Graco LineLazer V 250SPS Repair Parts

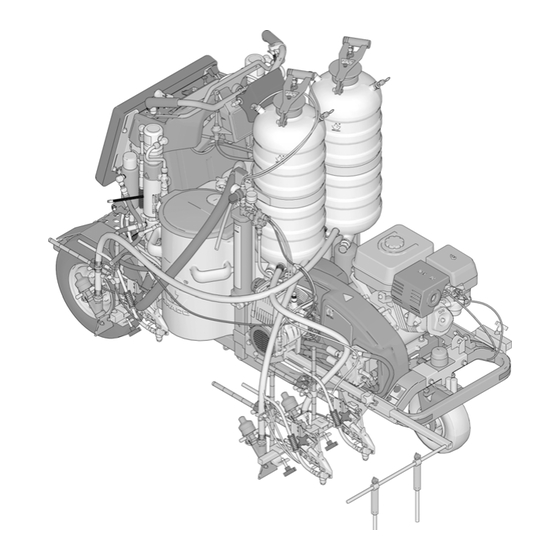

Self-propelled line striper

Hide thumbs

Also See for LineLazer V 250SPS:

- Repair parts (72 pages) ,

- Operation (42 pages) ,

- Manual (8 pages)

Table of Contents

Advertisement

Quick Links

Repair - Parts

LineLazer V 250

Self-Propelled Line Striper

For the application of line striping materials.

For professional use only. For outdoor use only.

Not for use in explosive atmospheres or hazardous locations.

Maximum Operating Speed: 10 mph (16 kph)

Maximum Operating Pressure: 3300 psi (22.8 MPa, 228 bar)

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this manual and in related manuals.

Be familiar with the controls and the proper usage of the equipment.

Save these instructions.

Pressurized

Model

Guns

Bead System

17H471

2

No

17H472

3

No

17H473

2

Yes - 2 Tank

25P365

2

Yes - 2 Tank

17H474

3

Yes - 2 Tank

17H466

1

No

17H467

2

No

17H468

1

Yes - 1 Tank

17J951

2

Yes - 1 Tank

17H469

2

Yes - 2 Tank

Related Manuals:

3A3393

Operation

311254

Gun

309277

Pump

3A3428

Auto-Layout Applications Methods

332230

Pressurized Bead System (PBS)

3A6981

Steering Cable Replacement

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

and 250

SPS

Description

LLV 250

DC

LLV 250

DC

LLV 250

DC

LLV 250

DC

LLV 250

DC

LLV 250

SPS

LLV 250

SPS

LLV 250

SPS

LLV 250

SPS

LLV 250

SPS

DC

3A3394H

EN

Advertisement

Table of Contents

Summary of Contents for Graco LineLazer V 250SPS

- Page 1 Yes - 2 Tank LLV 250 Related Manuals: 3A3393 Operation 311254 309277 Pump 3A3428 Auto-Layout Applications Methods 332230 Pressurized Bead System (PBS) 3A6981 Steering Cable Replacement Use only genuine Graco replacement parts. The use of non-Graco replacement parts may void warranty.

- Page 2 Removal ......34 Graco Standard Warranty ....73 Installation .

-

Page 3: Battery Replacement

Battery Replacement Battery Replacement Installation NOTICE To reduce the risk of battery damage and shorts, always connect NEGATIVE (black wire) last. Removal 1. Place battery on operator platform. Connect two red wires to positive (+) post of the battery. 1. Battery may be removed from the back of the unit by sliding it out above the operator platform. -

Page 4: Fuse Replacement

Fuse Replacement Fuse Replacement 1. Remove fuse cover. 4. Use needle-nose pliers to install new fuse. 2. Use needle-nose pliers to remove old fuse and 5. Replace cover. inspect it for an open circuit. 3. If fuse is open, a wire has shorted to the frame or aux- iliary lighting requires too much power. -

Page 5: Forward/Reverse Cable Replacement

Forward/Reverse Cable Replacement Forward/Reverse Cable 5. Loosen four screws and remove belt cover. Replacement Removal 1. If equipped with a Pressurized Bead System, remove pressurized bead tanks and compressor. See Pressurized Bead System manual 332230. ti19128a 2. Remove tank lids and siphon tubes. 6. - Page 6 Forward/Reverse Cable Replacement Installation 4. Verify that the handlebar forward/reverse lever does not touch handlebar grips. Adjust cable and ball joints if needed. 1. Install new cable (148) by following same route as old cable is being removed. 5. Install belt cover and tighten four screws. 2.

-

Page 7: Steering Cable Replacement

Steering Cable Replacement Steering Cable Replacement Removal 2. Remove six screws and control shroud. 1. Loosen four screws and remove pad. ti23930a ti23931a 3A3394H Repair - Parts... - Page 8 Steering Cable Replacement 3. Apply parking brake. Raise front wheel off the 5. On front wheel fork, remove locknut (3) and ball joint ground and support frame on two jack stands. (40) from fork. Remove ball joint (40) from cable (48) and save if not replacing.

- Page 9 Steering Cable Replacement Installation 5. Install ball joint (40) onto cable (48) and match threads on other side of handlebar. Install ball joint (40) into handlebar and tighten locknut (3). 1. Install new cable (48) by following same route as old cable is being removed.

-

Page 10: Front Wheel Replacement

Front Wheel Replacement Front Wheel Replacement Removal Installation 1. Apply parking brake. Raise front wheel off ground 1. Insert two spacers (36) into wheel (35) and slide into and support frame on two jack stands. fork (34). ti19693a ti20125a 2. Remove locknut (39) from axle bolt (37) and remove axle bolt (37) from fork (34). -

Page 11: Parking Brake Service

Parking Brake Service Parking Brake Service Removal Installation 1. Remove tire, wheel hub, and fender. See, Wheel 1. Install lever (14) with pin (B) and clip (13). Motor Removal, page 41. 2. Use screwdriver to install spring (15). 2. Remove clips (13) from three pins (A). Remove pins 3. -

Page 12: Rear Wheel And Wheel Motors

2. Remove four lug nuts (22) and wheel (16). ti18589a 3. Remove pin (56), castle nut (21b) and wheel hub (22b). Wheel hub may require a wheel puller; not supplied by Graco. ti18589a Rear Wheel Installation 1. Replace wheel and install lug nuts. Alternately tighten lug nuts opposite of each other. - Page 13 Rear Wheel and Wheel Motors Wheel Motor Installation Wheel Sensor Replacement Removal 1. Connect two hydraulic hoses (112) to wheel motor (21a) and insert wheel motor (21a) into frame (1). 1. Loosen four screws and remove pad. 2. Install wheel motor (21a) and fender (19) with four bolts (78) and lock nuts (79).

- Page 14 Rear Wheel and Wheel Motors 5. Use wrench to remove screw (6), clamp (5), and 4. Press gun trigger control button and rotate hub by wheel sensor (4). hand exactly three turns. ti18564a ti19329a NOTE: Sensor is working properly if the measure display reads 12.3 to 12.7 ft (3.75 to 3.87 m).

-

Page 15: Recycling And Disposal

Recycling and Disposal Recycling and Disposal Rechargeable Battery Disposal End of Product Life Do not place batteries in the trash. Recycle batteries At the end of the product’s useful life, dismantle and according to local regulations. In the USA and Canada, recycle it in a responsible manner. -

Page 16: Troubleshooting

Troubleshooting Troubleshooting General Problem Cause Solution Turn key switch to ON. Choke engine and pull Battery is discharged. recoil starter rope. Engine will not crank Key switch is defective. Replace key switch. Main wire harness is defective. Replace wire harness, see Notes, page 49. Excessive hydraulic load. - Page 17 Intake line to pump inlet is not tight. Tighten intake line to pump inlet. Hydraulic motor is worn or damaged. Bring sprayer to Graco distributor for repair. Suction tube strainer is clogged. Clean strainer Suction tube air leak. Tighten suction tube Drain line to paint hopper is clogged.

- Page 18 Troubleshooting Problem Cause Solution Turn pressure adjusting knob clockwise to Pressure setting too low. increase pressure. See Operation manual. Low stall or run pressure shown on Pump break-in period takes up to 100 gallons display New pump or new packings. of material.

- Page 19 Dot size setting is too small Increase dot size. Pressure is too low Increase pressure to 1000 psi. * Use only Graco approved hydraulic fluid 169236 (5 gallons / 18.9 liter) or 207428 (1 gallon / 3.8 liter) 3A3394H Repair - Parts...

- Page 20 Notes Notes 3A3394H Repair - Parts...

Need help?

Do you have a question about the LineLazer V 250SPS and is the answer not in the manual?

Questions and answers