Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Grundfos FireSAFE+ CRI 5-5

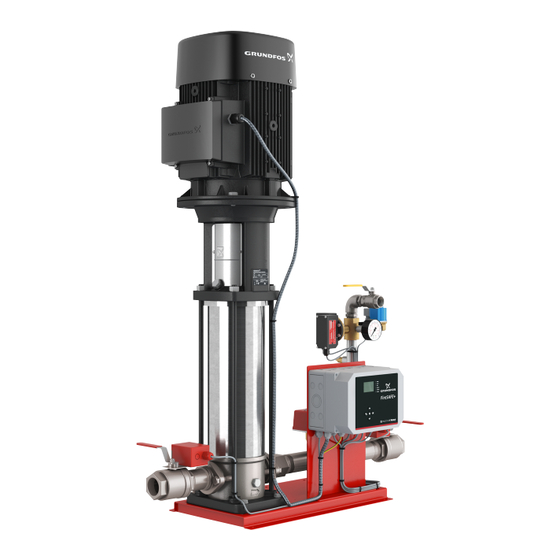

- Page 1 GRUNDFOS INSTRUCTIONS FireSAFE+ Residential range, Grundfos firefighting system Installation and operating instructions FireSAFE+ Residential range Installation and operating instructions (all available languages) http://net.grundfos.com/qr/i/93070260...

- Page 3 FireSAFE+ English (GB) Installation and operating instructions ............4 EU declaration of conformity .

-

Page 4: Table Of Contents

General safety warnings ..... . 5 The symbols and hazard statements below may appear in Grundfos installation and operating instructions, safety instructions and Product introduction. -

Page 5: General Safety Warnings

The flow switch can be a normally engineers holding UKAS accredited certification (FIRAS/ closed or normally open type. Grundfos only recommends the use LPCB/IFCC). of flow switches that are approved by fire standards. -

Page 6: Intended Use

The product has been specifically designed to power and relay The product has been specifically designed to operate automatically digital signals. The signals can come from any source, but Grundfos and to assist system designers and installers in complying with the... -

Page 7: Features

2.3.5 Cooling line settings The cooling line characteristics can be programmed through the USB route and the settings file. Grundfos have approved one setting that suits all pump models. Any changes to this are the installer's or user’s responsibility. -

Page 8: Receiving The Product

CAUTION Grundfos disclaim any responsibility for using the product to pump Harm of body liquids that poses health hazards through touch, ingestion or Minor or moderate personal injury inhalation of fumes or gases emitted by the liquid. -

Page 9: Water Storage Tanks And Mains Water Connection

4.3 Water storage tanks and mains water connection With the permission of the Water Utility company, it may be possible to connect the product directly to the town water mains with a dedicated inlet pipe. The diameter of the pipe must match the pump inlet as an absolute minimum. - Page 10 1-ph, 220-230 V 50 Hz Pipework Suction Delivery Unit Model Length Width Height centerline diameter diameter weight Product code height Type L1 (mm) L2 (mm) L3 (mm) W1 (mm) H (mm) CL (mm) (inch) (inch) (kg) CRI 5-5 1120 1.25" 1.25"...

-

Page 11: Installation

If repair is required, contact Grundfos. Place the product on a solid, flat and level foundation that can support the weight of the product when it is filled with water. - Page 12 Pos. Description Remark LNC, E & N, normally closed valve. Cooling line valve LNO, E & N, normally open valve. 240 VAC, 5 A maximum. Pump 2 LEN, 240 VAC, 13 A maximum. Mains Input LEN, 240 VAC, 15 A. Water level input COM-NC switch to open on low water condition.

- Page 13 NC COM NO PE NC COM NO PE NC COM NO PE NC COM NO PE NC COM NO PE NC COM NO PE Sensor wiring detail Pos. Description Pressure 1 Pressure 2 Flow Low water Phase monitor Monitored valve Pos.

-

Page 14: Installation Checklist

5.3 Installation checklist During the installation phase, do not apply mains power or water to the product. Step Done Activity Action/check/notes Fully read and study this manual. Unpack, inspect for completeness and any damage. Report to supplier or customer. Check that the installation location meets all the requirements in this manual and the latest applicable standard. -

Page 15: Commissioning The Product

6. Commissioning the product Do not attempt to start the pump until the system has been filled with water and both the pump and the system WARNING have been primed or vented. Electric shock Death or serious personal injury ‐ Make sure that all protective coverings are held Running the pump dry may permanently damage it. -

Page 16: System Verification Checklist

Related information 7. Setting the product 7.5 Pressure switch setting 8.2 Operating panel 6.2 System verification checklist Before the system is signed off and handed over to the customer, the performance of the whole system must be verified. Step Done Activity Action/check/notes Fully read and study this manual. Inspect the installation. -

Page 17: Setting The Product

Flow Switch activated? - Yes 13. Reassemble the controller front cover. Two text files are available from your local Grundfos agent for customising the product. • settings.txt - allows all programmable parameters to be adjusted Pump run log •... -

Page 18: Updating The Software

Device Name: FireSAFE+ Device Name: FireSAFE+ Grundfos Pumps Ltd. Grundfos Pumps Ltd. 01525 85 00 00 01525 85 00 00 Installer Name: INSTALLER NAME 1 Installer Name: INSTALLER NAME 1 INSTALLER NAME 2 INSTALLER NAME 2 INSTALLER NAME 3 INSTALLER NAME 3... -

Page 19: Factory Settings

The factory setting may not be ideal for the site application. This standard. Contact Grundfos. can be adjusted. The operating range of the pressure switches are 0.7 - 14 bar and 2-42 bar. -

Page 20: Operation

8. Operation 8.2 Operating panel WARNING Electric shock Death or serious personal injury ‐ The product must be earthed and provided with protection against indirect contact in accordance with local regulations. ‐ Only use Residual Current Breaker with Over-Current (RCBO). ‐... -

Page 21: Servicing The Product

9. Servicing the product 9.2 Annual inspection and test Grundfos recommends that the full fire protection system is tested DANGER and inspected every 12 months. This includes the product and Magnetic field ensures that the system remains in first class working order. This is Death or serious personal injury also a requirement within installation standards. -

Page 22: Annual Inspection And Test Checklist

9.4 Spare parts 11. Fault finding 9.4 Spare parts 10.1 Frost protection Conduct Grundfos Service for spare parts and advice regarding the The product must be protected from freezing conditions. product. The product may require trace heating or lagging. If the product is being stored during periods of frost, it must be 10. -

Page 23: Fault Finding

11. Fault finding Fault event, LED Fault detected Remedy • Check that the mains power is available to the product and voltage is in range. See section Operating conditions. • Check that the power cable termination at PCB end is electrically sound. See POWER LED not section Electrical connection. -

Page 24: Pump Does Not Reach The Duty Point But Continues To Run

Reset the service timer. See section Operating panel. For more specific details, take a copy of the log files for analysis. For system operation problems, see the dedicated sections for diagnosis. Contact your system installer or Grundfos for anything else. Related information 5.2 Electrical connection... -

Page 25: Technical Data

Nominal Closed valve Model Bailey & Mackey Ltd. head (bar) flow (l/min) head (bar) Pressure switch Range: 0.7 - 14 bar and 2-42 bar FireSAFE+ CRI 5-5 2.13 96.67 3.14 Pressure gauge FireSAFE+ CRI 5-12 5.44 96.67 7.83 0-10 bar, 0-16 bar and 0-28 bar... -

Page 26: Product Manuals

1. Use the public or private waste collection service. • upgrading the product 2. If this is not possible, contact the nearest Grundfos company or • removing the system altogether. service workshop. 14.2 Dismantling the product... - Page 27 EU declaration of conformity GB: EU declaration of conformity For products with CE marking on the nameplate. We, Grundfos, declare under our sole responsibility that products (1) declared below are in conformity with the relevant union harmonisation legislation (2), harmonised standards or other technical specifications (3).

- Page 28 • The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012/3032 Standards used: BS EN IEC 63000:2018 This Declaration of Conformity is valid together with Grundfos publication number 93070260. Sunderland, 30/May/2024 Ryan Appleby Engineering Manager...

- Page 29 Unit 1, Ground floor, Siu Wai industrial Turkey www.ba.grundfos.com Centre GRUNDFOS Pumps NZ Ltd. GRUNDFOS POMPA San. ve Tic. Ltd. Sti. E-mail: grundfos@bih.net.ba 29-33 Wing Hong Street & 68 King Lam 17 Beatrice Tinsley Crescent Gebze Organize Sanayi Bölgesi Street, Cheung Sha Wan...

- Page 30 93070260 06.2024 ECM: 1396992 www.grundfos.com...

Need help?

Do you have a question about the FireSAFE+ CRI 5-5 and is the answer not in the manual?

Questions and answers