 70° F/39° C rise booster. EUCCW Steam high temperature flight-type conveyor dishwasher with built-in EUCC steam booster in 40°...

-

Page 7: Table Of Contents

E series Upright Conveyor Dishwashers Revisions to this manual ____________________________________________________________ i Limited Warranty _______________________________________________________________ iv Operating Instructions ___________________________________ Construction How to Operate your Dishwasher: Step by Step Cleaning and Maintenance Troubleshooting Installation _____________________________________________ The plumbing and electrical connection diagram, (P&E). -

Page 8: Limited Warranty

"Champion" and installed within the United States and Canada to be free from defects in material and workman ship for a period of one (1) year after the date of installation or fifteen (15) months after the date of shipment by Champion, whichever occurs first. - Page 9 Contact your supervisor immediately if you have questions about the dishwasher. Contact your local authorized Champion service agency for technical support. Our National Service Department provides 24 hour support 365 days a year with a Toll-free number in the United States.

-

Page 10: Operating Instructions

What if you stood in your front yard while a friend stood in your back yard in order to plan a project. You tell him to move to the right, but he keeps moving to the left. We know what is wrong. You and he have a different reference point in relation to the house. - Page 11 _________ Operating Instructions All Models 1. The diagrams below show an example of one type of upright conveyor dishwasher. Your dishwasher may be different; however, the basic design is similar. 2. Study the diagrams and see if you can match features on your dishwasher.

- Page 12 (Consult your chemical supplier for instructions). 3. Check the interior of the dishwasher for foreign objects and remove. 4. Turn on the water supply to the dishwasher. 5. Turn on the main power switch at the building service disconnect switch.

- Page 13 Close all drains. Make sure floats, overflows, drain screens, and pump screens are clean and in place. Always slide the pump screens up and lift out. Check the bottom to make absolutely sure they are clean. Replace in reverse order...

- Page 14 To install the curtains: Locate the curtain hooks in each section. Place the curtain rod in the rear hook, then lift the opposite end of the curtain rod and place it in the front hook. Place the 19" long curtains at each end of the dishwasher.

- Page 15 Make sure all wash arm assemblies are locked in place. The auxiliary rinse section is equipped with an upper and lower rinse arm. Refer to the illustrations on the next page for a more detailed view of the spray arms.

- Page 16 Operation: Step by Step Operating Instructions ________ Operation: Step by Step TO REMOVE UPPER SPRAY ARM: TO INSTALL UPPER SPRAY ARM: LOCK RELEASES LOCKING LOCKING SLOT SLOT PREVENTS SPRAY ARM FROM DROPPING LOCKING LOCKING SLOT SLOT TAB PREVENTS SPRAY ARM...

- Page 17 Position the spray pipe so the rinse nozzle points toward 10 o'clock. Push the rinse pipe forward. Turn the auxiliary rinse pipe 1/4 turn clockwise to lock it in place. Note: The final rinse pipes are permanently installed and do not require assembly.

- Page 18 Operation: Step by Step Operating Instructions ________ Operation: Step by Step Install the scrap screens. 18. Install the scrap baskets if applicable. Make sure the screens are fully seated to the rear of the dishwasher and interlocked into the scrap basket.

- Page 19 Operation: Step by Step _________ Operating Instructions Operation: Step by Step Close all doors.

- Page 20 R-L shown The prewash tank is not heated so its temperature may be lower than the wash tank. This is okay. The final rinse temperature is checked when the dishwasher conveyor belt and wash pumps are running during normal operation.

- Page 21 Push the GREEN START BUTTON NOTE: to start the Pushing the green start conveyor belt. button: 1. Starts the conveyor belt. Push the RED STOP BUTTON to stop the conveyor belt. The wash pumps stop. Tank heaters continue to operate.

- Page 22 Load-end Start-Stop Station The person unloading the wares also has the ability to start and stop the dishwasher using the optional unload start-stop station (if it is installed .) Push the GREEN START BUTTON to start the conveyor belt.

- Page 23 An important safety feature designed to stop the con- veyor belt during operation is the shut-off shelf. This device is located at the very end of the unload section. The shut-off shelf moves backward when wares contact it as the belt moves forward.

-

Page 24: Daily Maintenance

Remove and clean scrap screens and baskets flushing with fresh water Clean drain screens and pump screens Wipe the exterior of the dishwasher with a soft cloth DO NOT HOSE WITH WATER Leave doors open so the dishwasher may better dry overnight Immediately report loose, broken or missing parts to your supervisor. -

Page 25: Troubleshooting

Operation: Step by Step Troubleshooting ______________... - Page 26 Troubleshooting Troubleshooting _____________ On occasion your machine may not operate as expected. Use the checklist below before you decide that a mechanical or electrical failure has occurred. Checklist Are the main disconnect switches, breakers, or motor overloads turned ON? Are the main water and steam supplies turned ON?

- Page 27 Scrap screen full ........Must be kept clean and in place Low water level in tank Check drain valves Pump motor rotation incorrect .... Reverse wires L1 and L2 in control cabinet Defective pump seal ......Contact service agency Insufficient final rinse or...

- Page 28 Troubleshooting Troubleshooting _____________ CONDITION CAUSE SOLUTION Low final rinse temperature Low incoming water temperature ..Raise incoming water temperature 140°F for 40°F rise booster 110°F for 70°FS rise booster 180°F without booster Defective thermometer ......Check or replace Defective thermostat ......

-

Page 29: Installation Instructions

2. The P&E was reviewed and approved by all authorized persons prior to shipment. 3. The sample diagram below illustrates the format and presentation of the data necessary to connect the dishwasher. 4. Study the diagram below. Contact the factory immediately if you do not have a copy of your installation's P&E. - Page 30 What if you stood in your front yard while a friend stood in your back yard in order to plan a project. You tell him to move to the right, but he keeps moving to the left. We know what is wrong. You and he have a different reference point in relation to the house.

- Page 31 ________ Installation Instructions All Models 1. The diagrams below show an example of one type of upright conveyor dishwasher. Your dishwasher may be different; however, the basic design is similar. 2. Study the diagrams and see if you can match features on your dishwasher.

- Page 32 Unpack and Place Installation Instructions _______ Installation IMPORTANT Read all of these instructions before beginning the installation Unpack and place Upright conveyor dishwashers ship in sections. Each section comes wrapped in a protective covering and secured to a wooden pallet. Labels note the total number of sections shipped, such as 1 of 4.

- Page 33 Check the utilities early Incorrect voltage, hot water supply, or steam piping may delay the completion of the installation Piping on the rear wall of the dishwasher may be removed to allow the dishwasher to pass through narrow openings if necessary.

- Page 34 (below the base) and note the position of piping, valves, and other components that may be in the way Carefully lift each section off the pallet. Screw the adjustable bullet- feet in as far as possible, then lower the section to the finished floor.

- Page 35 A left-to-right, (L-R), dishwasher is the reverse of a R-L dishwasher. 16. The "E" or Eco-rinse section is an option and may not be a part of your installation.The dashed lines between the "C" and "E" sections indicate that the "E" section usually ships as part of "C"...

- Page 36 21. Check the height of each section and determine which section is the highest due to floor variations. 22. Set the "C" section and adjust to its minimum height. 23. Level the "C" section side to side and front to back in several places with a bubble level.

- Page 37 31. Bolt all the HOOD sections together with twenty (20), 5/16-18 X 3/4" bolts, lockwashers and nuts included in the hardware kit. 32. Tighten the hood bolts in a cross- pattern to pull the sections together. 33. Silicon sealant should squeeze out of the section joints.

- Page 38 Section Assembly: Step by Step 34. Recheck the level of the assembled sections and adjust as needed to achieve a common level line. 35. Refer to the photo on the right. Arrows show the proper installation of the section u-clip.

- Page 39 Section Assembly: Step by Step ________ Installation Instructions Section Assembly: Step by Step...

- Page 40 Section Assemby: Step by Step Installation Instructions _______ Section Assemby: Step by Step Start at the unload end of the machine and pull the conveyor belt around the end sprockets until approximately 1-1/2 feet of belt rests on the upper track of the dishwasher.

- Page 41 15. Locate the conveyor belt drive assembly located at the unload end of the dishwasher. 16. Refer to the photos on the right and note the arrangement of the drive clutch components. IMPORTANT The ID of first clutch disk is larger than the bore of the drive shaft.

- Page 42 Section Assemby: Step by Step 21. The Installation Supervisor must inspect the position, level and proper connection of the piping connections. 22. Section joints must be capped by section u-clips and silicon must be trimmed around the hood joints. 23. Steam supply and condensate unions must be tight.

- Page 43 Section Assemby: Step by Step 28. Make sure solenoid coils are positioned correctly on the valve assemblies. 29. Vent stacks must be placed on the hood with vent handles facing the front of the dishwasher. 30. Panels must be rechecked for missing...

-

Page 44: Installation

Section Assemby: Step by Step Installation Instructions _______ Optional Blower Dryer Assemby: Step by Step Electric or Steam checked and installed in the dishwasher. REFER TO THE BLOWER- DRYER SERVICE MANUAL P/N 114316 The blower dryer comes in electric or steam. - Page 45 Proper internal wiring connections are extremely important. Miswired or loose connections can be difficult to troubleshoot and repair. As the Installation Supervisor, it is your responsibility to inspect and approve all electrical connections as well as all other installation procedures.

- Page 46 Wait 45-seconds for the sealant to firm slightly. Then wipe the joint with a damp cloth. Do not wait longer than 1 minute for the sealant to firm. The sealant will not wipe correctly. If the sealant dries longer than 1 minute, DO NOT try to wipe the joint.

- Page 47 Section Assemby: Step by Step ________ Installation Instructions Section Assemby: Step by Step Study the photos on the right. The top photo shows a correctly sealed joint. 10. The stainless steel must be wiped with Isopropyl alcohol to remove dust, oil film, and other contaminants.

- Page 48 Installation Instructions _______ Supply Connections Main Incoming Power The Main incoming power to the dishwasher is made at the top of machine in the control cabinet. The electrician must connect the power supply in accordance with the data stamped on the Machine Electrical Connection Plate.

- Page 49 CONNECTION DIAGRAM FOR THE LOCATION AND SIZE OF ALL UTILITIES. Steam and condensate connection BUILDING VENTILATION CONNECTIONS ARE MADE AT THE TOP OF THE "A" AND "D" SECTIONS. BUILDING VENTS MUST ALIGN WITH THE DISHWASHER CENTER-LINE AND MATCH THE SIZE OF THE DISHWASHER VENT DUCTS.

- Page 50 Supply Connections Installation Instructions _______ Supply Connections Chemical Dispensers Chemical dispensing systems are supplied by others. A connection point for detergent, and rinse-aid signals is provided in the in the top-mounted control cabinet. SIGNAL ONLY VENT FAN 120V COMMON RINSE AID...

-

Page 51: Initial Start-Up

• Check the interior of the machine and remove any foreign material. • Check the exterior of the machine — make sure that the conveyor belt is free of tape and foreign material. Baffles – Tank baffles redirect the flow of water from the spray arm systems back into the tanks. This prevents water loss and keeps the wash, rinse, and final rinse water in the proper tank. - Page 52 Allow sufficient time for the tank heat to reach operating temperature. Each temperature gauge is marked with its proper operating range. Move the conveyor shut-off shelf located at the end of the unload section toward the machine. This resets the automatic conveyor stop system.

- Page 53 Push the RED stop button. The conveyor belt will stop moving. Flip the power switch on the control cabinet to OFF. The red power light will go out. Open all the drain valves and check that the house drains can handle the flow.

- Page 54 Blank Page This Page Intentionally Left Blank...

-

Page 55: Service Replacement Parts

Service Replacement Parts... - Page 56 Disassembled Pump • Service Replacement Parts 100735 HEX HEAD,1/4-20 X 5/8 SST 100736 HEX HEAD,1/4-20 X 3/4 SS T 100754 SCREW,FLAT HEAD,10-32 X 1/2 SST 102500 PLUG,1/4"NPT SQ.HEAD,BRASS 102504 PLUG,1/2"NPT SQ.HEAD,BRASS 106407 WASHER,LOCK,3/8 SPLIT,SST 106482 WASHER,LOCK,1/4 SPLIT,SST 107690 HEX PLAIN JAM NUT,3/8-16 SST...

- Page 57 Service Replacement Parts • Disassembled Pump 405923...

- Page 58 Pump Installation 3HP, C3/C4 • Service Replacement Parts 100154 HEX PLAIN NUT,5/16-18 SST 100739 HEX HEAD,5/16-18 X 3/4 SST 100740 HEX HEAD,5/16-18 X 1 SS T 102376 WASHER,FLAT,5/16 x 3/4 x.06 SST 104203 CLAMP,HOSE,M52,71/95,SST GEAR TYPE 104640 GASKET,PUMP SUCTION RACK/CC/UC...

- Page 59 Service Replacement Parts • Pump Installation 3HP, C3/C4 452958...

- Page 60 Right-Left Pump Installation 1HP, B-30 Prewash • Service Replacement Parts 100154 HEX PLAIN NUT,5/16-18 SST 100739 HEX HEAD,5/16-18 X 3/4 SST 100740 HEX HEAD,5/16-18 X 1 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST 104203 CLAMP,HOSE,SST GEAR TYPE 104640 GASKET,PUMP SUCTION RACK/CC/UC 106013 WASHER,LOCK,5/16 SPLIT,SST 109926 FITTING,COMPRESSION,5/8OD X 1/2"MNPT,ELL,BRASS...

- Page 61 Service Replacement Parts • Right-Left Pump Installation 1HP, B-30 Prewash 452959...

- Page 62 Left-Right Pump Installation 1HP, B-30 Prewash • Service Replacement Parts 100154 HEX PLAIN NUT,5/16-18 SST 100739 HEX HEAD,5/16-18 X 3/4 SST 100740 HEX HEAD,5/16-18 X 1 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST 104203 CLAMP,HOSE,M52,71/95,SST GEAR TYPE 104640 GASKET,PUMP SUCTION RACK/CC/UC 106013 WASHER,LOCK,5/16 SPLIT,SST 109926 FITTING,COMPRESSION,5/8OD X 1/2"MNPT,ELL,BRASS...

- Page 63 Service Replacement Parts • Left-Right Pump Installation 1HP, B-30 Prewash 452960...

- Page 64 Left-Right Pump Installation 3HP, B-30 Prewash • Service Replacement Parts 100154 HEX PLAIN NUT,5/16-18 SST 100739 HEX HEAD,5/16-18 X 3/4 SST 100740 HEX HEAD,5/16-18 X 1 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST 104203 CLAMP,HOSE,M52,71/95,SST GEAR TYPE 104640 GASKET,PUMP SUCTION RACK/CC/UC 106013 WASHER,LOCK,5/16 SPLIT,SST 109926 FITTING,COMPRESSION,5/8OD X 1/2"MNPT,ELL,BRASS...

- Page 65 Service Replacement Parts • Left-Right Pump Installation 3HP, B-30 Prewash 452962...

- Page 66 Right-Left Pump Installation 3HP, B-30 Prewash • Service Replacement Parts 100154 HEX PLAIN NUT,5/16-18 SST 100739 HEX HEAD,5/16-18 X 3/4 SST 100740 HEX HEAD,5/16-18 X 1 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST 104203 CLAMP,HOSE,M52,71/95,SST GEAR TYPE 104640 GASKET,PUMP SUCTION RACK/CC/UC 106013 WASHER,LOCK,5/16 SPLIT,SST 109926 FITTING,COMPRESSION,5/8OD X 1/2"MNPT,ELL,BRASS...

- Page 67 Service Replacement Parts • Right-Left Pump Installation 3HP, B-30 Prewash 452961...

- Page 68 Right-Left Pump Installation Auxiliary Rinse • Service Replacement Parts 100023 STREET ELBOW,3/4"NPT X 90,SST 100051 NIPPLE,3/4"NPT X CLOSE,SST 100154 HEX PLAIN NUT,5/16-18 SST 100739 HEX HEAD,5/16-18 X 3/4 SST 100740 HEX HEAD,5/16-18 X 1 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST 102554 UNION,3/4"NPT, SST...

- Page 69 Service Replacement Parts • Right-Left Pump Installation Auxiliary Rinse 452991...

-

Page 70: Washer,Lock,1/4 Split,Sst

Wash System Installation C8 Wash, Rinse • Service Replacement Parts 100734 HEX HEAD,1/4-20 X 1/2 SST 100755 SCREW,FLAT HEAD,1/4-20 X 1/2 SST 104414 O-RING,1 X 1 1/4 X 1/8 106014 HEX ACORN PLAIN NUT,1/4-20 SST 106026 WASHER,FLAT,1/4x5/8x.06 SST 106482 WASHER,LOCK,1/4 SPLIT,SST... - Page 71 Wash System Installation C8 Wash, Rinse • Service Replacement Parts 452954...

- Page 72 Right-Left Wash System Installation 30" Prewash • Service Replacement Parts 100734 HEX HEAD,1/4-20 X 1/2 SST 100755 SCREW,FLAT HEAD,1/4-20 X 1/2 SST 104414 O-RING,1 X 1 1/4 X 1/8 106014 HEX ACORN PLAIN NUT,1/4-20 SST 106026 WASHER,FLAT,1/4x5/8x.06 SST 106482 WASHER,LOCK,1/4 SPLIT,SST...

- Page 73 Service Replacement Parts • Right-Left Wash System Installation 30" Prewash 452955...

- Page 74 Left-Right Wash System Installation 1HP 30" Prewash • Service Replacement Parts 100734 CAP SCREW,HEX HEAD,1/4-20 X 1/2 SST 100755 SCREW,FLAT HEAD,1/4-20 X 1/2 SST 104414 O-RING,1 X 1 1/4 X 1/8 106014 HEX ACORN PLAIN NUT,1/4-20 SST 106026 WASHER,FLAT,1/4x5/8x.06 SST...

- Page 75 Service Replacement Parts • Left-Right Wash System Installation 1HP 30" Prewash 452956...

- Page 76 Wash System Installation • C4 Single Tank 100734 HEX HEAD,1/4-20 X 1/2 SST 100755 SCREW,FLAT HEAD,1/4-20 X 1/2 SST 104414 O-RING,1 X 1 1/4 X 1/8 106014 HEX ACORN PLAIN NUT,1/4-20 SST 106026 WASHER,FLAT,1/4x5/8x.06 SST 106482 WASHER,LOCK,1/4 SPLIT,SST 108875 COTTER PIN,3/32 X 1/2 UNEVEN...

- Page 77 Service Replacement Parts • Wash System Installation • C4 Single Tank 452957...

- Page 78 Wash System Installation • C6 Wash Rinse 100734 HEX HEAD,1/4-20 X 1/2 SST 100755 SCREW,FLAT HEAD,1/4-20 X 1/2 SST 104414 O-RING,1 X 1 1/4 X 1/8 106014 HEX ACORN PLAIN NUT,1/4-20 SST 106026 WASHER,FLAT,1/4 x 5/8 x .06 SST 106482...

- Page 79 Service Replacement Parts • Wash System Installation C6 Wash, Rinse 452957...

- Page 80 Electric Tank Heat Installation C4 Wash w/o scrap basket • Service Replacement Parts 100123 PETCOCK,1/4"NPT FEMALE,BRASS 100134 ELBOW,STREET,1NPT X 90,MI 100184 NIPPLE,3/4"NPT X CLOSE,BRASS 100209 NIPPLE,1/2"NPT X CLOSE,BRASS 100571 UNION,3/4"NPT,BRASS 100979 BUSHING,REDUCING,1 1/2"NPTx1"NPT,BI 102288 ELBOW,1/2"NPT X 90 DEG,M.I. 102398 BUSHING,REDUCING,1 1/4"NPTx1/2"NPT,BRASS 102399 BUSHING,REDUCING,1 1/4"NPTx3/4"NPT,BRASS...

- Page 81 Service Replacement Parts • Electric Tank Heat Installation C4 Wash w/o scrap basket 453090...

- Page 82 Electric Tank Heat Installation C4 Rinse w/ scrap basket • Service Replacement Parts 105780 UNION,1"NPT, MALLEABLE IRON 105782 NIPPLE,1/2"NPT X CLOSE.,B.I. 105786 NIPPLE,1/2"NPT X 3" LG.,B.I. 105847 NIPPLE,1"NPT X CLOSE,B.I. 105850 NIPPLE,1"NPT X 2" LG.,B.I. 105881 NIPPLE,1 1/2"NPT X CLOSE,B.I.

- Page 83 Blank Page This Page Intentionally Left Blank...

- Page 84 Electric Tank Heat Installation C4 Rinse w/o scrap basket • Service Replacement Parts 100007 SCREW,TRUSS HEAD,10-32 x 3/8 SST 100109 WELD-STUD,1/4-20 X 1/2 LG.SST 100154 HEX PLAIN NUT,5/16-18 SST 100198 WELD-STUD,10-32 X 1/2 LG.SST 100547 LOCKNUT,1/2" NPT,SST 100740 HEX HEAD,5/16-18 X 1 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST...

- Page 85 Service Replacement Parts • Electric Tank Heat Installation C4 Rinse w/o scrap basket 453092...

- Page 86 Electric Tank Heat Installation C4 Wash w/ scrap basket • Service Replacement Parts 100097 SCREW,TRUSS HEAD,10-32 x 1/2 SS T 100100 SCREW,ROUND HEAD,8-32 x 1/4 SS T 100154 HEX PLAIN NUT,5/16-18 SST 100547 LOCKNUT,1/2" NPT,SST 100740 HEX HEAD,5/16-18 X 1 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST...

- Page 87 Service Replacement Parts • Electric Tank Heat Installation C4 Wash w/ scrap basket 453123...

- Page 88 Electric Tank Heat Installation C4 Rinse w/ scrap basket • Service Replacement Parts 100097 SCREW,TRUSS HEAD,10-32 x 1/2 SST 100100 SCREW,ROUND HEAD,8-32 x 1/4 SST 100154 HEX PLAIN NUT,5/16-18 SST 100547 LOCKNUT,1/2" NPT,SST 100740 HEX HEAD,5/16-18 X 1 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST...

- Page 89 Service Replacement Parts • Electric Tank Heat Installation C4 Rinse w/ scrap basket 453176...

- Page 90 100007 SCREW,TRUSS HEAD,10-32 x 3/8 SST 100109 WELD-STUD,1/4-20 X 1/2 LG.SST 100154 HEX PLAIN NUT,5/16-18 SST 100198 WELD-STUD,10-32 X 1/2 LG.SST 100547 LOCKNUT,1/2" NPT,SST 100740 HEX HEAD,5/16-18 X 1 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST 106013 WASHER,LOCK,5/16 SPLIT,SST 106026 WASHER,FLAT,1/4x5/8x.06 SST 106486...

- Page 91 453094...

- Page 92 Electric Booster Element Configuration • Service Replacement Parts NOTE: The location of a booster heater element is critical for the proper repair of the booster. VERIFY THE LOCATION OF ITEM NO. 3 EUCCW-6 / EUCC-6 EUCCW-4 / EUCC-4 40°F / 22° Rise...

- Page 93 Service Replacement Parts • Electric Booster Element Configuration NOTE: The location of a booster heater element is critical for the proper repair of the booster. VERIFY THE LOCATION OF ITEM NO. 3 EUCCW-6 / EUCC-8 40°F / 22° Rise BOOSTER ASSY,ELEC,R-L,18kW@208V...

- Page 94 Electric Booster Element Configuration • Service Replacement Parts NOTE: The location of a booster heater element is critical for the proper repair of the booster. VERIFY THE LOCATION OF ITEM NO. 3 & 4 EUCCW-6 / EUCC-6 EUCCW-4 / EUCC-4 70°F / 39° Rise...

- Page 95 Service Replacement Parts • Electric Booster Element Configuration NOTE: The location of a booster heater element is critical for the proper repair of the booster. VERIFY THE LOCATION OF ITEM NO. 3 & 4 EUCCW-8 / EUCC-8 70°F / 39° Rise BOOSTER ASSY,ELEC,R-L,32kW@208V...

- Page 96 Electric Booster Element Configuration • Service Replacement Parts NOTE: The location of a booster heater element is critical for the proper repair of the booster. VERIFY THE LOCATION OF ITEM NO. 3 & 4 EUCC-4 / EUCC-3 40°F / 22° Rise BOOSTER ASSY,ELEC,R-L,16kW@208V...

- Page 97 Electric Booster Element Configuration • Service Replacement Parts NOTE: The location of a booster heater element is critical for the proper repair of the booster. VERIFY THE LOCATION OF ITEM NO. 3 & 4 EUCC-4 / EUCC-3 70°F / 39° Rise BOOSTER ASSY,ELEC,R-L,28kW@208V...

- Page 98 Electric Booster Installation Left-Right • Service Replacement Parts 100003 HEX PLAIN NUT,1/4-20 SST 100097 SCREW,TRUSS HEAD,10-32 x 1/2 SST 100100 SCREW,ROUND HEAD,8-32 x 1/4 SST 100109 WELD-STUD,1/4-20 X 1/2 LG.SST 100113 CAP,3/4" NPT SST 100154 HEX PLAIN NUT,5/16-18 SST 100734...

- Page 99 Service Replacement Parts • Electric Booster Installation Left-Right 453006Left-Right...

- Page 100 HEX GRIP NU T,1/4-20 SST W/NYLO N 108576 BOOSTER HEATER COVE R 109069 THERMOSTAT WITH CAPILLA RY 109682 THERMOSTAT COVER BOX 109925 FITTING, COM P 5/8 OD X 1/2 MPT BRASS 109985 O-RING,BOOSTER HEATE R 11056 1 THERMOSTAT WITH CAPILLA RY 206668 ANGLE,ELECTRIC BOOSTER SUPPORT 206669...

- Page 101 PLUG 1/2NPT BRASS SQ.HEAD ---- 102521 TEE 3/4NPT BRASS ---- 107550 VALVE PRESS REDUCING 3/4 N250 ---- 109879 FITT COMP 7/8OD X 3/4MPT BRASS ---- 110768 STRAINER LINE 3/4i BRASS ---- 111437 VALVE, 3/4 IN HW J&E 109903 KIT, REPAIR 3/4"...

- Page 102 Electric Booster Installation Right-Left • Service Replacement Parts 100003 HEX PLAIN NUT,1/4-20 SST 100109 WELD-STUD,1/4-20 X 1/2 LG.SST 100156 LOCKNUT,3/4" NPT,BRASS 100516 STREET ELBOW,1/2"NPT X 90,SST 100734 CAP SCREW,HEX HEAD,1/4-20 X 1/2 SST 102461 NIPPLE,1/2"NPT X 2"LG.,SST 106026 WASHER,FLAT,1/4x5/8x.06 SST...

- Page 103 Service Replacement Parts • Electric Booster Installation Right-Left 453006Right-Left...

- Page 104 102504 PLUG, 1/2NPT BRASS, SQUARE HD. ---- 102549 UNION, 1/2NPT BRASS ---- 106418 COCK, 1/2 AIR FEMALE ---- 109925 FITT, COMP, 5/8OD X 1/2MPT ---- 110134 NIPPLE, 1/4 X 2-1/2 BRASS ---- 114182 COUPLING, REDUCER, 1/2 X 1/4 BRASS 1...

- Page 106 Final Rinse Installation EUCCW8 • Service Replacement Parts 100003 HEX PLAIN NUT,1/4-20 SST 100109 WELD-STUD,1/4-20 X 1/2 LG.SST 100585 LOCKNUT,1" NPT,BRASS 100734 HEX HEAD,1/4-20 X 1/2 SST 106026 WASHER,FLAT,1/4x5/8x.06 SST 106482 WASHER,LOCK,1/4 SPLIT,SST 106530 NOZZLE,VEE-JET,#8020, SPRAY FAN @20 PSI 113716...

- Page 107 Service Replacement Parts • Final Rinse Installation EUCCW8 452989...

- Page 108 Blank Page This Page Intentionally Left Blank...

- Page 109 Blank Page This Page Intentionally Left Blank...

- Page 110 Cold Water Fill Piping Sub-assembly • Service Replacement Parts 100209 NIPPLE,1/2"NPT X CLOSE,BRASS 100500 VACUUM BREAKER,1/2" NPT BRONZE 108349 REPAIR KIT 100704 NIPPLE,RTOE,1/2"NPT X 1 3/4"LG.,SST 100709 LOCKNUT,1/2" NPT,BRASS 102435 ELBOW, 1/2"NPT x 90 DEG,BRASS 102436 ELBOW,1/2"NPT X 90, SST 102438 ELBOW,STREET,1/2"NPT X 90, BRASS...

- Page 111 Service Replacement Parts • Cold Water Fill Piping Sub-assembly 601831...

- Page 112 Electric Booster Piping Assembly • Service Replacement Parts Item Part Description Qty. 100184 NIPPLE,3/4"NPT X CLOSE,BRASS 100571 UNION,3/4"NPT,BRASS 102444 ELBOW,STREET,3/4"NPT X 90, BRASS 102504 PLUG,1/2"NPT SQ.HEAD,BRASS 102521 TEE, 3/4"NPT, BRASS 102525 TEE,RED,3/4"x1/2"x3/4"NPT, BRASS 107550 VALVE,PRESSURE REGULATING,3/4"NPT BRONZE FITTING, COMP 7/8 OD X 3/4 MPT BRASS...

- Page 113 Service Replacement Parts • Electric Booster Piping Assembly 601833...

- Page 114 #120-1 Steam Booster Installation RL • Service Replacement Parts 100140 HEX PLAIN NUT,3/8-16 SST 100153 HEX HEAD,3/8-16 X 1 SST 100154 HEX PLAIN NUT,5/16-18 SST 100739 HEX HEAD,5/16-18 X 3/4 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST 104618 WASHER,FLAT,3/8x7/8x.06 SST 106013 WASHER,LOCK,5/16 SPLIT,SST...

- Page 115 Service Replacement Parts • #120-1 Steam Booster Installation RL 452942...

- Page 116 #120-1 Steam Booster Assembly RL 40-70°F • Service Replacement Parts 100123 PETCOCK,1/4"NPT FEMALE,BRASS 100134 ELBOW,STREET,1NPT X 90,MI 100184 NIPPLE,3/4"NPT X CLOSE,BRASS 100209 NIPPLE,1/2"NPT X CLOSE,BRASS 100571 UNION,3/4"NPT,BRASS 100979 BUSHING,REDUCING,1 1/2"NPTx1"NPT,BI 102288 ELBOW,1/2"NPT X 90 DEG,M.I. 102398 BUSHING,REDUCING,1 1/4"NPTx1/2"NPT,BRASS 102399 BUSHING,REDUCING,1 1/4"NPTx3/4"NPT,BRASS 102402 BUSHING,REDUCING,1/2"NPTx1/4"NPT,BI...

- Page 117 Service Replacement Parts • #120-1 Steam Booster Assembly RL 40-70°F 601829...

- Page 118 #120-1 Steam Booster Assembly RL 40-70°F • Service Replacement Parts Item Part Description Qty. 105780 UNION,1"NPT, MALLEABLE IRON 105782 NIPPLE,1/2"NPT X CLOSE.,B.I. 105786 NIPPLE,1/2"NPT X 3" LG.,B.I. 105847 NIPPLE,1"NPT X CLOSE,B.I. 105850 NIPPLE,1"NPT X 2" LG.,B.I. 105881 NIPPLE,1 1/2"NPT X CLOSE,B.I.

- Page 119 Blank Page This Page Intentionally Left Blank...

- Page 120 #120-1 Steam Booster Installation LR • Service Replacement Parts 100140 HEX PLAIN NUT,3/8-16 SST 100153 HEX HEAD,3/8-16 X 1 SST 100154 HEX PLAIN NUT,5/16-18 SST HEX HEAD,5/16-18 X 3/4 SST 100739 102376 WASHER,FLAT,5/16x3/4x.06 SST 104618 WASHER,FLAT,3/8x7/8x.06 SST 106013 WASHER,LOCK,5/16 SPLIT,SST...

- Page 121 Service Replacement Parts • #120-1 Steam Booster Installation LR 452943...

- Page 122 #120-1 Steam Booster Assembly LR 40-70°F • Service Replacement Parts 100123 PETCOCK,1/4"NPT FEMALE,BRASS 100134 ELBOW,STREET,1NPT X 90,MI 100184 NIPPLE,3/4"NPT X CLOSE,BRASS 100209 NIPPLE,1/2"NPT X CLOSE,BRASS 100571 UNION,3/4"NPT,BRASS 100979 BUSHING,REDUCING,1 1/2"NPTx1"NPT,BI 102288 ELBOW,1/2"NPT X 90 DEG,M.I. 102398 BUSHING,REDUCING,1 1/4"NPTx1/2"NPT,BRASS 102399 BUSHING,REDUCING,1 1/4"NPTx3/4"NPT,BRASS 102402 BUSHING,REDUCING,1/2"NPTx1/4"NPT,BI...

- Page 123 Service Replacement Parts • #120-1 Steam Booster Assembly LR 40-70°F 601830...

- Page 124 #120-1 Steam Booster Assembly LR 40-70°F • Service Replacement Parts Item Part Description Qty. 105780 UNION,1"NPT, MALLEABLE IRON 105782 NIPPLE,1/2"NPT X CLOSE.,B.I. 105786 NIPPLE,1/2"NPT X 3" LG.,B.I. 105847 NIPPLE,1"NPT X CLOSE,B.I. 105850 NIPPLE,1"NPT X 2" LG.,B.I. 105881 NIPPLE,1 1/2"NPT X CLOSE,B.I.

- Page 125 Blank Page This Page Intentionally Left Blank...

- Page 126 Steam Coil Heat Installation C4 Wash, Rinse,15-30 PSI • Service Replacement Parts Item Part Description Qty. 100002 HEX HEAD,1/4-20 X 1 3/8 SST 100007 SCREW,TRUSS HEAD,10-32 x 3/8 SST 100023 STREET ELBOW,3/4"NPT X 90,SST 100109 WELD-STUD,1/4-20 X 1/2 LG.SST 100134...

- Page 127 Service Replacement Parts • Steam Coil Heat Installation C4 Wash, Rinse, 15-30 PSI 453050...

- Page 128 Steam Coil Heat Installation C4 Wash, Rinse,15-30 PSI • Service Replacement Parts 107033 WASHER,FLAT,.208X.438X.047 SST 107136 SCREW,HEX HEAD,10-32 x 3/8 SST 107488 NIPPLE,1/2"NPT X 3 1/2" LG.,B.I. 107966 HEX GRIP NUT,10-32 SST W/NYLON 107967 HEX GRIP NUT,1/4-20 SST W/NYLON 108345...

- Page 129 Blank Page This Page Intentionally Left Blank...

- Page 130 Steam Coil Heat Installation C3 Wash, Rinse,15-30 PSI • Service Replacement Parts 100002 HEX HEAD,1/4-20 X 1 3/8 SST 100007 SCREW,TRUSS HEAD,10-32 x 3/8 SST 100023 STREET ELBOW,3/4"NPT X 90,SST 100109 WELD-STUD,1/4-20 X 1/2 LG.SST 100134 ELBOW,STREET,1NPT X 90,MI 100147...

- Page 131 Service Replacement Parts • Steam Coil Heat Installation C3 Wash, Rinse,15-30 PSI 453146...

- Page 132 Steam Coil Heat Installation C3 Wash, Rinse,15-30 PSI • Service Replacement Parts 107033 WASHER,FLAT,.208X.438X.047 SST 107136 SCREW,HEX HEAD,10-32 x 3/8 SST 107488 NIPPLE,1/2"NPT X 3 1/2" LG.,B.I. 107966 HEX GRIP NUT,10-32 SST W/NYLON 107967 HEX GRIP NUT,1/4-20 SST W/NYLON 108345...

- Page 133 Blank Page This Page Intentionally Left Blank...

- Page 134 Steam Coil Heat Installation Auxiliary,15-30 PSI • Service Replacement Parts 100007 SCREW,TRUSS HEAD,10-32 x 3/8 SST 100051 NIPPLE,3/4"NPT X CLOSE,SST 100109 WELD-STUD,1/4-20 X 1/2 LG.SST 100134 ELBOW,STREET,1NPT X 90,MI 100147 ELBOW,STREET,1/2NPT X 90,MI 100154 HEX PLAIN NUT,5/16-18 SST 100198 WELD-STUD,10-32 X 1/2 LG.SST 100547 LOCKNUT,1/2"...

- Page 135 Service Replacement Parts • Steam Coil Heat Installation Auxiliary,15-30 PSI 453051...

- Page 136 Steam Coil Heat Installation AUX. Auxiliary,15-30 PSI • Service Replacement Parts 106026 WASHER,FLAT,1/4x5/8x.06 SST 106486 WASHER,LOCK,#10 SPLIT,SST 106789 NIPPLE,1"NPT X 3 1/2" LG.,B.I. 107033 WASHER,FLAT,.208X.438X.047 SST 107136 SCREW,HEX HEAD,10-32 x 3/8 SST 107966 HEX GRIP NUT,10-32 SST W/NYLON 107967 HEX GRIP NUT,1/4-20 SST W/NYLON...

- Page 137 Blank Page This Page Intentionally Left Blank...

- Page 138 Steam Injector Heat Installation C4/C8,15-30 PSI • Service Replacement Parts 100003 HEX PLAIN NUT,1/4-20 SST 100007 SCREW,TRUSS HEAD,10-32 x 3/8 SST 100134 ELBOW,STREET,1NPT X 90,MI 100154 HEX PLAIN NUT,5/16-18 SST 100547 LOCKNUT,1/2" NPT,SST 100734 HEX HEAD,1/4-20 X 1/2 SST 100740...

- Page 139 Service Replacement Parts • Steam Injector Heat Installation C4/C8,15-30 PSI...

- Page 140 Steam Injector Heat Installation C4/C8,15-30 PSI • Service Replacement Parts 107136 SCREW,HEX HEAD,10-32 x 3/8 SST 107966 HEX GRIP NUT,10-32 SST W/NYLON 107967 HEX GRIP NUT,1/4-20 SST W/NYLON 108345 GASKET,HEATER/STANDPIPE 109069 THERMOSTAT,CONTROL,WITH CAPILLARY 109683 FLANGE,BLOCKOFF,HEATER/CROSSFLOW 10005 VALVE,1"NPT STEAM,ACSO 110007 KIT, REPAIR 111371 NIPPLE,TOE,1"NPT X 7"LG.,SST...

- Page 141 Blank Page This Page Intentionally Left Blank...

- Page 142 Steam Injector Heat Installation Auxiliary RL,15-30 PSI • Service Replacement Parts 100003 HEX PLAIN NUT,1/4-20 SST 100007 SCREW,TRUSS HEAD,10-32 x 3/8 SST 100134 ELBOW,STREET,1NPT X 90,MI 100154 HEX PLAIN NUT,5/16-18 SST 100516 STREET ELBOW,1/2"NPT X 90,SST 100547 LOCKNUT,1/2" NPT,SST 100740...

- Page 143 Steam Injector Heat Installation Auxiliary RL,15-30 PSI...

- Page 144 Drain Installation B-30 Prewash RL • Service Replacement Parts 100110 WELD-STUD,1/4-20 X 3/4 LG.SST 100141 HEX GRIP NUT,1/4-20 SST,CTR LOCK 100154 HEX PLAIN NUT,5/16-18 SST 100161 ELBOW,2"NPT X 90,GALVANIZED 100735 HEX HEAD,1/4-20 X 5/8 SST 100739 HEX HEAD,5/16-18 X 3/4 SST...

- Page 145 Service Replacement Parts • Drain Installation B-30 Prewash RL 452973...

- Page 146 Drain Installation B-30 Prewash LR • Service Replacement Parts 100110 WELD-STUD,1/4-20 X 3/4 LG.SST 100141 HEX GRIP NUT,1/4-20 SST,CTR LOCK 100154 HEX PLAIN NUT,5/16-18 SST 100161 ELBOW,2"NPT X 90,GALVANIZED 100735 HEX HEAD,1/4-20 X 5/8 SST 100739 HEX HEAD,5/16-18 X 3/4 SST...

- Page 147 Service Replacement Parts • Drain Installation B-30 Prewash LR 452974...

- Page 148 Drain Installation C4 Wash, Rinse • Service Replacement Parts 100110 WELD-STUD,1/4-20 X 3/4 LG.SST 100141 HEX GRIP NUT,1/4-20 SST,CTR LOCK 100154 HEX PLAIN NUT,5/16-18 SST 100735 HEX HEAD,1/4-20 X 5/8 SST 100739 HEX HEAD,5/16-18 X 3/4 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST...

- Page 149 Service Replacement Parts • Drain Installation C4 Wash, Rinse 452975...

- Page 150 Drain Installation Auxiliary LR • Service Replacement Parts 100110 WELD-STUD,1/4-20 X 3/4 LG.SST 100141 HEX GRIP NUT,1/4-20 SST,CTR LOCK 100154 HEX PLAIN NUT,5/16-18 SST 100735 HEX HEAD,1/4-20 X 5/8 SST 100736 HEX HEAD,1/4-20 X 3/4 SST 100739 HEX HEAD,5/16-18 X 3/4 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST...

- Page 151 Service Replacement Parts • Drain Installation Auxiliary LR 452977...

- Page 152 Drain Installation D5 Unload • Service Replacement Parts 100154 HEX PLAIN NUT,5/16-18 SST 100587 PLUG,1 1/2"NPT SQ.HEAD,B.I. 100739 CAP SCREW,HEX HEAD,5/16-18 X 3/4 SST 106013 WASHER,LOCK,5/16 SPLIT,SST 107340 CLAMP,HOSE,M28,33/57,SST GEAR TYPE 107342 DRAIN BASKET ASSY,DUO B02-050 107473 DRAIN TAILPIECE RINSE 109184 NIPPLE,TOE,1 1/4"NPT X 4"...

- Page 153 Service Replacement Parts • Drain Installation D5 Unload 453045...

- Page 154 Drain Installation B4 Prewash RL • Service Replacement Parts 100110 WELD-STUD,1/4-20 X 3/4 LG.SST 100141 HEX GRIP NUT,1/4-20 SST,CTR LOCK 100154 HEX PLAIN NUT,5/16-18 SST 100161 ELBOW,2"NPT X 90,GALVANIZED 100735 HEX HEAD,1/4-20 X 5/8 SST 100739 HEX HEAD,5/16-18 X 3/4 SST...

- Page 155 Service Replacement Parts • Drain Installation B4 Prewash RL 453095...

- Page 156 Drain Installation B4 Prewash LR • Service Replacement Parts 100110 WELD-STUD,1/4-20 X 3/4 LG.SST 100141 HEX GRIP NUT,1/4-20 SST,CTR LOCK 100154 HEX PLAIN NUT,5/16-18 SST 100161 ELBOW,2"NPT X 90,GALVANIZED 100735 HEX HEAD,1/4-20 X 5/8 SST 100739 HEX HEAD,5/16-18 X 3/4 SST...

- Page 157 Service Replacement Parts • Drain Installation B4 Prewash RL 453096...

- Page 158 Drain Installation C3 Wash,Rinse • Service Replacement Parts 100110 WELD-STUD,1/4-20 X 3/4 LG.SST 100141 HEX GRIP NUT,1/4-20 SST,CTR LOCK 100154 HEX PLAIN NUT,5/16-18 SST 100735 HEX HEAD,1/4-20 X 5/8 SST 100739 HEX HEAD,5/16-18 X 3/4 SST 101920 NIPPLE,TOE,2"NPT X 5 3/4" LG.,GALV 102376 WASHER,FLAT,5/16 x 3/4 x .06 SST...

- Page 159 Service Replacement Parts • Drain Installation C3 Wash,Rinse 453101...

- Page 160 Electric Eyes, Start-Stop Station, Flushing Nozzles • Service Replacement Parts 105994 CLAMP,HOSE,M10,14/27,SST GEAR TYPE 107003 LOAD PLACARD ELEC EYE 107033 WASHER,FLAT,.208X.438X.047 SST 107136 SCREW,HEX HEAD,10-32 x 3/8 SST 107966 HEX GRIP NUT,10-32 SST W/NYLON 110837 ELBOW,1/2" CONDUIT,SEALTITE 111325 NOZZLE FLUSH-N POLISHED CHROME...

- Page 161 Service Replacement Parts • Electric Eyes, Start-Stop Station, Flushing Nozzles 900725 KIT, GREEN START SWITCH Items - 8, 11,18 900726 KIT, RED START SWITCH Items - 9,10,18 601833...

- Page 162 WASHER,LOCK,3/8 SPLIT,SST 106521 SPROCKET,50B8,5/8 BORE KEY,1/4 X 1/4 X 2 1/2" LG.SST 106679 107183 MOTOR, 1/2HP UC/CC DRIVE,MV 3PH KEY 1/4 X 1/4 X 1 1/2 SST 107305 SPROCKET, TORQUE LIMITER,350AG26 108013 108088 SHEAVE,AK46,3/4 BORE HEX GRIP NUT,3/8-16 SST W/NYLON...

- Page 163 Service Replacement Parts • Idle Shaft Assembly 452960...

- Page 164 WASHER,LOCK,3/8 SPLIT,SST 106521 SPROCKET,50B8,5/8 BORE KEY,1/4 X 1/4 X 2 1/2" LG.SST 106679 107183 MOTOR, 1/2HP UC/CC DRIVE,MV 3PH KEY 1/4 X 1/4 X 1 1/2 SST 107305 SPROCKET, TORQUE LIMITER,350AG26 108013 108088 SHEAVE,AK46,3/4 BORE HEX GRIP NUT,3/8-16 SST W/NYLON...

- Page 165 Service Replacement Parts • Drive Assembly HUB,TORQUE LIMITER #350A 100485-1 100485-2 FRICTION DISC, #350A CLUTCH PRESSURE PLATE, #350A TORQUE LIMITER 100485-3 SPRING WASHER, #350A TORQUE LIMITER 100485-4 LOCKWASHER, #350A TORQUE LIMITER 100485-5 ADJUSTING NUT, #350A TORQUE LIMITER 100485-6 BUSHING, #350A TORQUE...

- Page 166 Peg and Peg w/Upper Rod Conveyor Belts • Service Replacement Parts...

- Page 167 Service Replacement Parts • Peg and Peg w/Upper Rod Conveyor Belts...

- Page 168 Flat and Insulated Conveyor Belts • Service Replacement Parts...

- Page 169 Service Replacement Parts • Flat and Insulated Conveyor Belts...

- Page 170 Stainless Steel Conveyor Belt • Service Replacement Parts...

- Page 171 Service Replacement Parts • Stainless Steel Conveyor Belt...

- Page 172 Vent Cowl Installation • Service Replacement Parts HEX GRIP NUT, 4-40 SST W/NYLON 107016 NAMEPLATE, CHAMPION 109158 SCREW, ROUND HEAD, 4-40 x 1/2 SST 110110 VENT COWL WELDMENT, UCW-04 329806 401486 VENT STACK 4 x 24...

- Page 173 Service Replacement Parts • Vent Cowl Installation 452960...

- Page 174 Curtain Installation B30/C8/ RL/LR • Service Replacement Parts HEX HEAD,1/4-20 X 1/2 SST 100734 106026 WASHER,FLAT,1/4x5/8x.06 SST 106482 WASHER,LOCK,1/4 SPLIT,SST 112445 CURTAIN,SHORT,14 X 32,NUCCW 114111 CURTAIN,LONG,19 X 34 1/4,EUCCW 204949 CURTAIN,SHORT,10 X 32,NUCCW AUX-RINSE. 205432 ROD,CURTAIN,5/16 X 32"LG.SST,UCCW 206581 ROD,CURTAIN,5/16 X 34 1/4"LG.SST,UCCW BAFFLE, CURTAIN HANGER.MANIFOLD MTD,LH...

- Page 175 Service Replacement Parts • Curtain Installation B30/C8/ RL/LR 452992/452933...

- Page 176 Curtain Installation B30/C4/AUX. RL/LR • Service Replacement Parts 100734 HEX HEAD,1/4-20 X 1/2 SST 106026 WASHER,FLAT,1/4x5/8x.06 SST 106482 WASHER,LOCK,1/4 SPLIT,SST 112445 CURTAIN, DISHWASHER,UC MACHINE 114110 CURTAIN, DISHWASHER,UC MACHINE 114111 CURTAIN, DISHWASHER,UC MACHINE 204949 CURTAIN, DISHWASHER,UC MACHINE 205432 ROD,CURTAIN,5/16 X 32"LG.SST,UCCW 206581 ROD,CURTAIN,5/16 X 34 1/4"LG.SST,UCCW...

- Page 177 Service Replacement Parts • Curtain Installation B30/C8/AUX. RL/LR 452992/452933...

- Page 178 Curtain Installation B4/C8/ RL/LR • Service Replacement Parts 100734 HEX HEAD, 1/4-20 X 1/2 SST 106026 WASHER,FLAT,1/4x5/8x.06 SST 106482 WASHER,LOCK,1/4 SPLIT,SST 112445 CURTAIN,SHORT,14 X 32,NUCCW 114111 CURTAIN,LONG,19 X 34 1/4,EUCCW 204949 CURTAIN,SHORT,10 X 32,NUCCW AUX. RINSE 205432 ROD,CURTAIN,5/16 X 32"LG.SST,UCCW 206581 ROD,CURTAIN,5/16 X 34 1/4"LG.SST,UCCW...

- Page 179 Service Replacement Parts • Curtain Installation B30/C8/ RL/LR 453132/453133...

- Page 180 Curtain Installation B4/C4/AUX. RL/LR • Service Replacement Parts HEX HEAD, 1/4-20 X 1/2 SST 100734 106026 WASHER,FLAT,1/4x5/8x.06 SST 106482 WASHER,LOCK,1/4 SPLIT,SST 112445 CURTAIN,SHORT,14 X 32,NUCCW 114111 CURTAIN,LONG,19 X 34 1/4,EUCCW 204949 CURTAIN,SHORT,10 X 32,NUCCW AUX. RINSE 205432 ROD,CURTAIN,5/16 X 32"LG.SST,UCCW 206581 ROD,CURTAIN,5/16 X 34 1/4"LG.SST,UCCW...

- Page 181 Service Replacement Parts • Curtain Installation B4/C4/AUX. RL/LR 453128/453129...

- Page 182 Curtain Installation B4/C4/AUX. RL/LR • Service Replacement Parts 100734 HEX HEAD, 1/4-20 X 1/2 SST 106026 WASHER,FLAT,1/4x5/8x.06 SST 106482 WASHER,LOCK,1/4 SPLIT,SST 112445 CURTAIN,SHORT,14 X 32,NUCCW 114111 CURTAIN,LONG,19 X 34 1/4,EUCCW 204949 CURTAIN,SHORT,10 X 32,NUCCW E2 205432 ROD,CURTAIN,5/16 X 32"LG.SST,UCCW 206581 ROD,CURTAIN,5/16 X 34 1/4"LG.SST,UCCW...

- Page 183 Service Replacement Parts • Curtain Installation B4/C4/AUX. RL/LR 453130/453131...

- Page 184 Curtain Installation B30/C6/AUX. RL • Service Replacement Parts 100007 SCREW,TRUSS HEAD,10-32 x 3/8 SST 100109 WELD-STUD,1/4-20 X 1/2 LG.SST 100154 HEX PLAIN NUT,5/16-18 SST 100198 WELD-STUD,10-32 X 1/2 LG.SST 100547 LOCKNUT,1/2" NPT,SST 100740 HEX HEAD, 5/16 X 18 X 1/2 SST 102376 WASHER,FLAT,5/16x3/4x.06 SST...

- Page 185 Curtain Installation B30/C6/ RL • Service Replacement Parts 453110...

- Page 186 Curtain Installation B30/C6/AUX. LR • Service Replacement Parts 100734 HEX HEAD, 1/4-20 X 1/2 SST 106026 WASHER,FLAT,1/4x5/8x.06 SST 106482 WASHER,LOCK,1/4 SPLIT,SST 112445 CURTAIN,SHORT,14 X 32,NUCCW 114111 CURTAIN,LONG,19 X 34 1/4,EUCCW 204949 CURTAIN,SHORT,10 X 32,NUCCW AUX. RINSE 205432 ROD,CURTAIN,5/16 X 32"LG.SST,UCCW 206581 ROD,CURTAIN,5/16 X 34 1/4"LG.SST,UCCW...

- Page 187 Curtain Installation B30/C6/ LR • Service Replacement Parts 453111...

- Page 188 Control Cabinet • Service Replacement Parts (Parts continued after next page)

- Page 189 Control Cabinet • Service Replacement Parts...

- Page 190 Control Cabinet • Service Replacement Parts...

- Page 191 Service Replacement Parts • Control Cabinet...

- Page 192 Suppport without Bucket EUCCW Screen Suppport witth Bucket EUCCW EUCCW Refuse Bucket Scrap Screen Refuse Bucket C3 and B C3 and B30 P/N 329113 P/N 329115 P/N 330188 P/N 329109 P/N 330213 EUCCW EUCCW EUCCW EUCCW Scrap Screen Scrap Screen...

- Page 193 Blank Page This Page Intentionally Left Blank...

- Page 194 Standard 30" Door Assembly• Service Replacement Parts 100734 HEX HEAD, 1/4-20 X 1/2 SST 100735 HEX HEAD, 1/4-20 X 5/8 SST 100750 SCREW, FLAT, 6-32 X 3/8 SST 104971 HEX GRIP NUT, 6-32 SST 106482 WASHER, LOCK, 1/4-20 SPLIT 107033...

- Page 195 Service Replacement Parts • Standard 30" Door Assembly•...

- Page 196 Split Door Assembly• Service Replacement Parts 100003 HEX PLAIN NUT 1/4-20 SST 100141 HEX GRIP NUT 1/4-20 SST 100142 HEX GRIP NUT 5/16-18 SST 104971 HEX GRIP NUT, 6-32 SST 100734 HEX HEAD, 1/4-20 X 1/2 SST 100736 HEX HEAD, 1/4-20 X 3/4 SST...

- Page 197 Service Replacement Parts • Split Door Assembly•...

- Page 198 Blank Page This Page Intentionally Left Blank...

- Page 199 Fuses and Overloads ----------------------------------------------------------------------------------------------------- 200 Timers ------------------------------------------------------------------------------------------------------------------------- 202 Electric Eyes ---------------------------------------------------------------------------------------------------------------- 203 Float Switches -------------------------------------------------------------------------------------------------------------- 205 Thermostats ----------------------------------------------------------------------------------------------------------------- 207 Motors ------------------------------------------------------------------------------------------------------------------------- 208 Mechanical ...........................210 Pump Seal Replacement ------------------------------------------------------------------------------------------------ 210 Tighten Conveyor Belt ---------------------------------------------------------------------------------------------------- 214 Replace Electric Booster Control Thermostat --------------------------------------------------------------------- 218...

- Page 200 Blank Page This Page Intentionally Left Blank...

-

Page 201: Precautions

USA National Service M-F • 8 AM - 5PM EST Toll-free: 1 (800) 858-44772 In the USA, a factory technician will return your call after-hours and during holidays. Canadian National Service M-F • 8:30 AM - 4:30PM EST Toll-free: 1 (800) 263-5798... -

Page 202: Utilities

Installed in all supply lines to allow for servicing of the machine. Pressure Regulating Valves Installed in the incoming water supply lines. Installed in the incoming steam supply lines as close to the machine as possible. Water Hammer Arrestor ASSE-1010 standard or equivalent, should be installed in the common water supply line at the service connection. - Page 203 Correct rotation for the conveyor drive motor is CCW as indicated by a direction arrow decal above the drive sprocket. Correct rotation for the pump motors is CW as viewed from the rear of the motor. Motors are multi-voltage supplied as 208-230/480VAC, 3PH. A 575VAC, 3PH motor is available in Canada.

-

Page 204: Basic Service

Switch Relay (5CR). The Final Rinse Fill Valve is energized through the normally open contacts on the Rinse Aid Relay and the Econo Rinse Tank starts to fill. As the Econo Rinse Tank fills the lower float on the Econo Rinse Tank Float Switch rises and closes it’s switch. When the Econo Rinse Tank is full the upper float rises and closes it’s switch. - Page 205 CR relay energized. The CR contacts in the booster heat circuit transfer control of the booster heaters form the Econo Rinse Fill Switch to the CR relay. The third set of CR contacts close to provide a machine running signal.

- Page 206 The tank fill valve opens. As the tank refills and the lower float switch is closed nothing will happen. When the tank is full the upper float switch closes and the fill switch relay is energized. The fill valve deenergizes and closes. The tank...

- Page 207 It is extremely important that you identify the options installed on the machine BEFORE you begin repairs. The basic operation of the upright conveyor is the same for all models. If you are not completely familiar with the design and operation of your machine, please read all the information contained in this manual before attempting any repairs.

-

Page 208: Fuses And Overloads

Circuit Tests Use a clip-on AC current tester to check the 3-phase motors and electric heaters. Use a VOM to test the 120VAC and the 24VAC control circuits and their associated components. Do not use chassis ground to perform voltage tests. - Page 209 Electrical Service Fuse Blocks—120VAC Control Voltage Two fuse blocks, located in the center rear of the main control cabinet protect the main control transformer. Each fuse block holds a 5 AMP fuse. The fuses are marked 1FU and 2FU on the electrical schematic.

-

Page 210: Timers

— Disconnect power to the machine at the main service switch. — Remove the defective timer and install the replacement. — Adjust the new timer setting to match the setting of the original timer. To Check the Pump Timer Setting: To Check the Final Rinse Timer Setting: —... -

Page 211: Electric Eyes

• The pump timer and the final rinse timer begin to time down. • The pump timer resets each time the beam is broken. Component Location— The Emitter is mounted on the back of the load section. The Receiver is mounted on the front of the load section. Cleaning—... - Page 212 Remove two screws holding electric eye covers. Rotate covers away from tunnel end so you can see indicator lights inside the covers. Do not remove eyes from covers. Make sure that the electric eyes are aligned opposite of each other across the belt.

-

Page 213: Float Switches

During Normal Operation: If the water level in a tank falls below the level of the top float, the top float moves down and its reed switch contacts open. When the water level falls below the level of the bottom float, the bottom float moves down and its reed switch opens. - Page 214 Basic Service ________________ Electrical Service Automatic Fill/Low Water Heat Protection A dual float switch controls the fill and heat circuit for its associated wash, eco-rinse, or power wash tank as well as the electric or steam booster heat. Note: The Power Rinse Tank dual float controls the heat circuit of the OPTIONAL Champion built-in booster (Steam or Electric).

-

Page 215: Thermostats

Immediately troubleshoot/repair the cause of the problem. Thermostat Locations: Electric booster thermostats are mounted on the base of the unload section of the dishwasher adjacent to the booster assembly. Wash tank thermostats are mounted inside their respective wash tank junction boxes. -

Page 216: Motors

(Motor full load amp ratings, (FLA), are stamped on motor nameplates). Motor runs hot and trips motor starter overload: Check for proper voltage between L1-L2, L2-L3, L1-L3. Check FLA on motor leads L1, L2, L3 using amp tester. (Motor full load amp (FLA) ratings are stamped on motor nameplate). -

Page 217: Do Not Work On An Energized Circuit

Motor Replacement: Note: Champion does not supply motor bearings, rotors, nor stators as separate service replacement parts. A motor is available as a service replacement part or as part of a complete pump/motor assembly. WARNING ! Electric shock may cause injury or death. -

Page 218: Mechanical

Disconnect the power to the machine. Disconnect the wires at the motor junction box. Make note of the motor connections in order to phase the replacement correctly. Remove pump/motor assembly to a clean work area. Follow the diagrams below for pump disassembly and seal replacement. - Page 219 Basic Service • Mechanical _____________________ Basic Service Mechanical Service • Pump Seal Replacement CONTINUED ON NEXT PAGE...

- Page 220 NOTE ! Replace the pump motor if motor shaft is grooved, pitted, or bent. Clean rust and debris from seal seat and motor shaft. Debur with fine finishing paper specifically designed for metal surfaces. Use a new seal assembly preferably from an unopened package.

- Page 221 Measure gap between impeller vanes and pump volute. Minimum clearance must be .030" [0.76 mm]. Rotate the motor shaft CW to check proper clearance. Reinstall assembly and test run checking for leaks. Look at the rear of the motor to make sure motor shaft rotation is CW.

-

Page 222: Tighten Conveyor Belt

DEATH. DO NOT WORK ON AN ENERGIZED CIRCUIT. Turn off the main power service disconnect switch. Attach a label to the breaker indicating that work is being made on the electrical circuit. NOTE ! READ ALL OF THE CONVEYOR BELT INSTRUCTIONS BEFORE YOU BEGIN TO ADJUST OR REPAIR THE CONVEYOR BELT SYSTEM. - Page 223 Mechanical Service • Tighten the Conveyor Belt WARNING ! MOVING CONVEYOR PARTS may cause INJURY OR DEATH. Keep hands and clothing clear of the belt. USE EXTREME CAUTION WHEN THE CONVEYOR BELT IS MOVING. Remove access panels at unload section "B" of dishwasher...

- Page 224 Basic Service • Mechanical Basic Service ________________ Mechanical Service • Tighten the Conveyor Belt Lift conveyor belt and check the distance between the top of the side access slot and the top of a conveyor belt rod.

- Page 225 Basic Service • Mechanical _________________________ Basic Service Mechanical Service • Tighten the Conveyor Belt Turn jacking bolts on bearing take-up assemblies to achieve proper conveyor belt tension. Check the belt tracking on the conveyor shaft sprockets and adjust take-up assemblies as...

-

Page 226: Replace Electric Booster Control Thermostat

USED IN AN ELECTRIC BOOSTER HEATER. IMPROPER INSTALLATION CAN CAUSE FINAL RINSE TEMPERATURE PROBLEMS. You will need a permanent marker such as a SHARPIE® or comparable in order to mark the control thermostat capillary tube. Do not crimp the thermostat capillary tube. - Page 227 Basic Service • Mechanical _______________________________ Basic Service Mechanical Service • Replace Electric Booster Control Thermostat Slide ferrule 8" away from the end of the thermostat probe and mark. Thread gland nut into booster tank fitting. 1" 8" Insert thermostat probe into booster tank taking care not to crimp capillary tube.

- Page 228 Blank Page This Page Intentionally Left Blank...

-

Page 229: Electrical Schematics

Electrical Schematics ______ Electrical Schematics... - Page 230 Blank Page This Page Intentionally Left Blank...

Need help?

Do you have a question about the EUCC Series and is the answer not in the manual?

Questions and answers